Wörner Stopper/Separating stops

Essential for efficient stop-and-go operation in production and assembly lines

If you're looking to decelerate, stop, or precisely position workpiece carriers, explore our new range of pallet stoppers from our partner Wörner — also referred to as pallet dampers or separating stops. These components ensure smooth and controlled carrier flow in your production line.

Contact us if you have any questions.

Contact us

Displacement stops products

Control of material flow at crossings, when changing between longitudinal and transverse transport. Narrow design fits between two parallel longitudinal sections.

Acceleration units products

Quickly accelerate the workpiece carrier to the conveyor speed after completion of the work cycle. Significant reduction in cycle time.

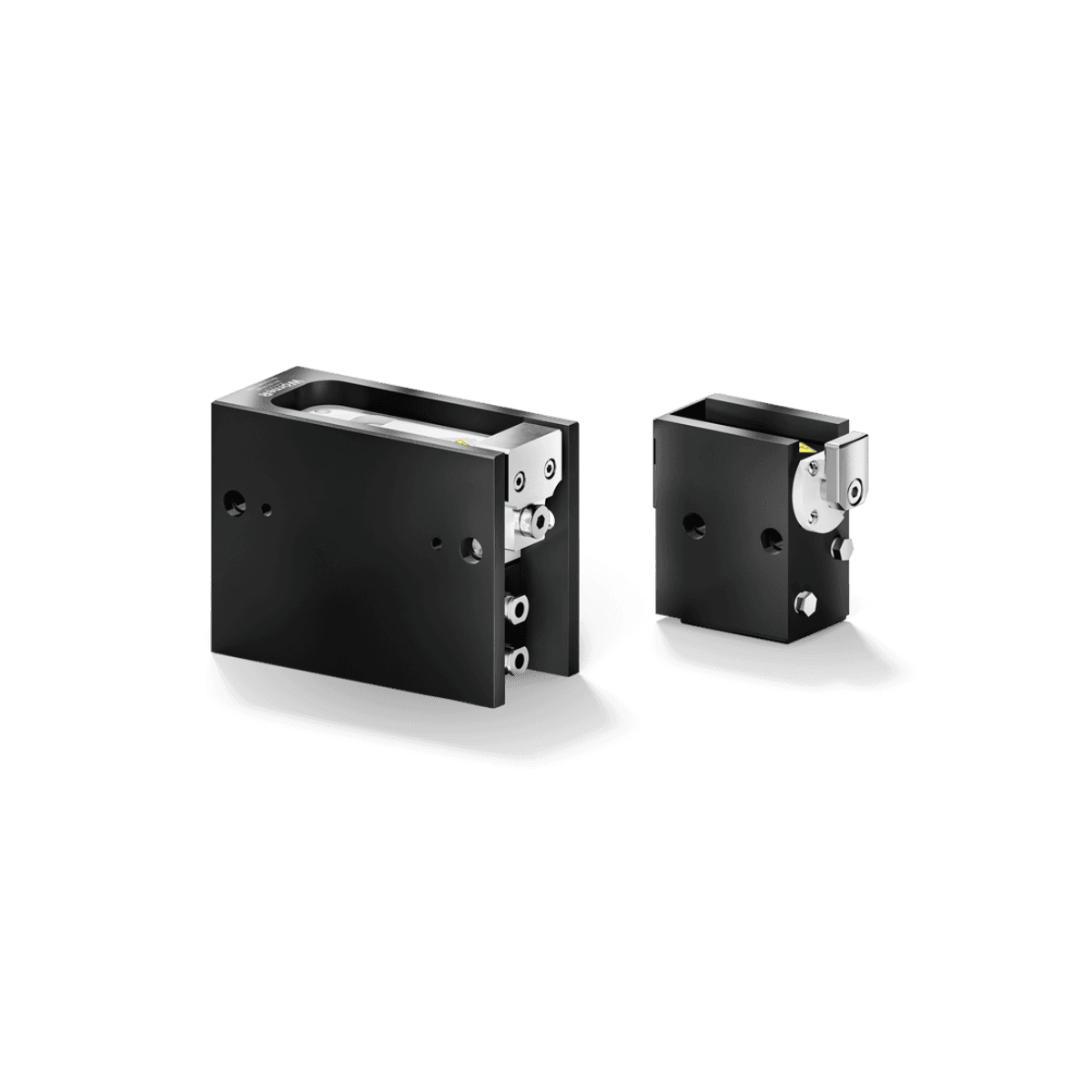

Anti-bounce stops products

Hold the workpiece carrier in position at the stop point with pinpoint accuracy and without rebound. Also, for blocking the material flow against the intended conveying direction.

