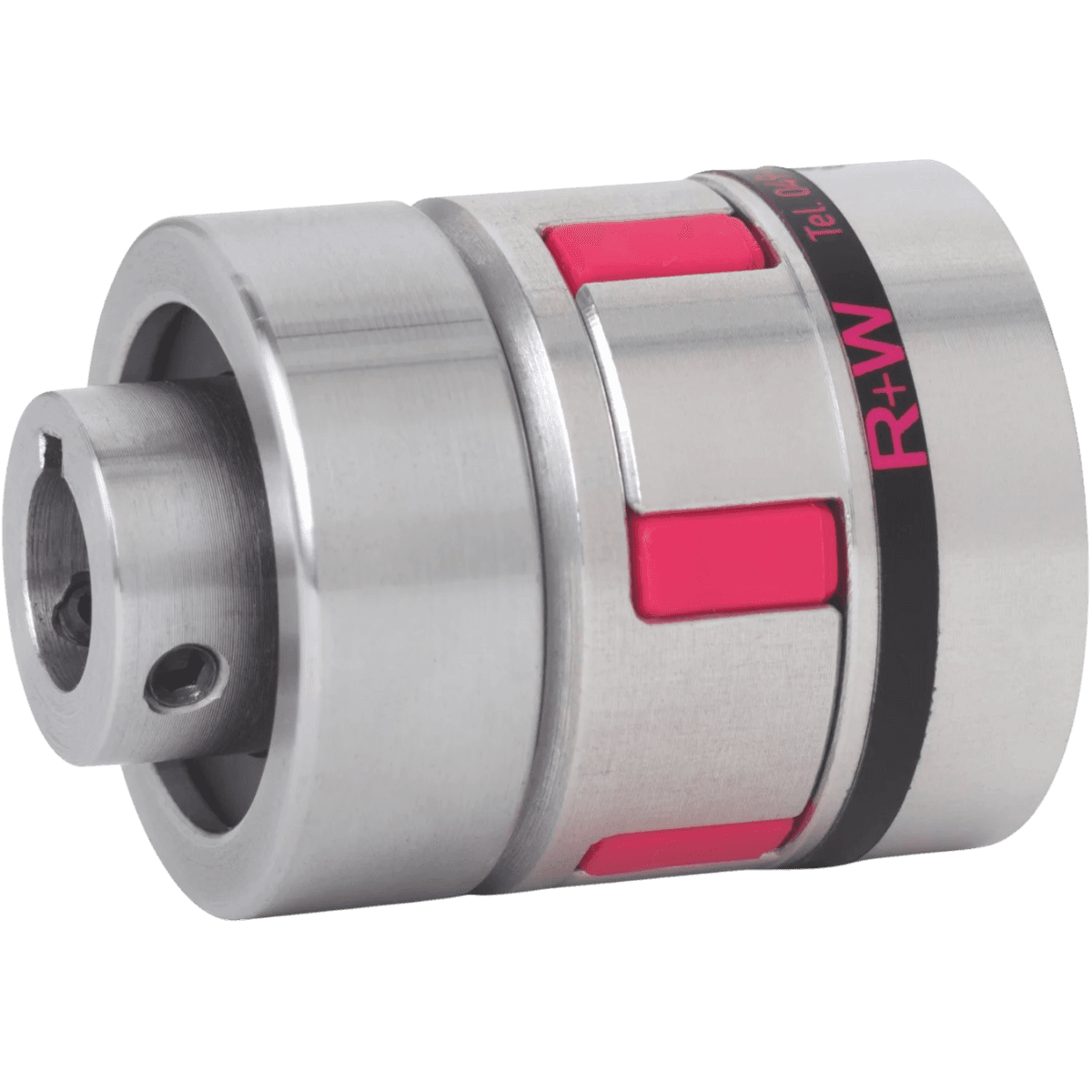

Torque limiters

Torque limiters form R+W operate on the spring-ball detent principle. If the torque exceeds the set limit value, the coupling completely disconnects the driving and driven components. This results in a mechanical separation within less than 5 ms in the event of a torque overload. The coupling system is completely backlash free and suitable for highly dynamic applications in modern drive technology.

Contact us if you have any questions.

