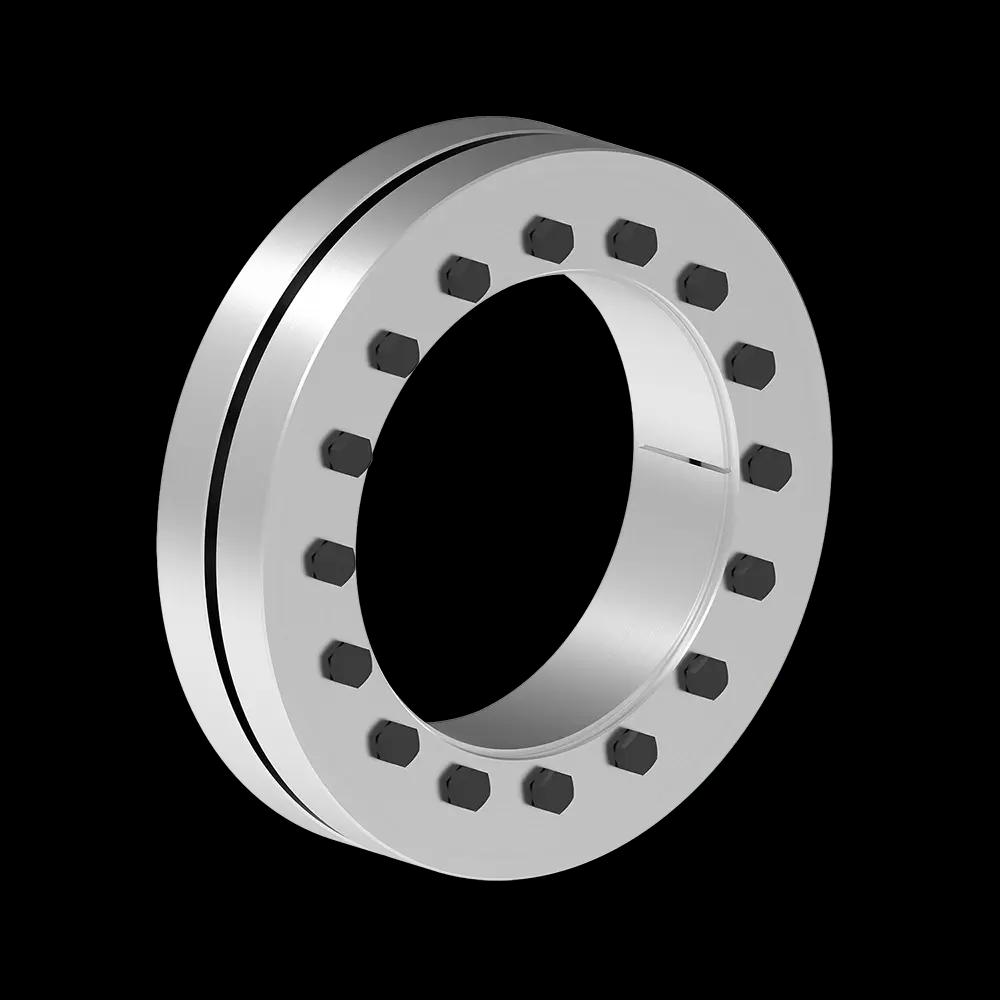

Shrink Disc RfN 4051

No other type of shaft-hub connection offers comparable properties in terms of fatigue strength under reversing loads and concentr

Lightweight 3-piece design for medium torques. The slim construction is ideal for thin hubs and hollow shafts.

Lightweight design for medium torque transmission – especially suitable for thin hubs and hollow shafts

Shrink discs are among the most modern types of clamping connections. Depending on the design, they essentially consist of one or two conical pressure rings and an inner ring. These components are axially clamped against each other using tension screws. The key difference compared to other internal locking devices is that pressure is applied externally to the hub. This means the shrink disc is not in the main force flow. Instead, the torque is transmitted via the contact surface between the shaft and hub without any intermediate elements. This provides a simple and cost-effective method to create an interference fit (shrink fit) for high-load shaft-hub connections.

Shrink disc suitable for medium torque levels in confined spaces

This offers significant advantages over traditional methods, where interference fits required complex calculations, tight manufacturing tolerances, and difficult assembly/disassembly procedures. Additionally, repair work poses no challenges regarding interchangeability or centering. No other shaft-hub connection offers comparable fatigue strength and runout accuracy.

Unlimited application possibilities – RINGFEDER shrink discs are suitable for mounting all types of hub bodies on shafts and axles. They can be used anywhere shrink fits, keyways, spline, polygon, or multi-spline connections were previously applied. For example: gears, chain wheels, levers, cams, rollers, belt or brake discs, flywheels, couplings, plug-on gear units, flanges, rope pulleys, running wheels.

- Lightweight design – suitable for medium torque levels in confined spaces

- Slotted inner ring – low loss forces and pressures on shaft and hub

- Compensation for small tolerance errors

- Maximum reliability – suitable for static, dynamic, and impact loads

- Simple part manufacturing – minimal requirements for the functional surfaces of the connected parts

- Easy interchangeability – RINGFEDER shrink discs operate without form-fit

- Simple assembly – no shoulder, key, or pin required; can be mounted anywhere on the shaft using standard screws and tools

- Low sensitivity to dirt – extended service life, as contact surfaces are tightly pressed together after tightening, preventing dirt and moisture from penetrating the functional surfaces

Shrink discs GT (split design)

In this configuration, depending on dimension X, longer clamping screws are required and must be ordered accordingly. If dimension "X" exceeds 2 · L1 (RfN 4051 Light Duty Series), a reduction of the transmittable torque by up to 50% must be expected for type GT.

Contact us