Direct Drive Rotary

Kollmorgen pioneered the development of direct drive technology, and today offers the broadest range of direct drive motors in the industry.

Mechanical transmissions — such as gearboxes, timing belts, pulleys or lead screws — increase machine size, weight and noise while introducing backlash and mechanical losses that reduce machine performance. Direct drive rotary and linear servo motors eliminate all these issues.

Kollmorgen DDR Housed Rotary, CDDR cartridge rotary and DDL Linear direct drive motors mount directly to the driven load, delivering industry-leading performance with improved accuracy, higher throughput, greater reliability and smooth, quiet operation to suit a wide range of machine-design needs.

Direct drive rotary and linear servo motors improve load acceleration, lower power consumption, reduce system inertia and ensure the greatest precision. And because direct drive motors eliminate the need for transmission components, your motion system is easier to integrate and practically maintenance-free. No gearbox to lubricate, no belts to tighten, no cams to wear — plus a dramatically increased mean time between failures (MTBF).

Contact us if you have any questions.

Contact usOur quality brands

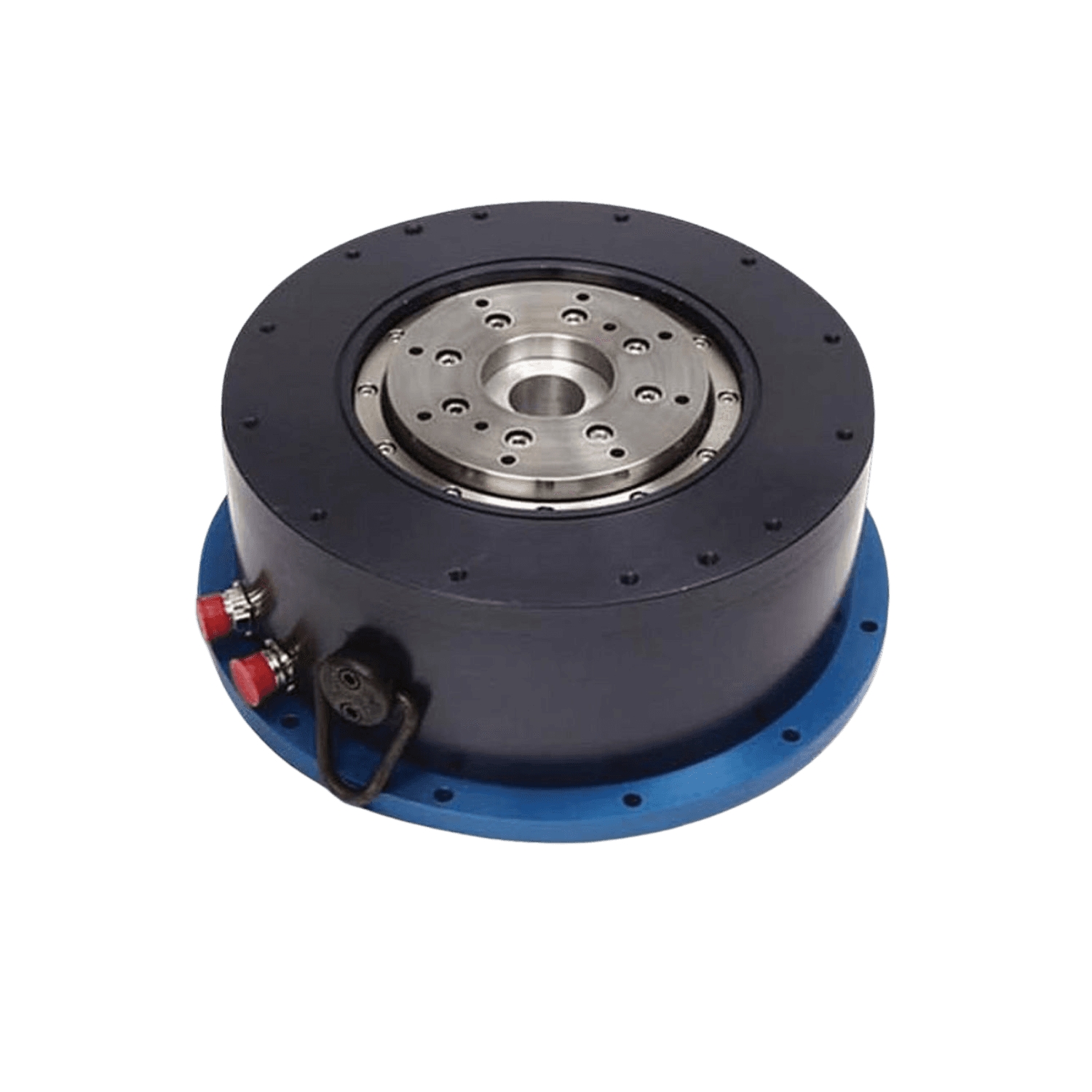

Housed D & DH Motors

Housed DDR servomotors offer high torque density, precise performance and zero maintenance in an easily installed servo solution.

