Rotary unions & winding technology

Rotary unions can be used to transfer media and information between rotating and stationary parts. Winding technology enables materials to be coiled onto – and uncoiled from – cores in an orderly manner.

Contact us if you have any questions.

Contact usOur quality brands

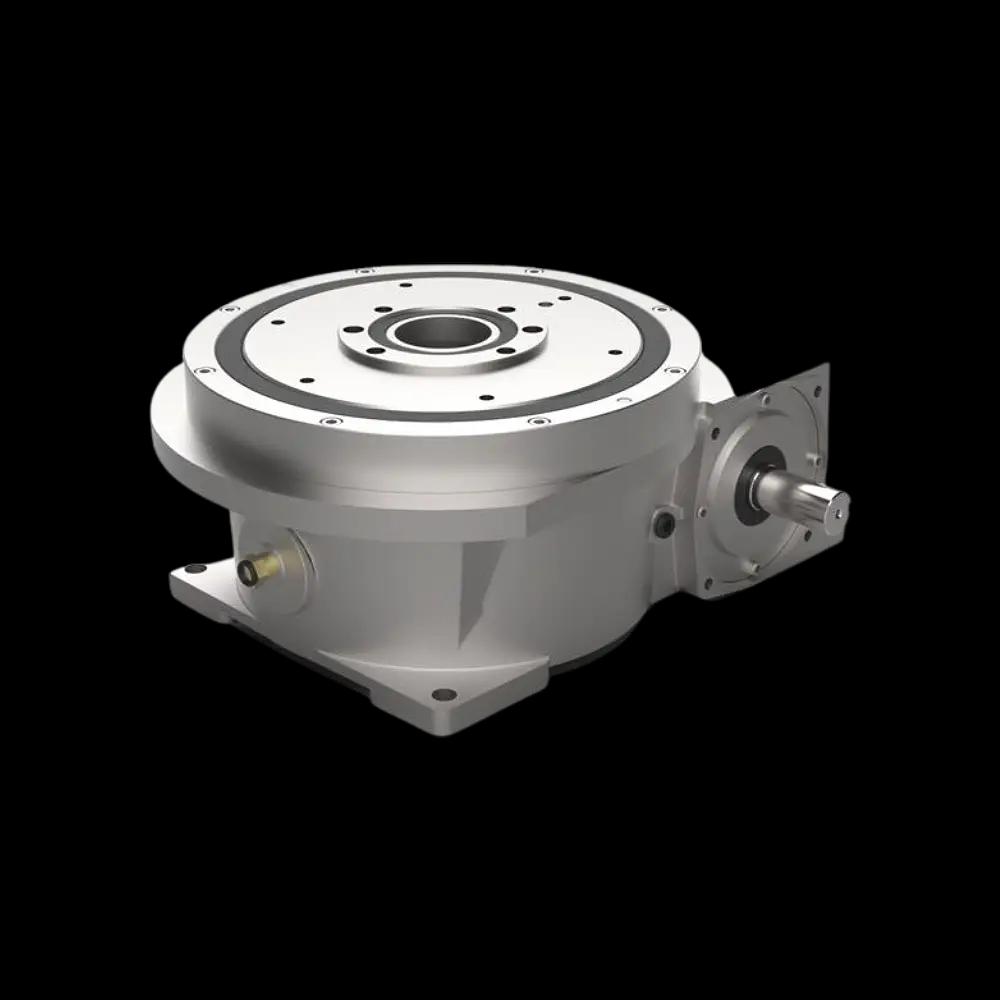

RDM Series Rotary Indexers

Reliable and Precise Rotary Indexing for Industrial Automation

