Locking Assemblies

Locking assemblies are high-quality, friction-locked shaft–hub connections specifically designed for the precise fastening of hub components such as gears, idler and chain wheels, levers, cams, belt and brake discs, mounted gear units, couplings, and flanges on shafts and axles. They are characterized by easy installation and removal, complete maintenance-free operation, and backlash-free power transmission.

Unlike external clamping systems such as shrink discs, locking assemblies are installed directly between the shaft and the hub. When the clamping screws are tightened, the inner and outer rings press firmly against the contact surfaces, creating a friction-based press fit. This connection reliably transmits high torques, axial and radial forces, as well as bending moments.

Compared to conventional connection methods such as shrink fits, keyway, interference fits, or polygonal connections, locking assemblies offer significant advantages. They stand out due to their excellent concentricity properties and high fatigue strength under alternating torque. As standardized machine elements, they are available in a wide range of versions and sizes and can also be supplied as customized special solutions to ensure optimal adaptation to individual requirements.

Contact us if you have any questions.

Contact us

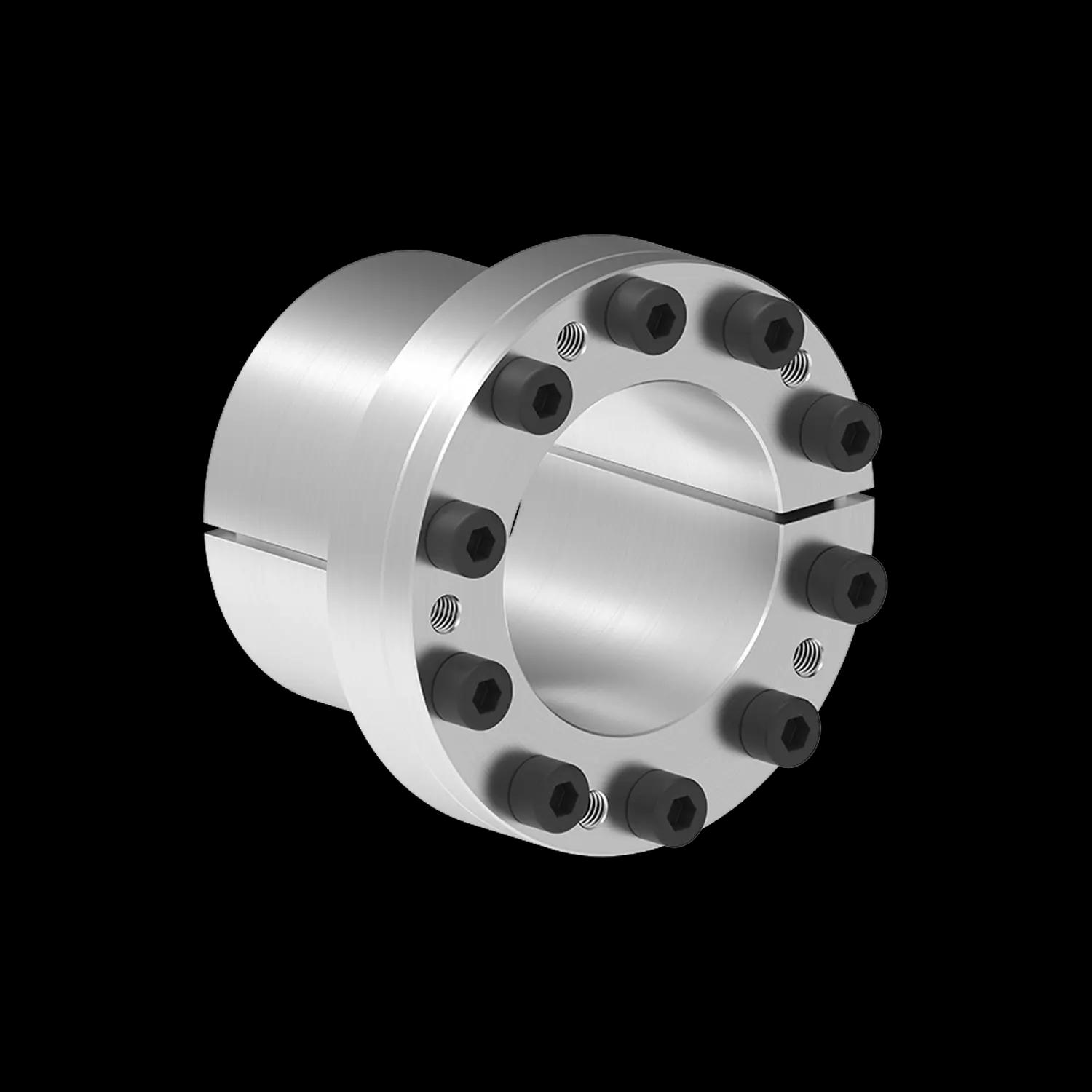

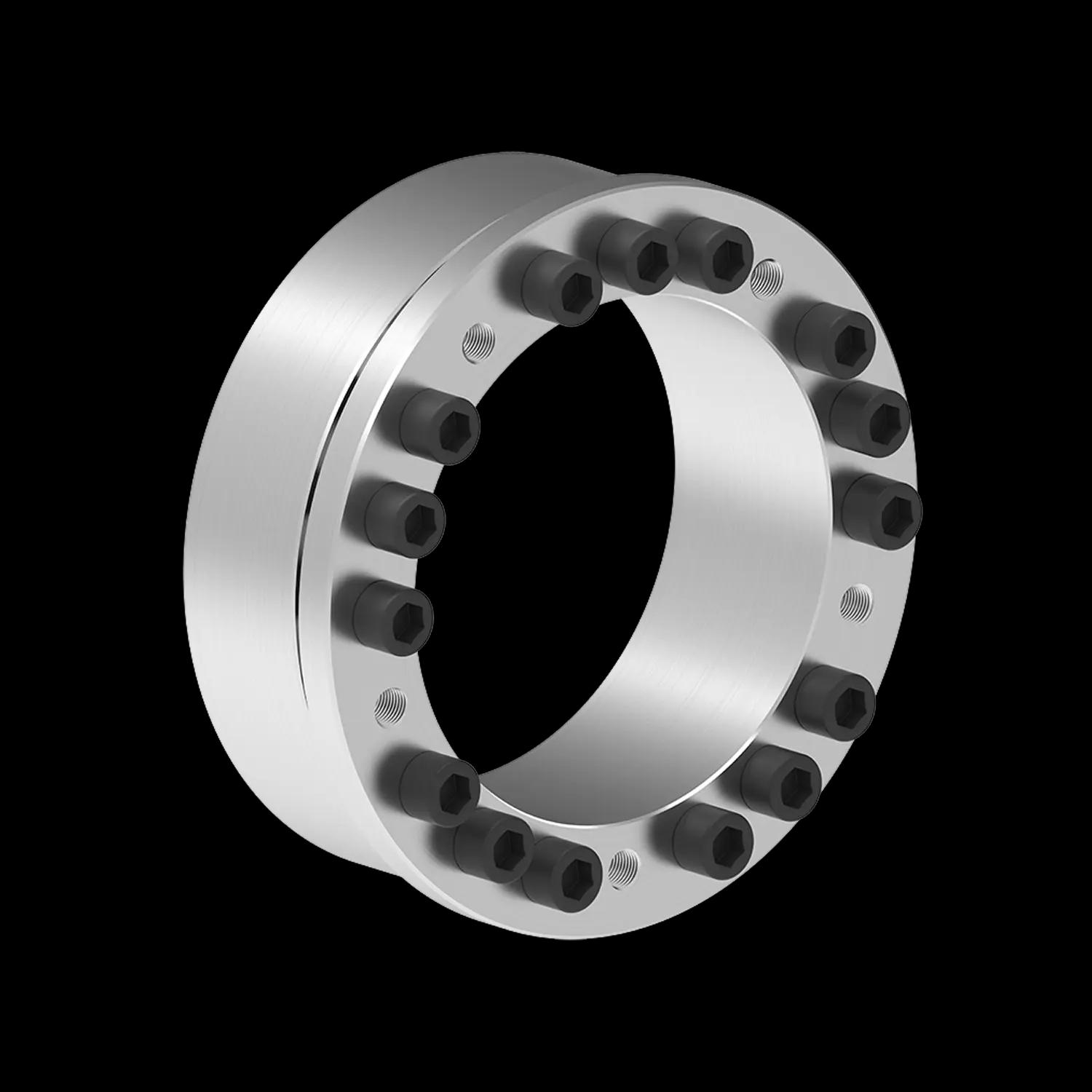

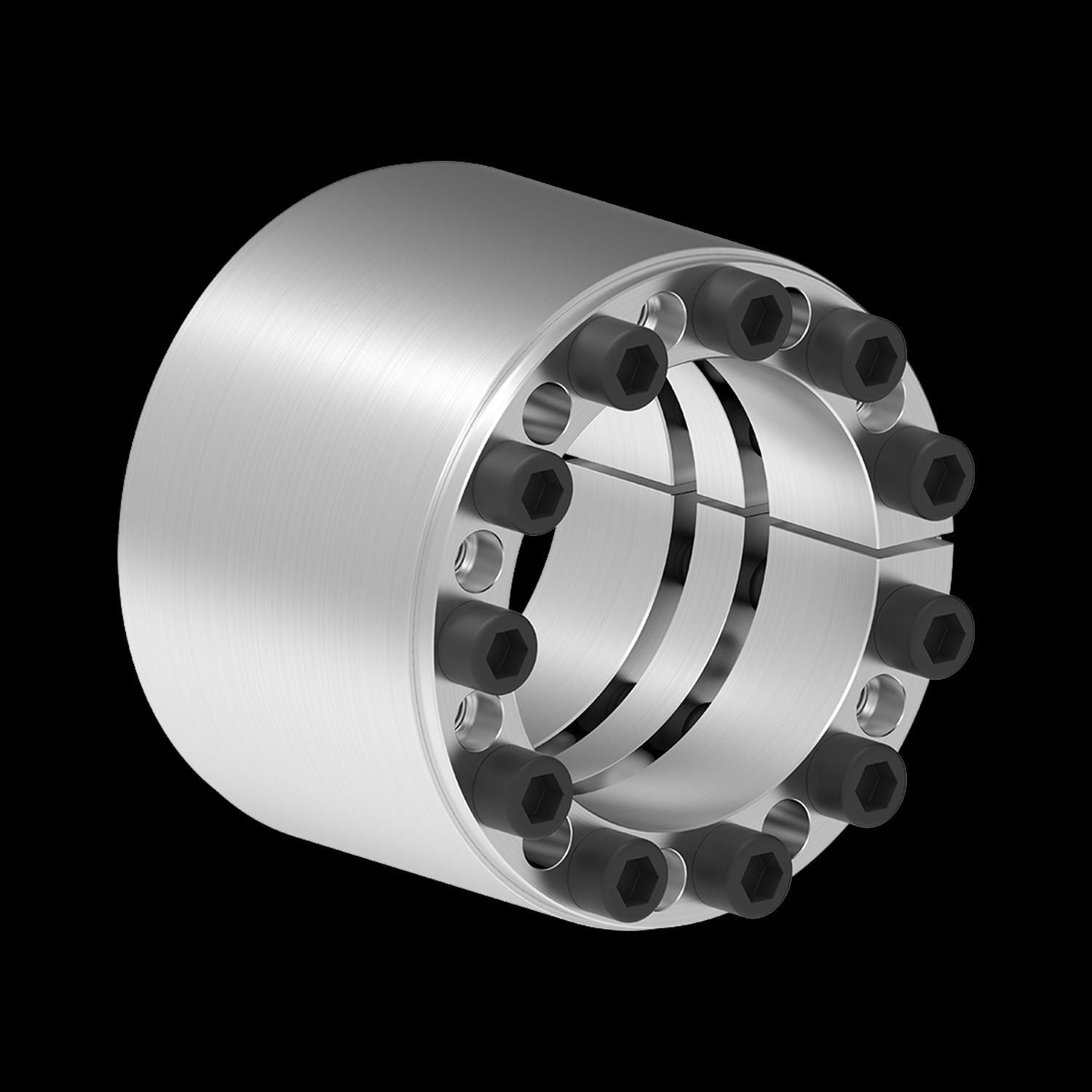

RfN 7515 locking assembly

Extended, three-piece design, self-centering. Suitable for bending moments and radial loads.

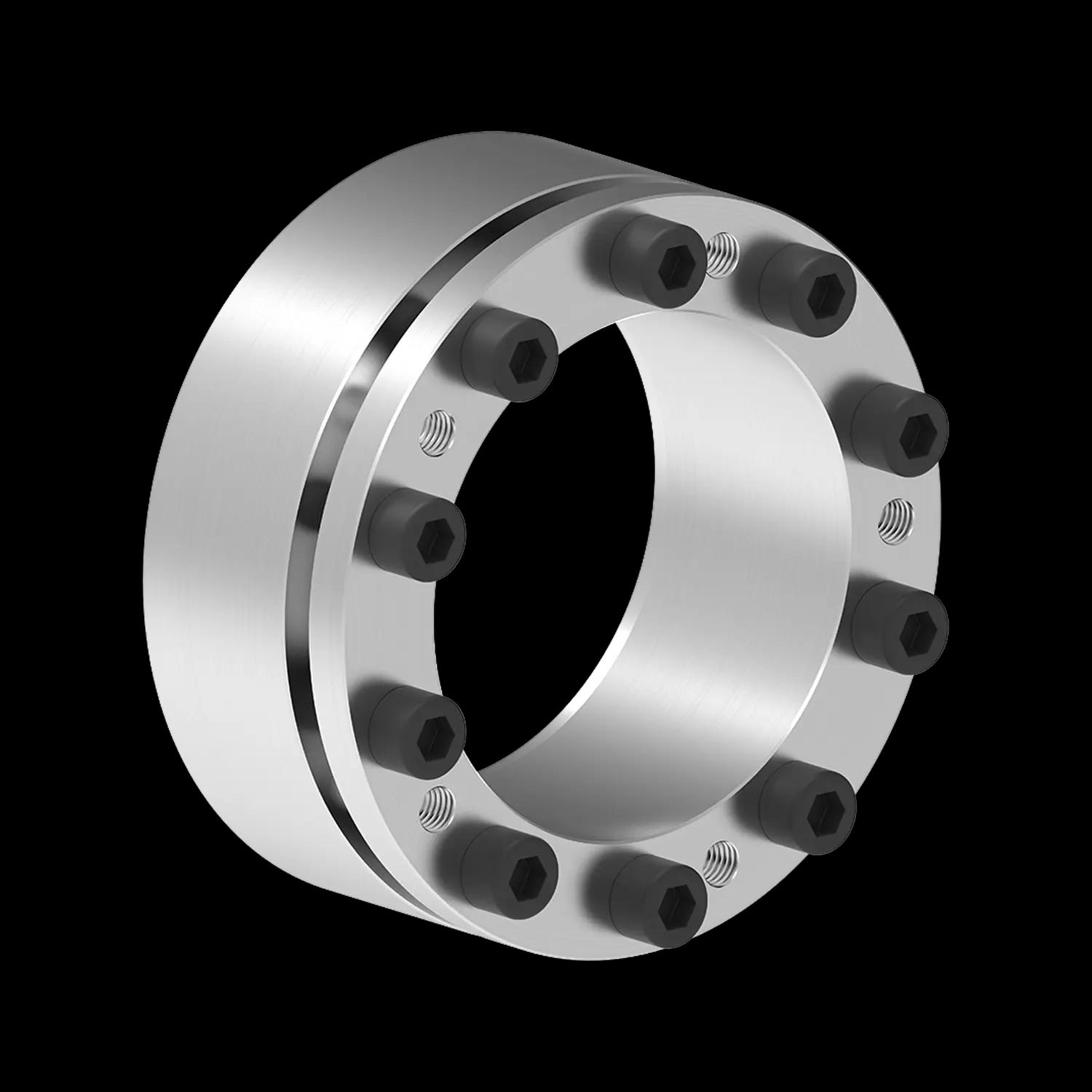

RfN 7110 locking assembly

A self-centering locking assembly with an especially compact design and no axial displacement stands out due to its unique construction.

