Elastic couplings

Shaft couplings are the ideal way to compensate for axial, radial and angular misalignment and are an effective solution for damping vibrations and torque impulses.

Contact us if you have any questions.

Contact us

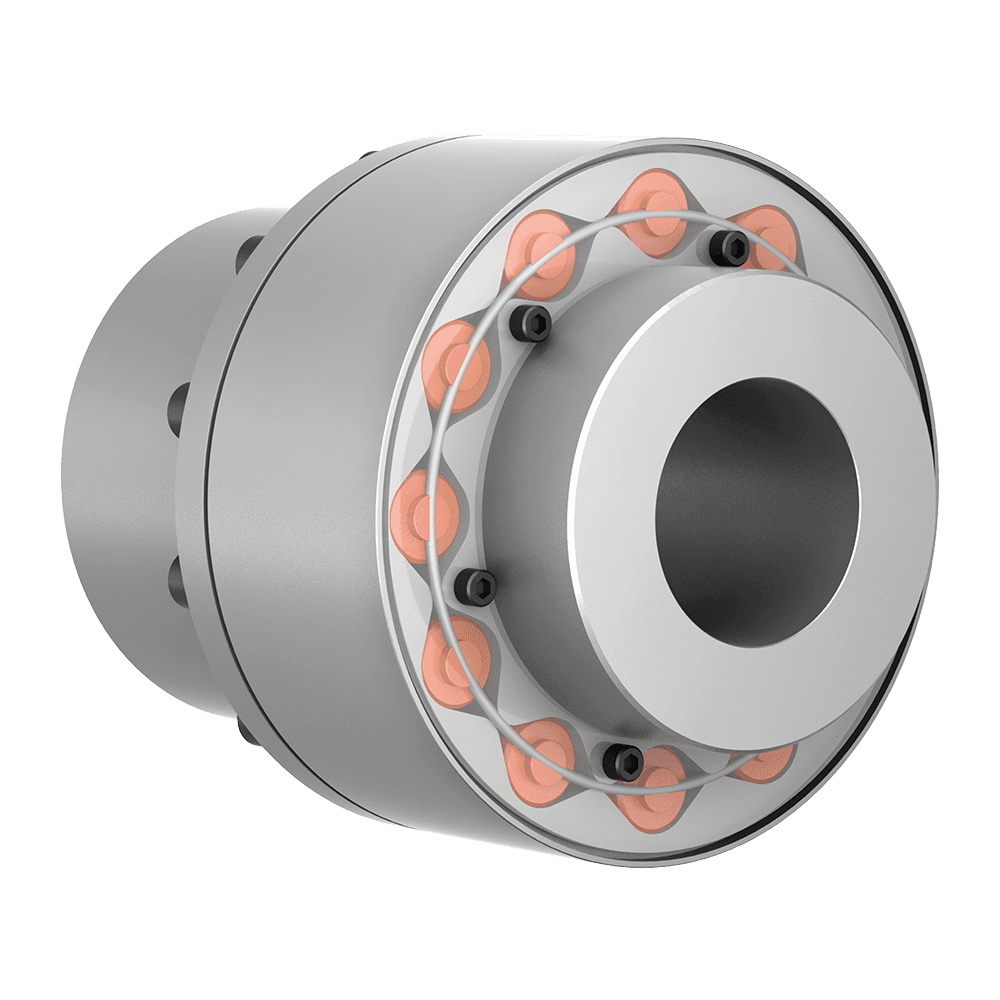

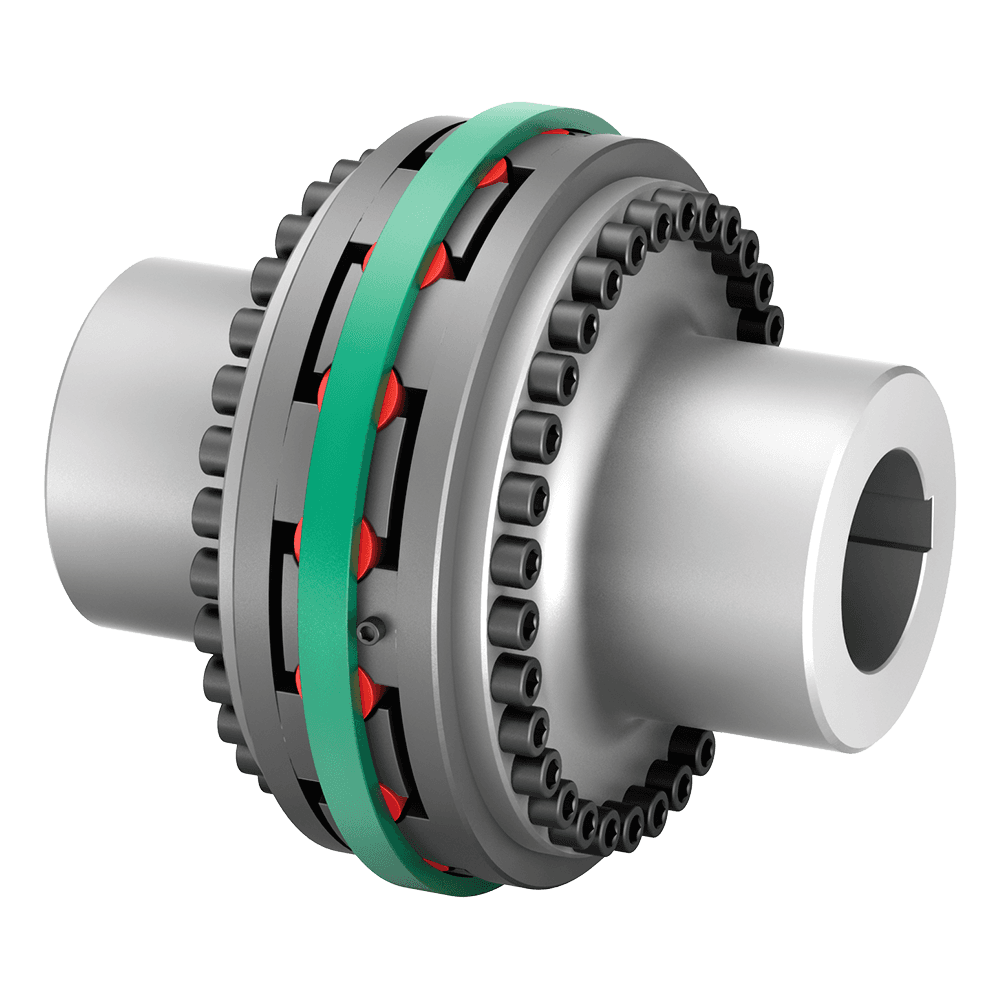

TNR 2428.2 torsional highflex coupling

Every drivetrain has its own characteristic torsional vibration behaviour. The newly developed RINGFEDER TNR provides the precise dynamic stiffness needed for each one.