GTB Servo Indexers

High-Precision Rotary Positioning for Industrial Automation

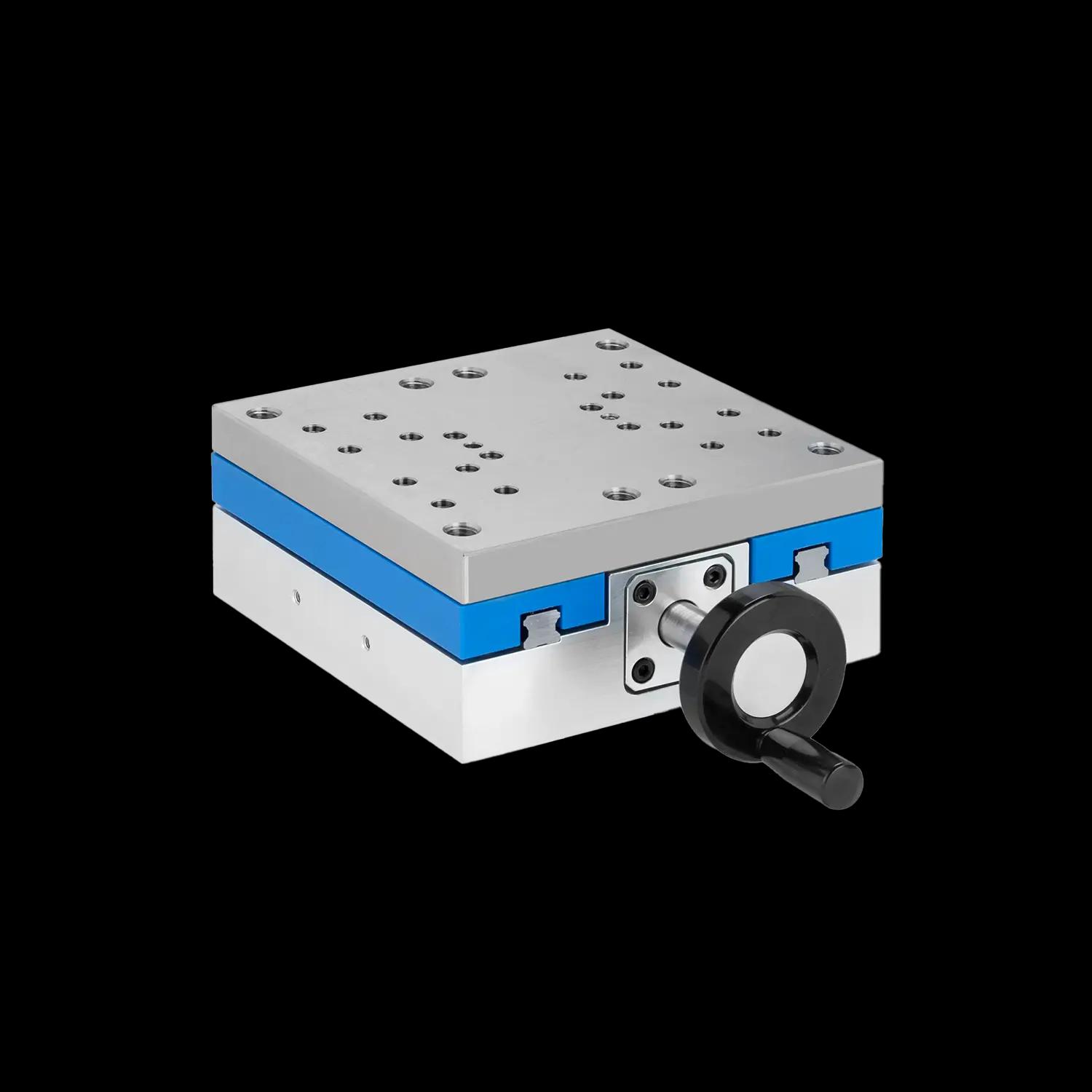

Radial and axial slides

Boschert Slide Axial/Radial enables accurate axial and radial adjustment for optimal shaft positioning in industrial applications.

Clamping cones

Boschert Clamping Cones provide high-torque grip on roll cores with customizable bore shapes and serrated designs.