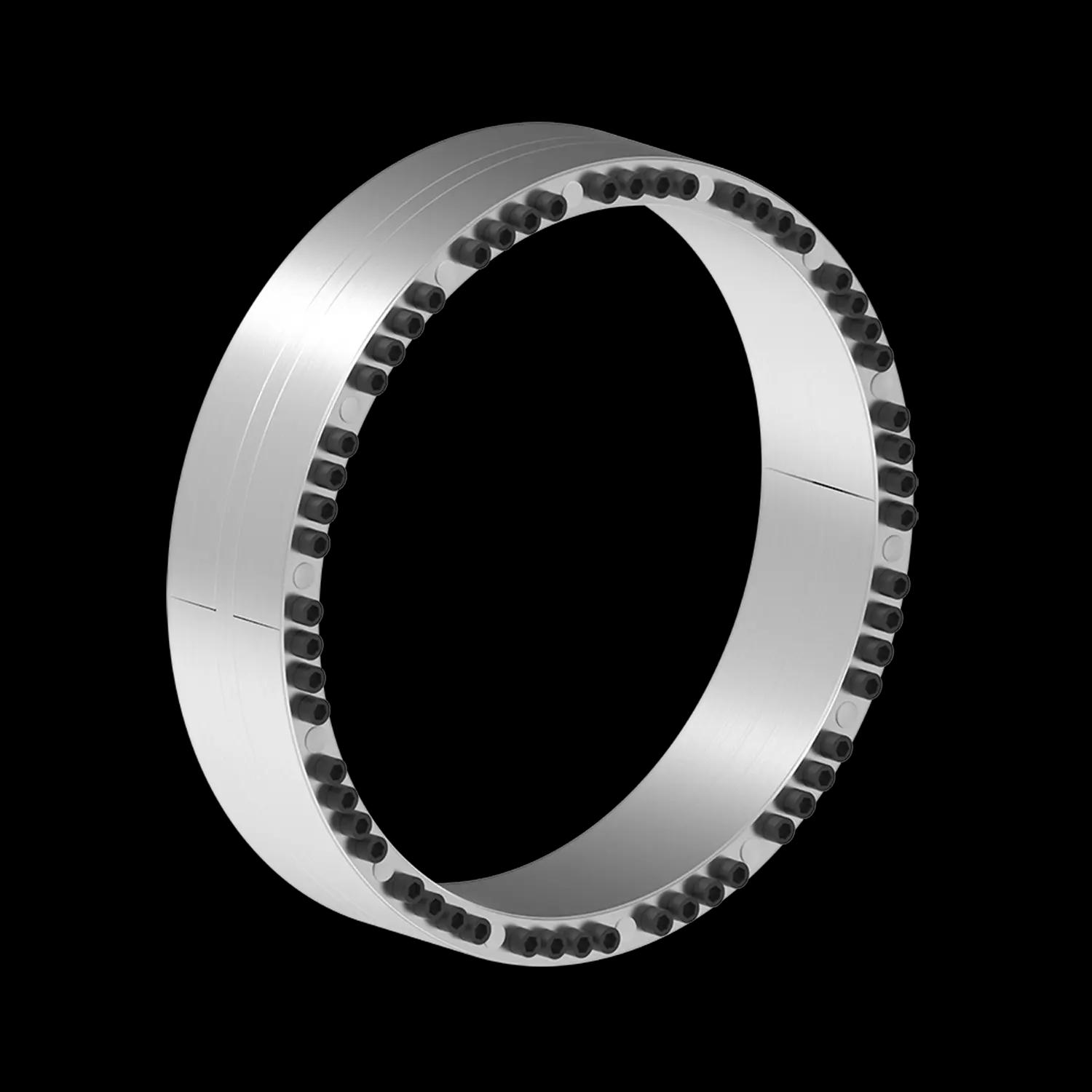

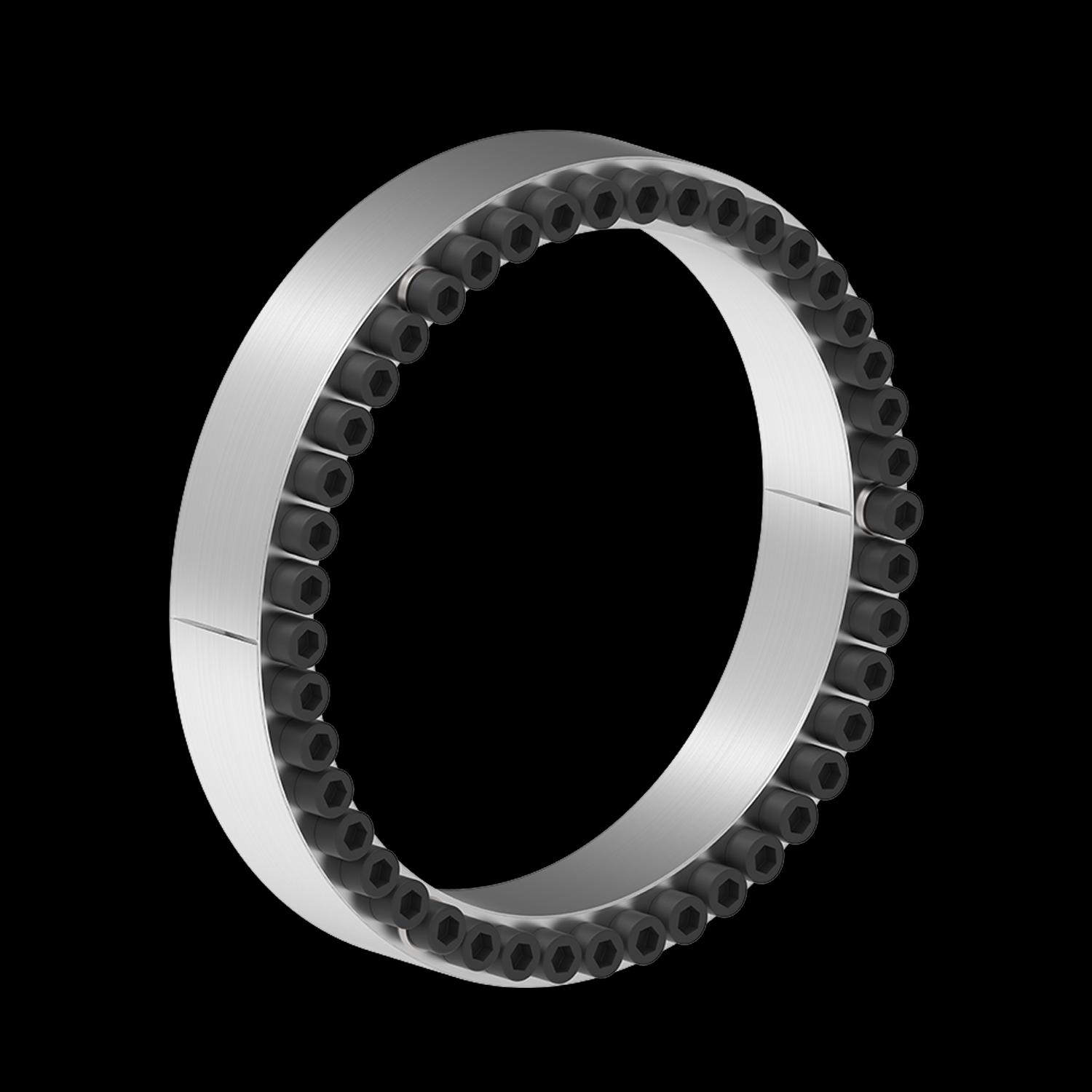

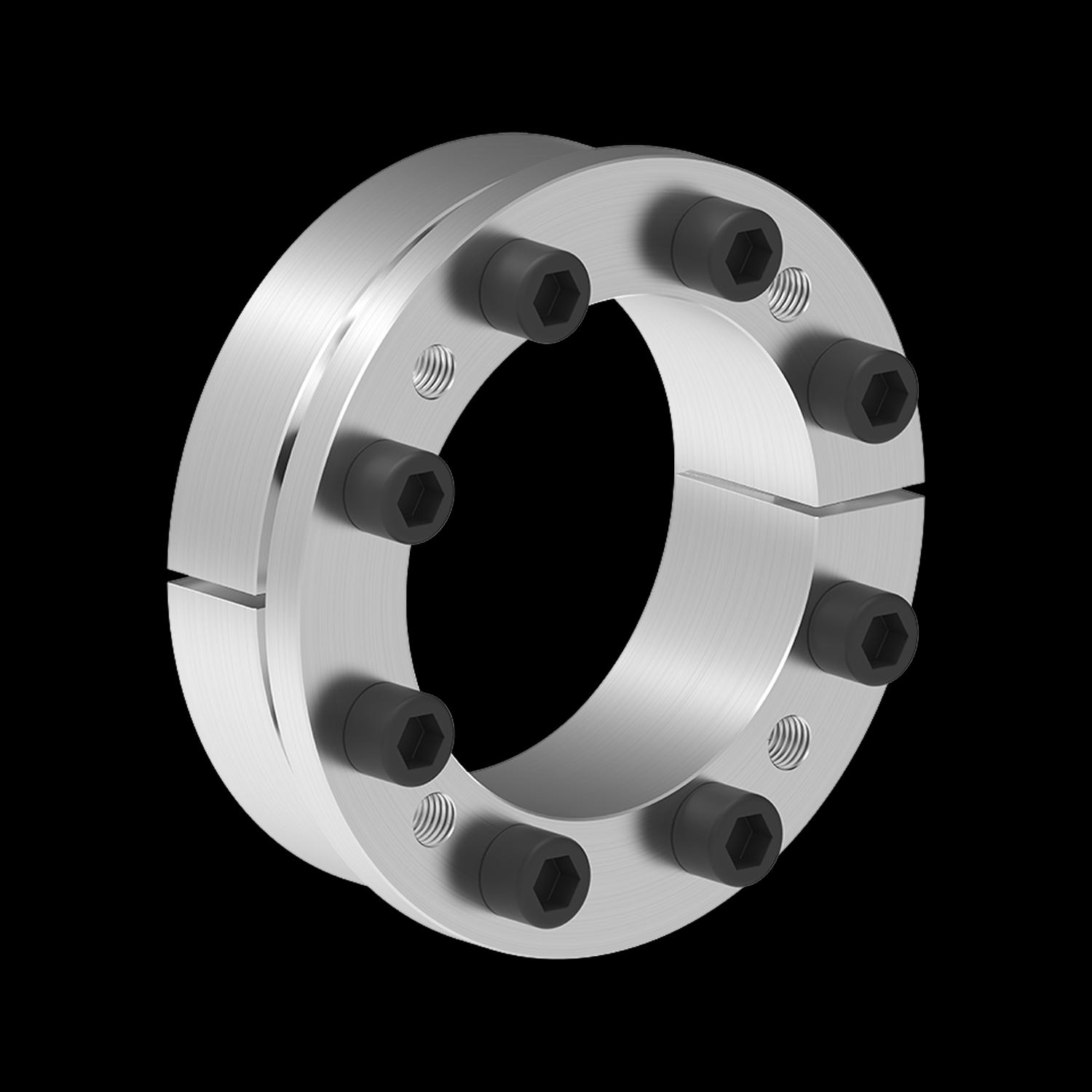

RfN 7061 locking assembly

Short, two-piece design, self-centering. Compact miniature locking assembly with low surface pressure.