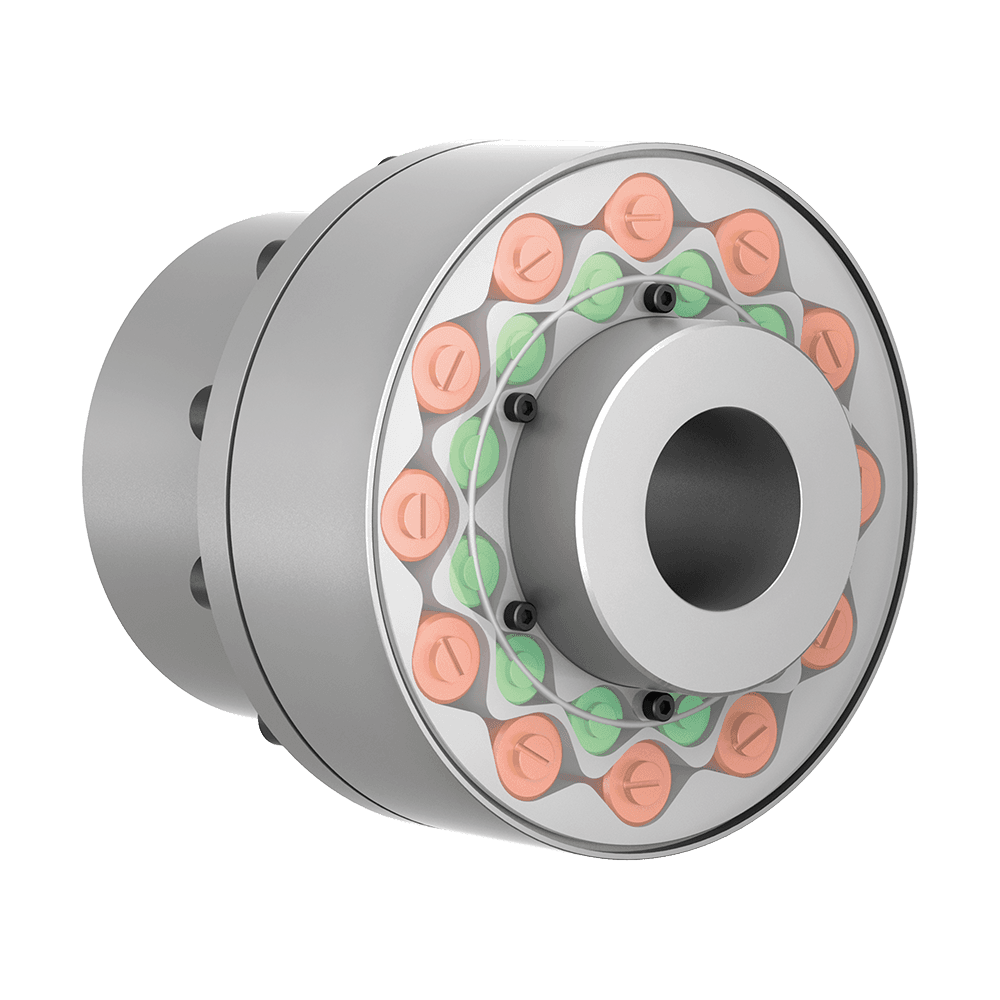

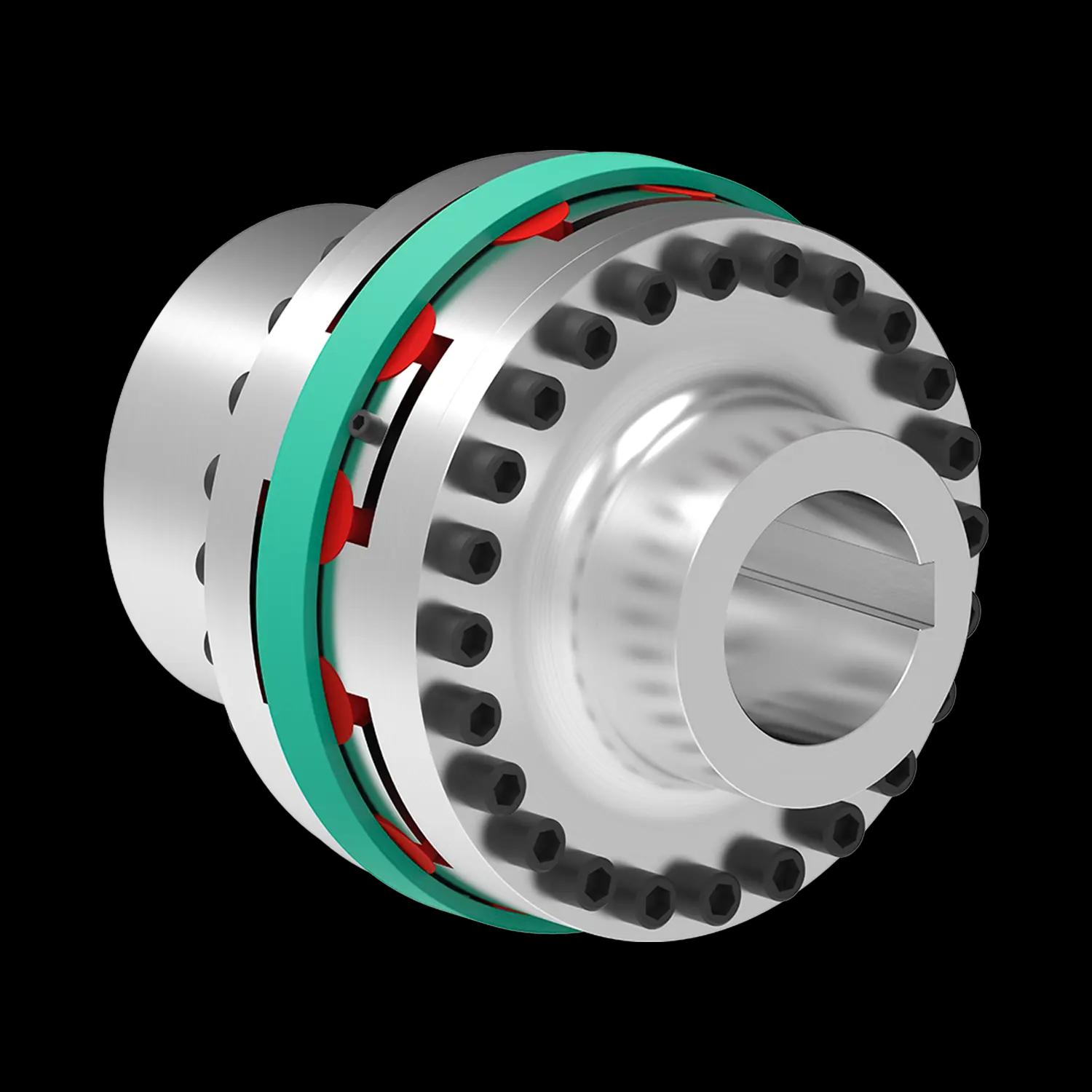

TNR 2428.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

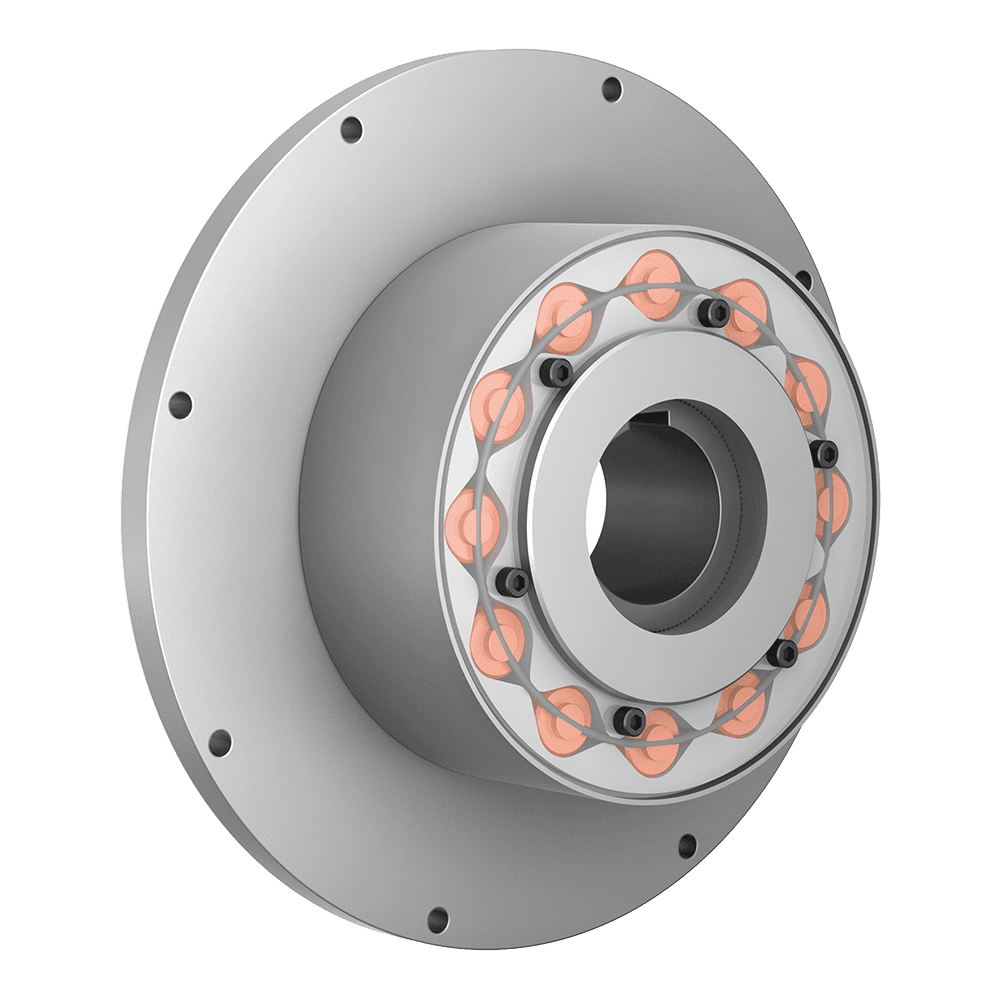

TNR 2425.2 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

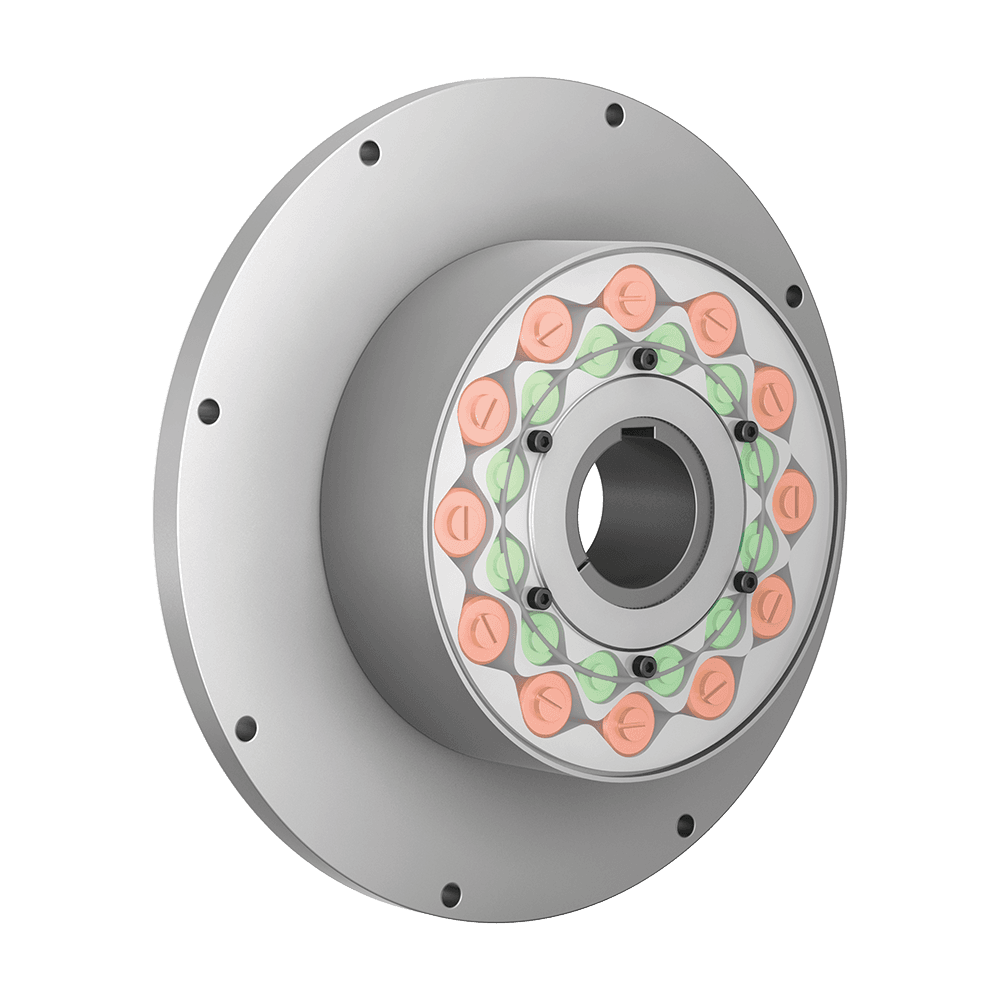

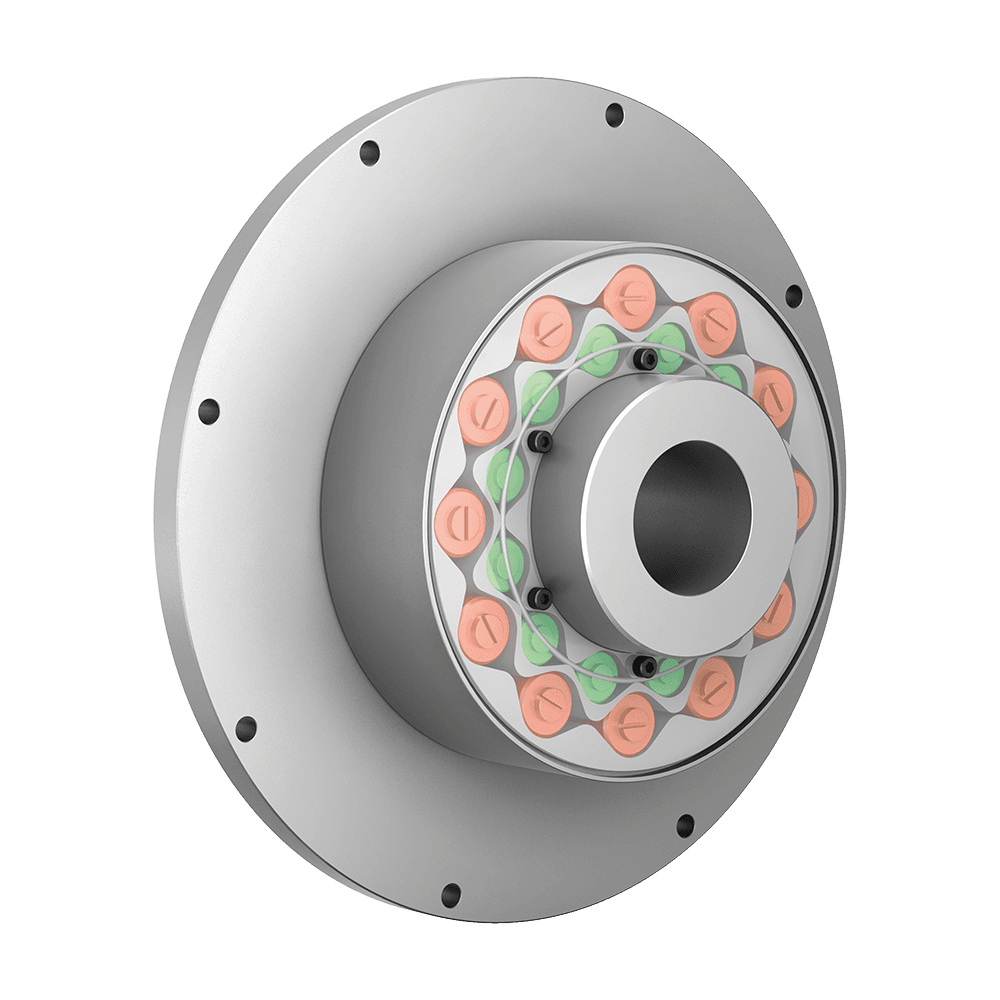

TNR 2425.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

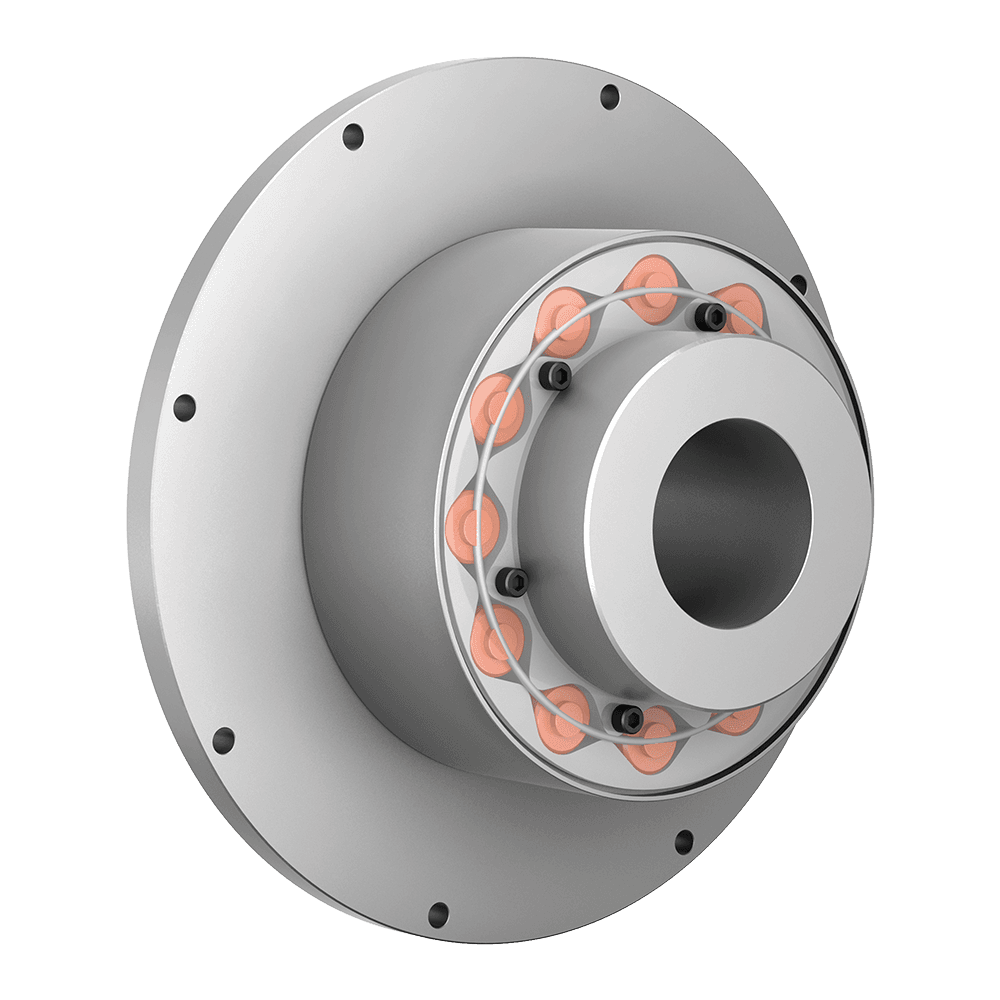

TNR 2424.2 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

