Coupling Technology

R+W shaft couplings and Ringfeder clamping shaft connections are key components in drive technology, ensuring efficient torque transmission between rotating shafts and compensation for misalignments. In our portfolio you will find a wide range of these elements, designed for various industrial applications.

Contact us if you have any questions.

Contact us

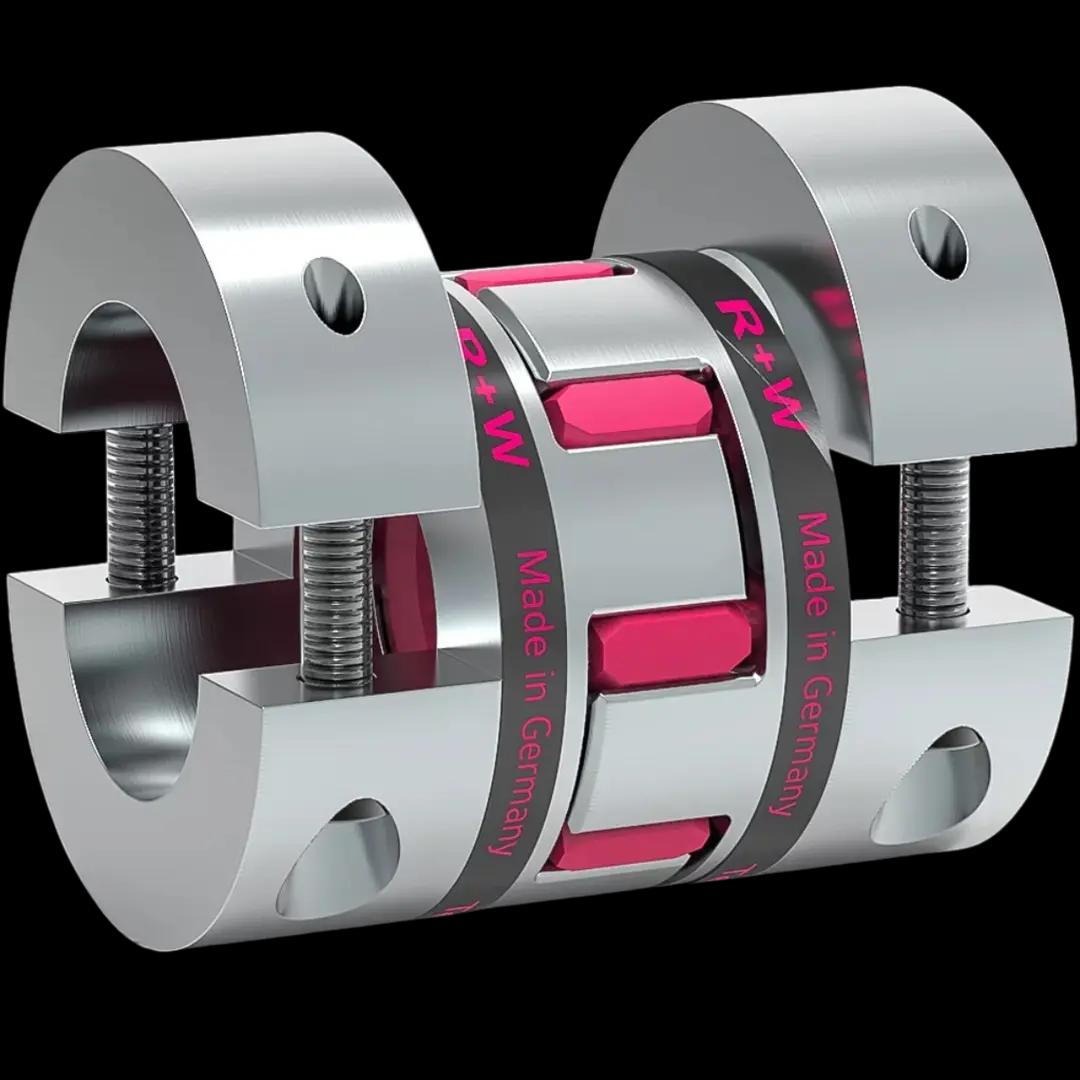

EK1 - Elastomer coupling

Low-priced, high concentricity, low backlash (keyway)