Contact usOur quality brands

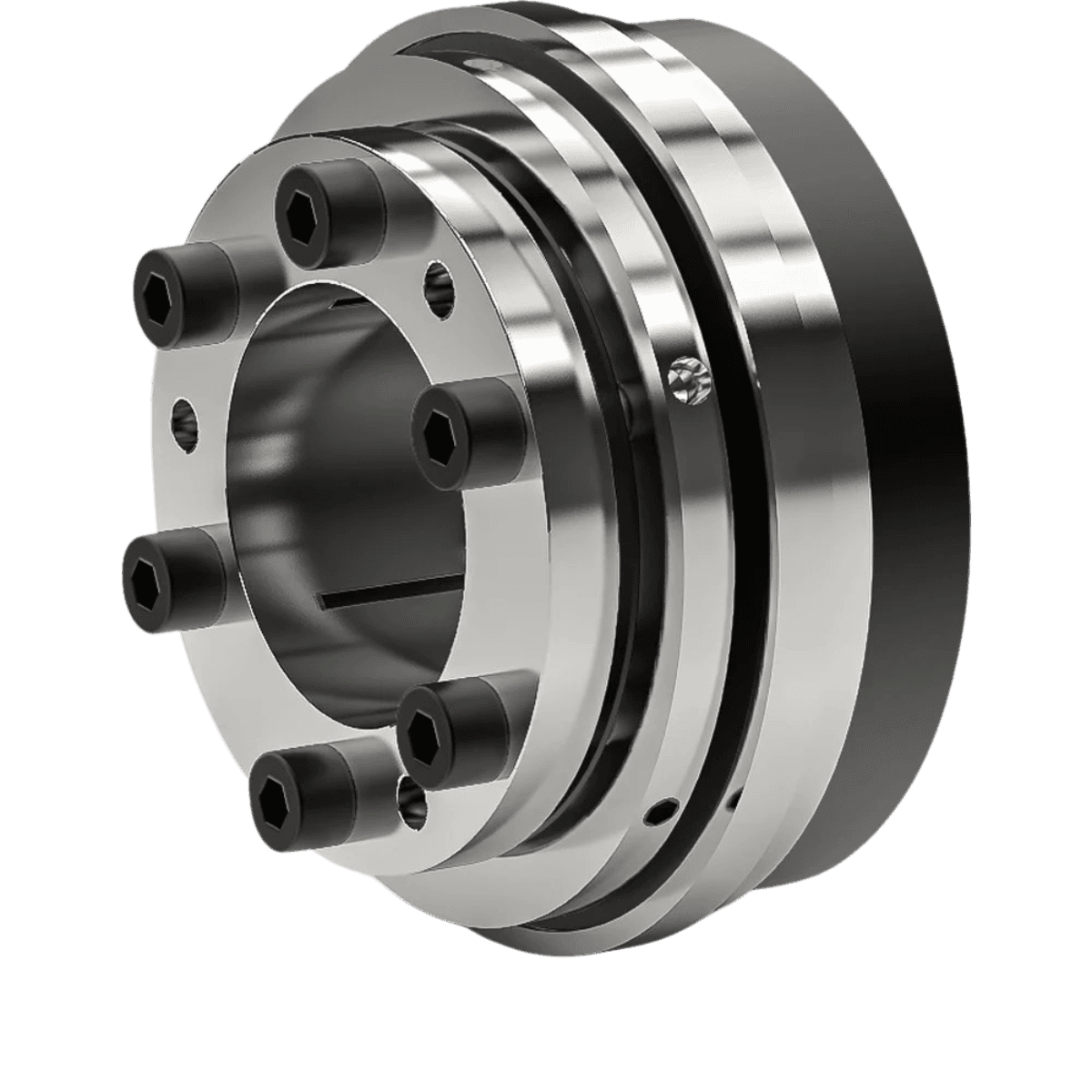

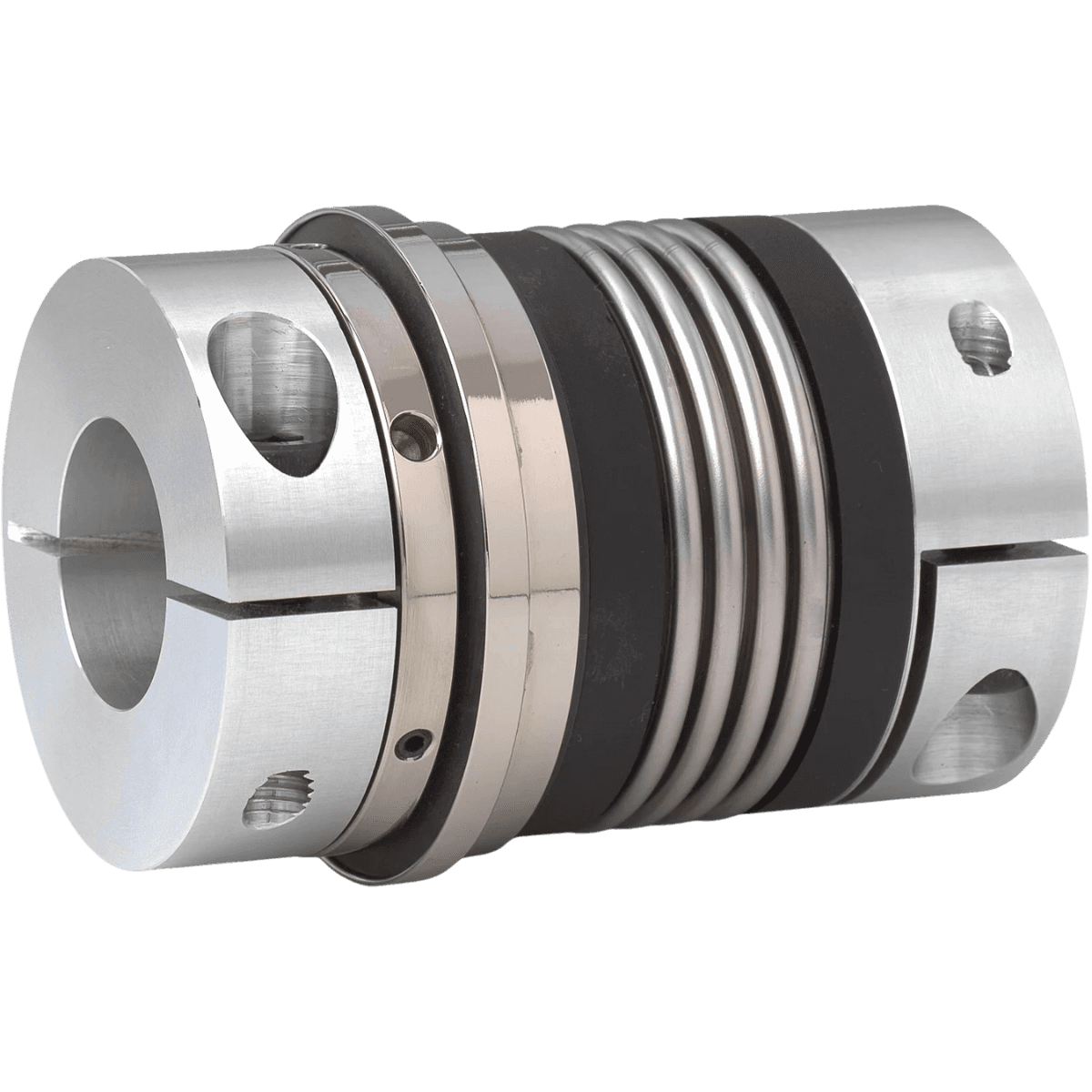

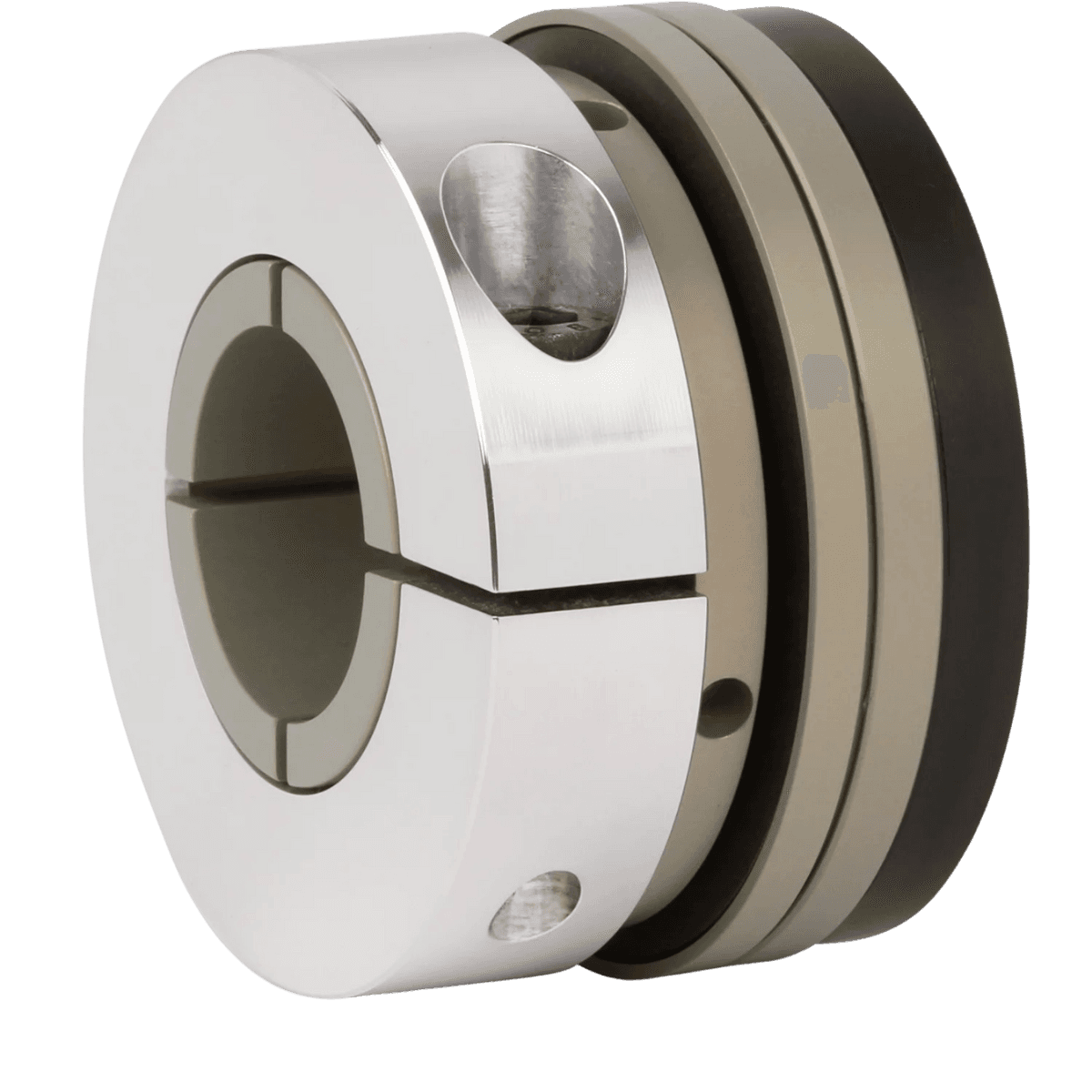

SK1 – Torque limiter

Safety system: hardened steel, Clamping ring: size 1.5 – 10 aluminium, Conical clamping bushing: size 15 – 2500 steel

