IKEUCHI – Precision Spray Nozzles & Fog Solutions for Every Industry

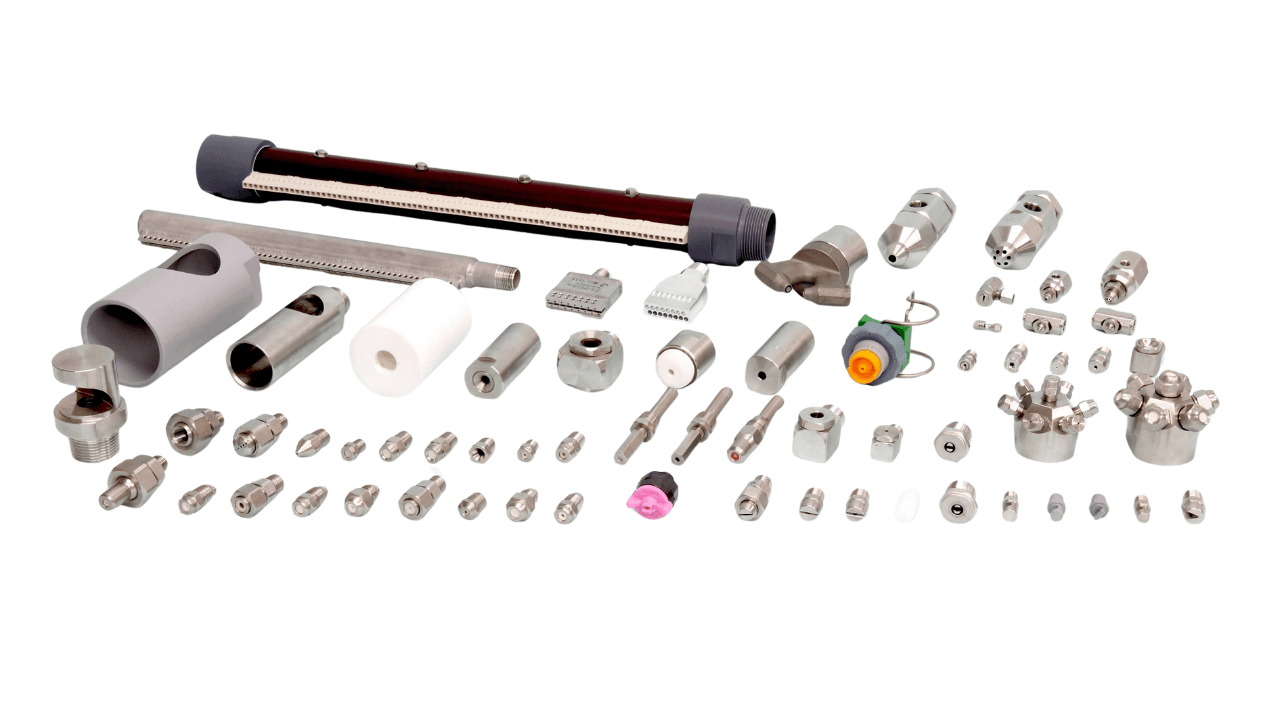

With over 42,000 standard spray nozzles, IKEUCHI provides innovative spray and fog technologies for a wide range of industrial applications, offering unmatched versatility, precision, and performance.

IKEUCHI’S spray nozzles and fog technologies have played a vital role in a broad range of industries.

With more than 42,000 standard nozzles to choose from, IKEUCHI offers a truly extensive lineup of products.

There are unlimited possibilities for our nozzles and nozzle-related products in any industry or application.

Features:

We define Dry Fog as a very fine fog with a uniform, mean droplet diameter (mean fog droplet size) of 10 μm or less.

Because Dry Fog's exceedingly fine spray droplets remain intact without bursting when they come into contact with objects such as walls and people, they do not wet these impact surfaces.

"Dry mist," despite its similar name, has much larger droplets than Dry Fog and has no specified droplet diameter as part of its definition. Dry mist droplet sizes vary significantly by producer and product.

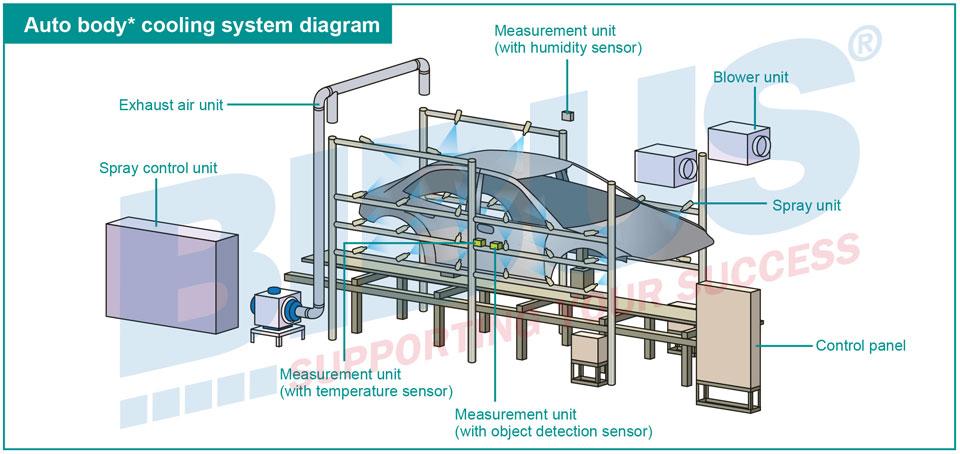

Enhance automotive production with a non-drain rapid cooling system that emits ultra-fine Dry Fog and Semi-Dry Fog®. This advanced cooling method ensures high-speed temperature reduction without wetting car bodies or components.