EK2 - Elastomer coupling

Easy mounting, high concentricity, vibration damping

EKL - Compact elastomer coupling

Short overall length, easy mounting, vibration damping

EKH - Elastomer coupling

Lateral mounting, easy installation and removal, high concentricity

EKZ - Intermediate spacer

High lateral misalignment, easy to mount, combine with any two hub design

EK6 - Elastomer coupling

High clamping pressure, very high concentricity, axial mountable

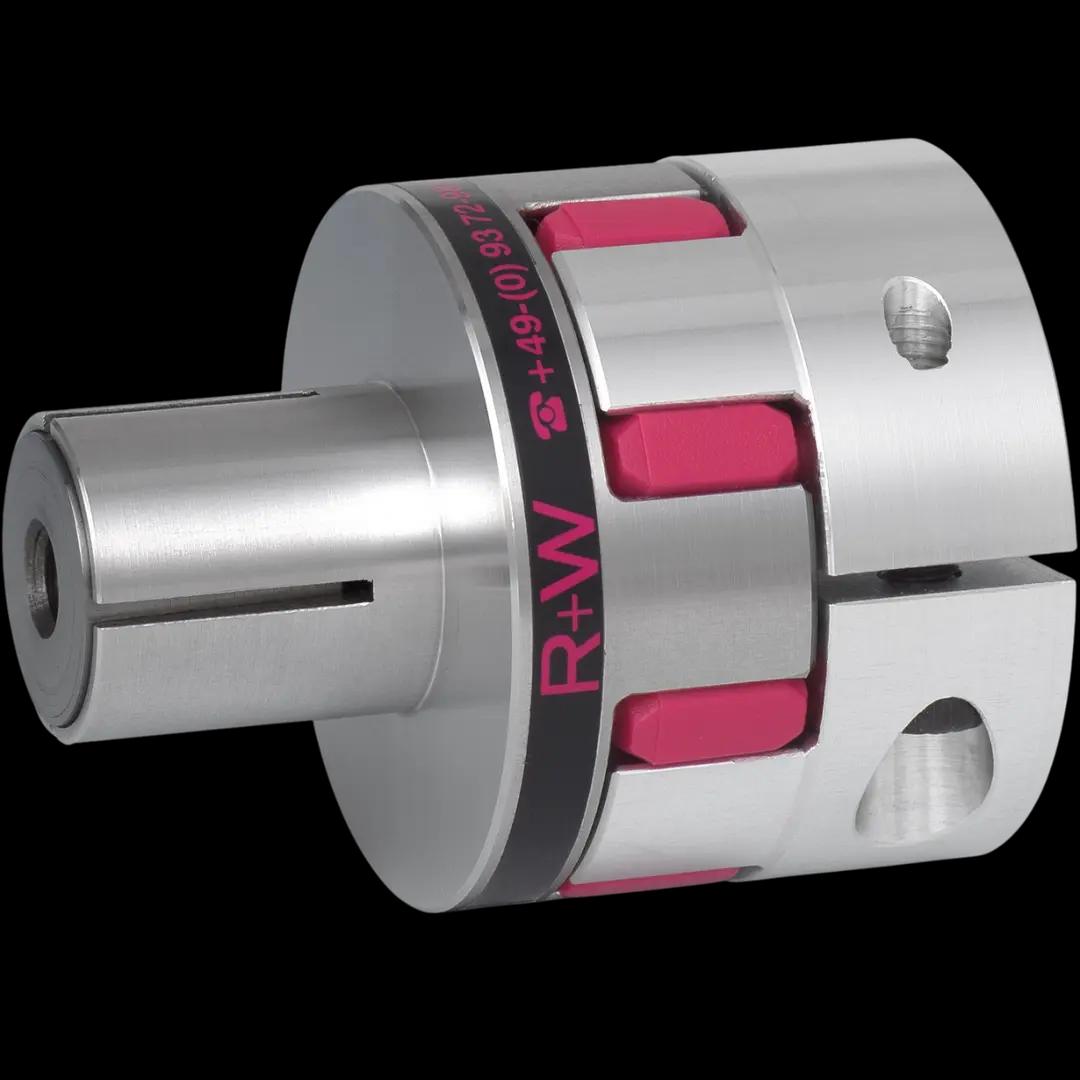

EK7 - Elastomer coupling

For hollow shaft mounting, short overall length, saves mounting space and costs

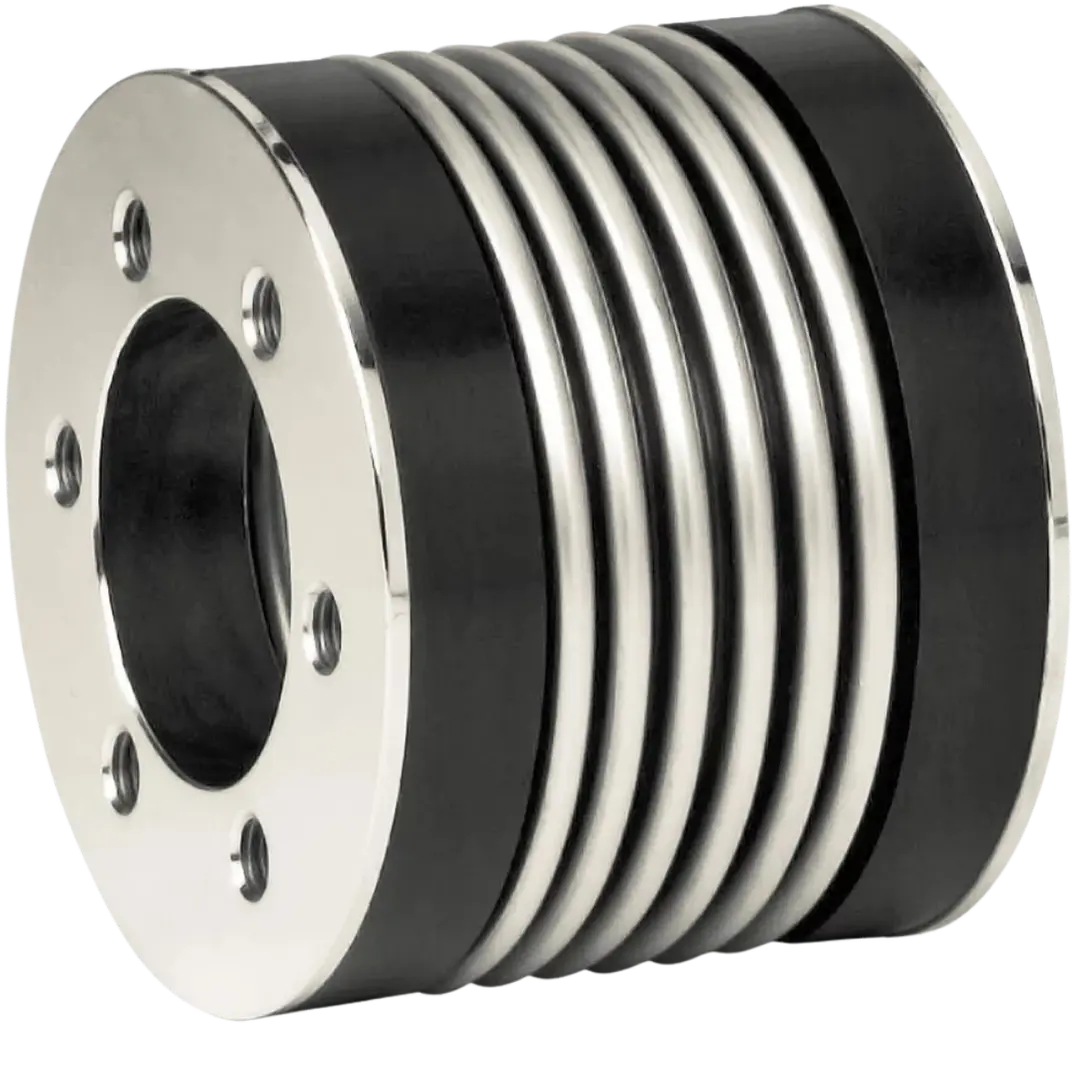

BK7 - Bellows coupling

For hollow shaft mounting, short design saves installation space, easy to mount

BK6 - Bellows coupling

Axial mounting possible, easy installation and removal, electrically and thermally insulating, absolutely backlash free and torsionally stiff

BK5 - Bellows coupling

Easy installation and removal, electrically and thermally isolating, absolutely backlash free and torsionally stiff

BK3 - Bellows coupling

High clamping pressure, high torque version, compact design

BK2 - Bellows coupling

Easy to mount, optional: bolt tensioning system in size 800 and up, light weight and low moment of inertia

BK1 - Metal bellows coupling

For simple flange mounting to special drive components, Custom flange patterns available