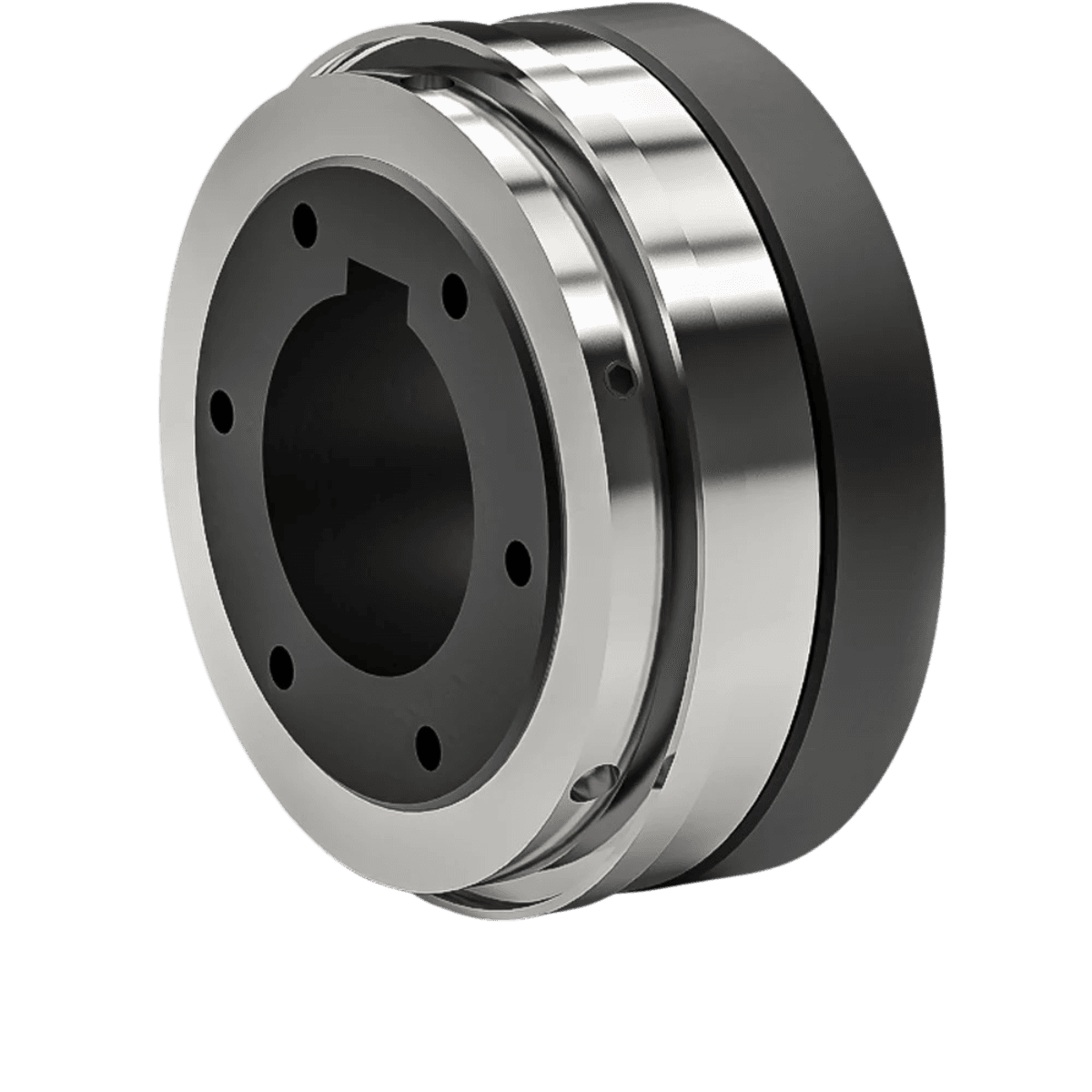

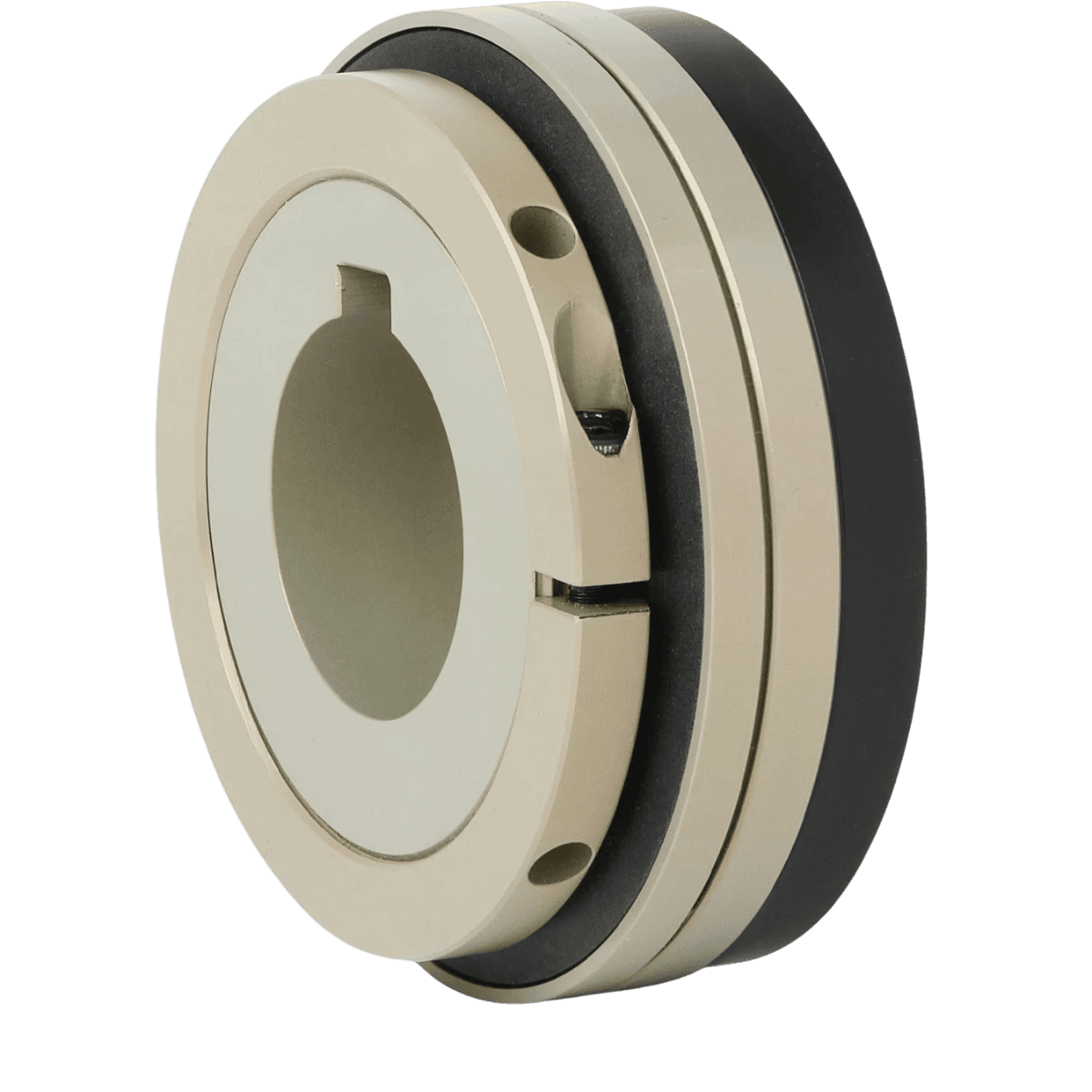

SKP – Torque limiter

Safety system: hardened steel, spring loaded ball-detent principal, with simple keyway connection

