Power Transmission

Power transmission elements that ensure safe and efficient power transmission from the motors to your machines.

Contact us if you have any questions.

Contact us

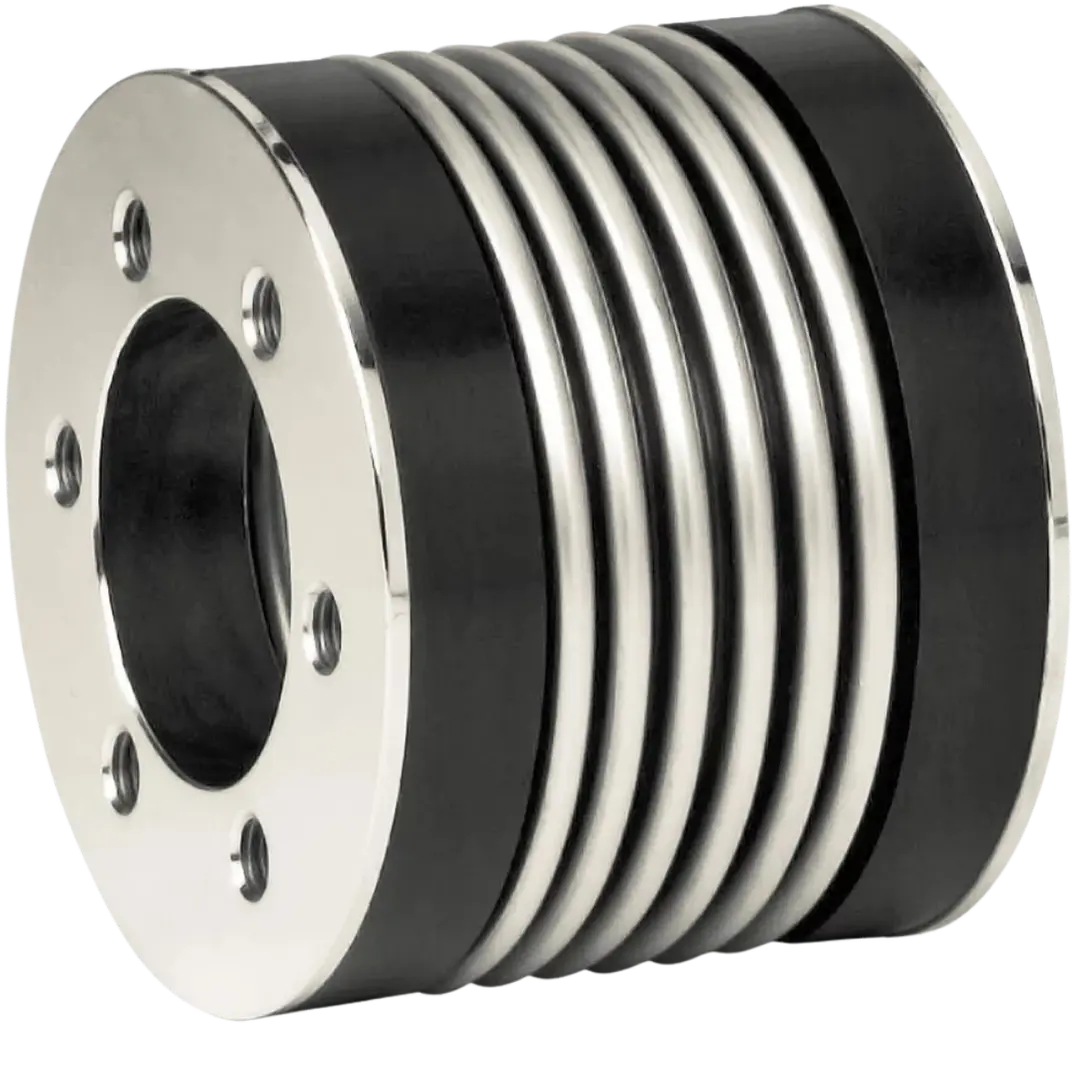

BK1 - Metal bellows coupling

For simple flange mounting to special drive components, Custom flange patterns available