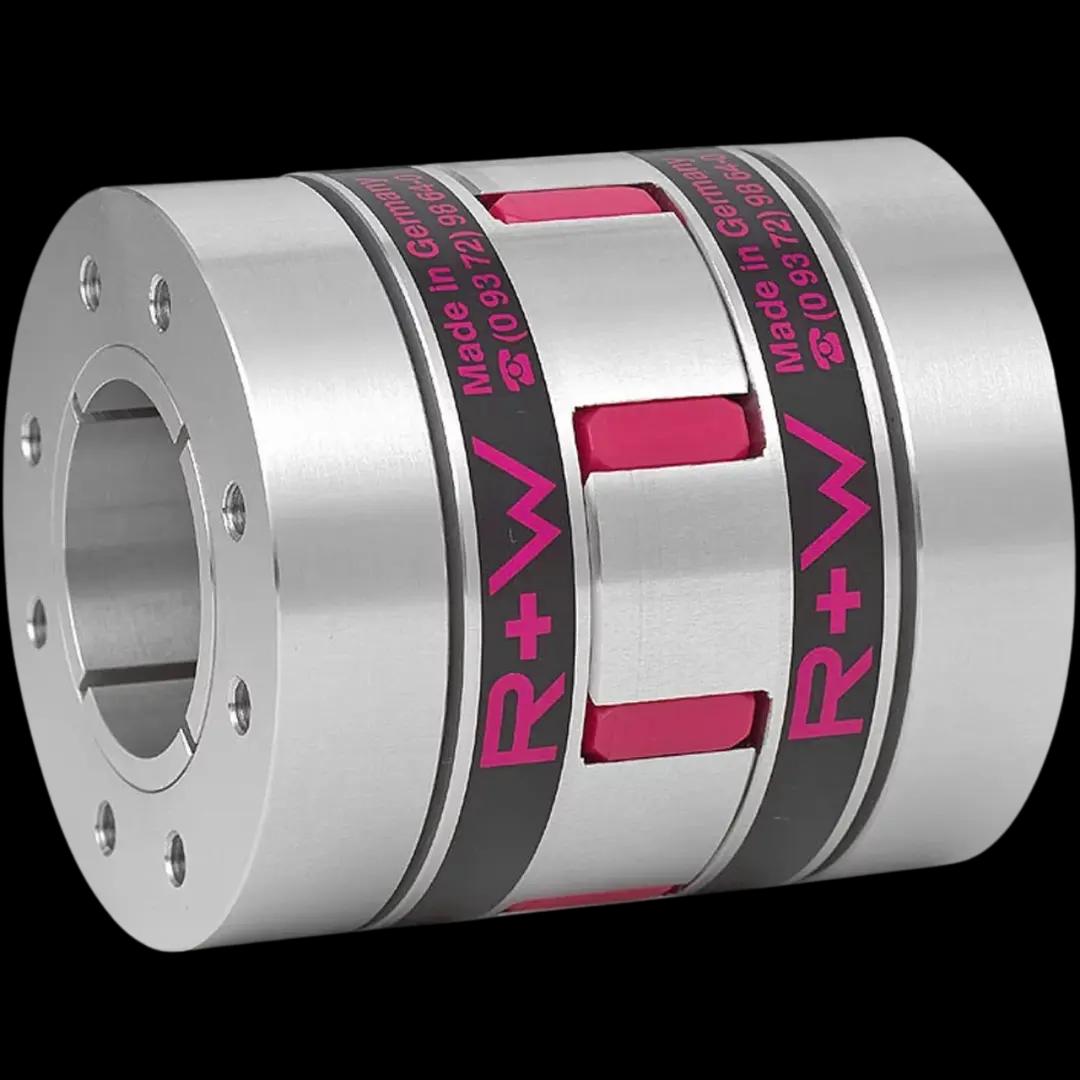

ES2 – Torque limiter

Two clamping hubs with one clamping screw each and concave driving jaws, Safety system: spring loaded ball-detent principle

ESL – Torque limiter

Two hubs, each with keyway, Safety system is integrated into one of the hubs

SKH – Torque limiter

Two clamping hubs with two clamping screw in each, Torque limiter system: spring loaded ball-detent principle

SKP – Torque limiter

Safety system: hardened steel, spring loaded ball-detent principal, with simple keyway connection