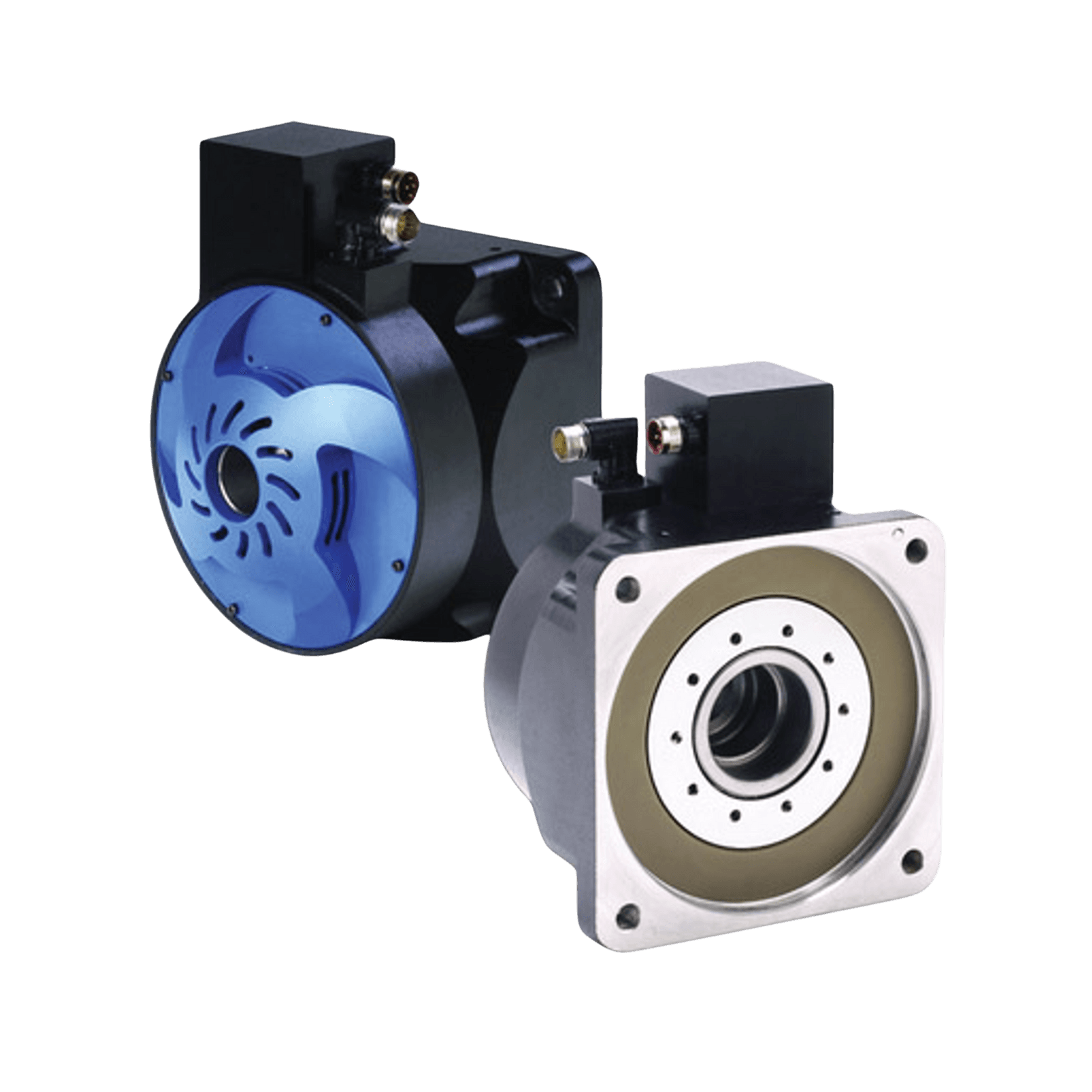

Cartridge DDR® Servo Motors

Cartridge DDR® servomotors combine the performance advantages of a frameless motor with the ease of installation of a full-frame motor.