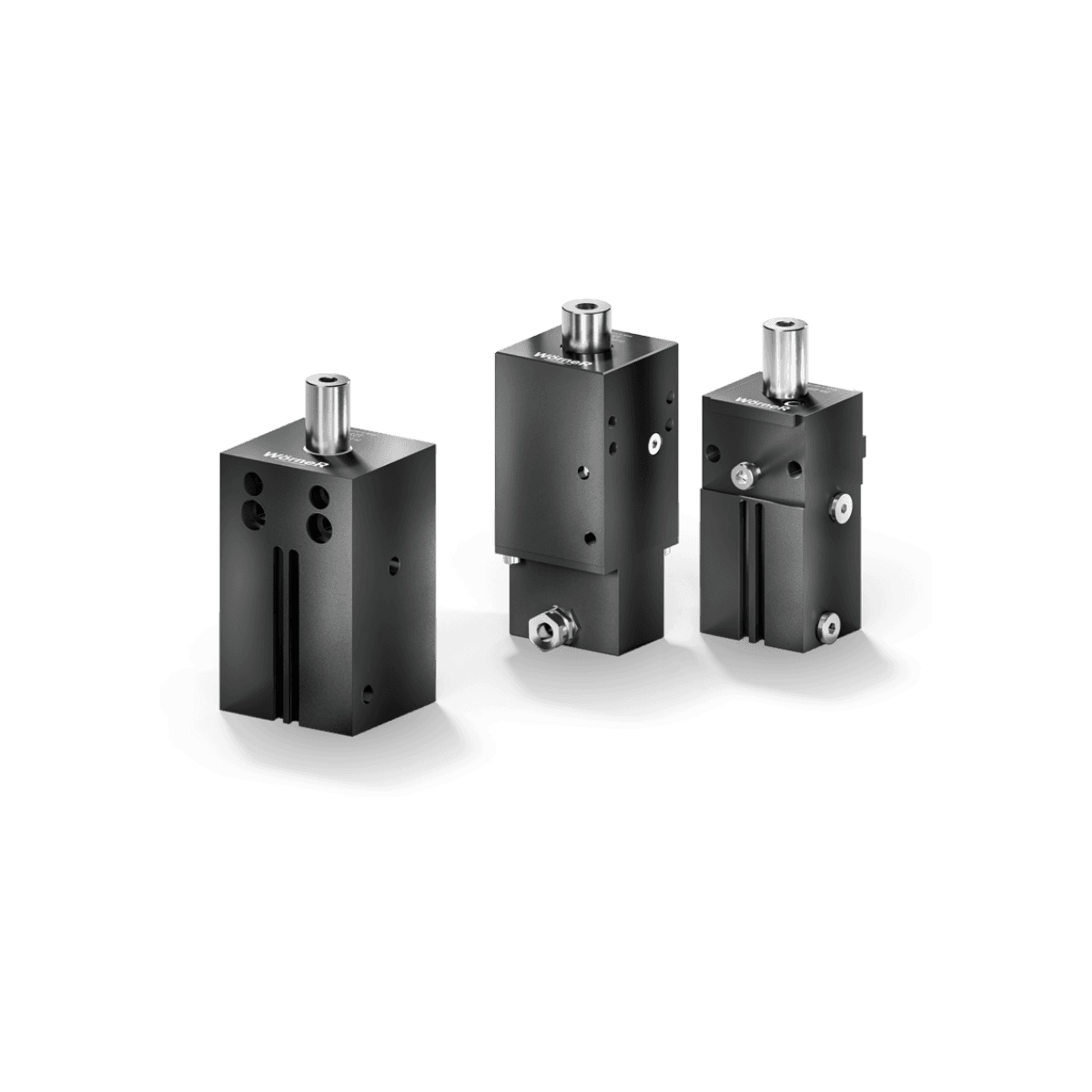

Index cylinders products

Particularly precise positioning and lifting of a workpiece carrier from the conveyor. Excellent alternative to lifting and positioning units, easier to handle and less expensive.