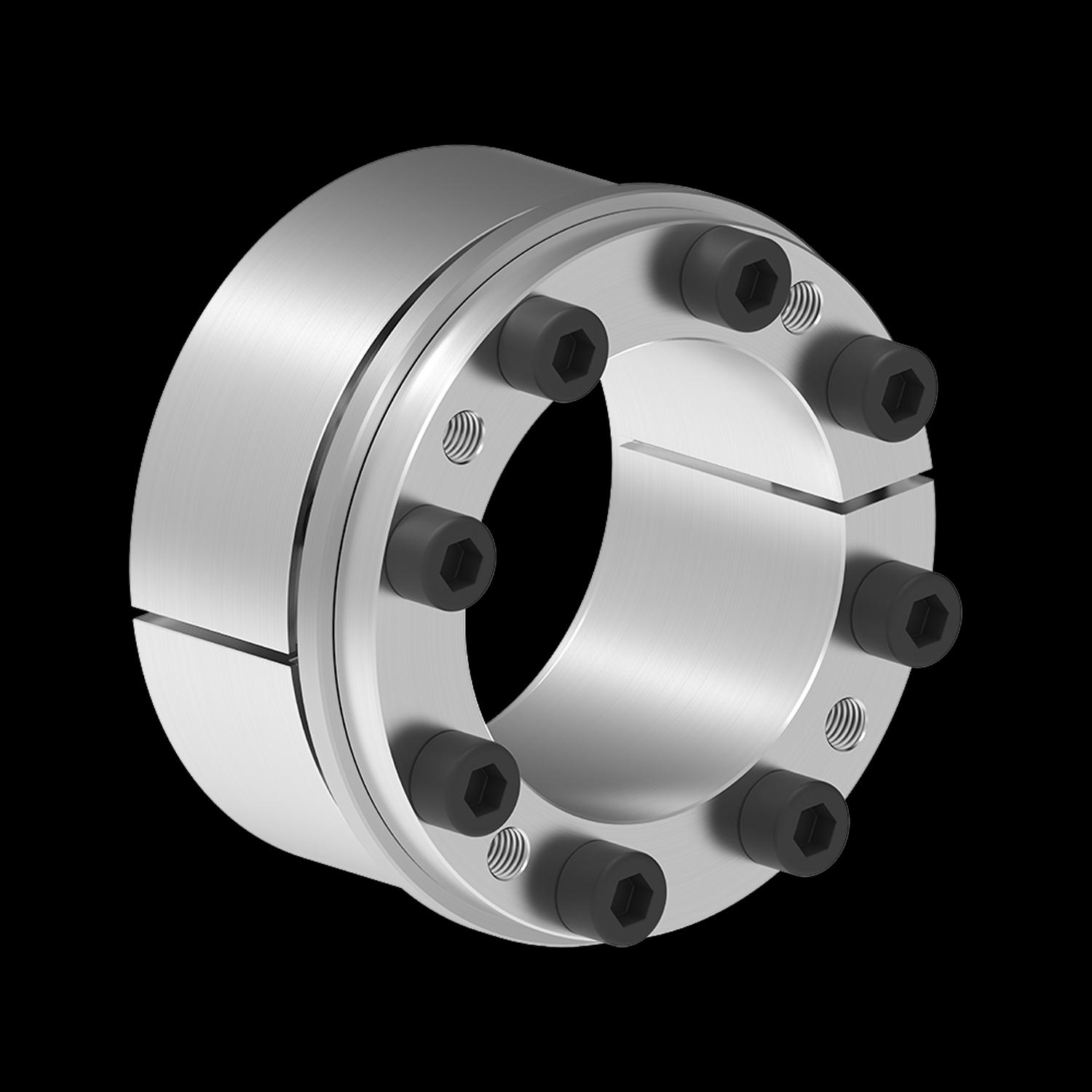

RfN 7015.1 locking assembly

Five-piece precision locking assembly, self-centering. No axial displacement of hub or shaft.

RfN 7015.0 locking assembly

Five-piece precision locking assembly, self-centering. No axial displacement of hub or shaft.