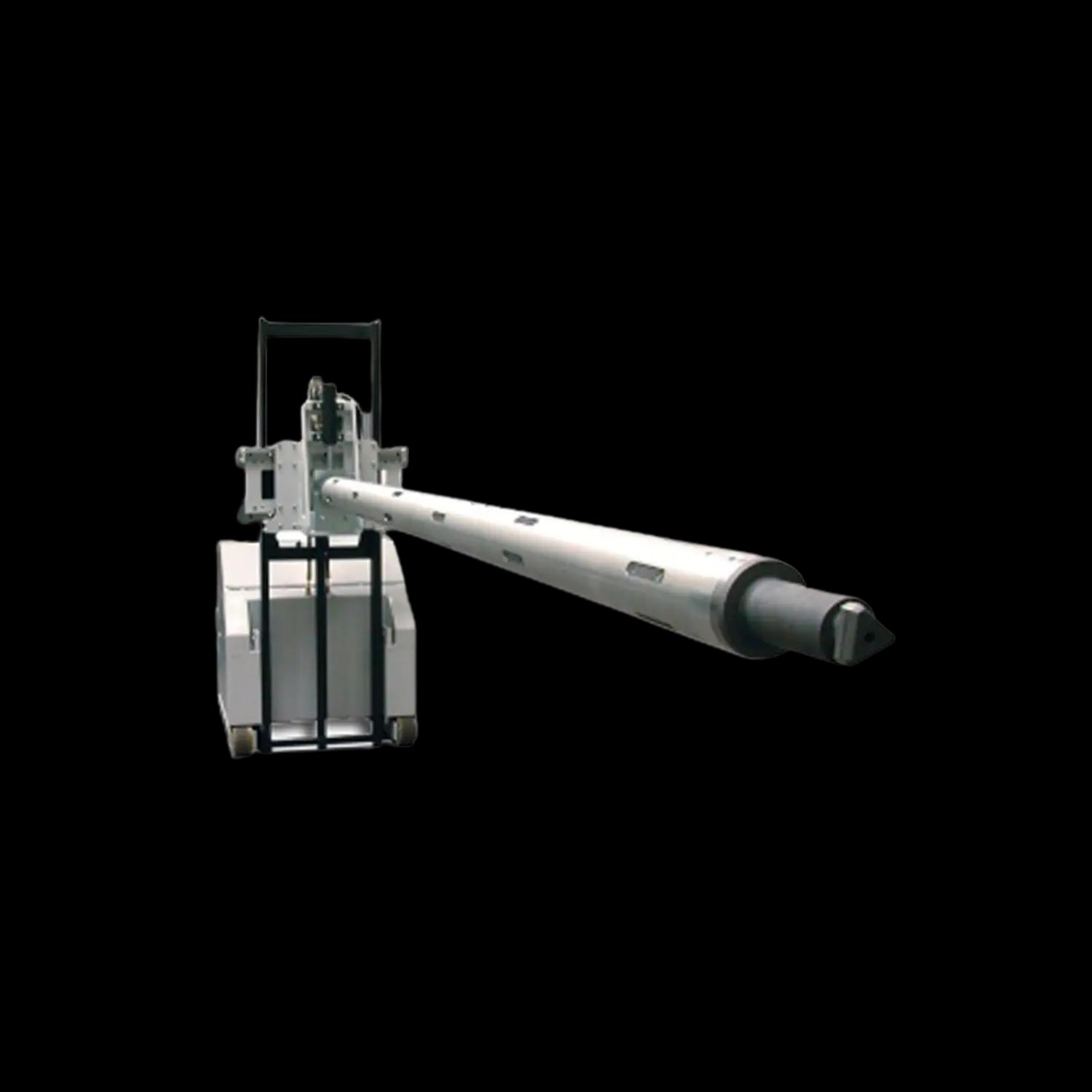

Mobile shaft puller

From light tambours to heavy expansion shafts – Vorwald Shaft Pullers offer mechanical efficiency, adaptability, and robust design for any production line.

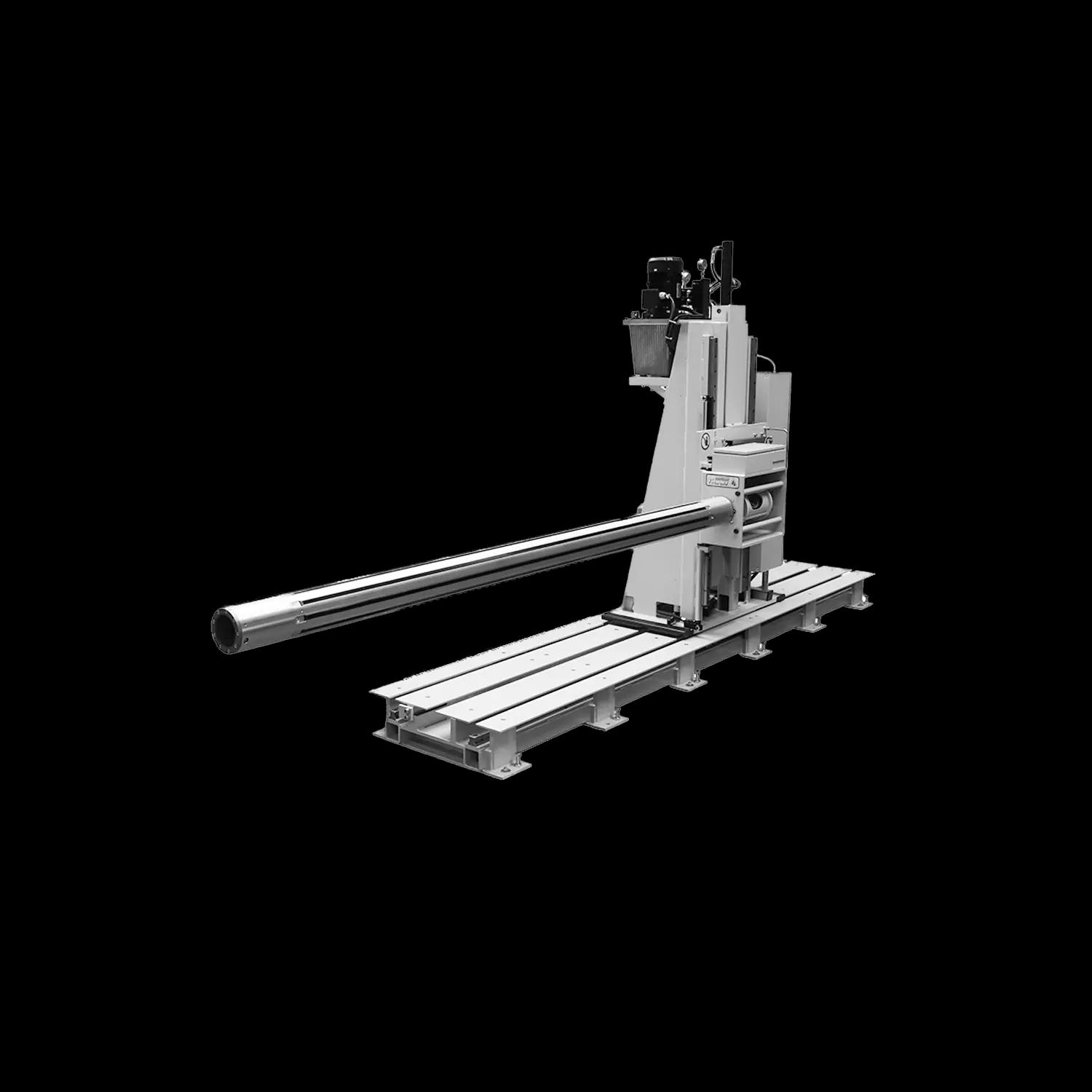

Stationary shaft puller

Capable of handling everything from small and lightweight expansion shafts/drums right through to those weighing several tonnes

Series 409 flat hose shaft

Series 409 by Vorwald: Flexible pneumatic expansion shaft designed for precision, strength, and ease of maintenance

Sliding chuck

The Boschert Sliding Safety Chuck ensures precise roll alignment, preventing damage and improving production efficiency with both manual and motorized options.

Easy Wind

Boschert Easy Wind simplifies web tension management with quick installation and reliable control for one or two rolls.

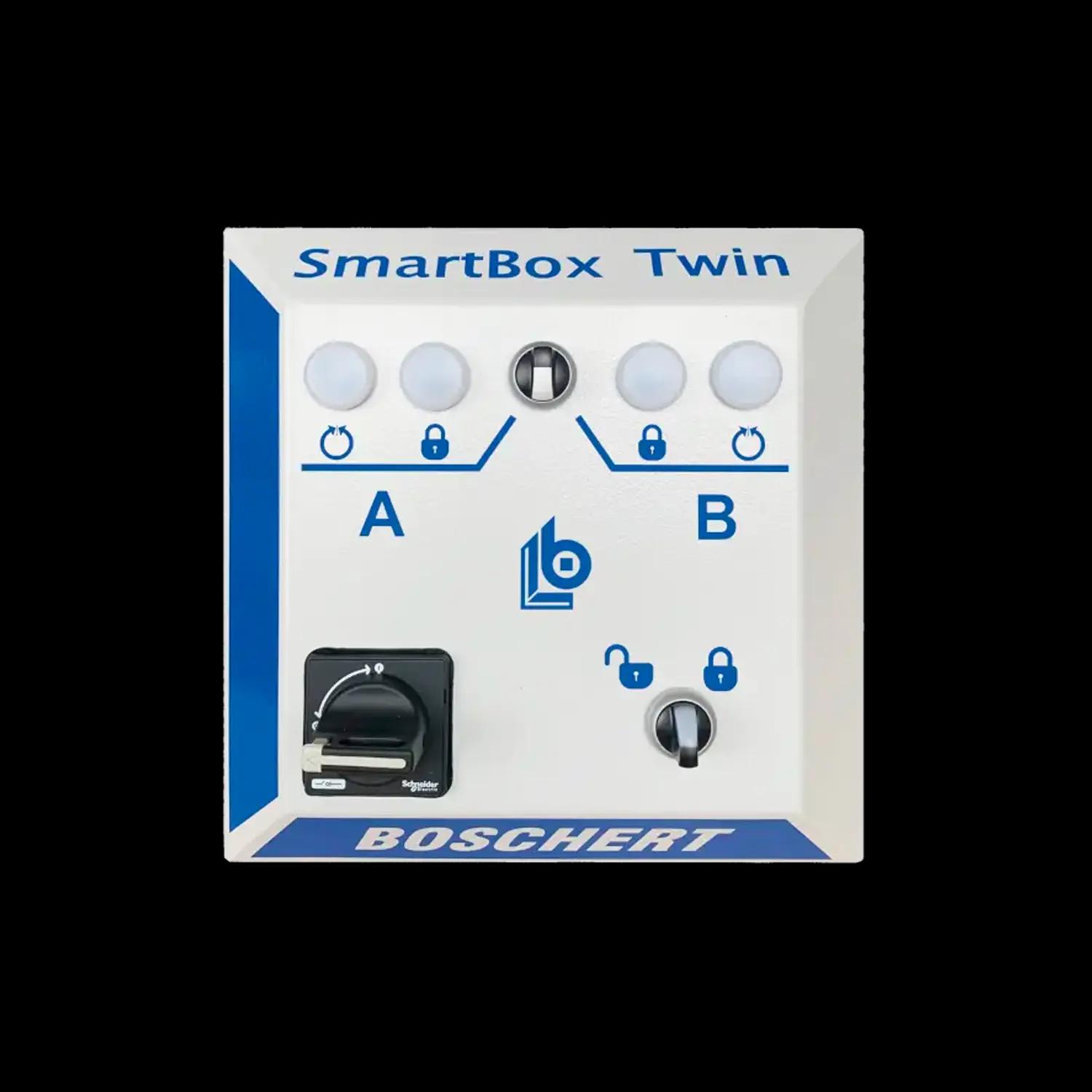

Smart Box

Autonomous chuck control without modifying your machine control system.

Multi-brake

Multi Calliper Brake offers modular torque control from 50Nm to 1200Nm – ideal for precise, quiet, and reliable web tension regulation.

Series DSB double disc brake

Double Disc Brakes (DSB) offer reliable, adjustable torque for smooth and efficient web handling.

Series ESB single disc brake

Single Disc Brake ESB ensures precise and reliable web tension control during unwinding processes, available in manual, pneumatic, and membrane cylinder configurations.

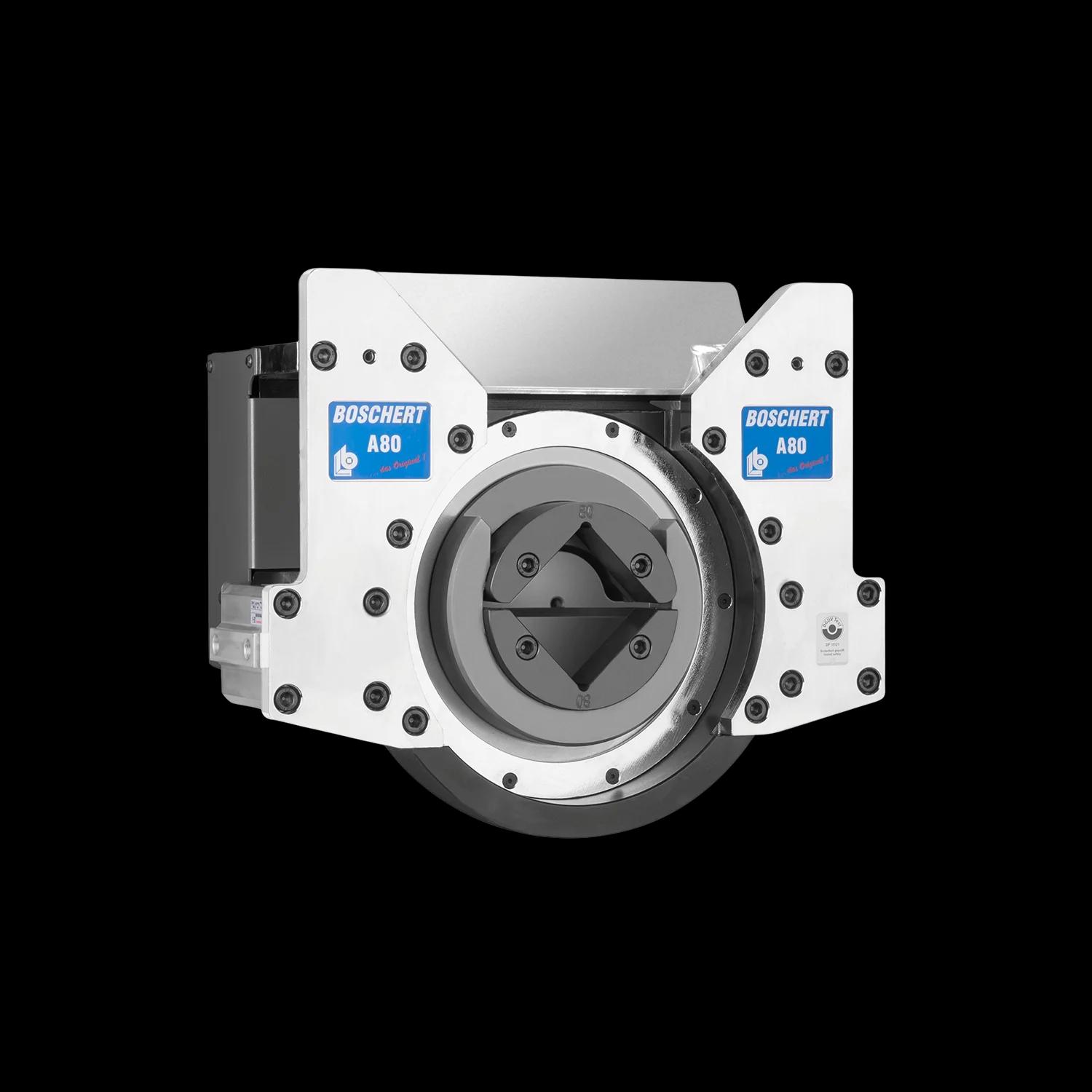

A-Chuck

The Boschert A-Chuck: Engineered for the future of industrial clamping.

P-Chuck

The P-Chuck enables quick, safe, and automated shaft clamping with pneumatic control.

