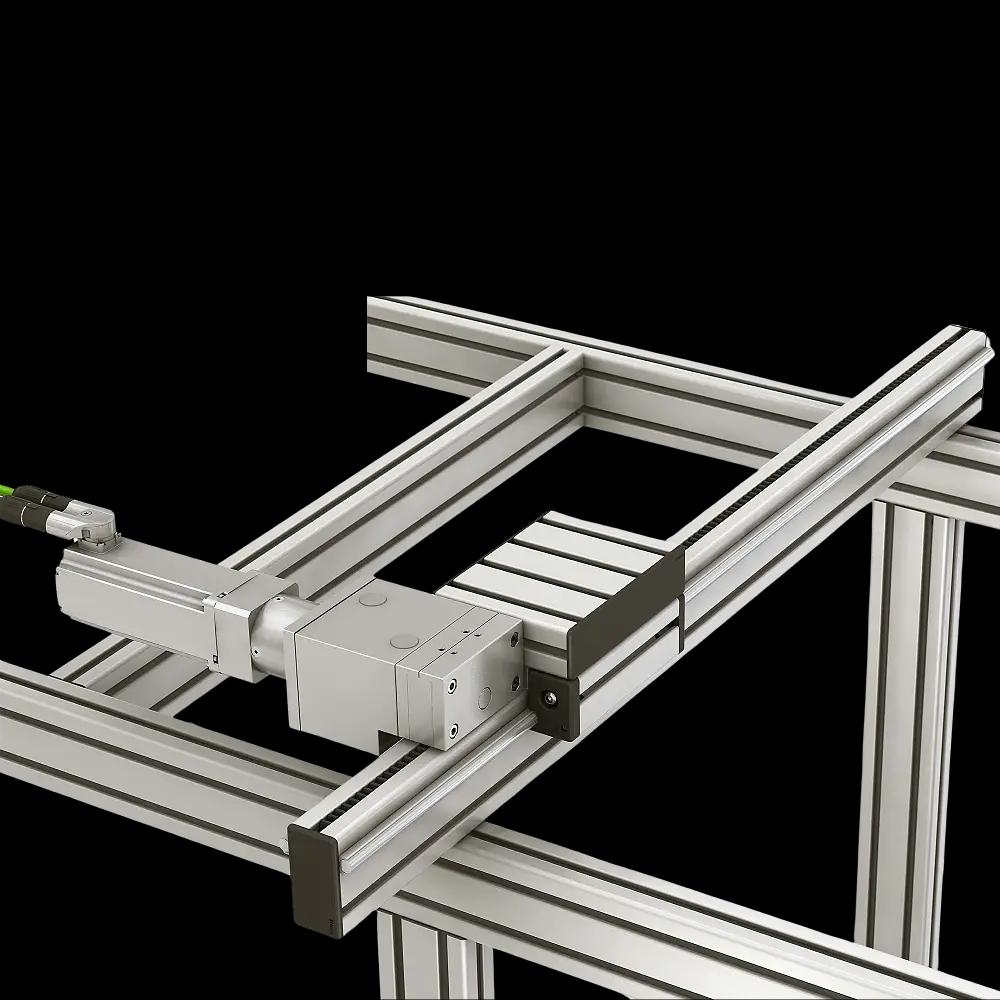

Linear slides

Precision in Motion: Linear Slides for Seamless Movement

Engineered for accuracy and durability, our linear slides ensure smooth, reliable motion in various applications.

Exploring Advanced Automation with Modular Linear Systems

In the ever-evolving world of automation, flexibility, precision, and efficiency are paramount. Modern automation systems need to be adaptable, scalable, and able to meet the diverse demands of industries ranging from robotics to manufacturing. One of the most essential components of such systems is the linear system, which plays a crucial role in enabling smooth, precise movement within machines. Modular linear systems, designed to offer customization and versatility, have become a game changer in this space.

The beauty of modular linear systems lies in their adaptability. They are not only available in a range of sizes and configurations but can be customized to suit specific operational needs. Whether you're looking for a simple, single-axis system or a complex multi-axis gantry, a modular approach makes it possible to build exactly what you need.

Types of Linear Units

Modular linear systems offer various types of linear units, each tailored to specific application requirements:

- Timing-Belt Drive Linear Units: Ideal for applications requiring high speed and reliability, these units support dynamic movements with short cycle times. They are commonly used in packaging and assembly lines where rapid movement is essential.

- Ball Screw Linear Units: These units are designed for applications demanding high power and precise positioning. They are suitable for tasks such as CNC machining and robotic assembly, where accuracy is critical.

- Chain Drive Linear Units: Known for their robustness, chain drive units are ideal for challenging environments. Their compact design and enclosed chain path make them suitable for vertical applications like lifting doors and material handling systems.

- Rack and Pinion Drive Linear Units: These units offer precise control and are capable of moving heavy loads. They are commonly used in applications such as automated storage and retrieval systems, where both precision and load capacity are essential.

The Key Components of a Modular Linear System

A modular linear system consists of several key components, each designed to work together seamlessly:

- Linear Guides: These provide the direction of movement, ensuring smooth travel with minimal friction. They come in different types, including recirculating ball guides and roller guides, each suited for specific load and motion requirements.

- Drive Units: These include motors and gearboxes that provide the necessary force to drive the system. With the right motor and gearbox combination, you can achieve the required speed, torque, and precision.

- Controllers and Sensors: These are crucial for monitoring and controlling the movement of the system. Sensors help track position, speed, and other critical variables, while controllers ensure the system operates according to the defined parameters.

- Linear Drives: Integrated drive systems combine the motor, gearbox, and controller into a single unit. These drives allow for seamless synchronization of movement, ensuring optimal performance even in complex applications.

- Accessories: Depending on the complexity of the system, additional accessories like actuators, mounting plates, and safety components may be added to ensure smooth integration into the broader system.

Why Choose a Modular Linear System?

Modular linear systems stand out because they allow for a higher degree of customization and flexibility compared to traditional fixed systems. Here are some key benefits:

- Customization: Tailor the system to your exact needs by selecting components that fit your application’s requirements for load, speed, and precision.

- Scalability: Easily adjust the system as your needs grow, whether you require a longer stroke, additional axes of movement, or increased payload capacity.

- Efficiency: Optimize the performance of your automation system with high-quality components that work seamlessly together, ensuring reliability and reducing downtime.

- Ease of Installation and Maintenance: Modular systems are designed for quick assembly and integration, and maintenance is simplified due to the ease of replacing individual components.

Modular linear systems are revolutionizing the way we approach automation. Their versatility, ease of customization, and integration capabilities make them ideal for a wide range of applications across various industries. Whether you're designing an assembly line or creating a precise robotic solution, a modular linear system can provide the reliability and performance you need to take your automation to the next level. By choosing the right components and customizing the system to your needs, you can ensure optimal performance and future-proof your automation strategy.

For more information on how modular linear systems can enhance your automation efforts, talk to BIBUS India sales team and explore the options available and see how these solutions can be tailored to meet your specific requirements.

Contact us