BK2 - Bellows coupling

Easy to mount, optional: bolt tensioning system in size 800 and up, light weight and low moment of inertia

BK3 - Bellows coupling

High clamping pressure, high torque version, compact design

BK5 - Bellows coupling

Easy installation and removal, electrically and thermally isolating, absolutely backlash free and torsionally stiff

BK6 - Bellows coupling

Axial mounting possible, easy installation and removal, electrically and thermally insulating, absolutely backlash free and torsionally stiff

BK7 - Bellows coupling

For hollow shaft mounting, short design saves installation space, easy to mount

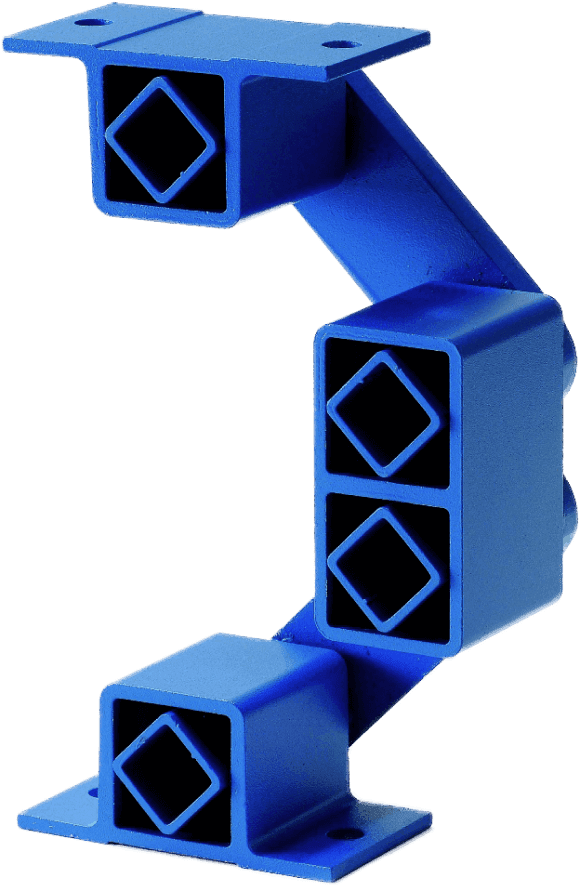

Oscillation Elements

ROSTA oscillating mountings ensure smooth, controlled vibration for screening, conveying, and processing applications — providing high efficiency, long service life, and maintenance-free operation.

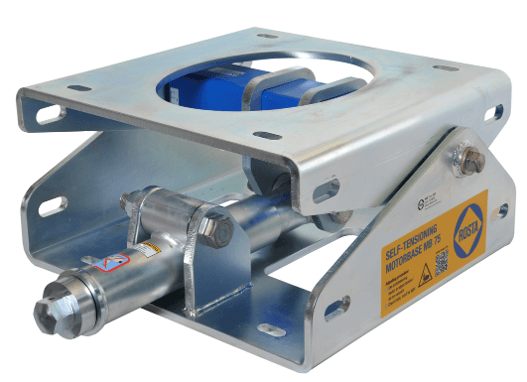

Motor Bases

ROSTA motor bases ensure rigid and geometrically stable installation of the electric motor, allow precise adjustment of the center distance and belt tension, reduce starting loads, and increase the service life of the drive.