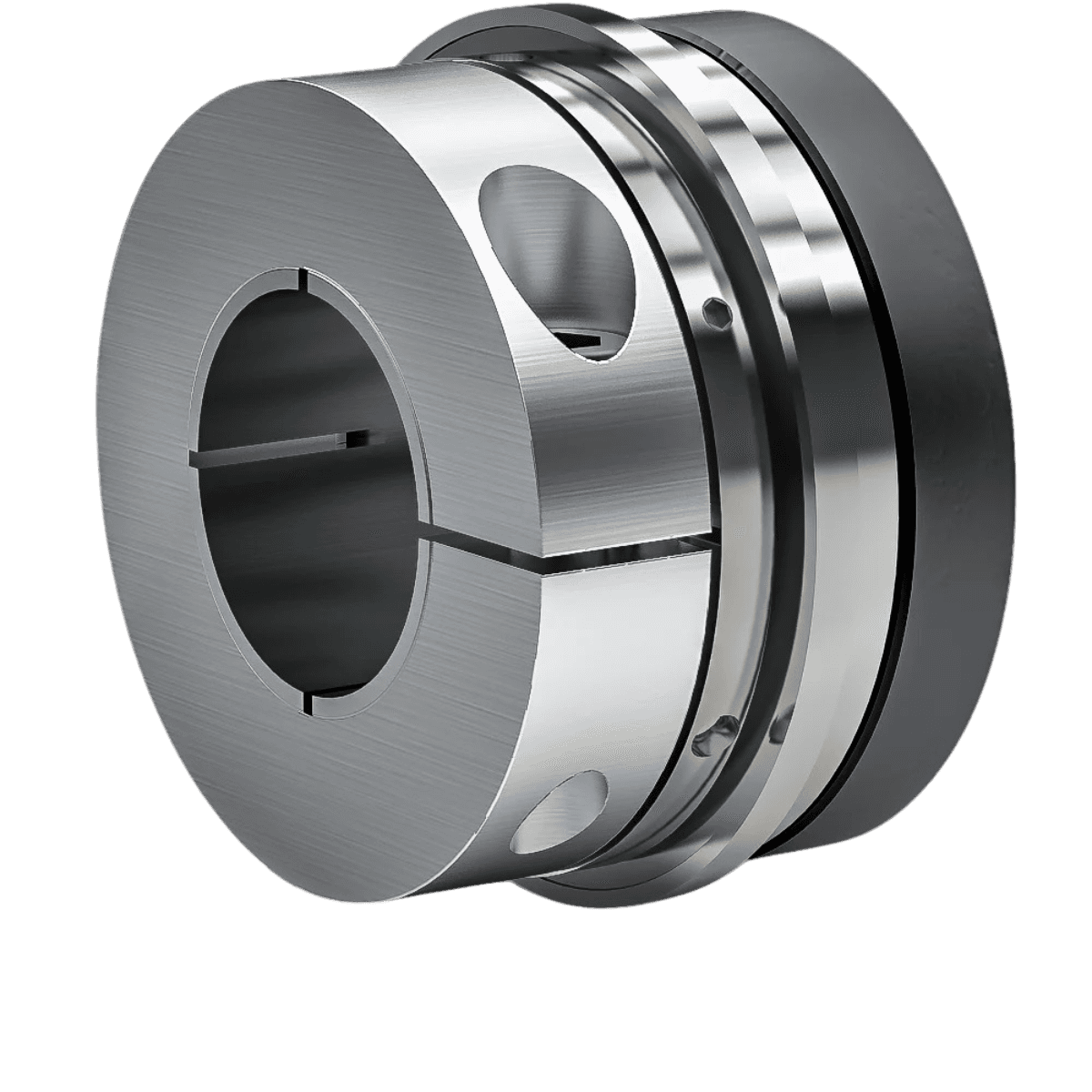

SKN –Torque limiter

With clamping ring and one clamping screw, Safety system: spring loaded ball-detent principle

SKH – Torque limiter

Two clamping hubs with two clamping screw in each, Torque limiter system: spring loaded ball-detent principle