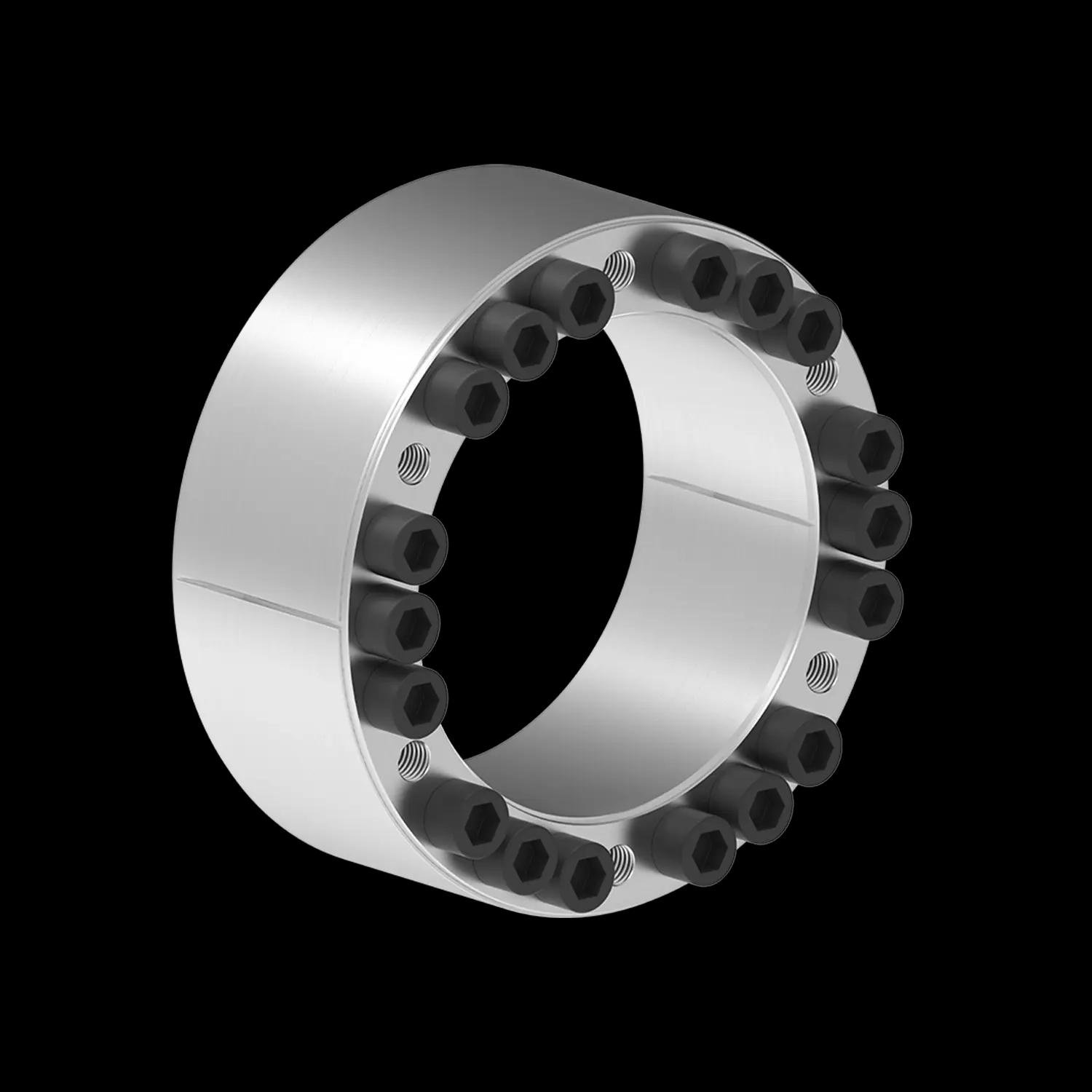

RfN 7014 locking assembly

Long, four-piece design, self-centering. The clamping cones prevent any axial displacement.

RfN 7013.1 Locking Assembly

Short, three-piece design with flange, self-centering. The flange prevents any axial displacement.