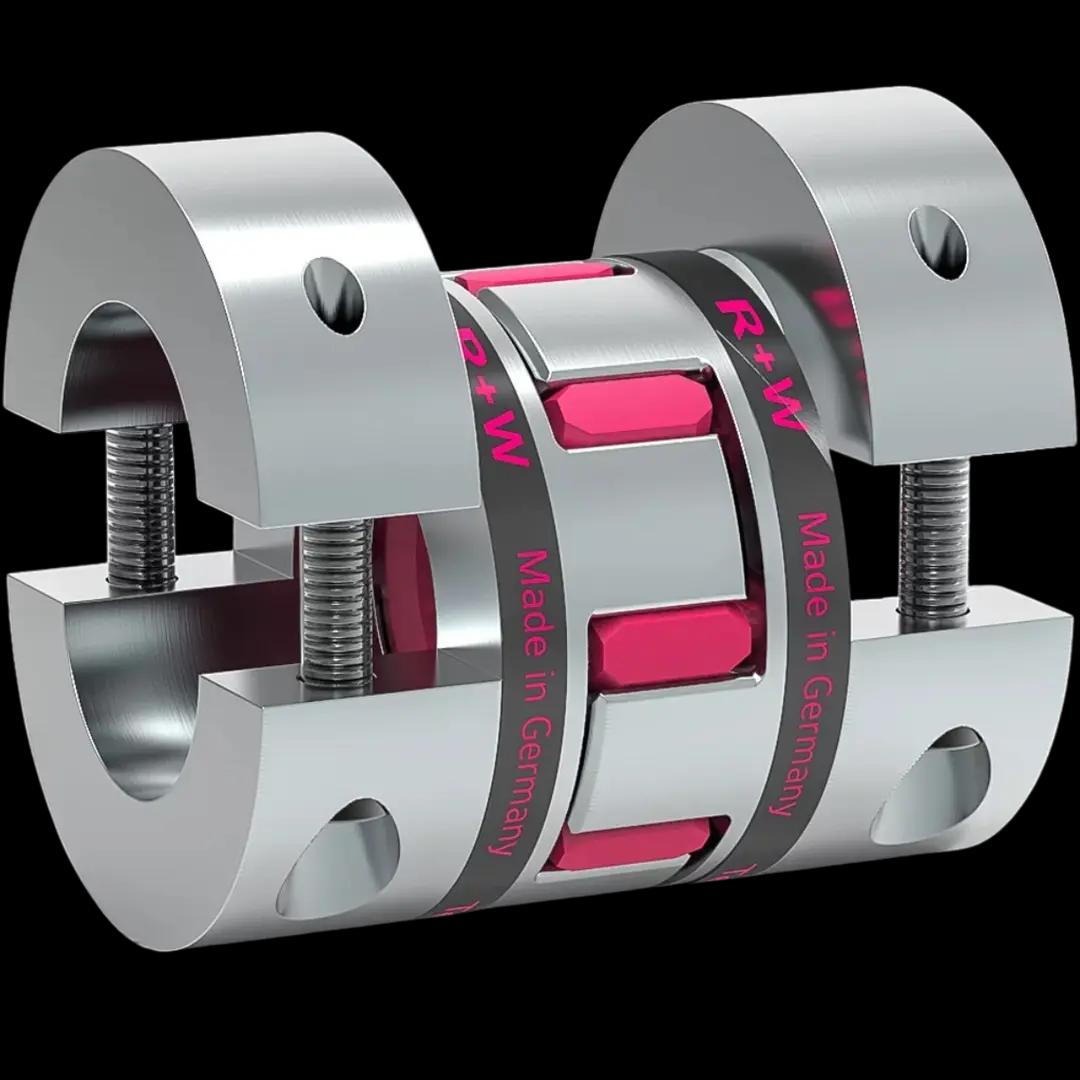

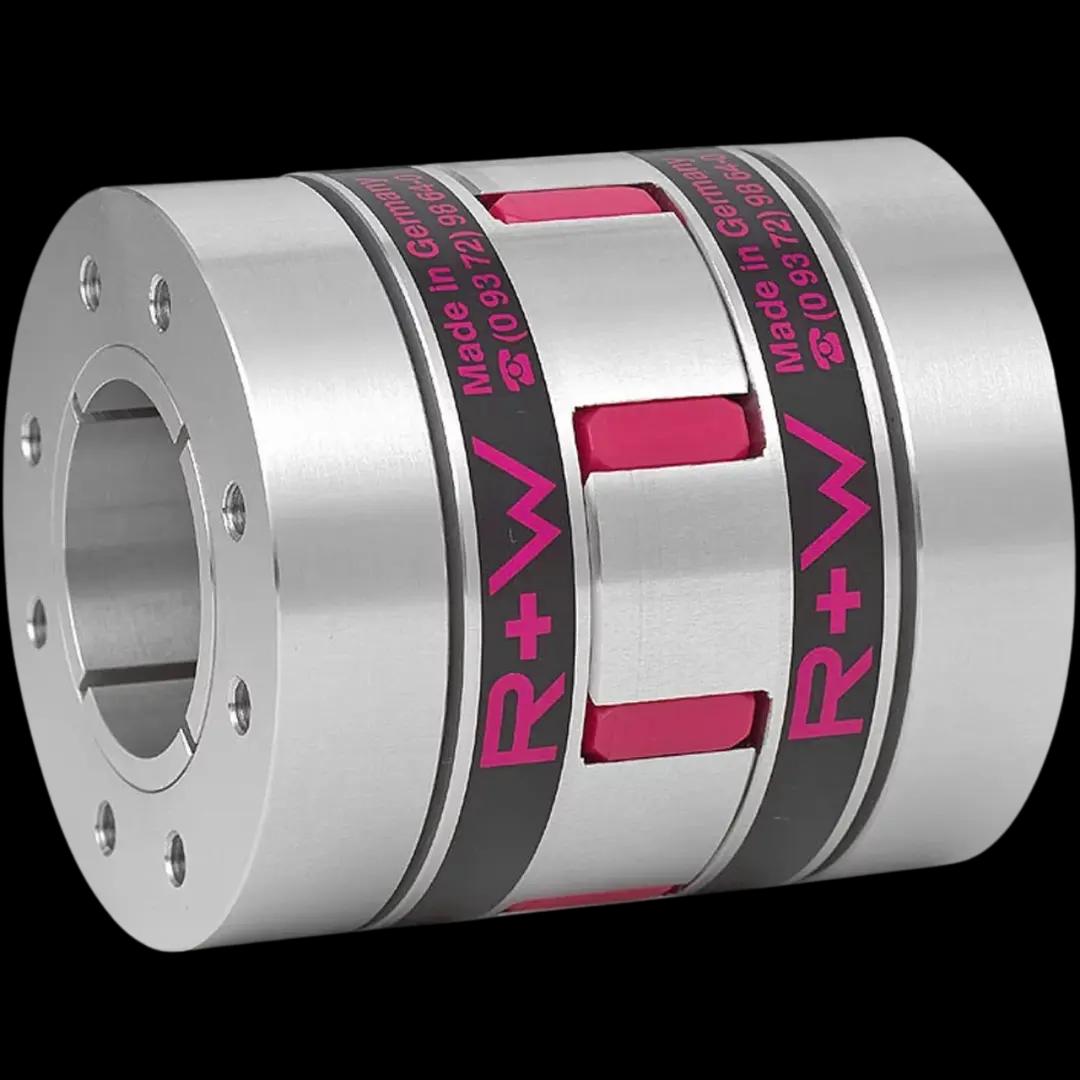

EK2 - Elastomer coupling

Easy mounting, high concentricity, vibration damping

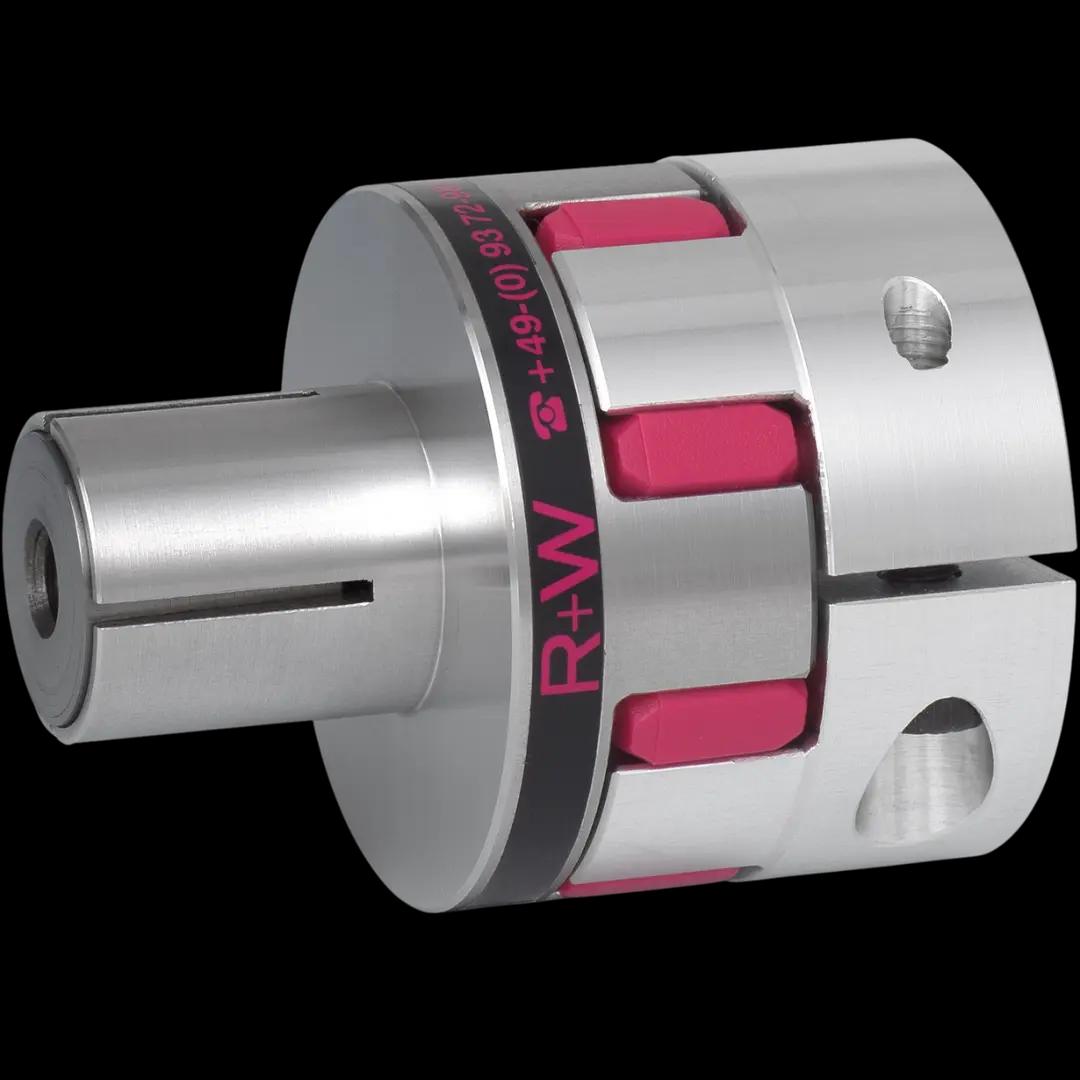

EKL - Compact elastomer coupling

Short overall length, easy mounting, vibration damping

EKH - Elastomer coupling

Lateral mounting, easy installation and removal, high concentricity

EKZ - Intermediate spacer

High lateral misalignment, easy to mount, combine with any two hub design

EK6 - Elastomer coupling

High clamping pressure, very high concentricity, axial mountable

EK7 - Elastomer coupling

For hollow shaft mounting, short overall length, saves mounting space and costs

EK1 - Elastomer coupling

Low-priced, high concentricity, low backlash (keyway)

Tension Elements

ROSTA – automatic belt and chain tensioners ensuring consistent performance, extended service life, and reduced maintenance.

Disc brake systems and components

The reliability and innovations of TWIFLEX in braking systems is an engineering solution that will address the most ambitious tasks for high-tech drive units and assemblies.

Rubber Suspension Elements

ROSTA – innovative rubber suspension elements for efficient vibration control in any industry