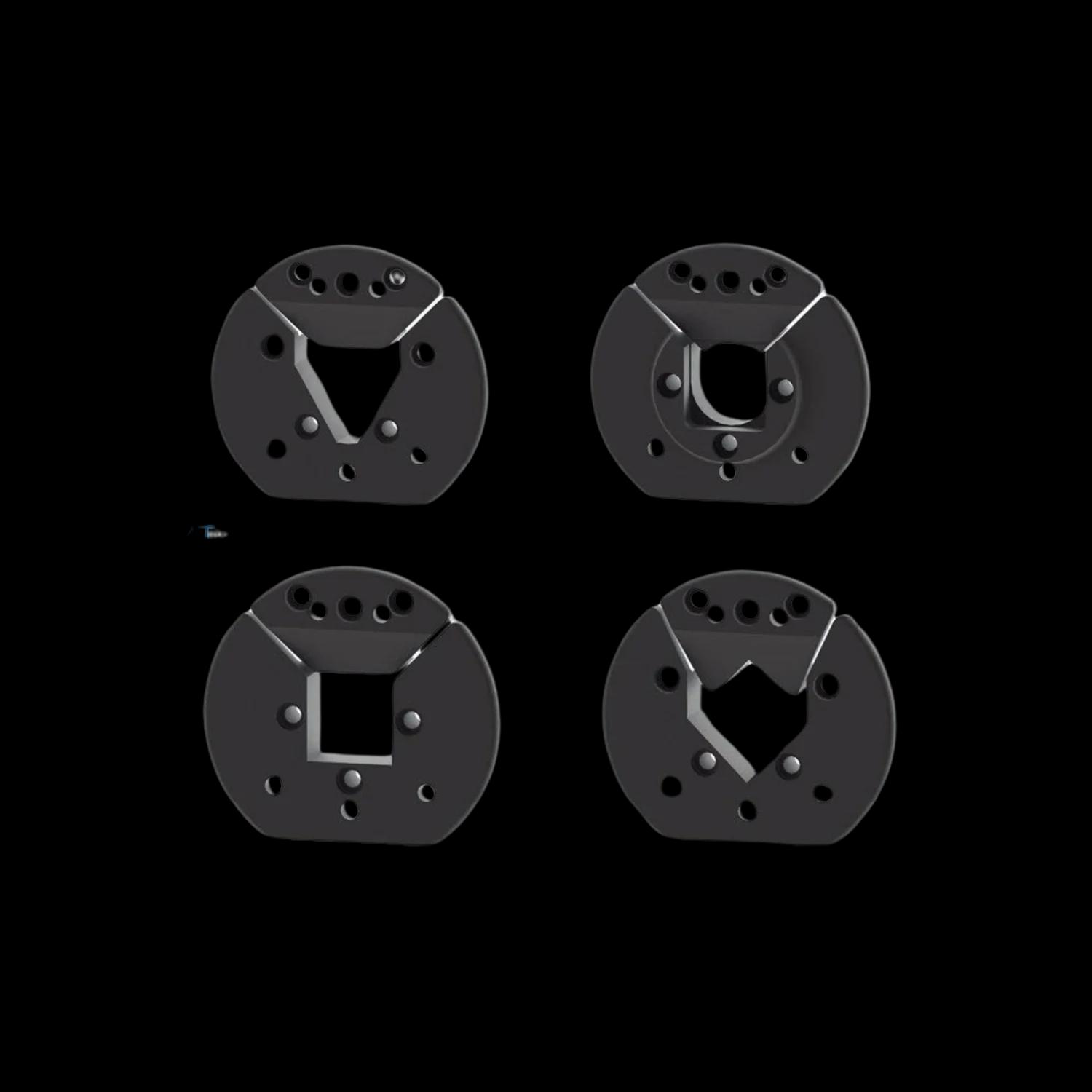

Wearing part inserts

The wearing parts (VT) can be easily replaced directly on the system.

