Stainless Steel Locking Connections

Locking connections made from stainless steel are the ideal solution for drive applications that demand maximum corrosion resistance. They are particularly preferred in demanding industries such as pump manufacturing, the food and beverage sector, and medical technology. Featuring high-strength precision rings and specially developed stainless steel screws, these connections offer effective protection against dirt accumulation and aggressive cleaning agents.

As a result, they not only support plant operators in meeting strict hygiene and cleanliness regulations, but also minimize the risk of costly downtime. Our stainless steel locking assemblies and shrink discs transmit torque as well as radial and axial forces completely backlash-free, while being entirely maintenance- and wear-free. They are readily available in a wide range of standard sizes and variants and can also be customized as tailor-made special solutions.

Contact us if you have any questions.

Contact us

Locking Element RfN 8006 stainless steel

RINGFEDER RfN 8006 locking elements provide a wear-free, compact, screwless shaft-hub connection.

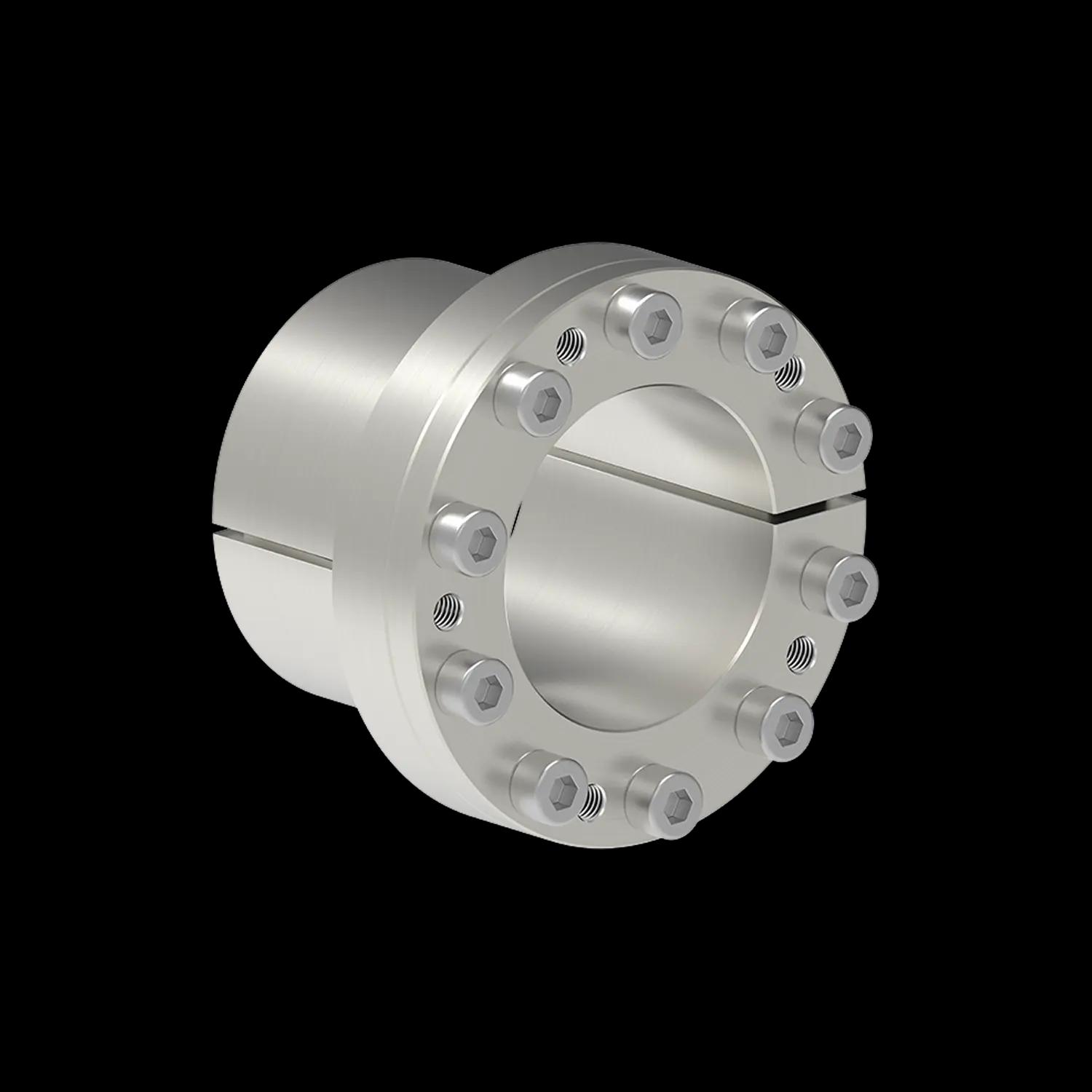

Locking Assembly RfN 7110 stainless steel

Compact, self-centering locking assembly without axial displacement. External clamping screws and low surface pressure enable a space-saving hub design.

Locking Assembly RfN 7061 stainless steel

Compact stainless steel locking assembly, self-centering design.

Locking Assembly RfN 7013.1 stainless steel

Locking assembly with excellent concentricity and stainless steel flange, self-centering design.

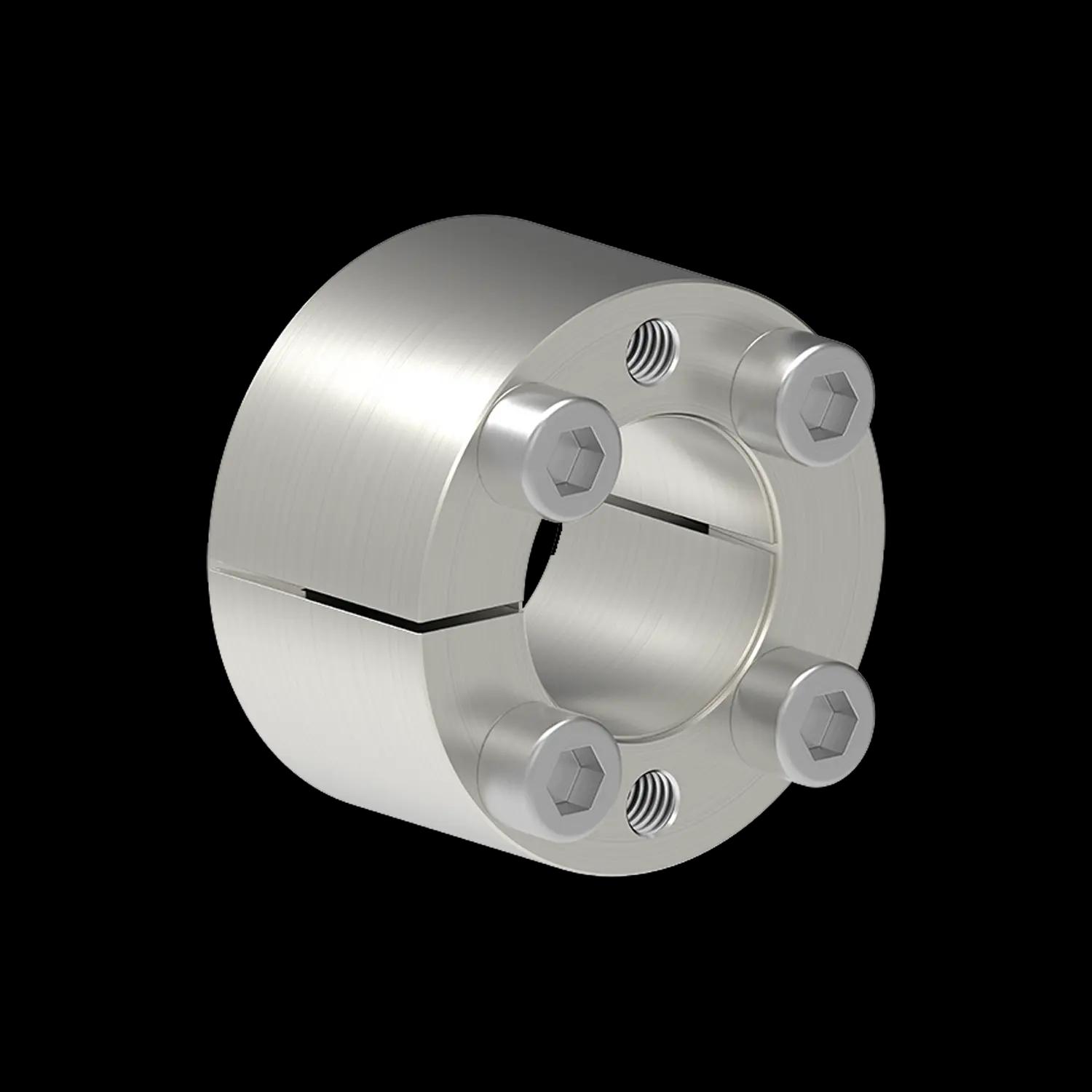

Locking Assembly RfN 7012 stainless steel

Narrow locking assembly made of stainless steel.