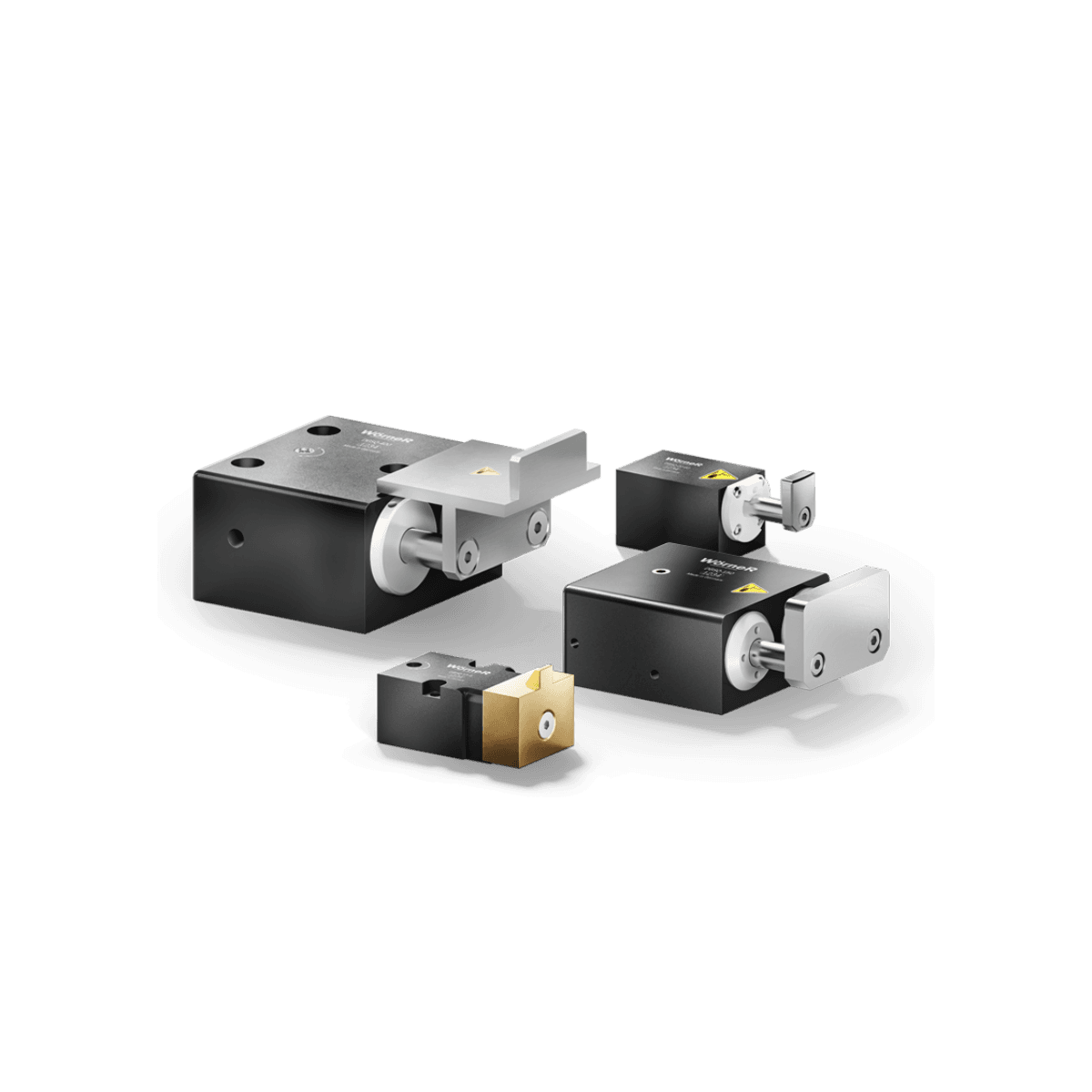

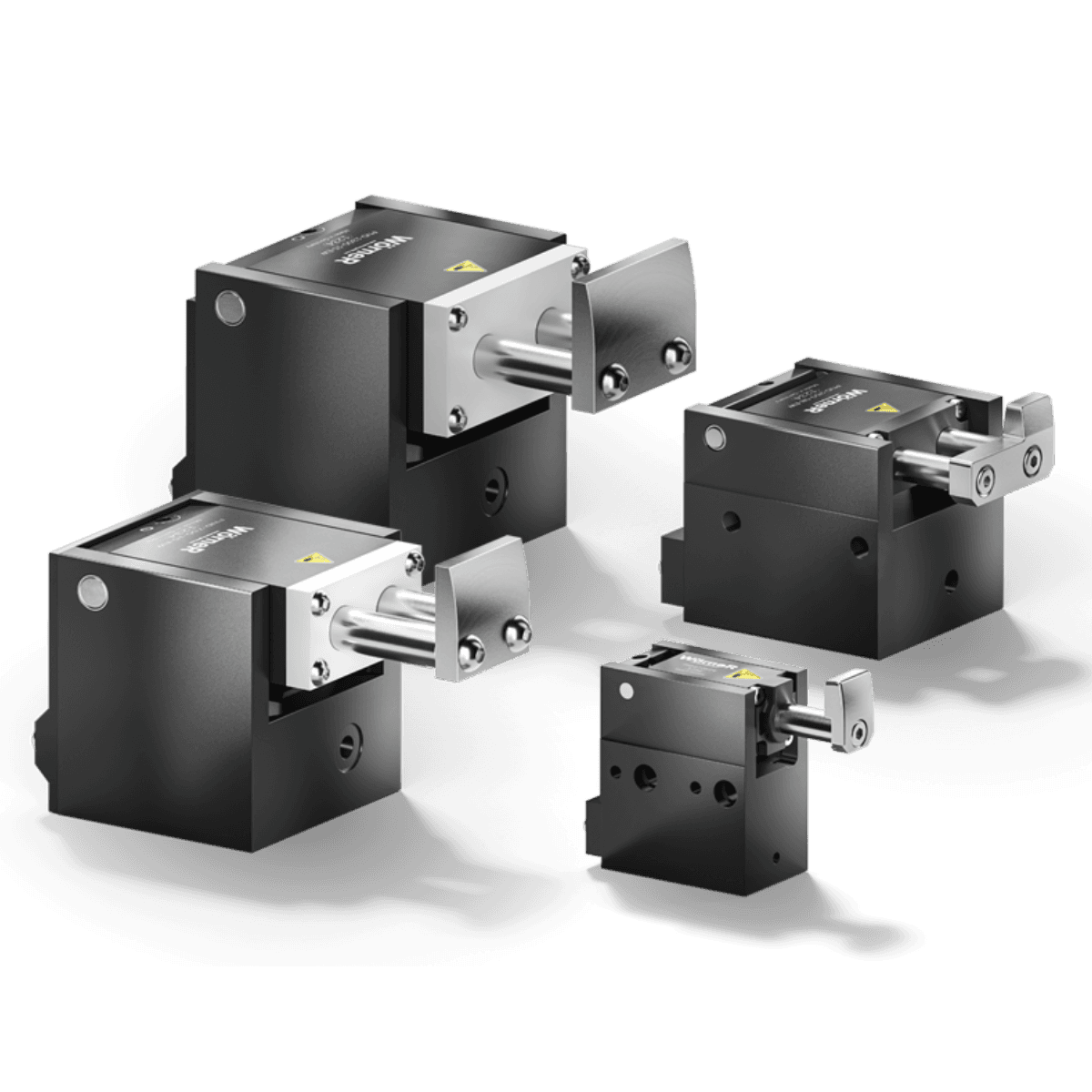

Angle dampers products

Smooth stopping and precise positioning of a workpiece carrier at a stop point, in conjunction with a change of direction or at the end of a stitch section. Without lowering function.