TNR 2424.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

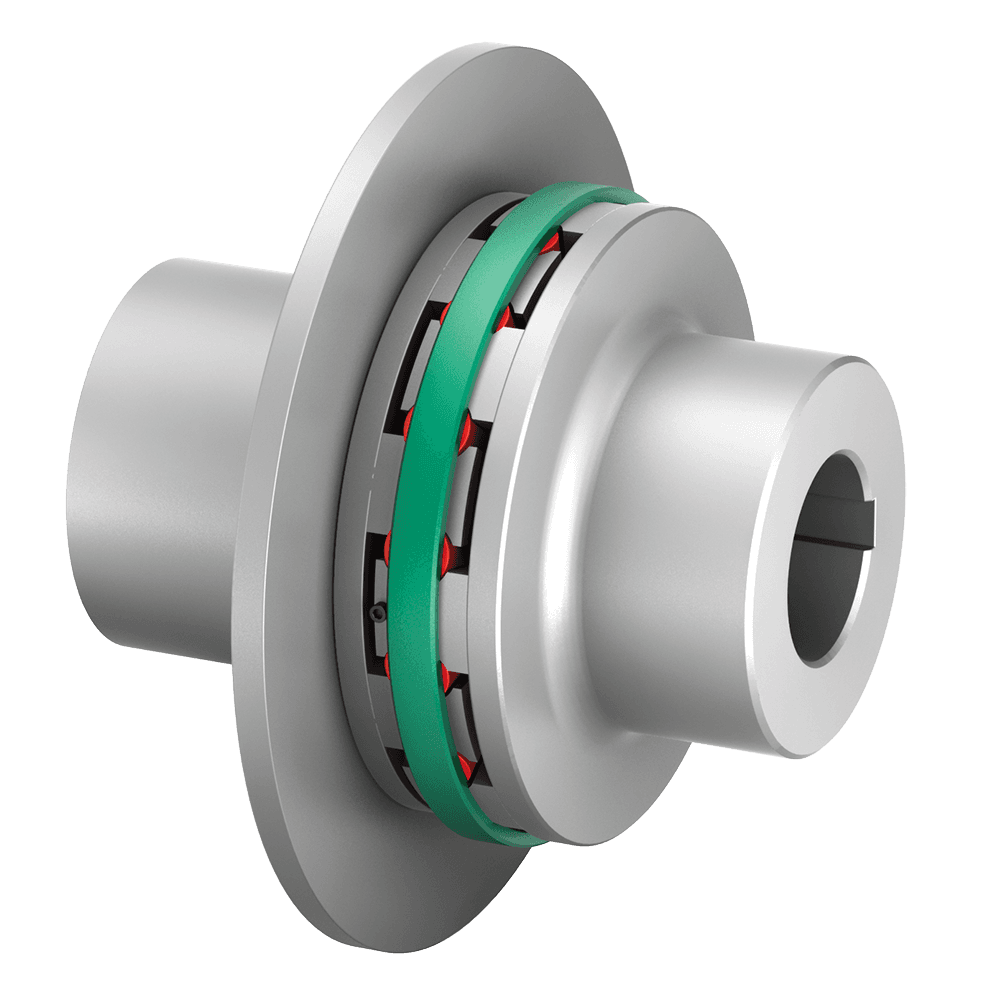

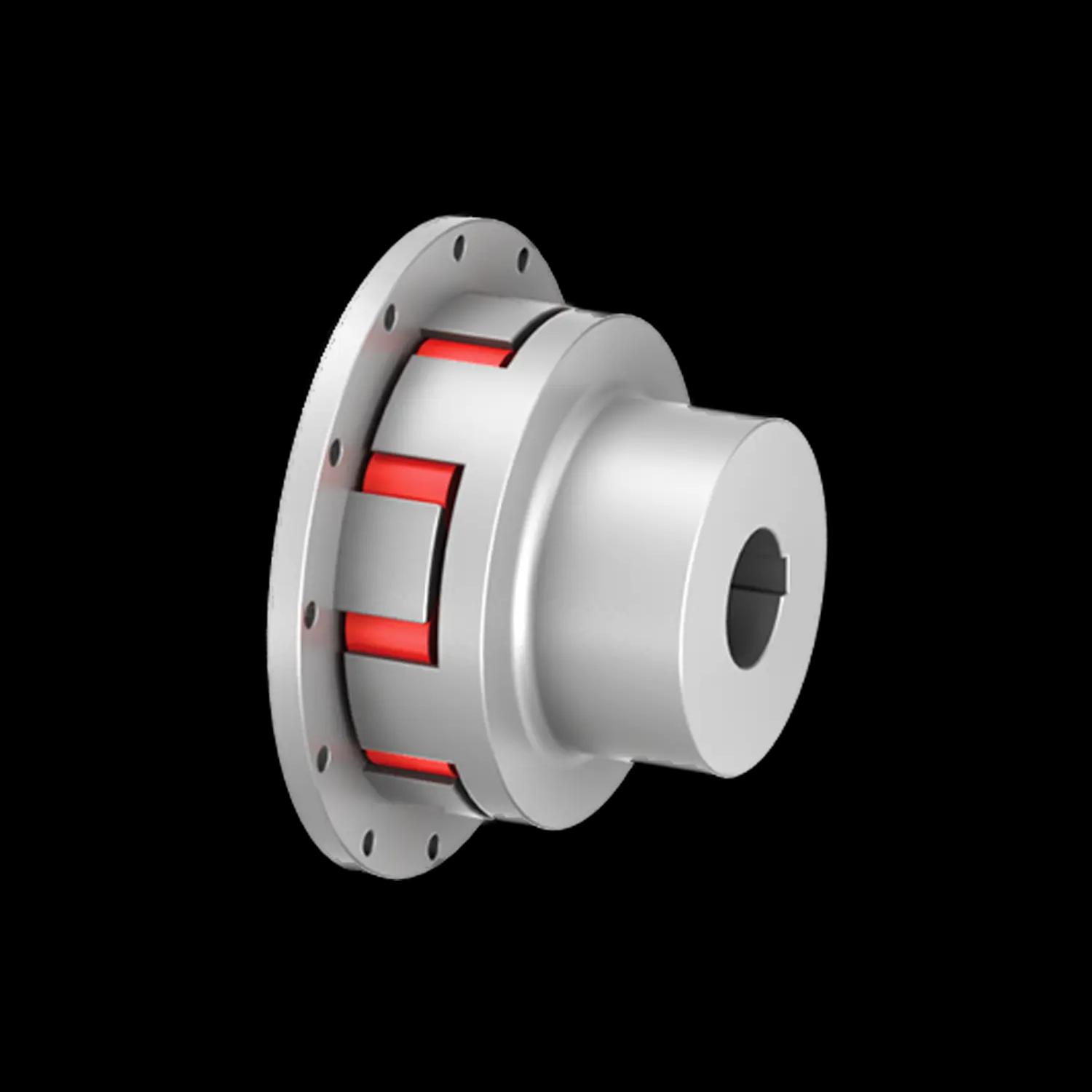

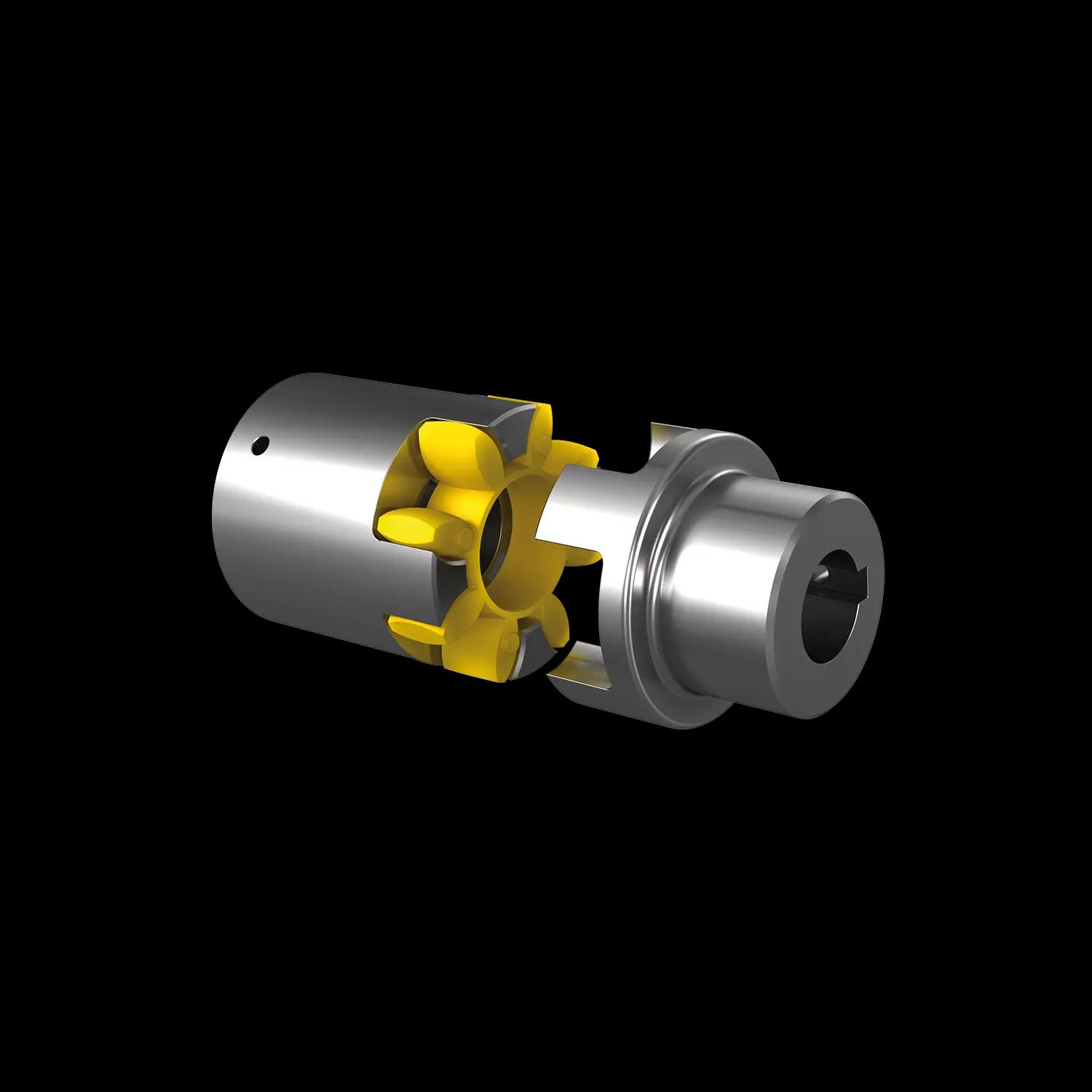

TNB BHDDV elastomer jaw coupling

The RINGFEDER TNB BHDDV coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

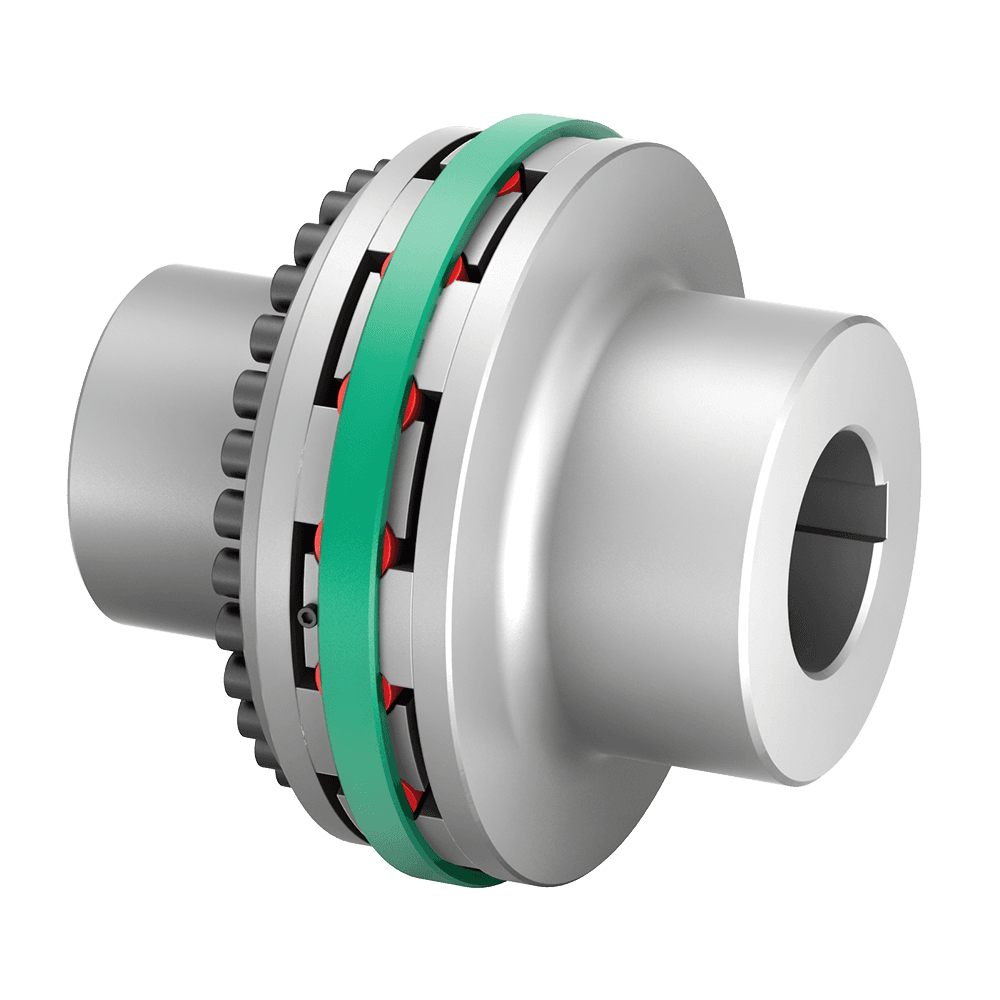

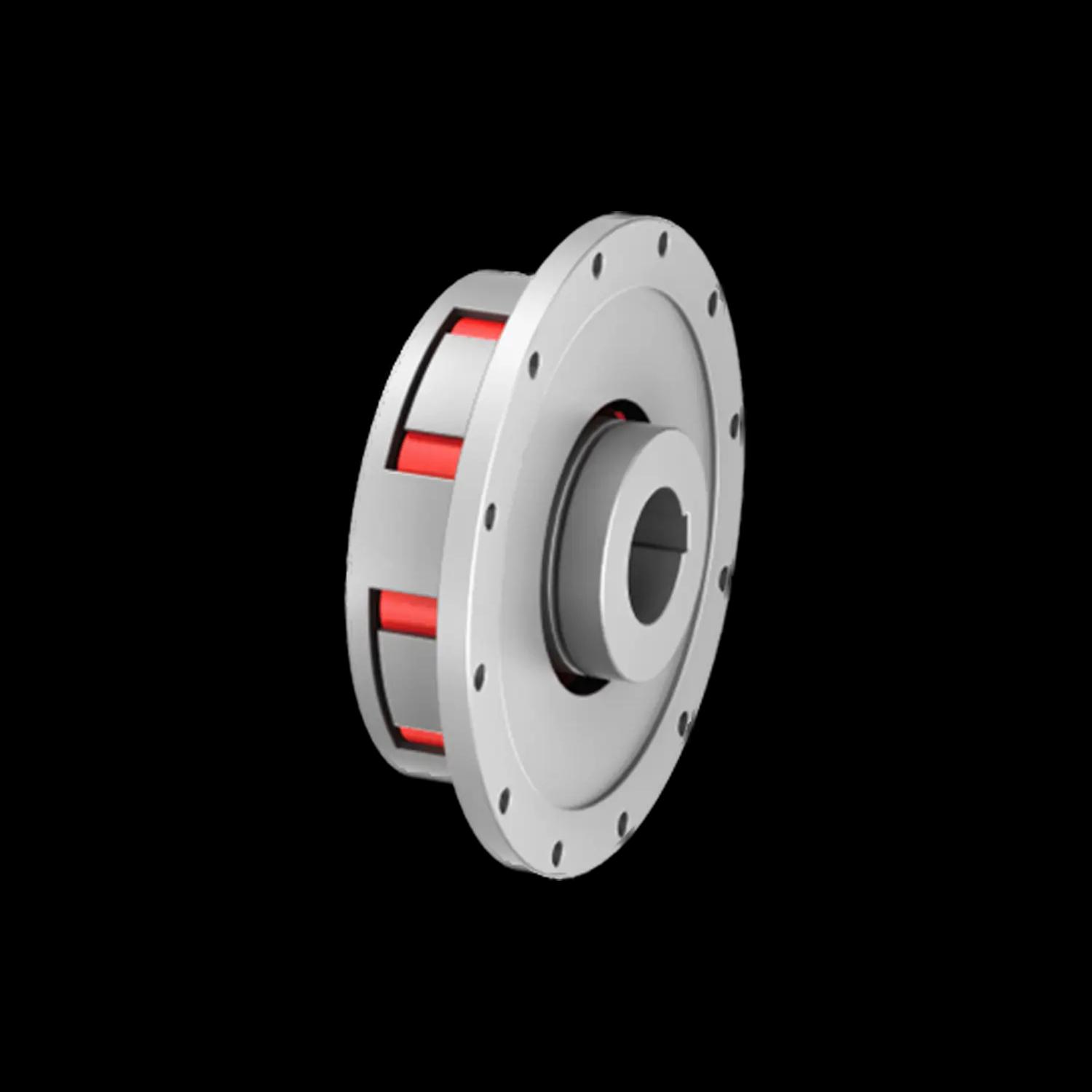

TNB BHDD elastomer jaw coupling

