Aluminium Table Frame Project – A Customized Solution by BIBUS India

Delivering Tailored Engineering Solutions

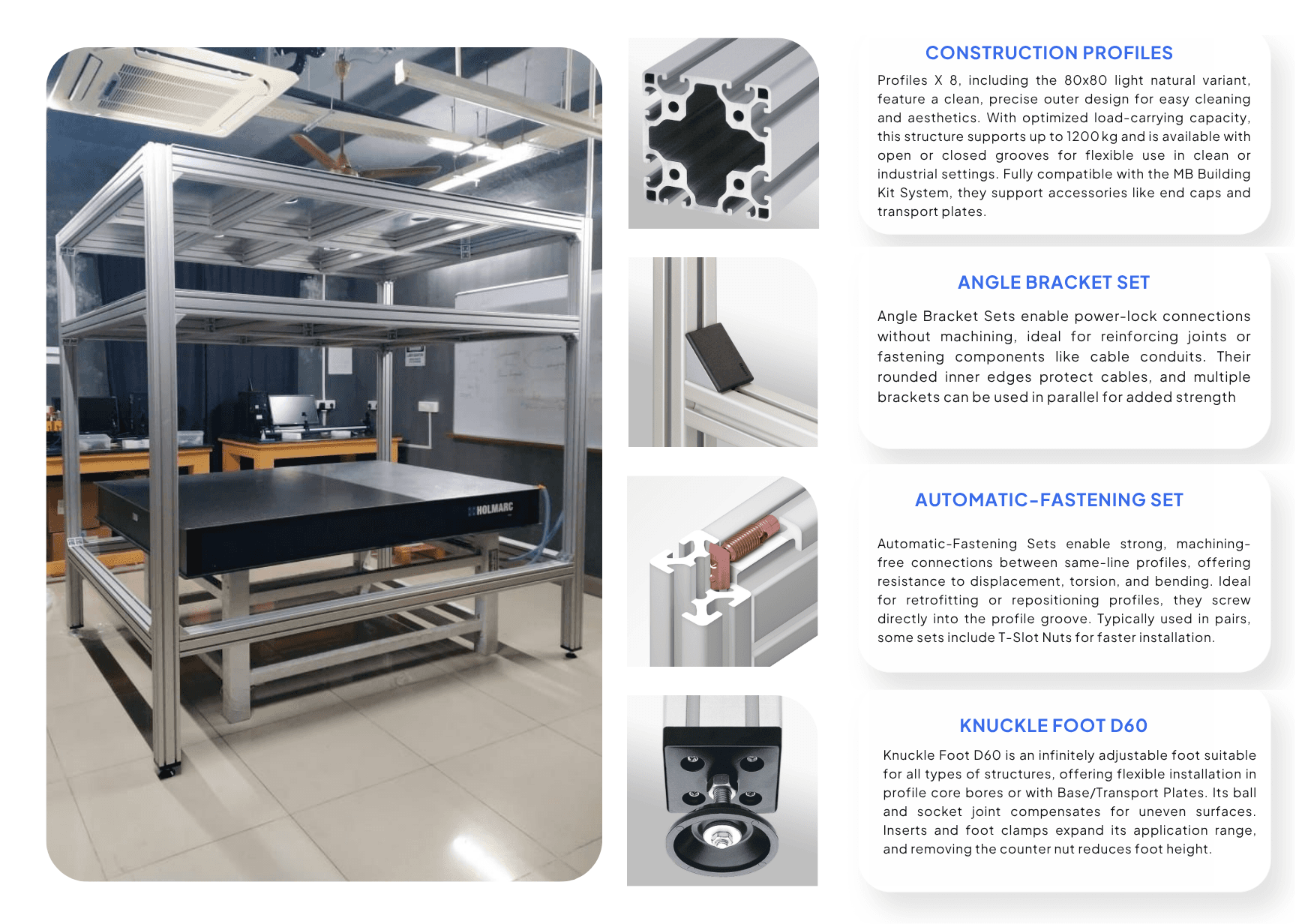

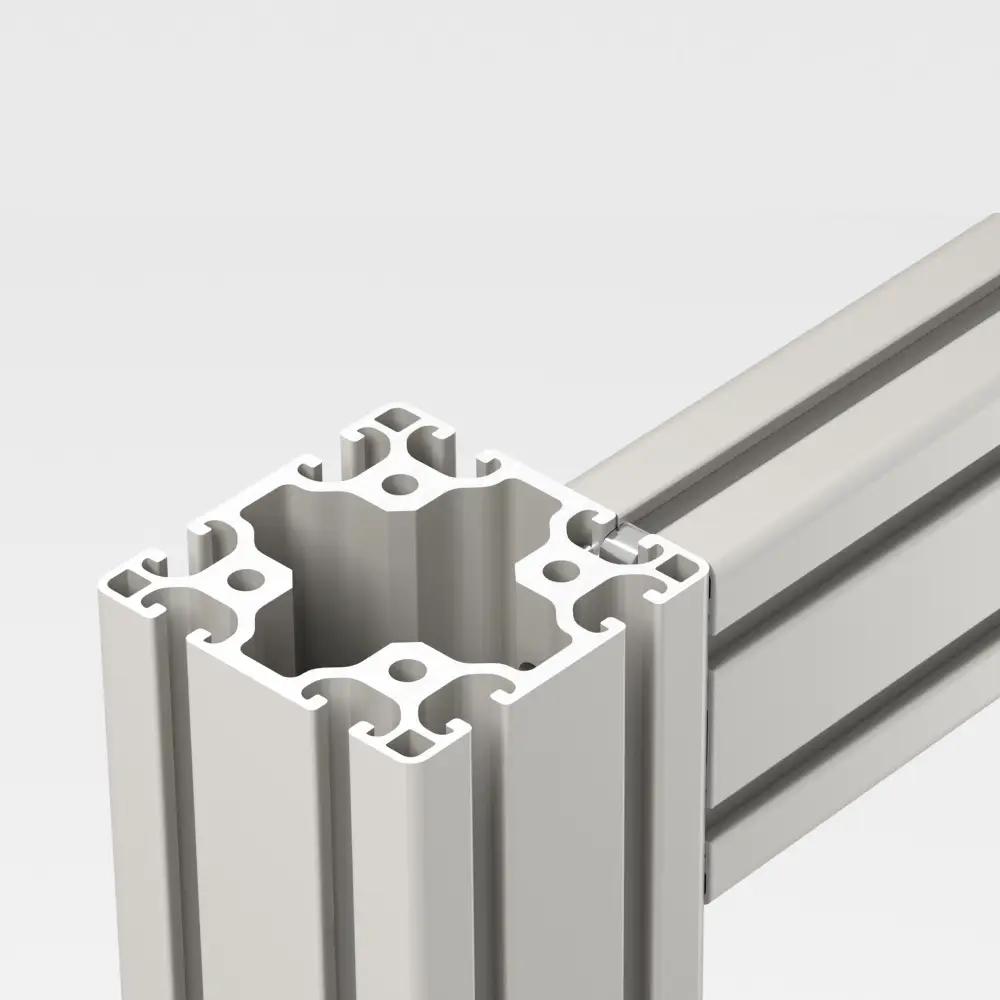

The foundation of the table frame was built using item Aluminium Construction Profiles, designed in product-line-specific modular dimensions. These profiles are available in various shapes such as rectangular, rounded, and angled, making them adaptable for a wide range of applications in machinery and factory equipment.

For this project, the Profile 8 80x80 light was used. Manufactured from high-quality anodized aluminium, this profile offers the strength needed for stability while being up to 26% lighter than the standard variant. Thanks to its eight open Line 8 profile grooves, it allows easy integration of accessories and future modifications. This weight-optimized design ensures excellent rigidity while keeping the structure efficient and cost-effective.

The aluminium profiles were assembled using versatile fastening technology from item, ensuring strong and reliable joints. A mix of Automatic-Fastening Sets and Angle Brackets provided high resistance against displacement, torsion, and bending, even under heavy load.

Automatic fasteners, which do not require any profile machining, made it possible to quickly assemble and adjust the structure without compromising strength. Angle Brackets further reinforced the joints, ensuring long-term stability. This combination of fastening solutions enabled the frame to be not only strong but also easily adjustable and reconfigurable.

To provide a stable and adaptable base, the structure was fitted with Levelling Knuckle Feet. These components compensate for uneven floors through their angle-adjustable foot plate and stepless height adjustment. With the ball-and-socket joint mechanism, the frame remains stable even on sloped or irregular surfaces.