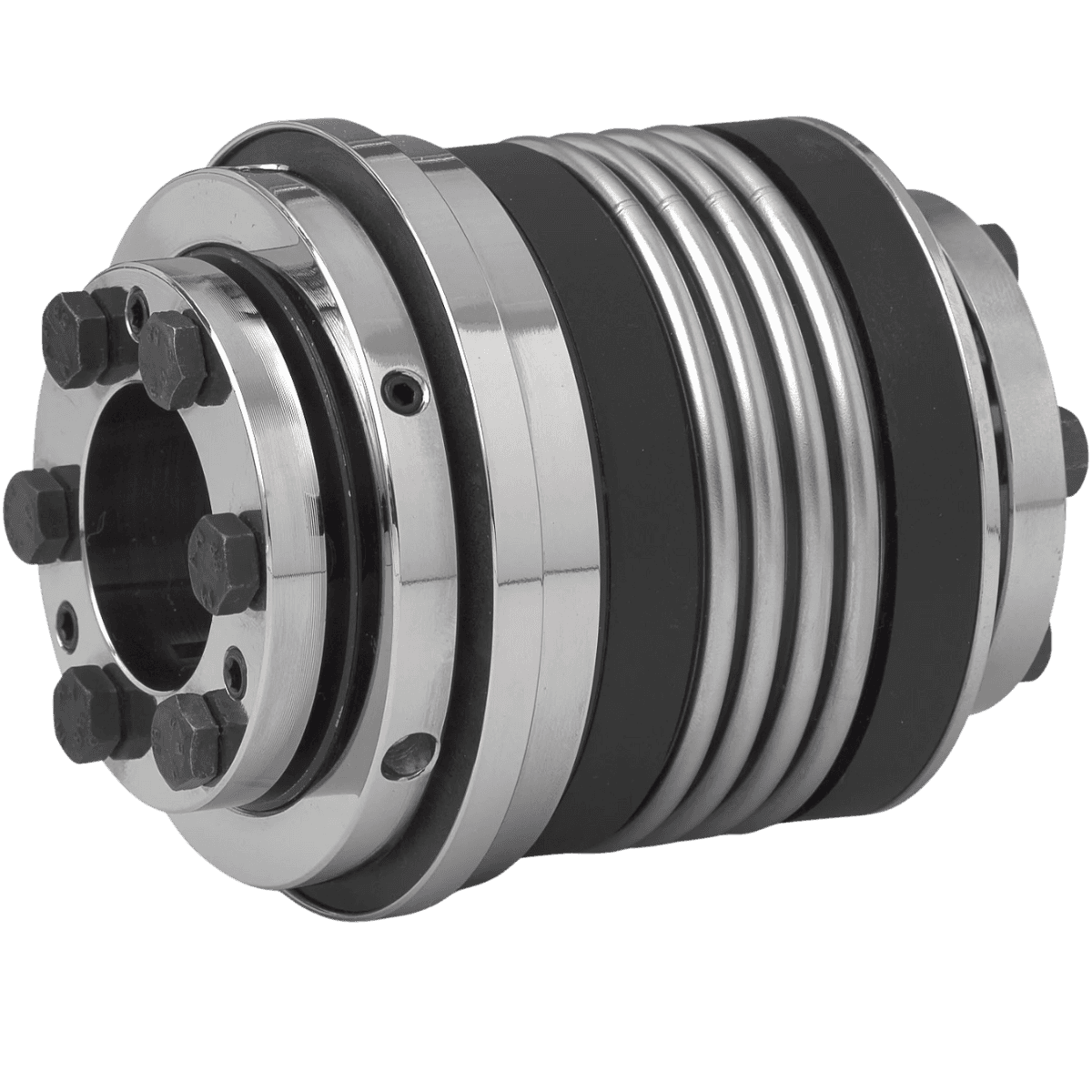

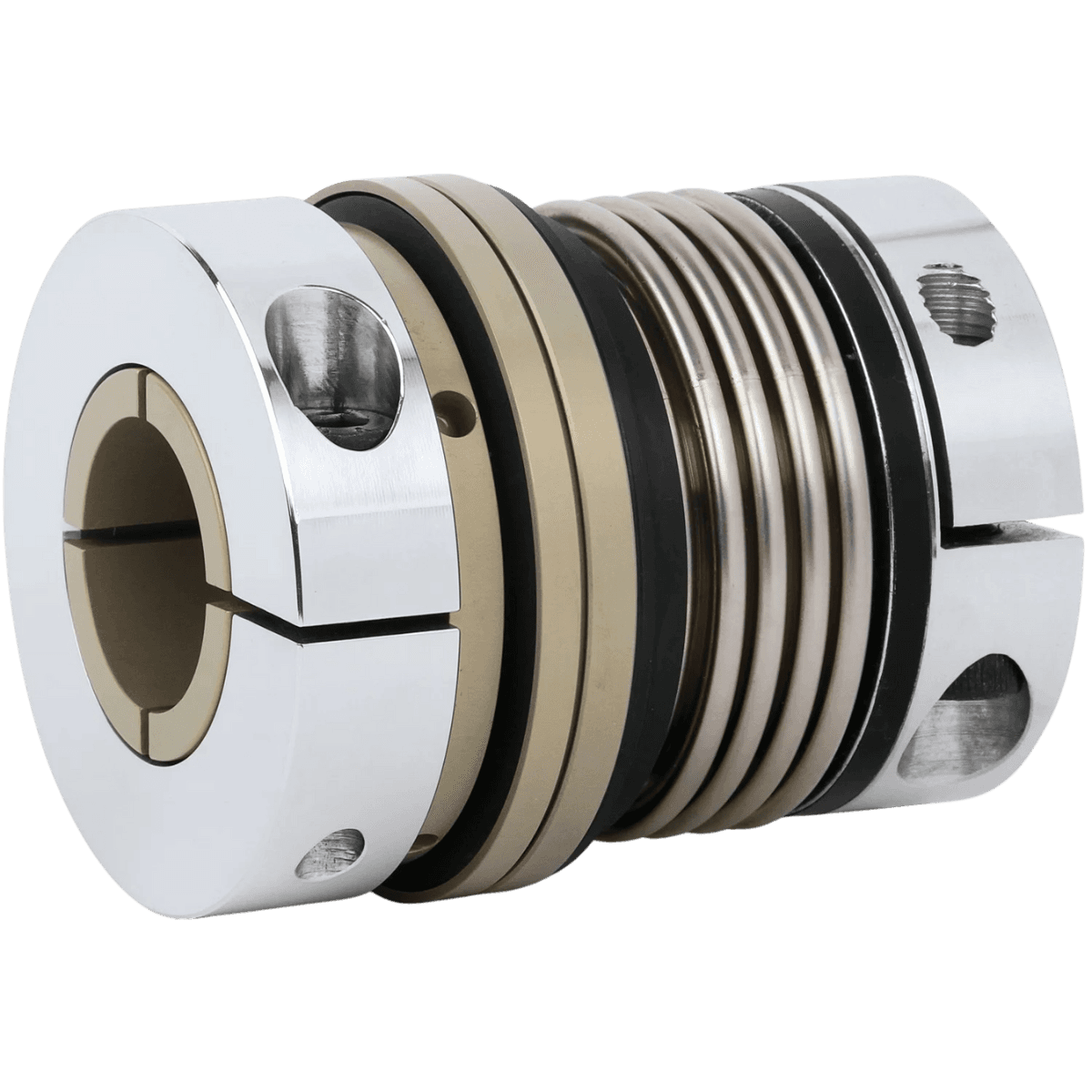

SK2 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

SK3 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