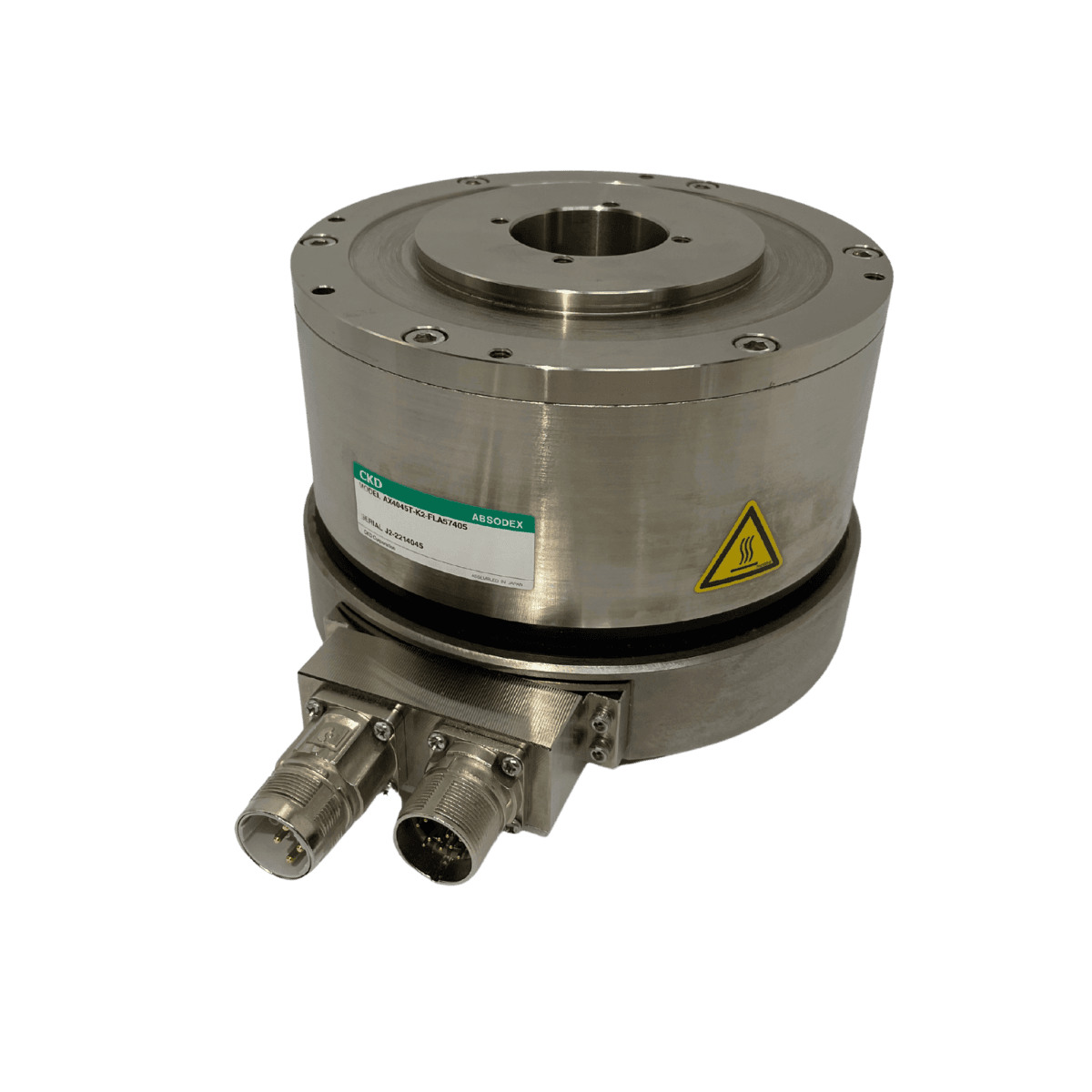

Absodex DDR Drive

This development places special emphasis on compliance with European industrial standards, while maintaining the high quality and reliability expected from CKD products.

TBM Series Frameless Motors

These torquer brushless motors are optimized to deliver high torque at relatively low speeds in low-voltage applications such as robotic joints, mobile robots and other battery-operated machines.

KBM Series Frameless Motors

The KBM™ Series provides low- and high-voltage motors (120–480 Vac) designed to be directly embedded in your machine using the machine’s own bearings to support the rotor.

Downloads

Kollmorgen Automation and Motion Control - Full-line Catalog.pdf

Kollmorgen Automation and Motion Control - Full-line Catalog.pdf