Additionally, Base Plates were used to firmly attach the feet to the aluminium profiles, ensuring maximum load-bearing capacity and vibration resistance. This makes the table frame suitable for both stationary and heavy-duty industrial use.

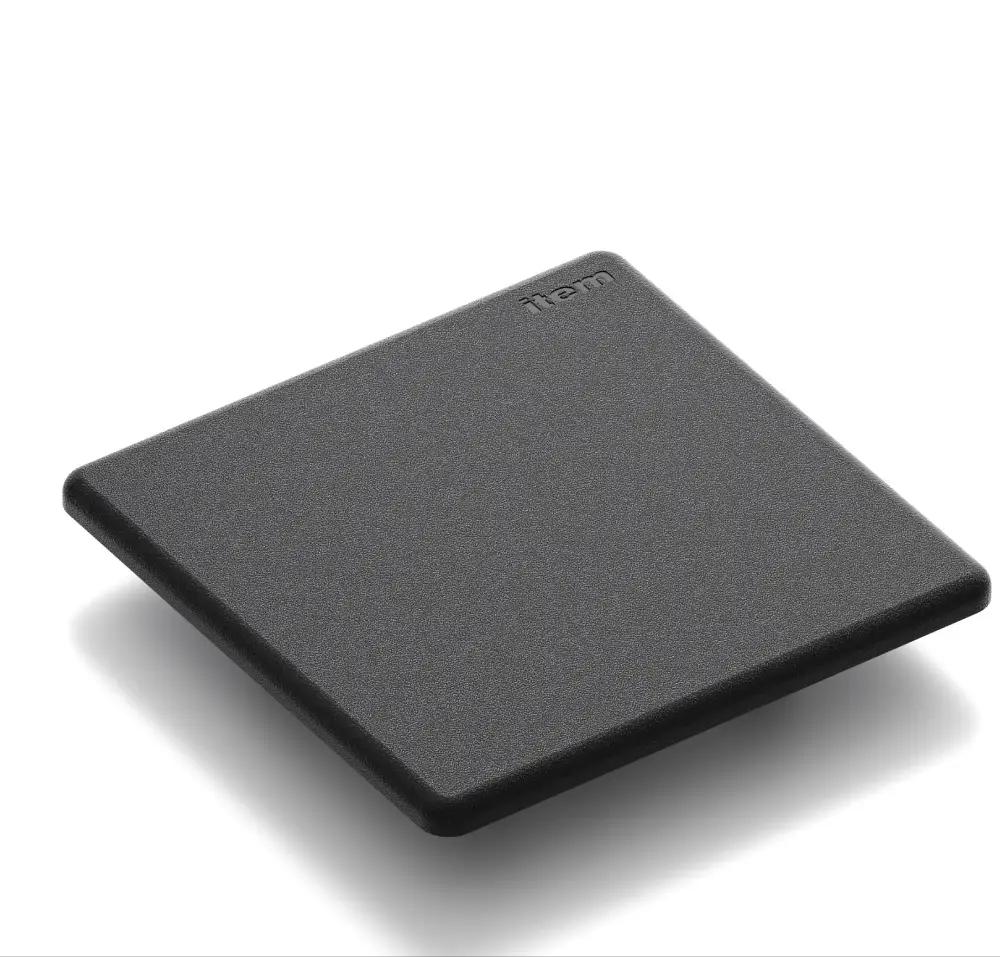

The project also integrated Caps and Cover Profiles for a clean, professional finish. Caps were used to seal the cut edges and drilled holes of the profiles, protecting them from dust, dirt, and vibrations. These also improve safety by covering sharp edges and ensuring smooth surfaces.

Meanwhile, cover profiles were used to close open grooves, not only enhancing the appearance but also preventing debris accumulation. This ensures long-lasting performance and reduces maintenance needs in demanding industrial environments.

The Aluminium Table Frame Project delivered by BIBUS India reflects our capability to provide customized, modular, and durable engineering solutions. By combining high-quality aluminium profiles, reliable fastening technology, stable foot elements, and protective caps, we ensured that the final product met the client’s requirements for strength, flexibility, and professional design.

With such tailor-made solutions, BIBUS India continues to support industries with projects that optimize performance and efficiency while maintaining simplicity and ease of use.