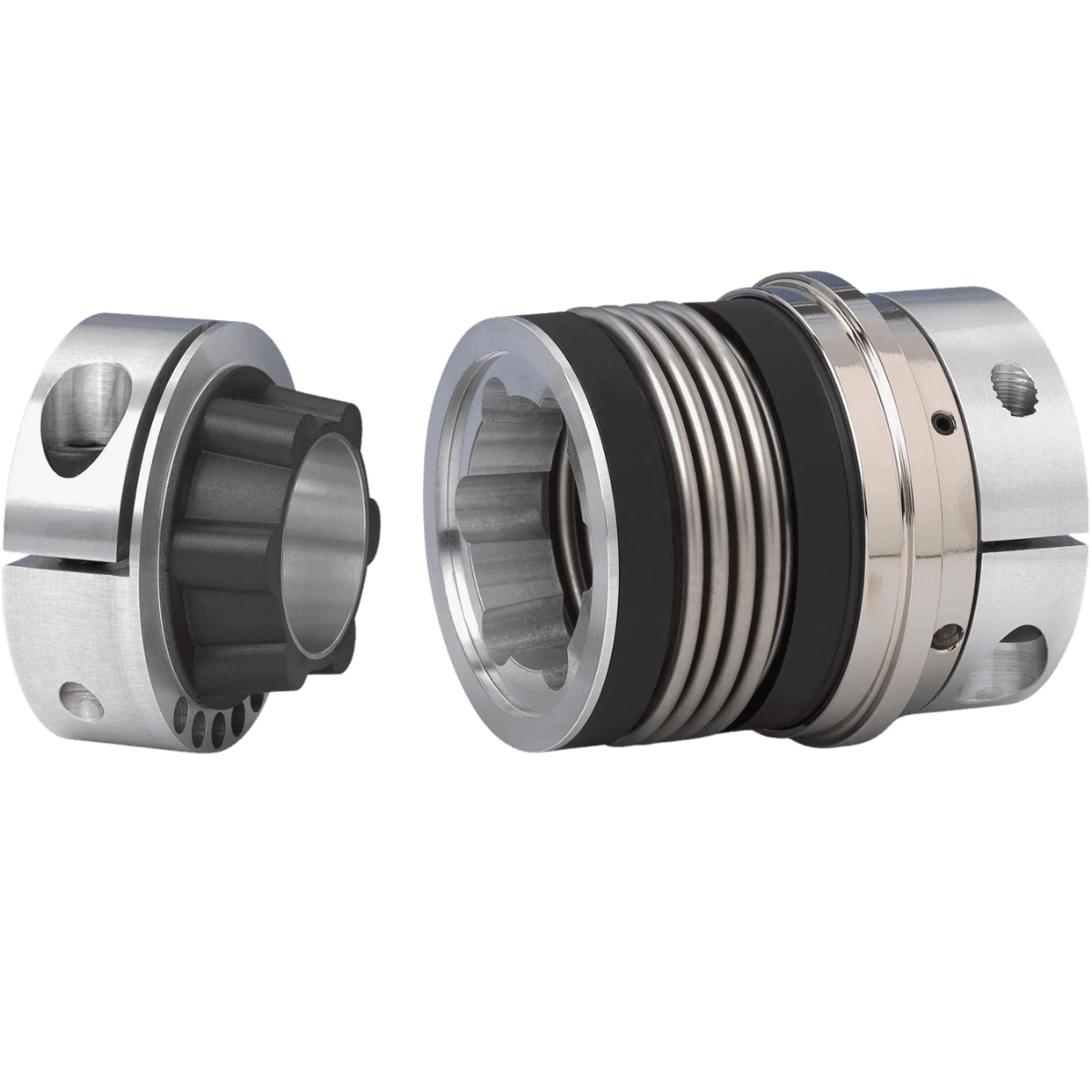

SK5 – Torque limiter

Two clamping hubs with one clamping screw each, and one of the clamping hubs with tapered male segment, Safety system: spring loaded ball-detent principle