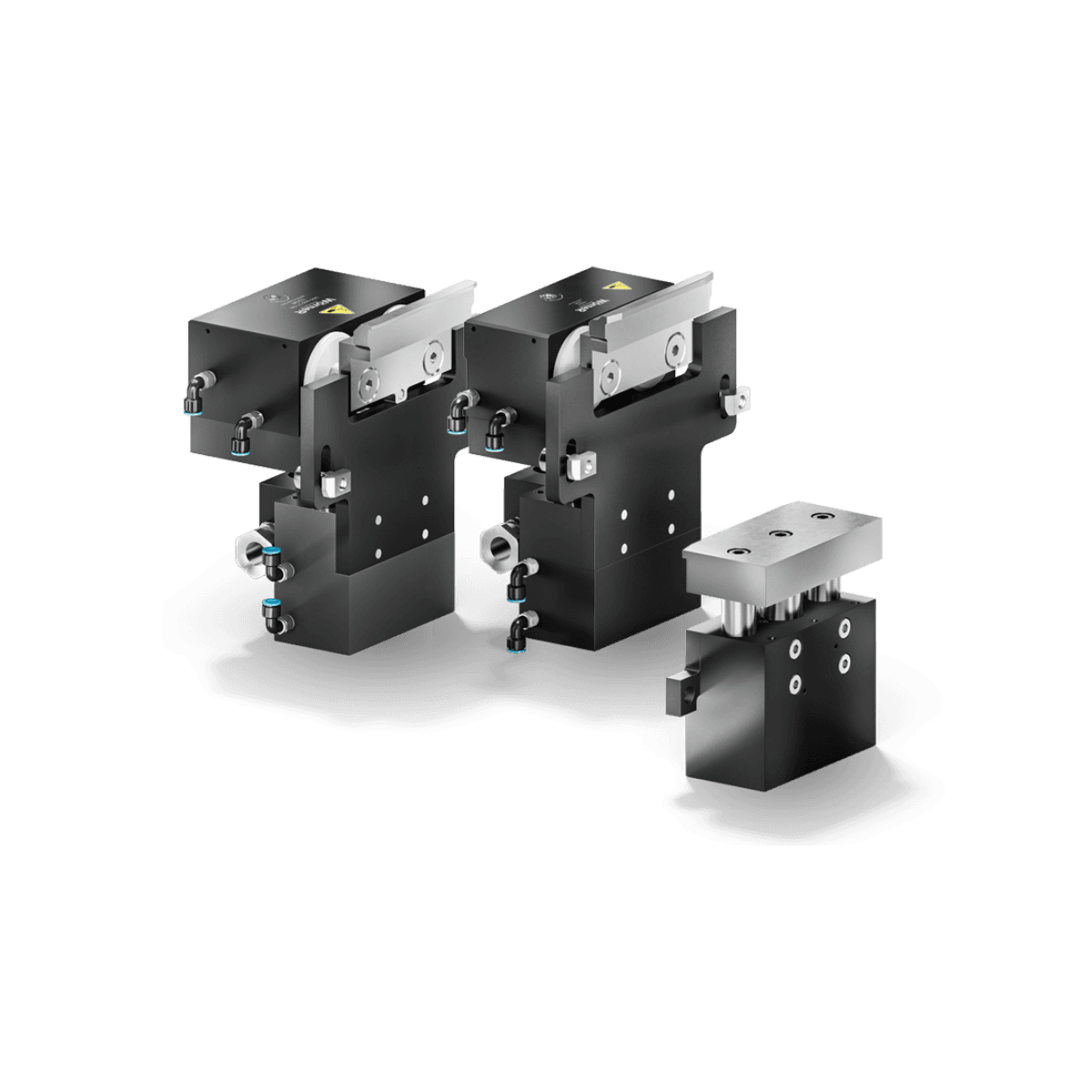

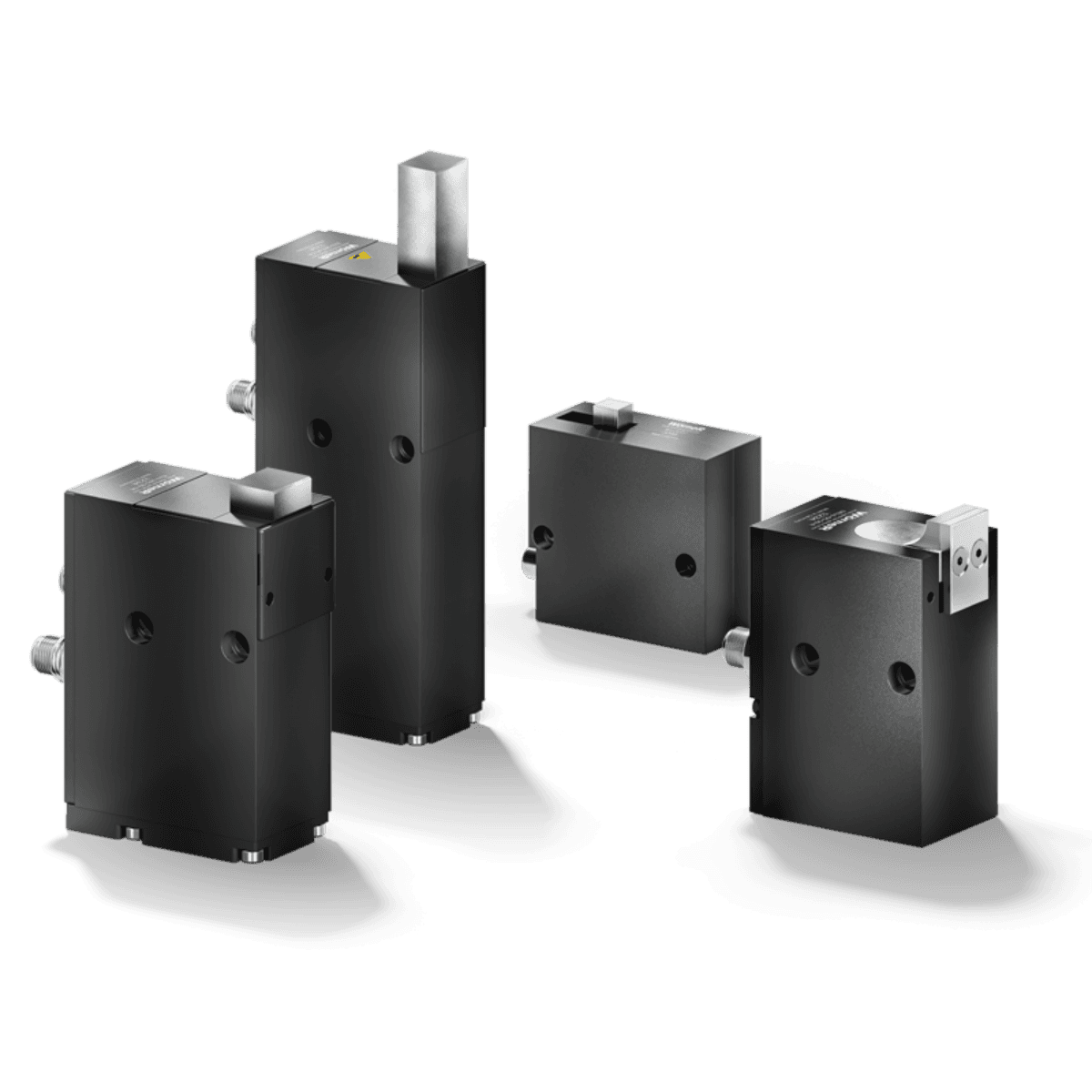

Stoppers for roller systems products

Particularly slim design, for use in roller conveyor systems. No rollers need to be omitted to make room for the stopper.

