Locking Assemblies for Bending Moments

Among the most demanding applications of our locking systems are conveyor drums, which are primarily used in large-scale conveying systems for raw materials such as iron ore, copper ore, or coal. The shaft–hub connections between the drum shaft and drum shell must not only transmit the required torque but also withstand continuous high axial and lateral forces as well as bending moments.

To meet these requirements, our locking assemblies for bending moments are specifically engineered for maximum material strength, high-quality surface finishes, and optimal internal stress distribution. This effectively prevents shaft breakage, axial displacement, or plastic deformation of the drum shell—helping to avoid costly repairs and unplanned production downtimes.

These backlash-free, friction-locked connections offer the highest operational safety in conveyor drum applications. Additionally, they stand out due to their ease of installation, complete freedom from wear and maintenance, and long-term reliability in industrial environments.

Contact us if you have any questions.

Contact us

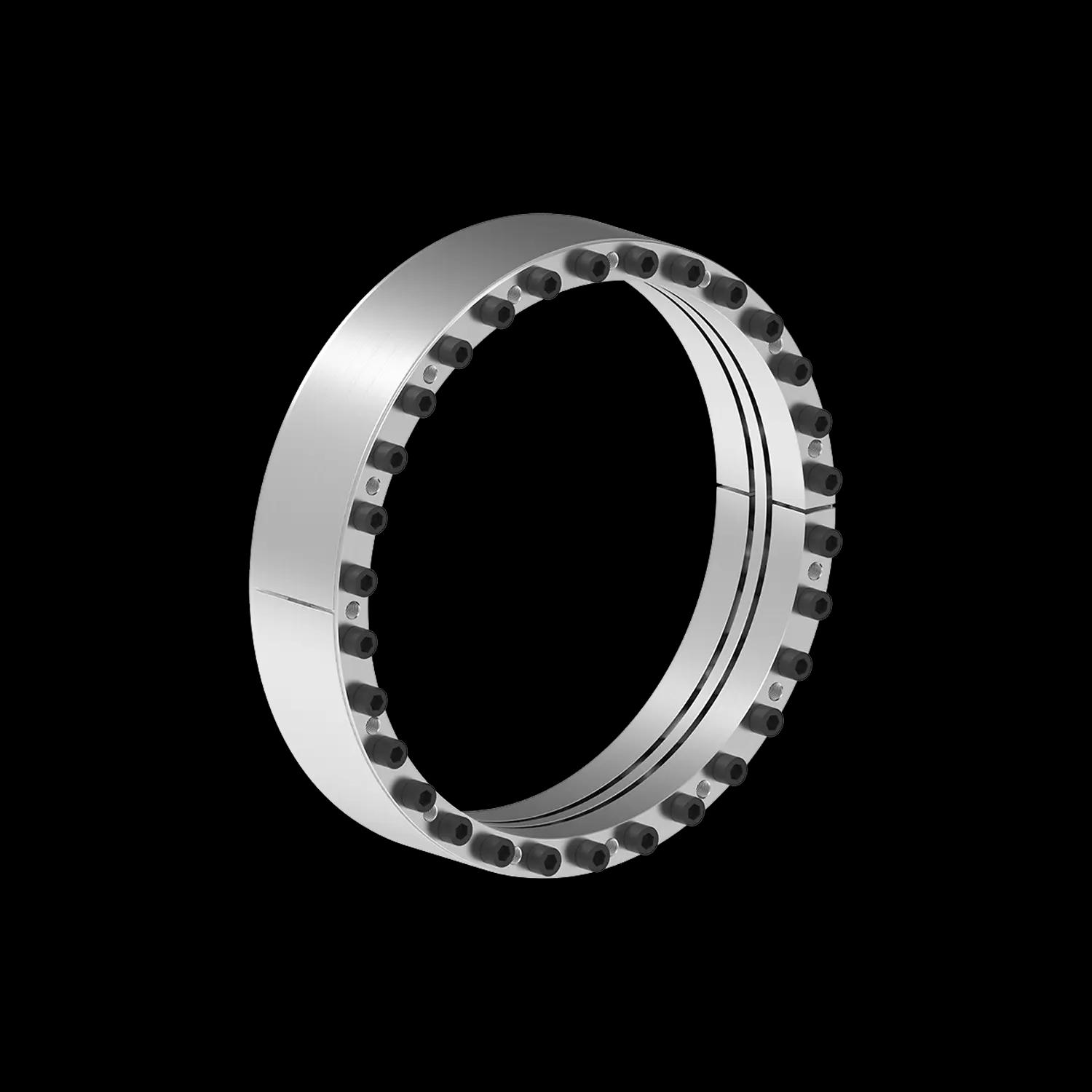

Locking assembly RfN 7515 for bending moments

Optimal for highest torques, axial and radial forces, self-centering.