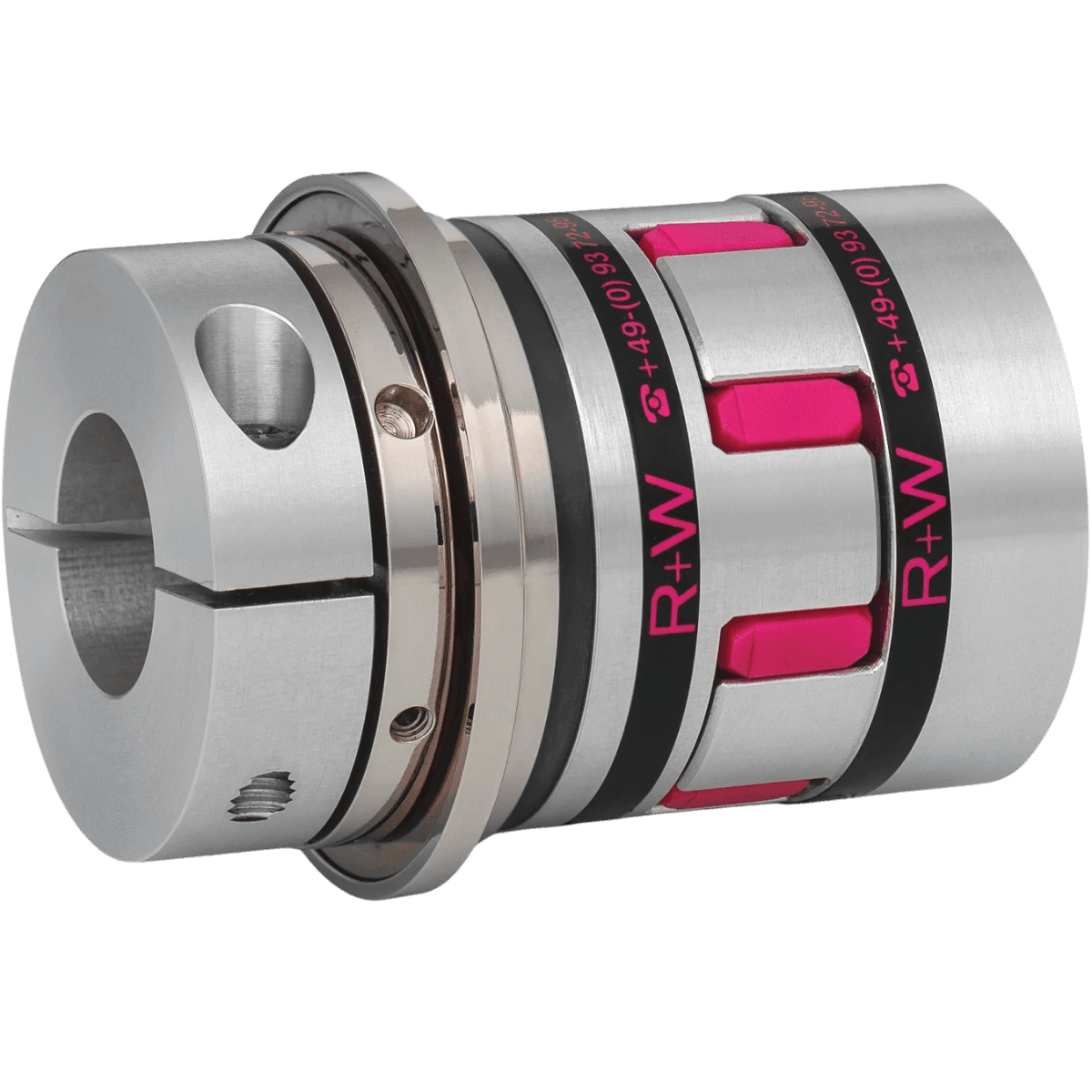

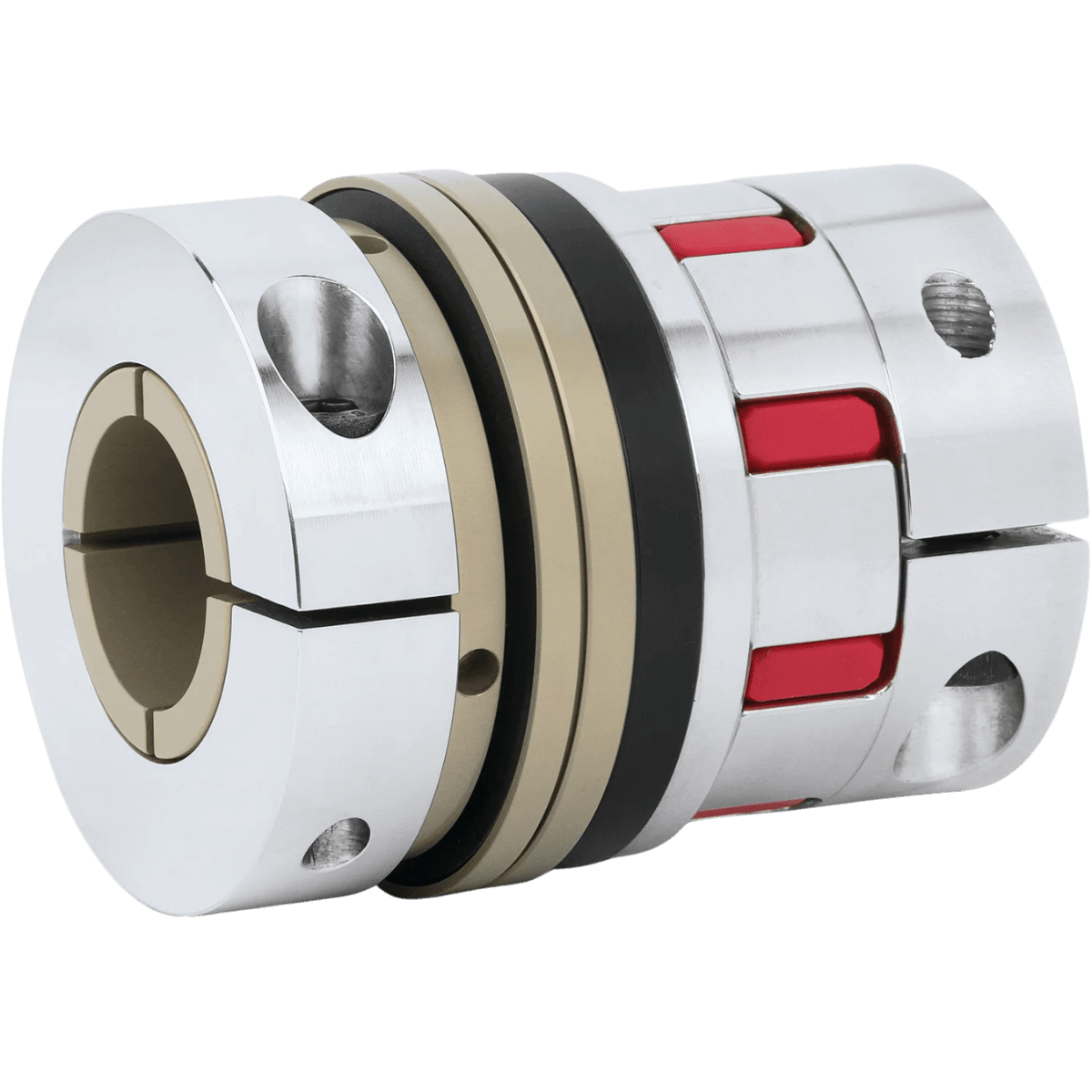

ES2 – Torque limiter

Two clamping hubs with one clamping screw each and concave driving jaws, Safety system: spring loaded ball-detent principle

SLN – Torque limiter

With clamping collar and a single clamping screw, Safety system: spring loaded ball-detent principle

SLP – Torque limiter

With DIN 6885 or ANSI B17.1 keyway, Safety system: spring loaded ball-detent principle