SKN –Torque limiter

With clamping ring and one clamping screw, Safety system: spring loaded ball-detent principle

SK5 – Torque limiter

Two clamping hubs with one clamping screw each, and one of the clamping hubs with tapered male segment, Safety system: spring loaded ball-detent principle

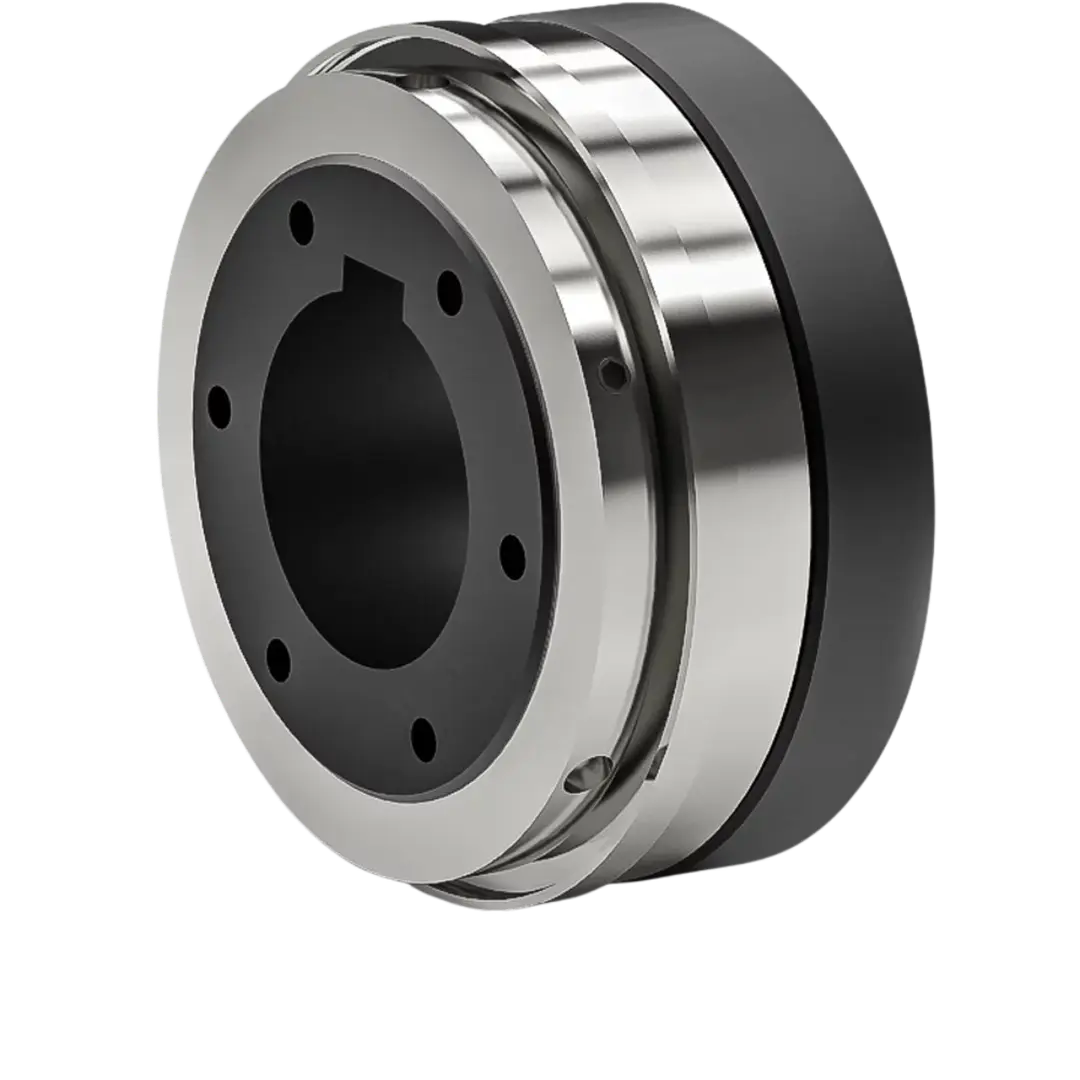

SK3 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

SK2 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

SK1 – Torque limiter

Safety system: hardened steel, Clamping ring: size 1.5 – 10 aluminium, Conical clamping bushing: size 15 – 2500 steel

Product catalogue in progress

Please be patient while we finalise our product details. We are continuously uploading new information.