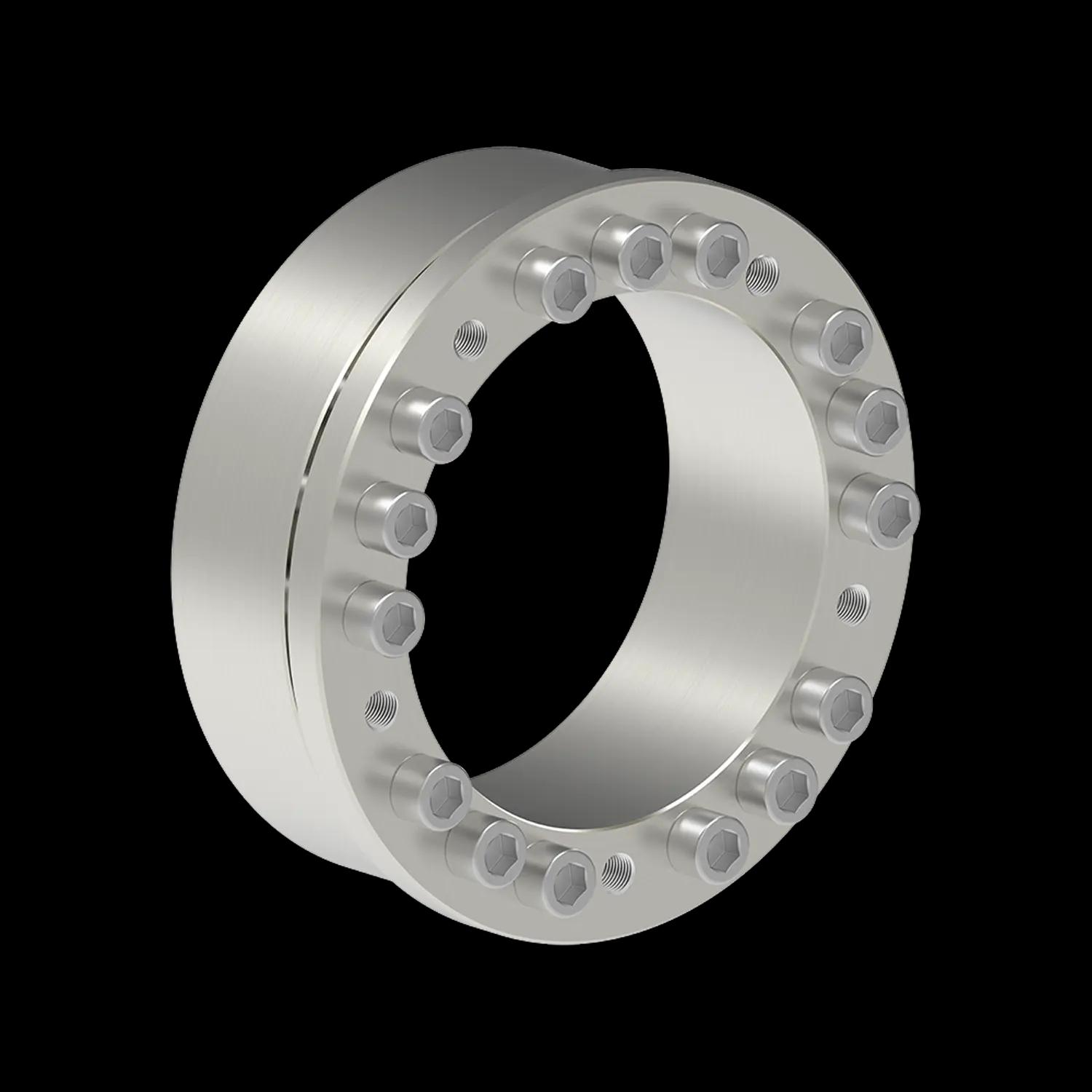

Shrink Disc RfN 4161 stainless steel

2-piece shrink disc made of stainless steel.