SL2 – Torque limiter

Clamping collar / clamping hub with one clamping screw each, Safety system: spring loaded ball-detent principle

SLE – Torque limiter

Clamping collar with clamping screw, Clamping hub with concave driving jaws and clamping screw, Safety system: spring loaded ball-detent principle

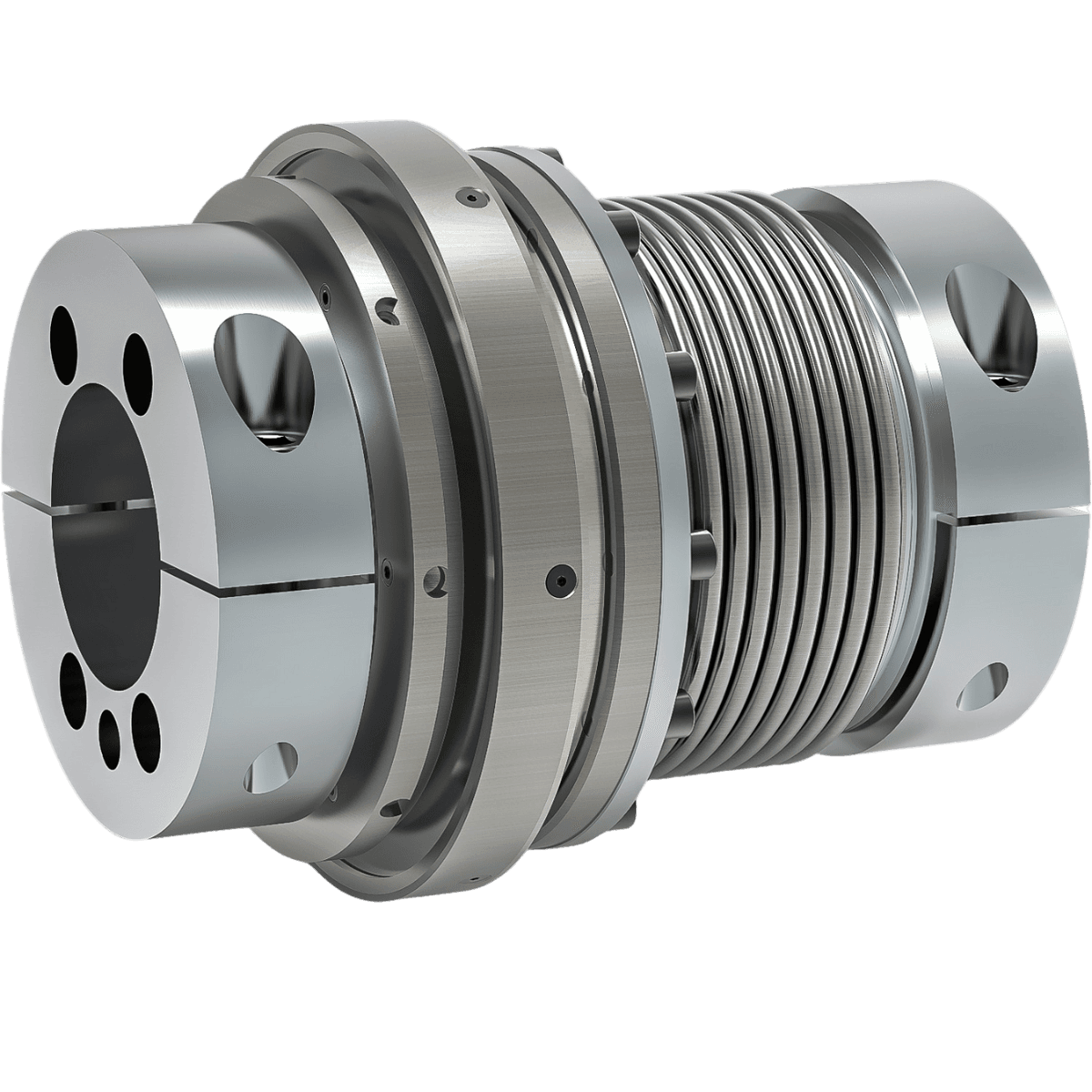

ESL – Torque limiter

Two hubs, each with keyway, Safety system is integrated into one of the hubs