The RINGFEDER TNB BHDD coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

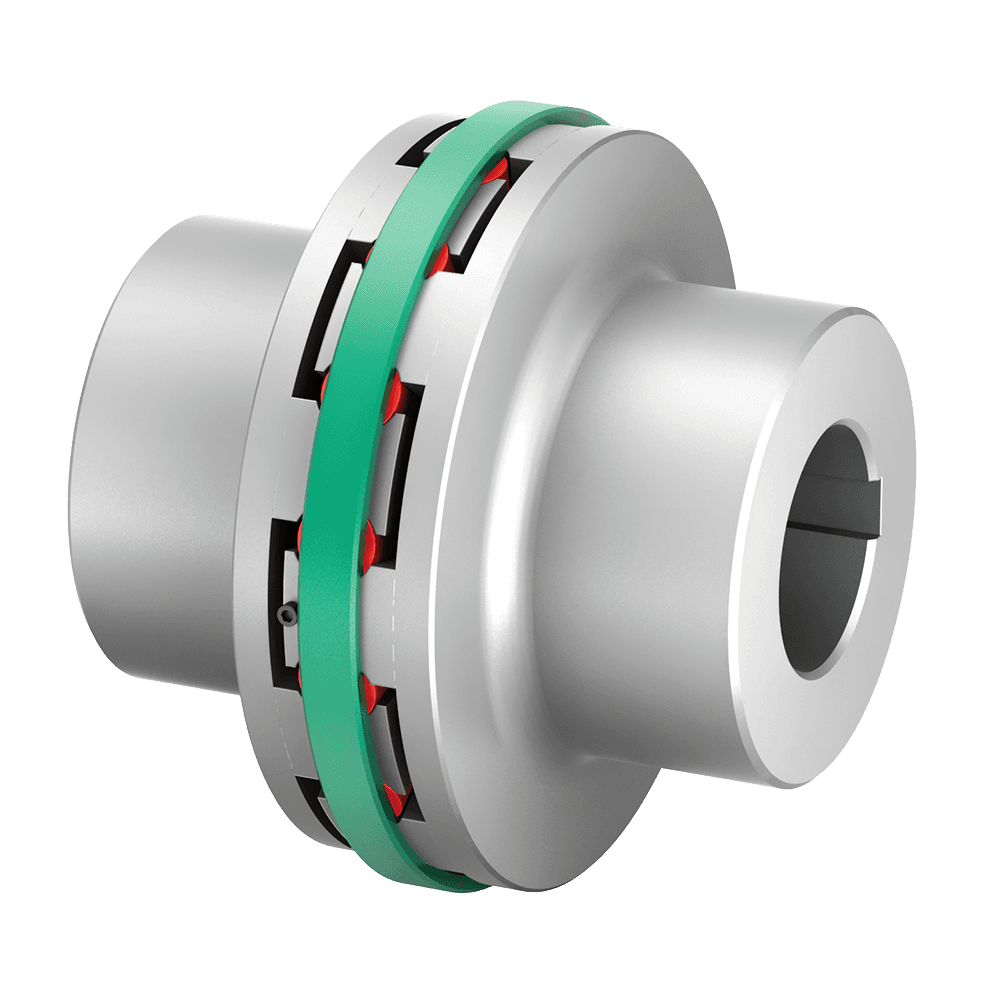

TNB BHD-BS elastomer jaw coupling

The RINGFEDER TNB BHD-BS coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNB BHD elastomer jaw coupling

The RINGFEDER TNB BHD coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

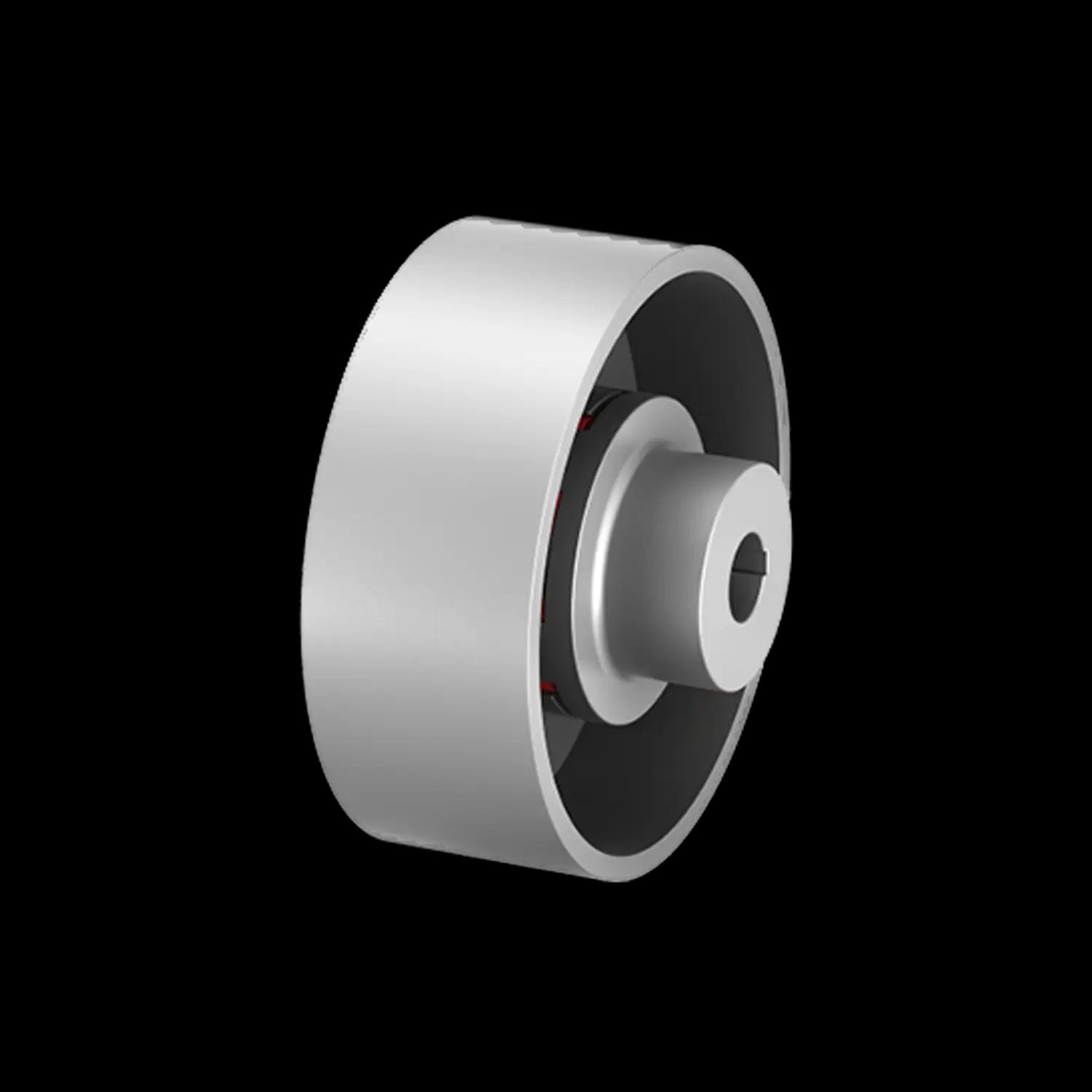

TNB BH elastomer jaw coupling

The RINGFEDER TNB BH coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNS S elastomer jaw coupling