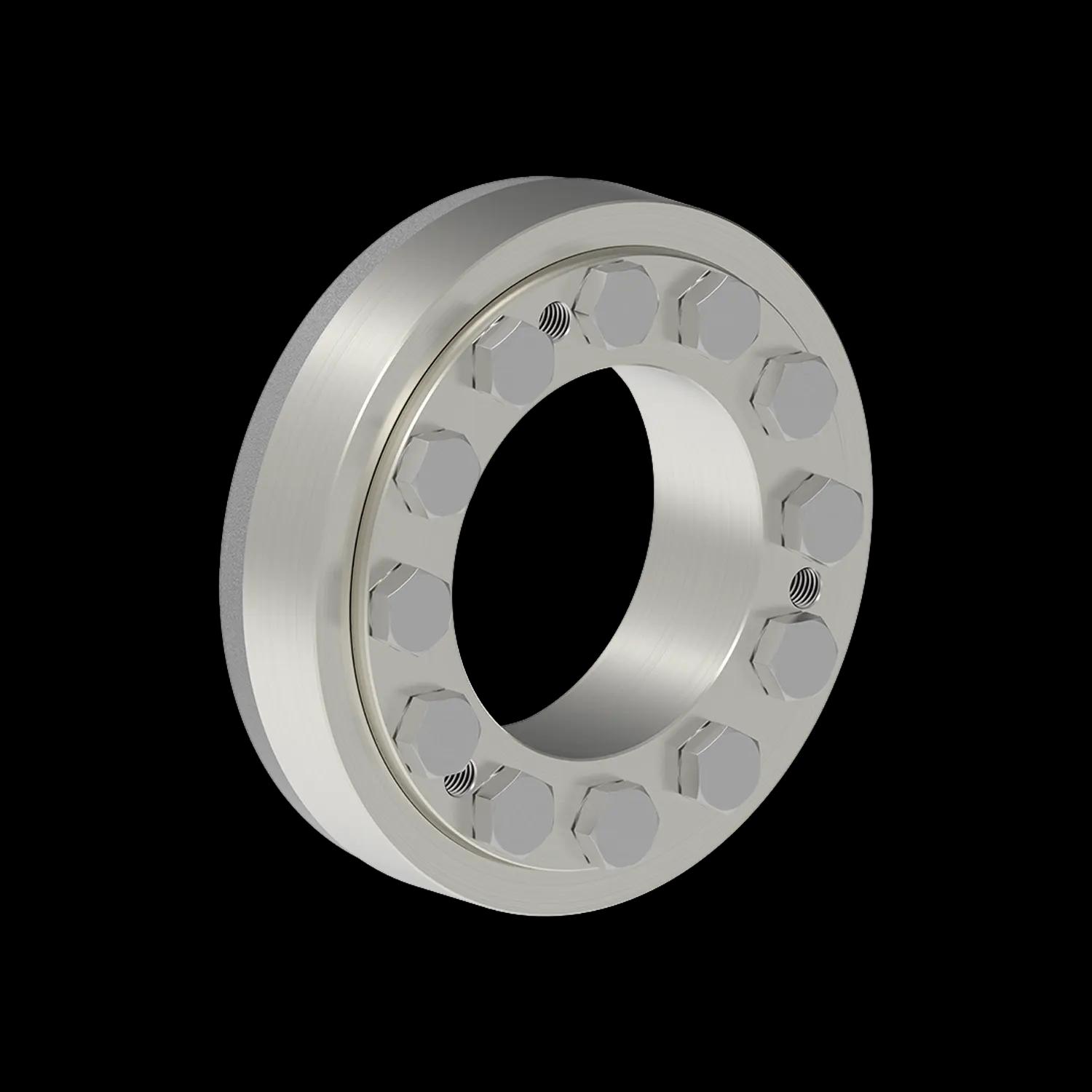

Shrink Disc RfN 4061 stainless steel

Ideal stress distribution and maximum corrosion resistance