Trusted Industrial Chain Solutions Backed by 100+ Years of Innovation

As Japan’s pioneering chain manufacturer since 1910, ZEXUS provides high-performance industrial chains for conveyors, water treatment, steel plants, and more—trusted for strength, reliability, and precision.

ZEXUS roller chains are manufactured to meet global standards, delivering superior performance, durability, and resistance to wear and elongation.

ANSI Roller Chain (JIS B 1801 Compliant)

The ANSI roller chain is ZEXUS's standard type, built in accordance with JIS B 1801. It features:

BS Roller Chain (British Standard)

The BS roller chain is manufactured to the British Standard, offering:

ZEXUS Double Capacity Chains revolutionize heavy-duty power transmission by delivering nearly double the breaking strength of conventional roller chains — while maintaining a single strand design.

Key Features:

Additional Options:

Freedom Series Chains are engineered to perform without the need for additional lubrication, making them ideal for applications where cleanliness, efficiency, and low maintenance are critical.

Key Features:

Suitable Industries:

O-Ring Chains are designed to retain internal lubrication using a built-in O-ring seal, ensuring smooth and long-lasting operation even when external oiling is difficult or undesirable.

Key Features:

Recommended Applications:

Attachment Double Pitch Roller Chains combine the durability of double pitch roller chains with custom attachments for flexible material handling and conveying applications.

Key Features:

Benefits:

Top Roller Chains feature rollers mounted on top of the chain, allowing goods to rest directly on the rollers while the chain continues to move underneath. This unique design enables controlled stopping, holding, or transferring of goods without halting chain operation.

Key Features:

Applications:

Standard sprockets are engineered through extensive experience to deliver superior performance and durability in chain-based power transmission systems.

Key Features:

Benefits:

Single-Double (SD) Sprockets are specially designed to engage two single-strand chains simultaneously, making them ideal for driving roller conveyors in synchronized motion.

Key Features:

Applications:

SCS2 Stainless Steel Sprockets are engineered for environments where corrosion resistance, durability, and minimal maintenance are critical. Designed to work in synergy with stainless steel chains, they deliver exceptional wear life and reliable performance.

Key Features:

Optional Saver Sprocket:

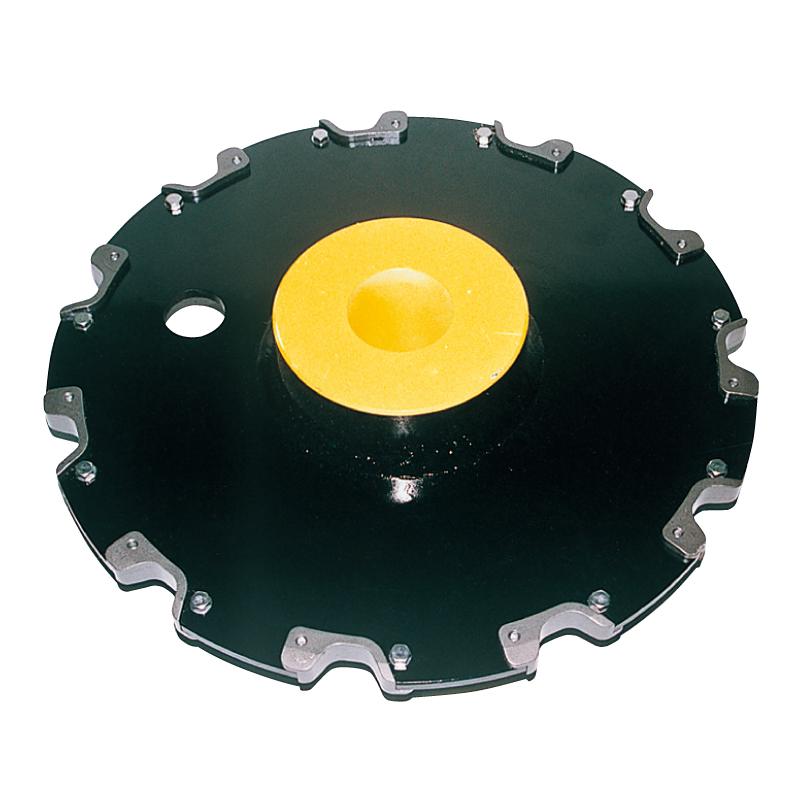

Replaceable Segment Teeth Sprockets are built for efficiency, longevity, and simplified maintenance, combining a durable main body with modular tooth segments that can be easily replaced without dismantling the entire sprocket.

Key Features:

Benefits: