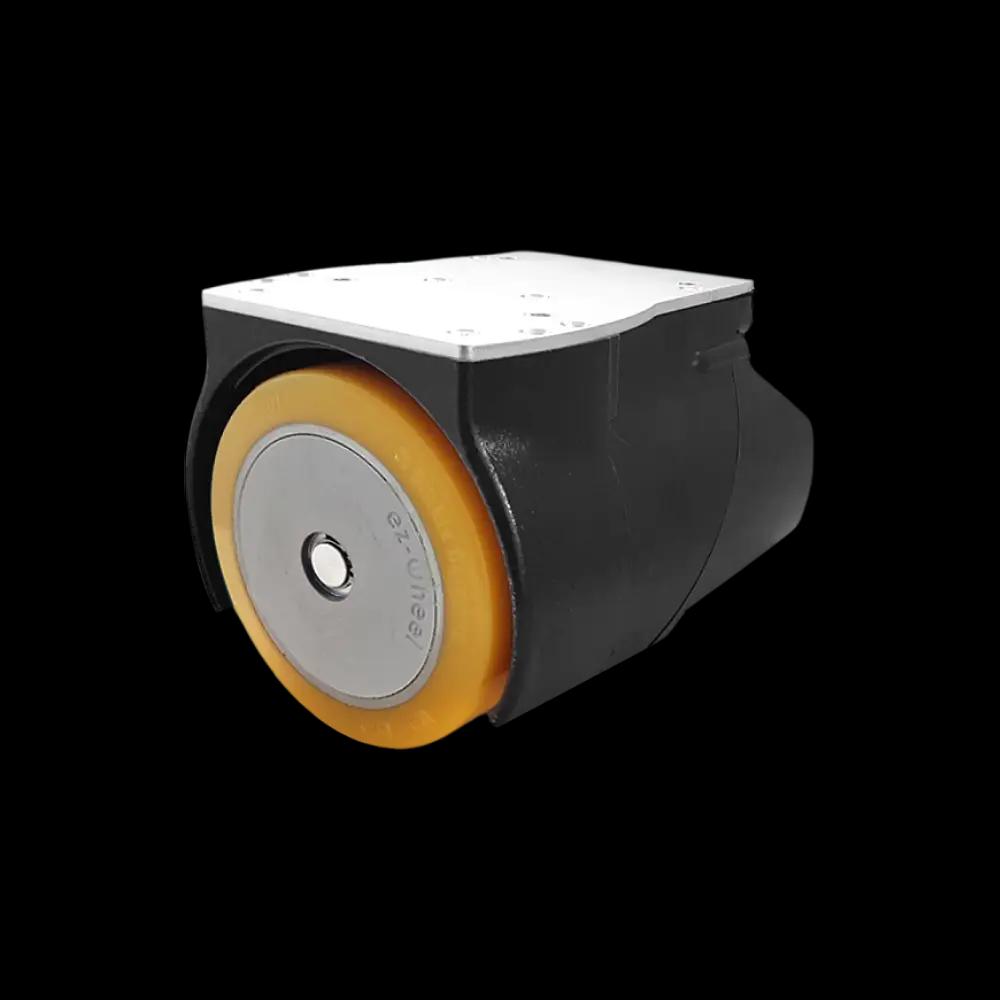

Assist Wheel Drive Series

Enhance Efficiency and Mobility with the Assist Wheel Drive Series – Designed for Heavy-Duty Industrial Applications.

Discover the powerful Assist Wheel Drive Series, offering robust performance, high load capacity, and seamless integration for industrial mobility solutions.

Revolutionizing Industrial Mobility with Assisted Electric Wheel Models

A leading innovator in industrial mobility solutions, EZ-Wheel now a part of IDEC offers cutting-edge electric wheel drive systems that enhance efficiency and safety in mobile equipment. By integrating advanced technologies into wheel drives, these solutions enable smooth, effortless movement in various industrial settings, from warehouses to manufacturing plants. Their products are designed to reduce operator strain, improve ergonomics, and increase productivity. Among the extensive range of products, the Assisted Model stands out, providing specialized solutions for businesses seeking high-performance mobility aids.