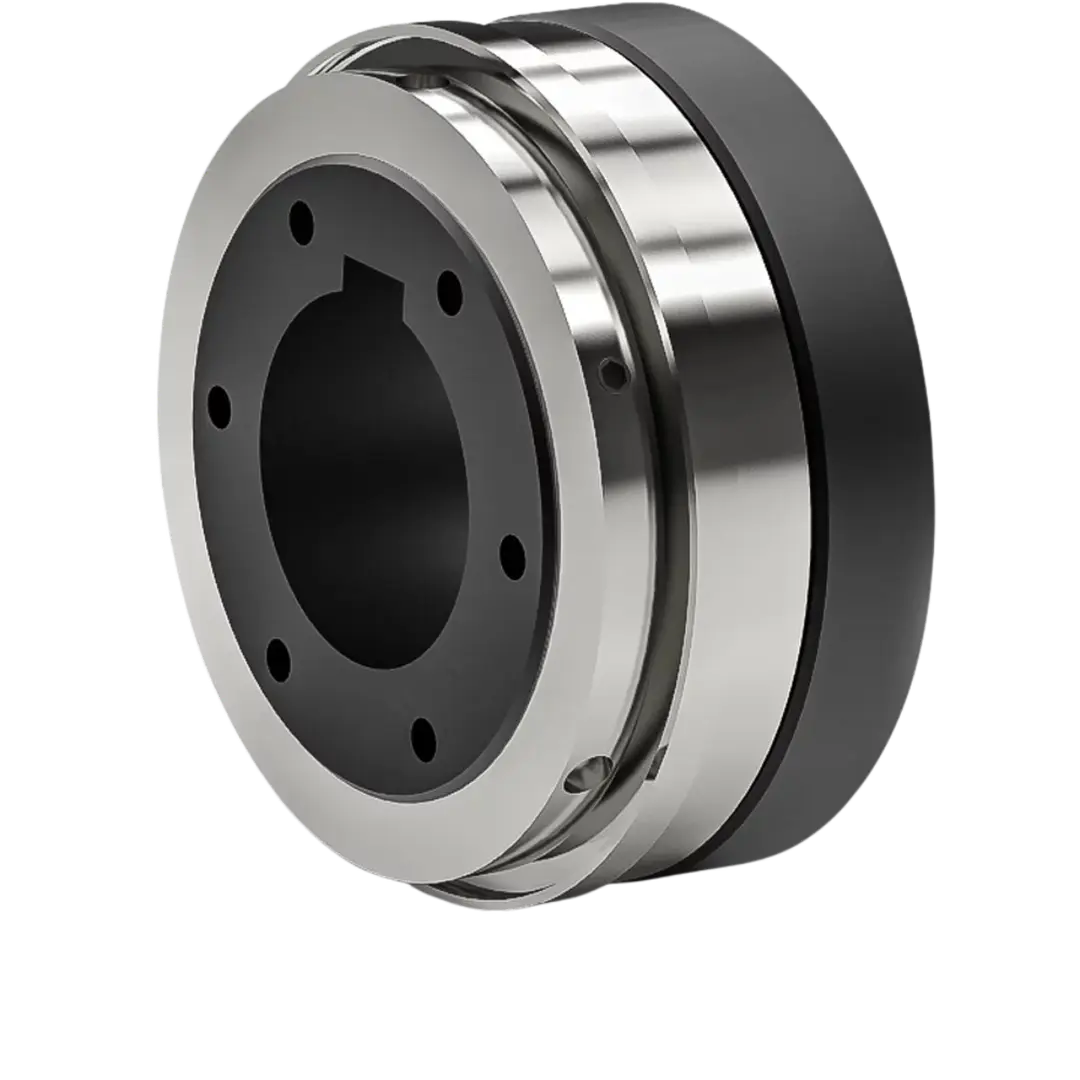

ES2 – Torque limiter

Two clamping hubs with one clamping screw each and concave driving jaws, Safety system: spring loaded ball-detent principle

ESL – Torque limiter

Two hubs, each with keyway, Safety system is integrated into one of the hubs

SKH – Torque limiter

Two clamping hubs with two clamping screw in each, Torque limiter system: spring loaded ball-detent principle

SKP – Torque limiter

Safety system: hardened steel, spring loaded ball-detent principal, with simple keyway connection

SKN –Torque limiter

With clamping ring and one clamping screw, Safety system: spring loaded ball-detent principle

SK5 – Torque limiter

Two clamping hubs with one clamping screw each, and one of the clamping hubs with tapered male segment, Safety system: spring loaded ball-detent principle

SK3 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle