Expansion couplings

Expansion couplings optimise winding processes by enabling rapid process changeovers, delivering high torque transmission and offering easy handling. They are suitable for a wide range of materials and diameters.

Contact us if you have any questions.

Contact usOur quality brands

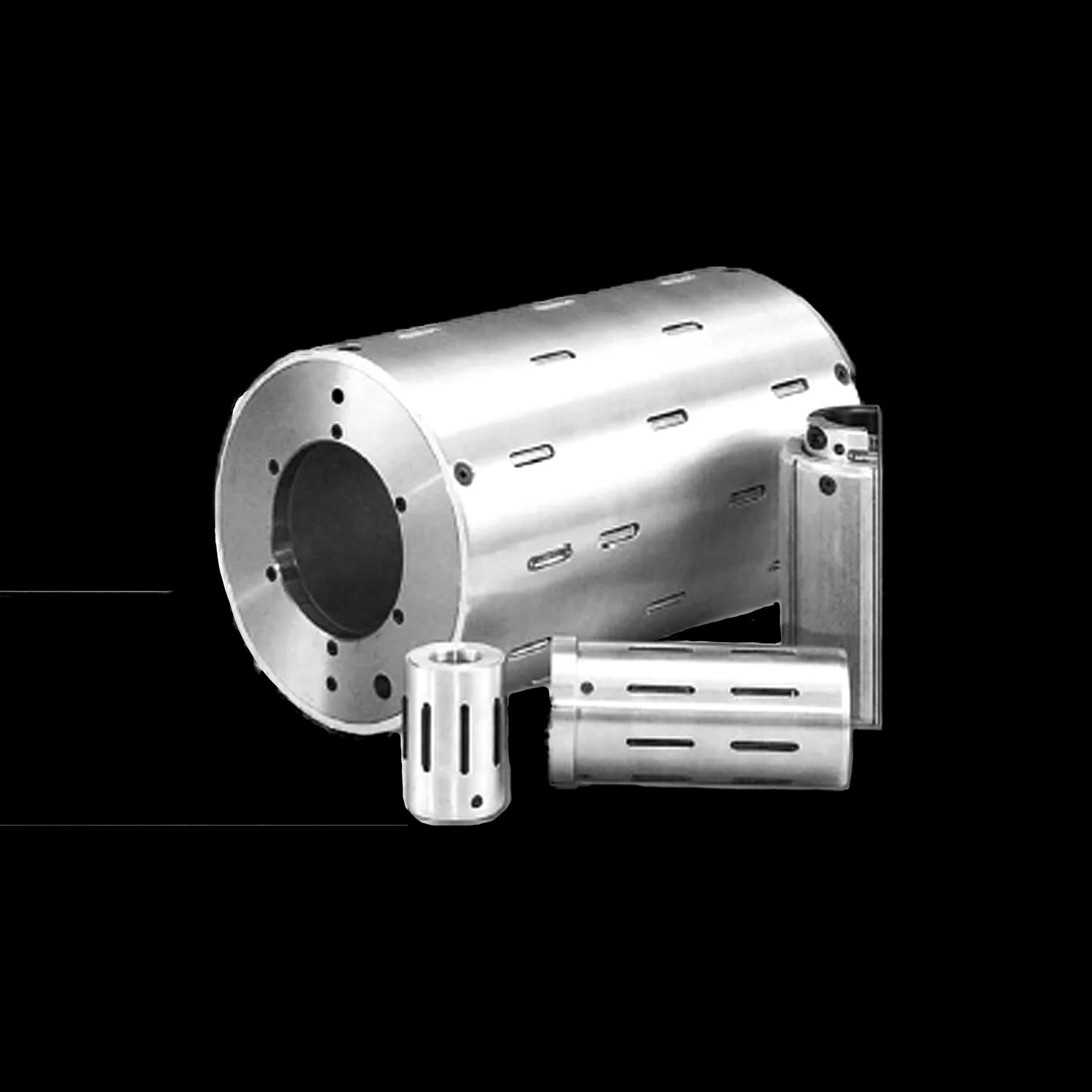

Series SPM and series SPZ pneumatic expansion couplings

Pneumatic Expansion Coupling Series SPM/SPZ: Innovative Secure Clamping for Thin-Walled Cores

Series SPA expansion coupling

The SPА Series pneumatic expansion coupling with individual expansion ledges offers a durable, lightweight alternative to mechanical clamping solutions.

Series SMB expansion coupling

Vorwald’s Series SMB pneumatic expansion coupling ensures quick conversion, core protection, and adaptability for various industries.

Series 609 pneumatic expansion coupling

Vorwald Series 609 Expansion Coupling – robust performance for industrial winding and unwinding applications.

Series 605 pneumatic expansion coupling

Precision in Motion – Vorwald 605 Series offers gentle power with strong grip for all your core holding needs.

Series 260 mechanical expansion coupling

Versatile, concentric clamping with the Series 260 – ideal for low to medium-duty applications with cost-efficiency in mind.

Downloads

Expansion_shafts_Questionnaire.pdf

Expansion_shafts_Questionnaire.pdf Expansion Couplings

Expansion Couplings