At least one coupling hub must be removed before the intermediate ring can be replaced.

TNS L elastomer jaw coupling

At least one coupling hub must be removed before the intermediate ring can be replaced.

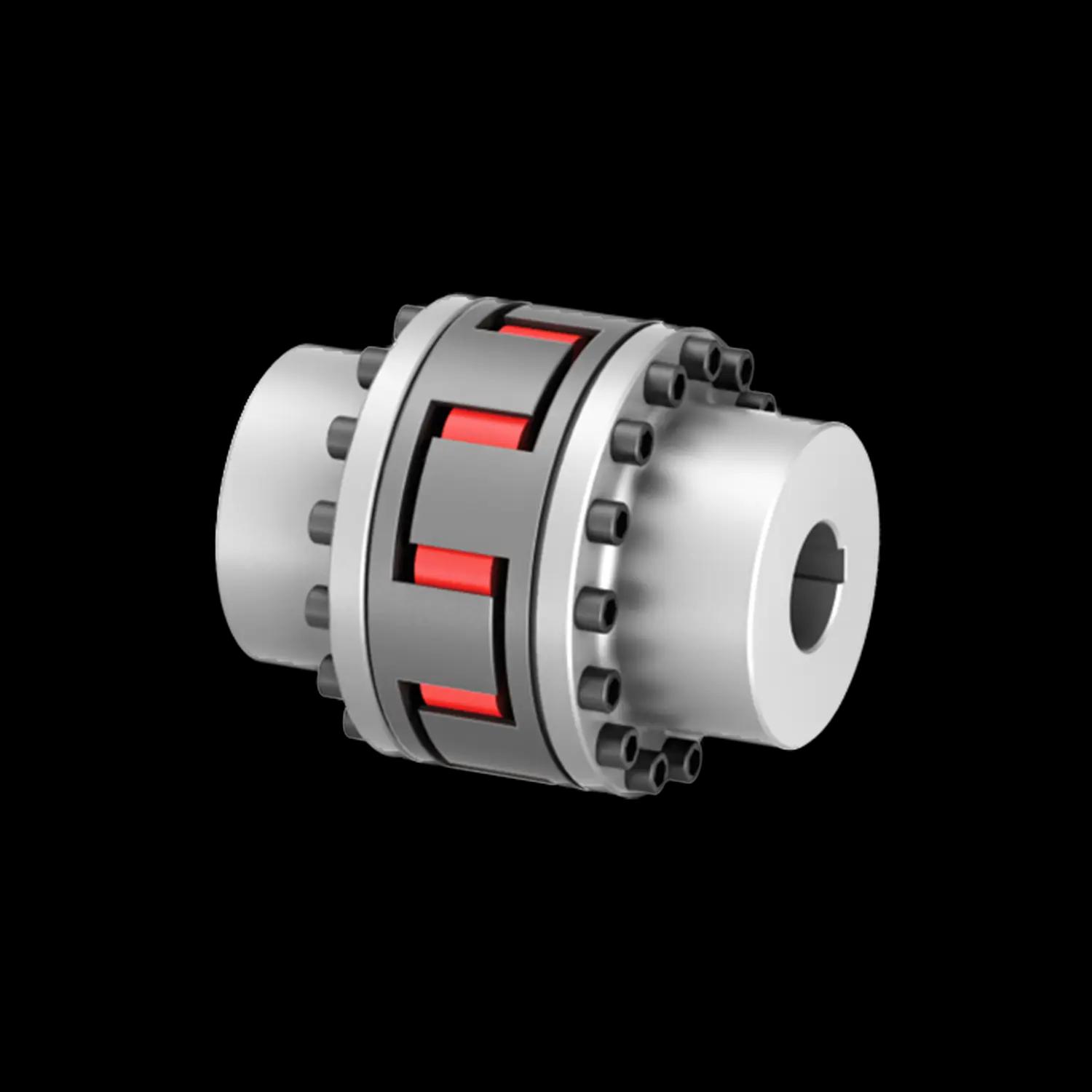

TNS SDD-5 elastomer jaw coupling

Thanks to the multi-piece hub, the intermediate ring can be replaced without having to move the coupling or machine axially. The intermediate ring can be replaced by lifting out the claw rings.

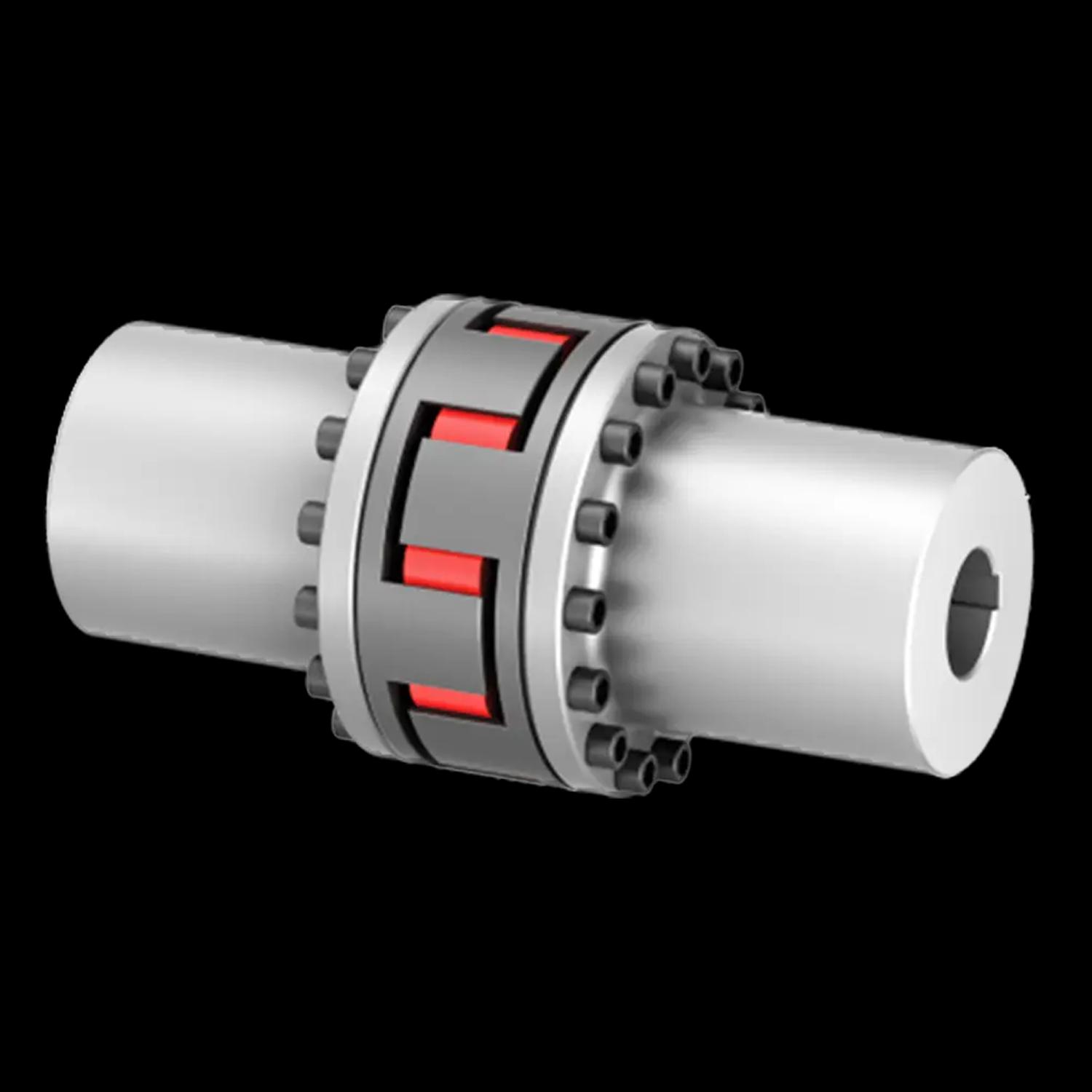

TNS SDDL-5 elastomer jaw coupling

Thanks to the multi-piece hub, the intermediate ring can be replaced without having to move the coupling or machine axially. The intermediate ring can be replaced by lifting out the claw rings.

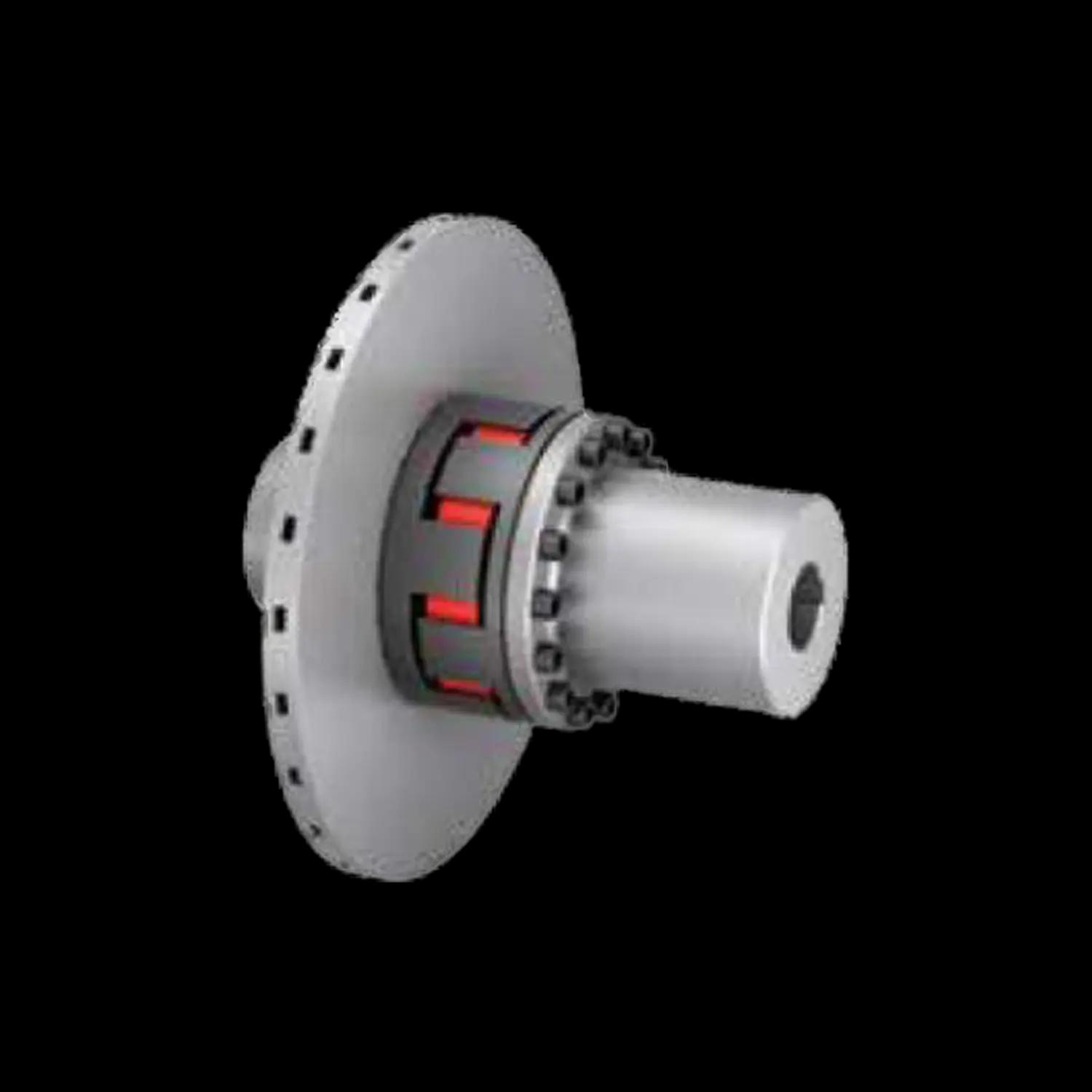

TNS SDDL-5-BS elastomer jaw coupling

Multi-piece design with flange hubs and brake disc.

TNS SDDL-5-BSV elastomer jaw coupling

Coupling with flange hubs, removeable claw rings, intermediate ring and internally vented brake disc

TNS S-BT elastomer jaw coupling

Version with standard hubs and brake drum.

TNS SX elastomer jaw coupling

One-piece elastomer jaw coupling with standard hub and claw flange

TNS SV elastomer jaw coupling

Highly compact design with one-piece inner hub and claw flange.

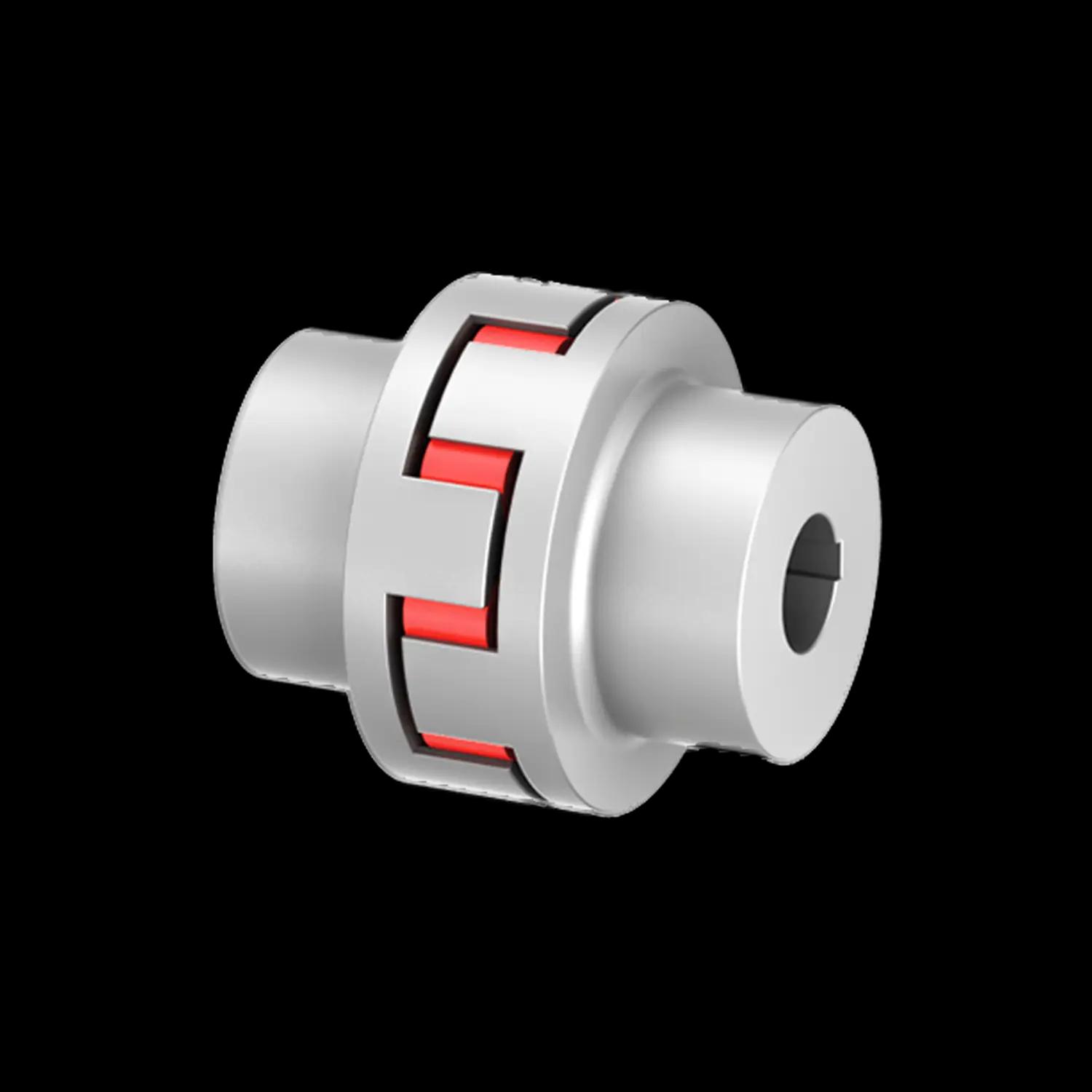

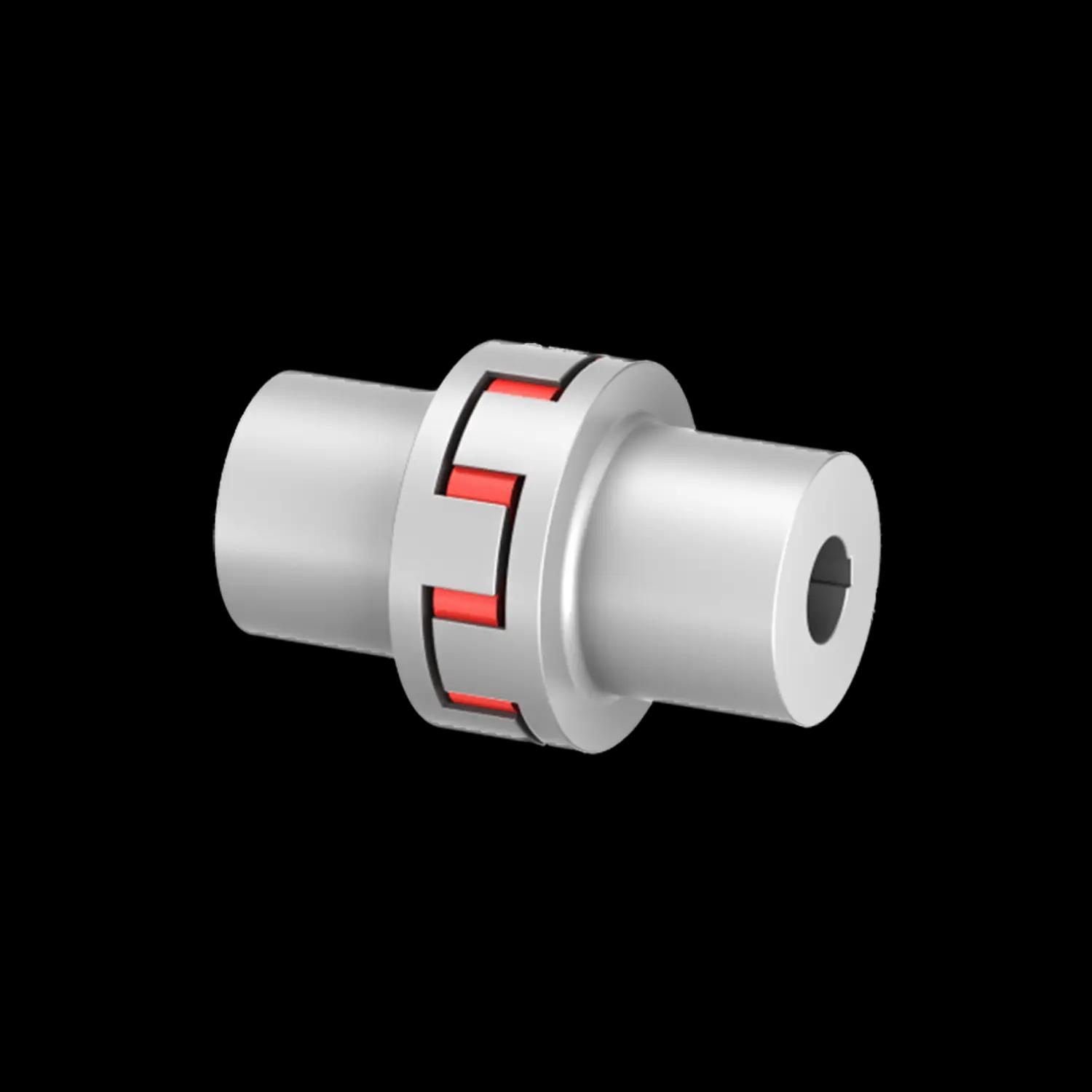

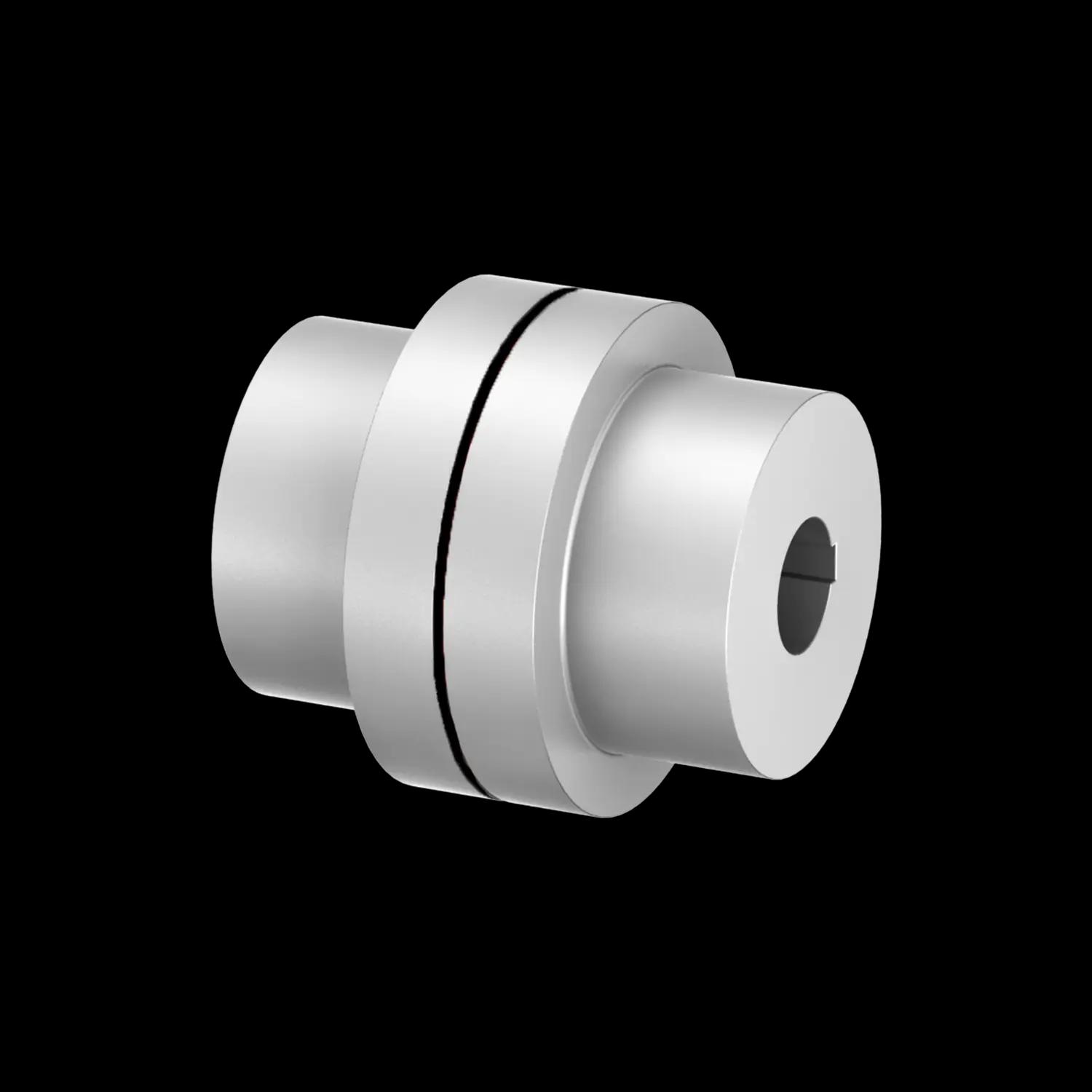

ECE 6118 jaw coupling

Standard shaft coupling made of aluminium in various sizes and with different hub types.

ECE 6418 jaw coupling

Steel version

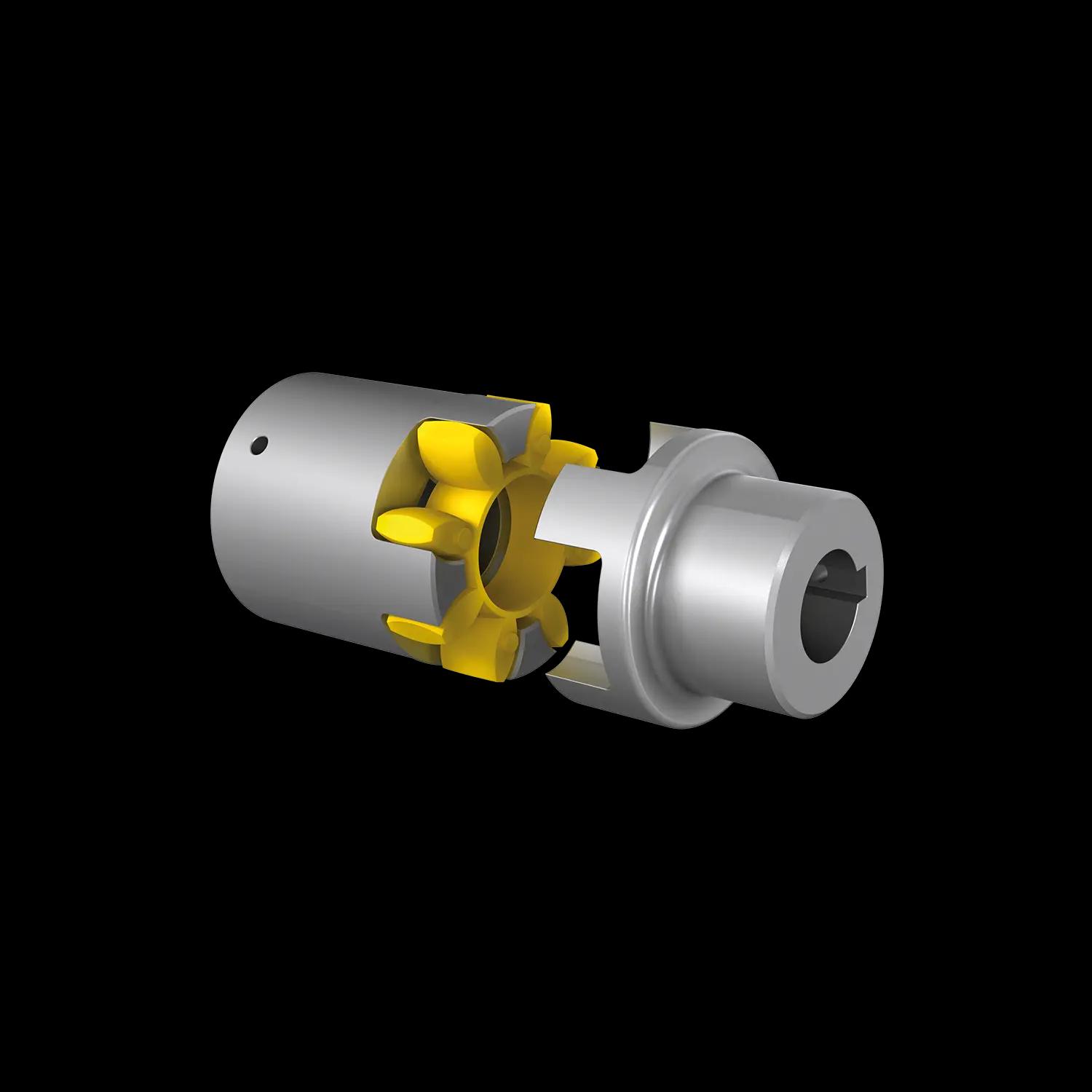

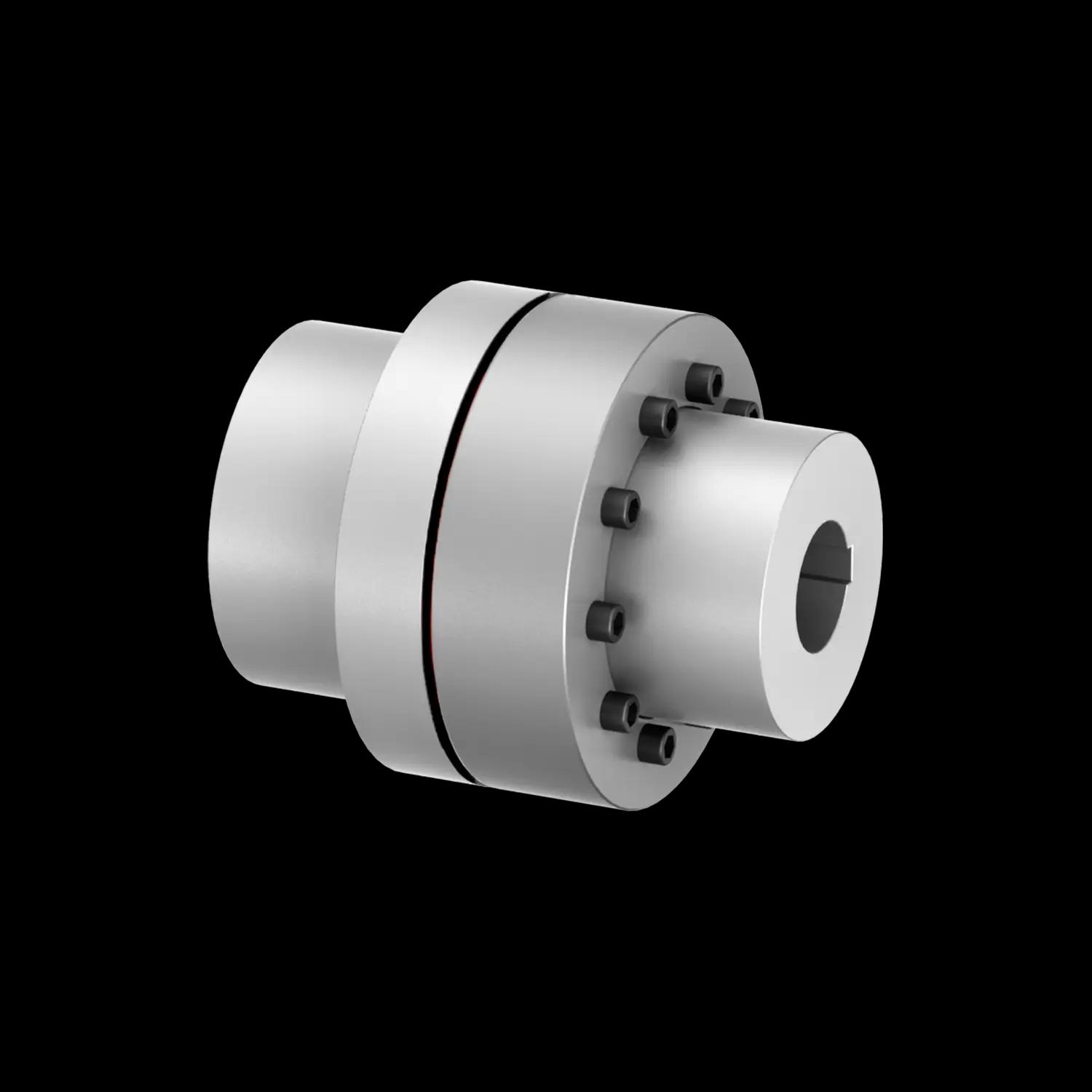

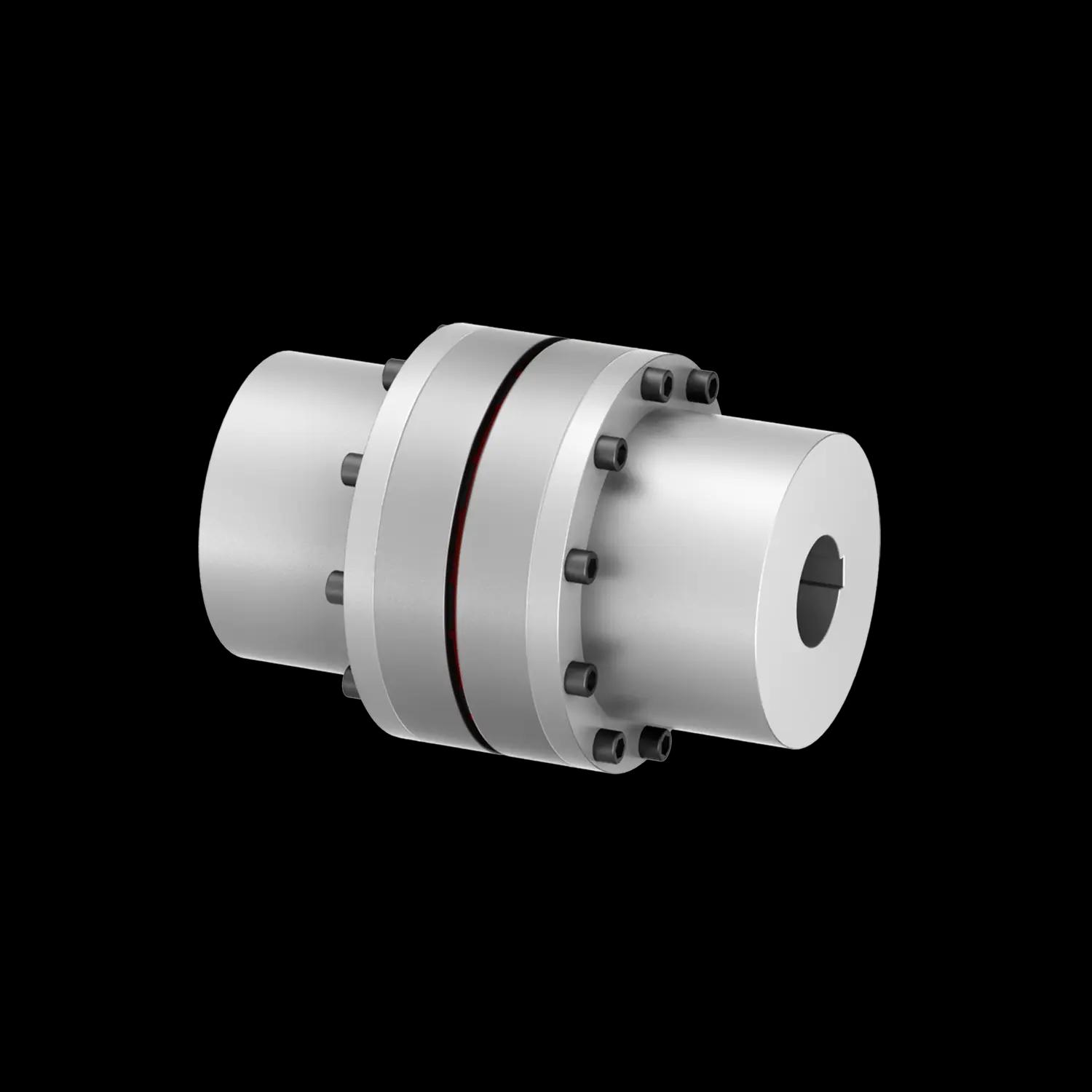

TNM E elastomer jaw couplings

Two-piece design with standard hubs

TNM G elastomer jaw couplings

A robust three-piece design that offers flexibility and easy separation for a wide range of industrial applications

TNM H elastomer jaw couplings

Easily accessible pump coupling with direction of rotation check

Downloads

Klauenkupplungen

Klauenkupplungen Elastomer Jaw Couplings

Elastomer Jaw Couplings Hochdrehelastische Kupplungen TNR

Hochdrehelastische Kupplungen TNR Torsional Highflex Couplings TNR

Torsional Highflex Couplings TNR