The Assist Wheel Drive (AWD) Model is engineered to assist in moving heavy or cumbersome equipment, making it easier to navigate challenging environments. This technology is particularly beneficial for Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). These systems provide an effortless and efficient means of transport while ensuring safety and adaptability across different industrial environments.

With the AWD, operators can move objects with significantly reduced manual effort, increasing operational efficiency and improving overall workplace safety. The assisted models integrate seamlessly with the existing framework of industrial equipment, making them a versatile solution for a wide range of applications.

Key Features of the AWD

The Assisted Model incorporates several innovative features that enhance its performance and usability:

- Load Capacity and Performance: Designed to support substantial loads, certain models can handle up to 1000 kg or more, depending on the configuration. This high load capacity makes it ideal for heavy-duty tasks in industrial environments.

- Brushless DC Motors: The inclusion of brushless DC permanent magnet motors ensures smooth and efficient operation. These motors provide the necessary torque to move heavy loads with ease, while offering durability and energy efficiency.

- Customizable Battery Options: Flexible battery configurations allow users to choose between different power capacities such as 70Wh or 140Wh for internal batteries. External batteries can also be added for continuous operation in environments requiring extended power.

- Safety Compliance and Integration: Designed with safety in mind, the Assisted Model features integrated safety controls that meet international standards. This includes sensors and safety mechanisms to prevent collisions and ensure safe navigation in environments with human presence. The use of safety scanners and SIL2/PLd certified controllers guarantees compliance with safety regulations.

- Durability and Environmental Resilience: The reinforced cast iron housing is built to withstand shocks and vibrations common in industrial environments, ensuring a long lifespan even in harsh working conditions.

- Ease of Integration: The design is highly adaptable, allowing seamless integration into existing industrial equipment. This flexibility enhances the performance of mobile equipment without requiring significant modifications.

Models in the Assist Wheel Drive Series

Several models within the Assisted Series cater to specific applications and load requirements

- 150 Series: A high-performance wheel drive system designed for heavy-duty industrial applications, capable of moving loads up to 1000 kg and featuring an integrated brushless DC motor for smooth and efficient movement.

- 160 Series: Tailored for the medical and healthcare industries, this compact yet powerful model is designed to move medical carts, beds, and other essential equipment with ease. It supports up to 750 kg and includes safety features to meet healthcare standards.

- SWD® Core: A safety gear motor used for AGVs and AMRs, supporting up to 1.5 tons and equipped with integrated safety controls for safe and smooth movement in autonomous systems.

Each of these models can be customized with additional accessories and can integrate with various mobile robotics systems for enhanced functionality.

Applications

AWD Models are utilized across various industries where mobility, safety, and efficiency are paramount. Some key applications include:

- Industrial Trolleys and Equipment: In manufacturing environments, Assisted Models are integrated into tool trolleys, rolling carts, and workstations, allowing for effortless movement of heavy tools and machinery.

- Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs): Used in logistics, warehouses, and production facilities for the automated movement of goods, Assisted Models enhance the mobility of AGVs and AMRs, improving operational efficiency and reducing manual labor.

- Medical Equipment: In hospitals and healthcare facilities, Assisted Models move medical carts, beds, and food trolleys. The 160 Series, in particular, is tailored to meet the unique mobility needs of the medical industry, providing a safe, smooth, and efficient solution for patient care equipment.

- Retail and Service Industries: In retail environments, these systems help move display racks, product trolleys, and other mobile fixtures. Their ability to seamlessly integrate into existing equipment enhances the flexibility and speed of service delivery.

- Logistics and Warehousing: In logistics, where moving heavy items is common, the Assisted Model's load capacity and safety features make it ideal for streamlining the transport of goods across large facilities.

The Assist Wheel Drive Models represent a significant advancement in industrial mobility solutions, offering versatile, high-performance systems that enhance efficiency, safety, and ergonomics. With customizable features, safety compliance, and ease of integration, these systems provide businesses with a powerful tool for improving productivity in industrial environments. Whether moving heavy equipment in a factory or facilitating the transport of medical carts in a hospital, Assisted Models help reduce manual labour and ensure smooth, safe operations.

Contact us