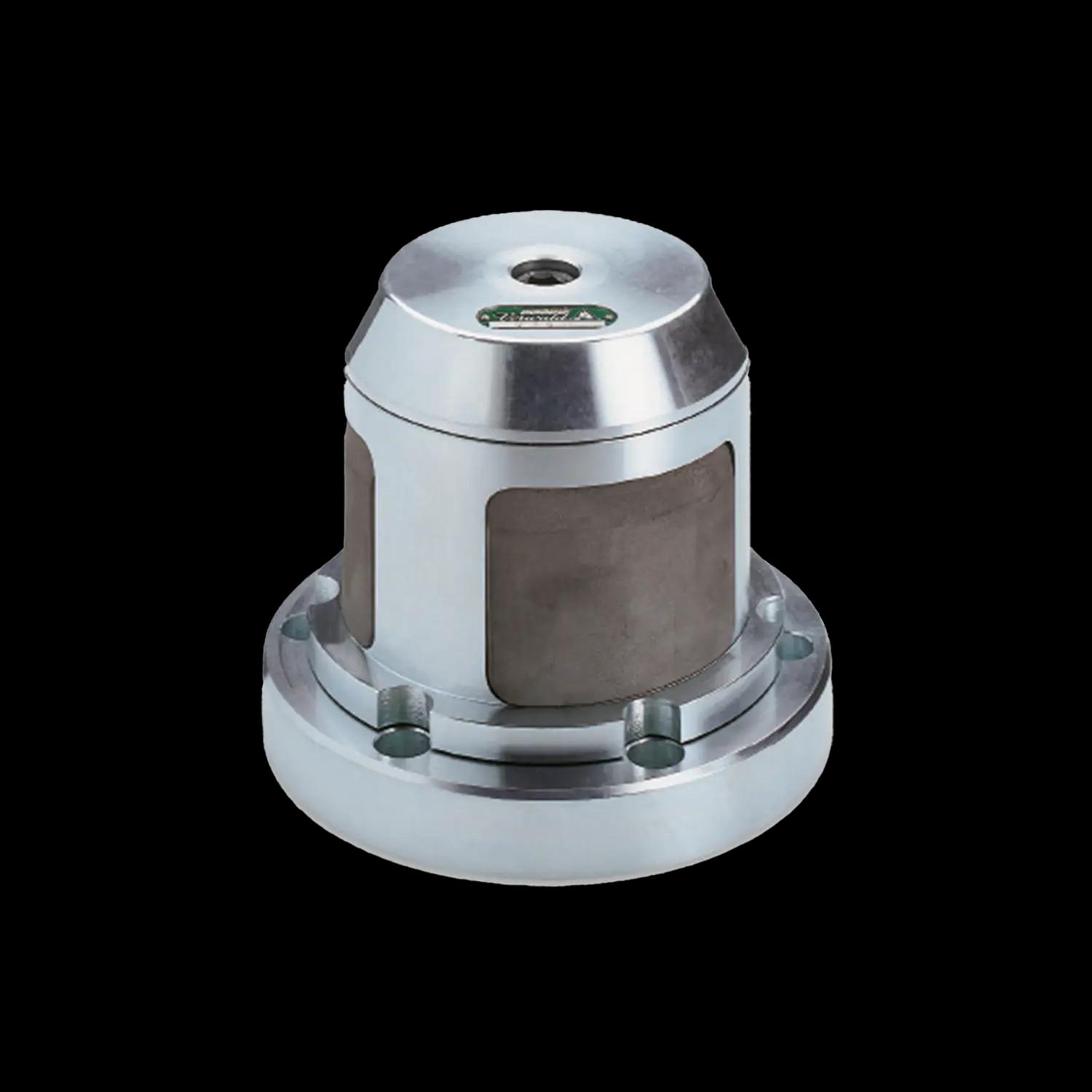

VT-Chuck

The Boschert VT Chuck delivers efficient maintenance, flexibility in shaft geometry, and superior winding shaft support

C-Chuck

The original Boschert C-Chuck delivers safety, performance, and durability for winding applications

Series 900 adapter

The Vorwald series 900 adapter with individual expansion lugs or expansion leaves is required for applications that call for frequent changes between different core sizes.

Series 841 mechanical expansion chuck

The Vorwald series 841 expansion chuck is suitable for shaftless rewinding and winding machines with medium torques.

Series 834 Rollmatic mechanical expansion chuck

Activated by applied torque. The expansion leaves are twisted and activated by the web tension.

Series 831 mechanical expansion chuck

The axial force exerted on the core causes the expansion lugs to expand centrically.

Series 860 and series 861 expansion chucks

Versatile mechanical expansion chucks with customizable expansion lugs or leafs for secure, concentric clamping in winding processes.

Series 811 expansion chuck

Discover the high-performance Vorwald Series 811 – engineered for precision clamping, high torque transmission, and quick adaptability across all core diameters from 50 to 500 mm.

Series 404 friction shaft

Vorwald Series 404 pneumatic friction shafts ensure consistent web tension and clean winding without abrasion – ideal for challenging materials.