Key Benefits:

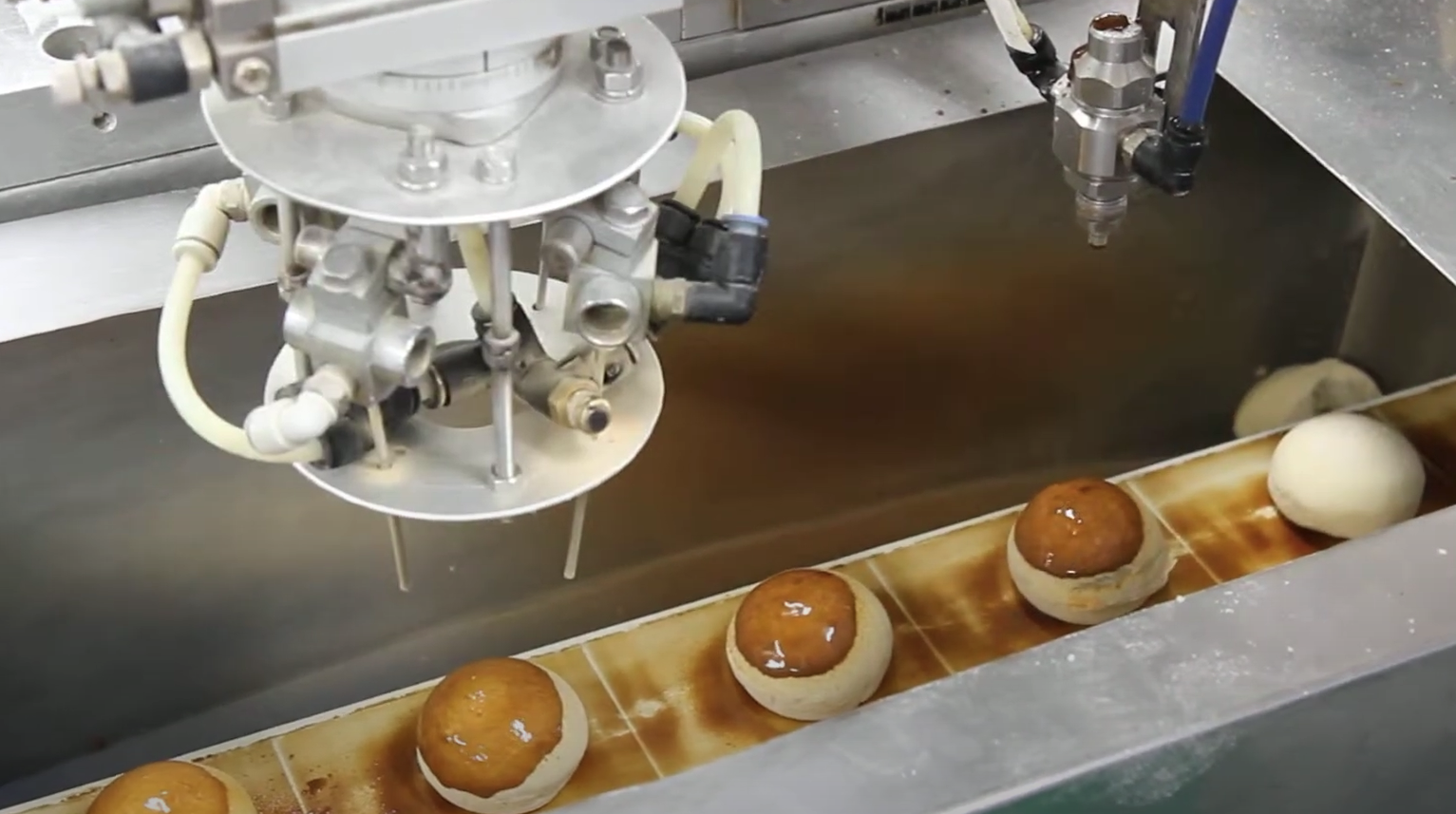

Automate your food production with high-performance spray nozzles designed for safety, consistency, and cost-efficiency. These nozzles are critical to achieving hygienic, uniform, and high-quality results across various food and beverage applications.

Applications Include:

Key Benefits:

Our solutions contribute to the production of delicious and reliable food products, helping manufacturers meet modern efficiency and quality demands.

With decades of experience in the steel industry, our spray nozzle technology has been trusted since 1983 for its performance and durability in the most demanding environments.

Key Applications in Steel Production:

Our pneumatic spray nozzles are engineered to withstand high temperatures, harsh chemicals, and abrasive conditions, ensuring long-lasting performance in steel mills and foundries worldwide.

Airborne dust particles pose health, safety, and environmental challenges, especially in open or industrial environments. Our advanced dust control systems are engineered to tackle these issues efficiently.

Two Effective Methods of Dust Suppression:

Benefits of Our Dust Control Systems:

Our solutions are customizable to meet your specific application needs — both indoor and outdoor.