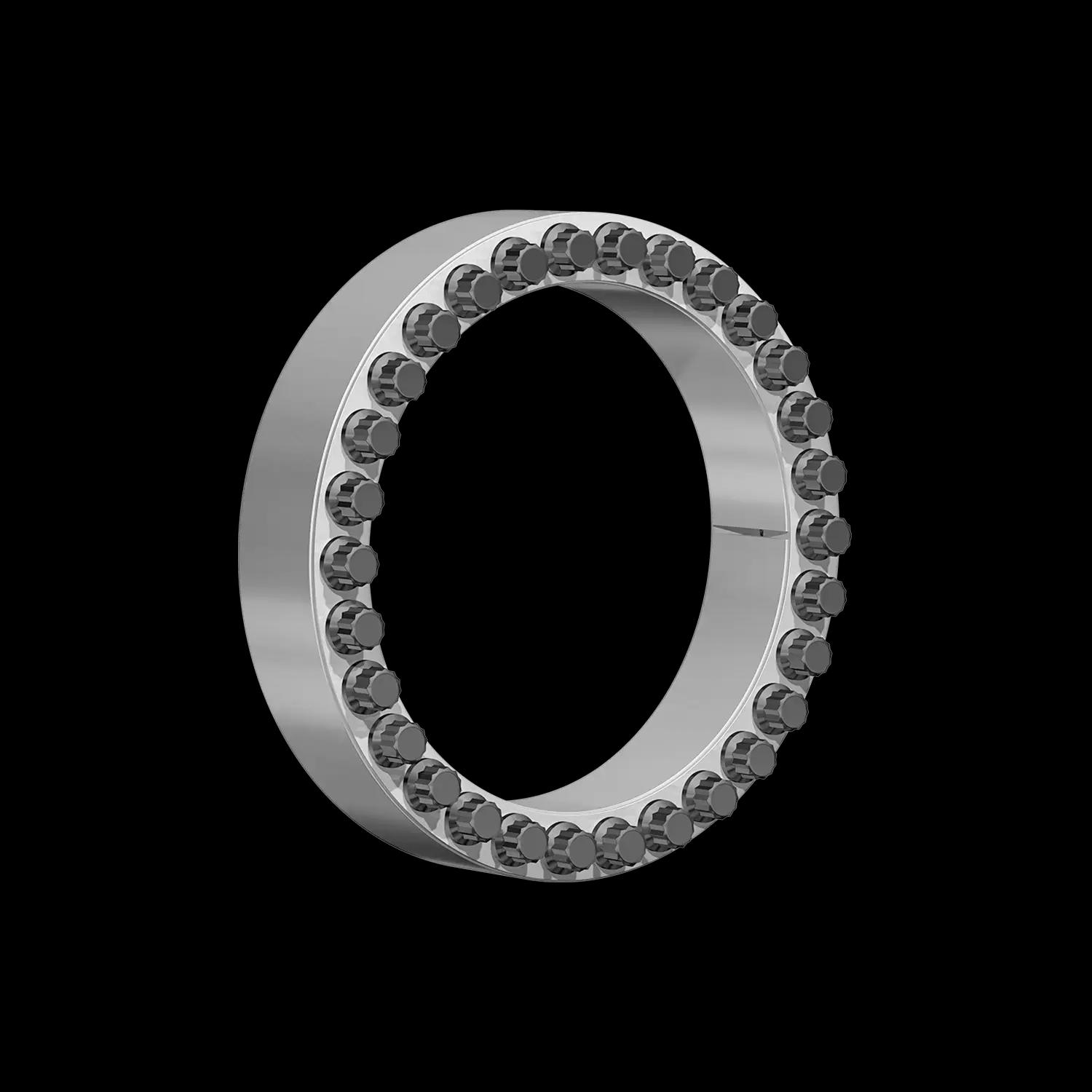

RfN 7015.1 locking assembly for bending moments

Transmits high combined forces and moments. Excellent centering capability.