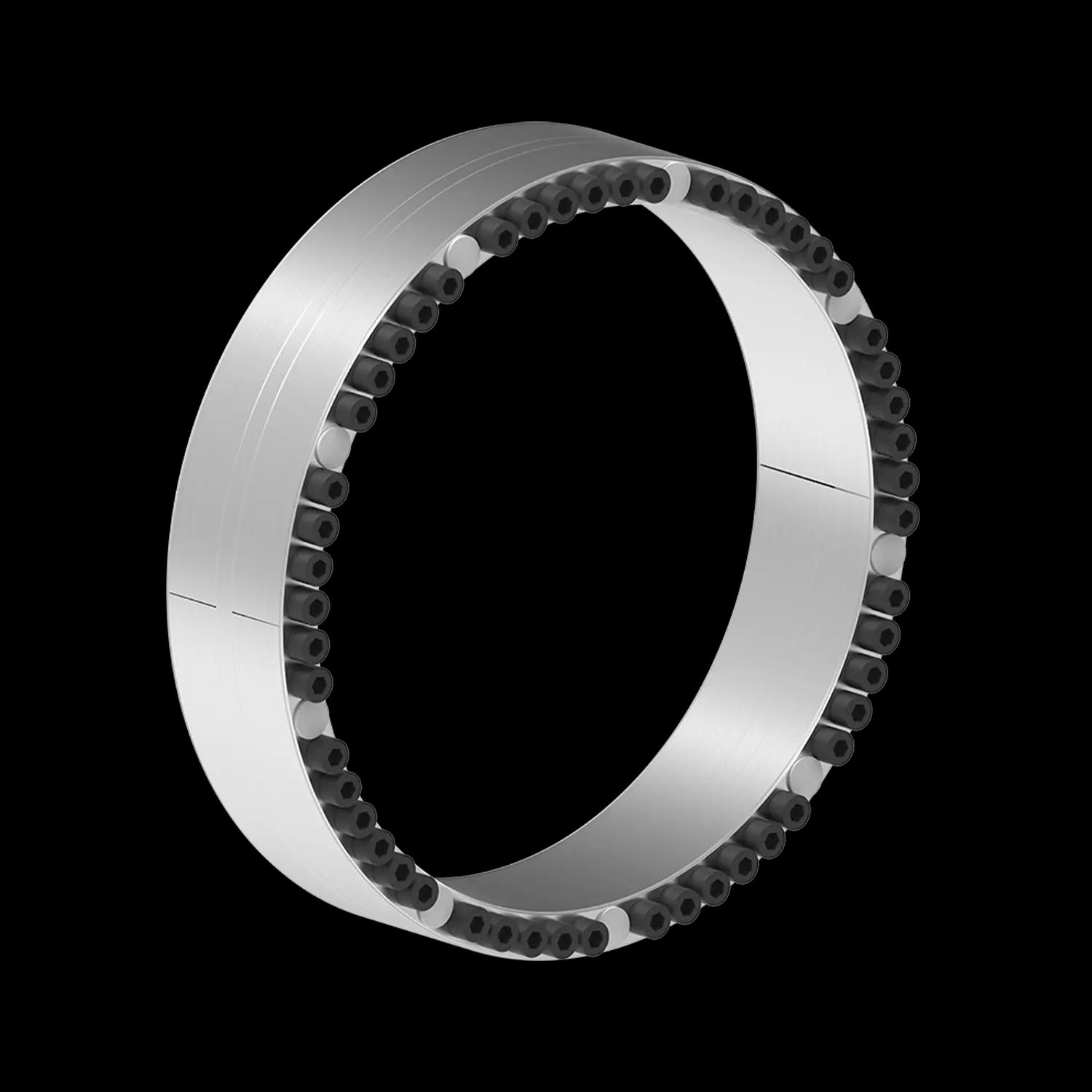

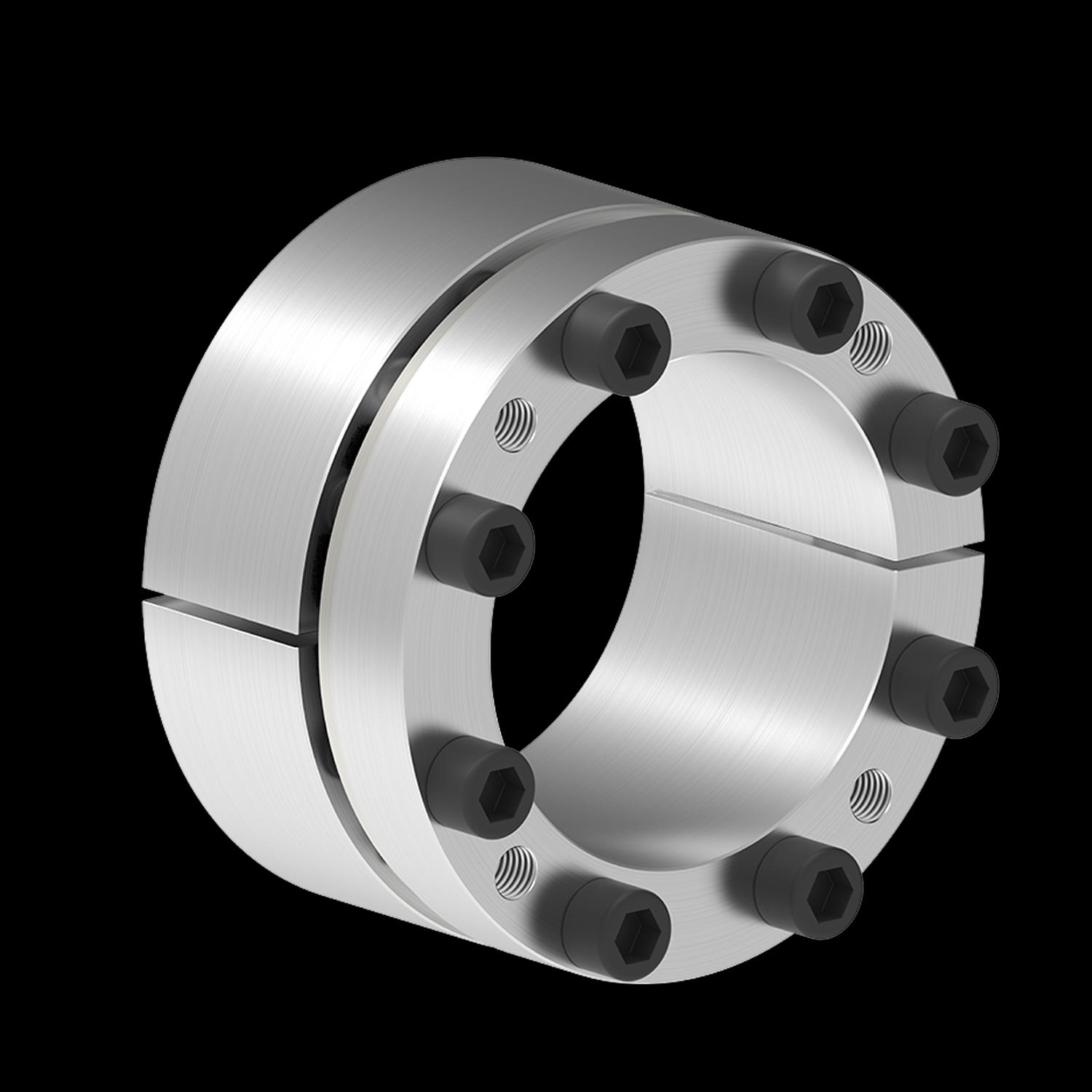

RfN 7013.0 Locking Assembly

Short, three-piece design, self-centering

RfN 7012.2 Locking Assembly

Identical to RfN 7012, but equipped with optimized screws for high bending moment applications.

RfN 7012 Locking Assembly

Slimmest four-piece design. Due to the clamping cones, no axial displacement occurs. Self-releasing.

RfN 7007 Locking Assembly

The RfN 7007 locking assembly is a variant of the proven RfN 7004 model and inherits all of its positive features.

RfN 7006 Locking Assembly

The locking assembly from the RfN 7006 series offers an impressive range of beneficial features.

RfN 7005 Locking Assembly

Long, three-piece design for high torques, self-centering

RfN 7004 Locking Assembly

The RfN 7004 locking assembly is an extended version of the proven RfN 7003 series.

RfN 7003 Locking Assembly

Short, two-piece design, self-centering

Downloads

locking_assemblies_ringfeder.pdf

locking_assemblies_ringfeder.pdf