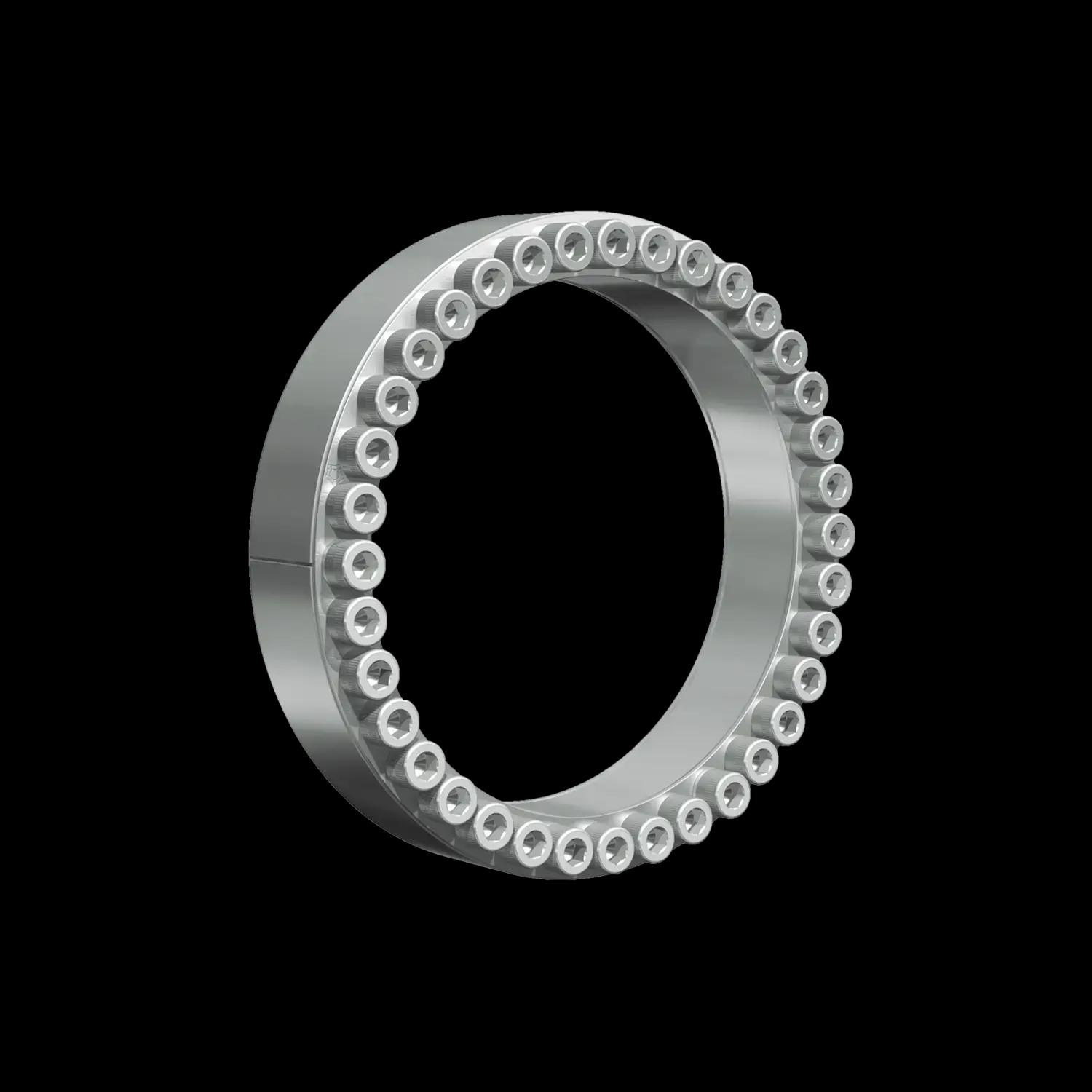

RfN 7015.0 locking assembly for bending moments

Transmits high combined forces and moments. Excellent centering capability.

RfN 7012.2 locking assembly for bending moments

Identical to RfN 7012, optimized for extreme loads.

RfN 7012 locking assembly for bending moments

Slimmest designs for universal applications.

Downloads

locking_assemblies_for_bending_loads_ringfeder_worgsa.pdf

locking_assemblies_for_bending_loads_ringfeder_worgsa.pdf