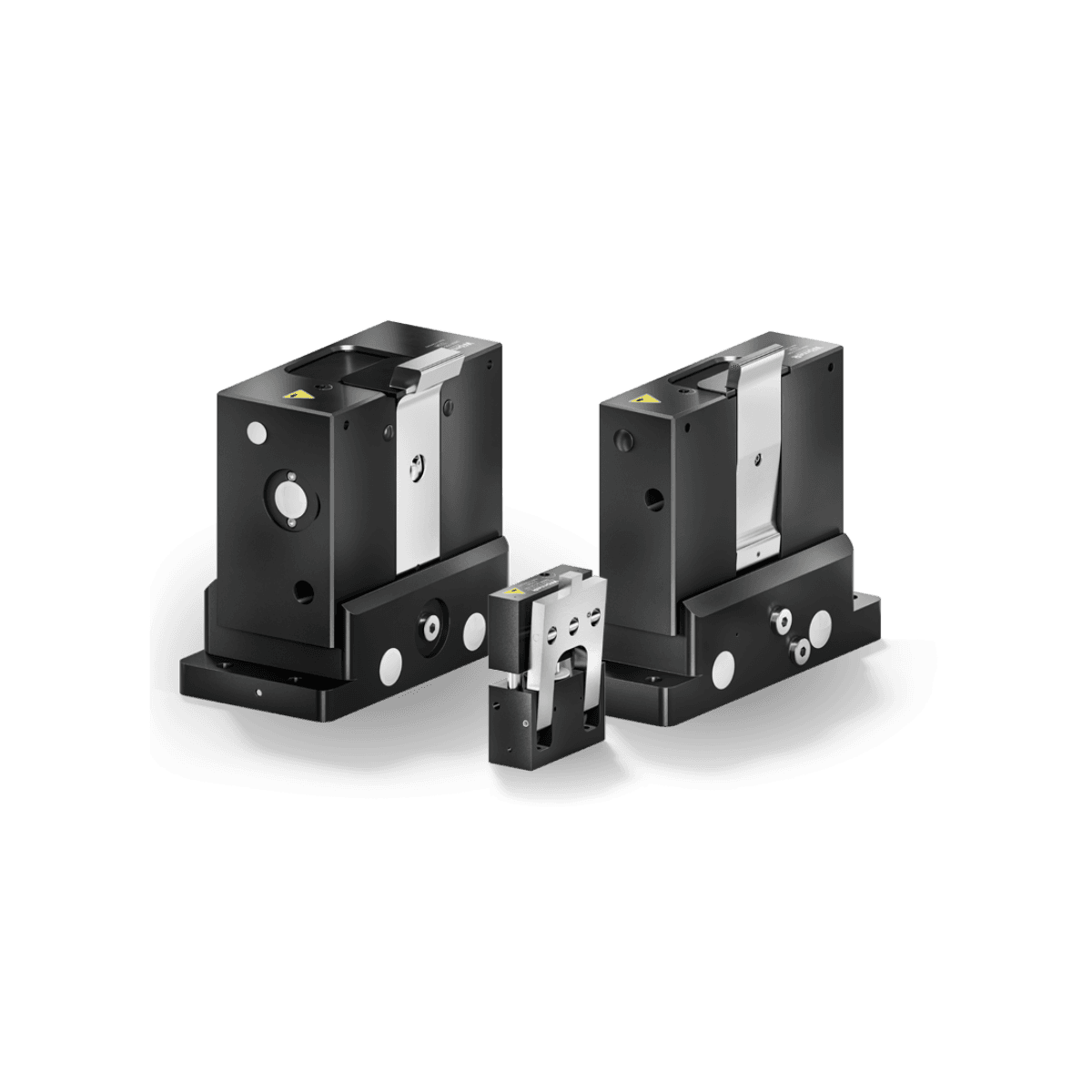

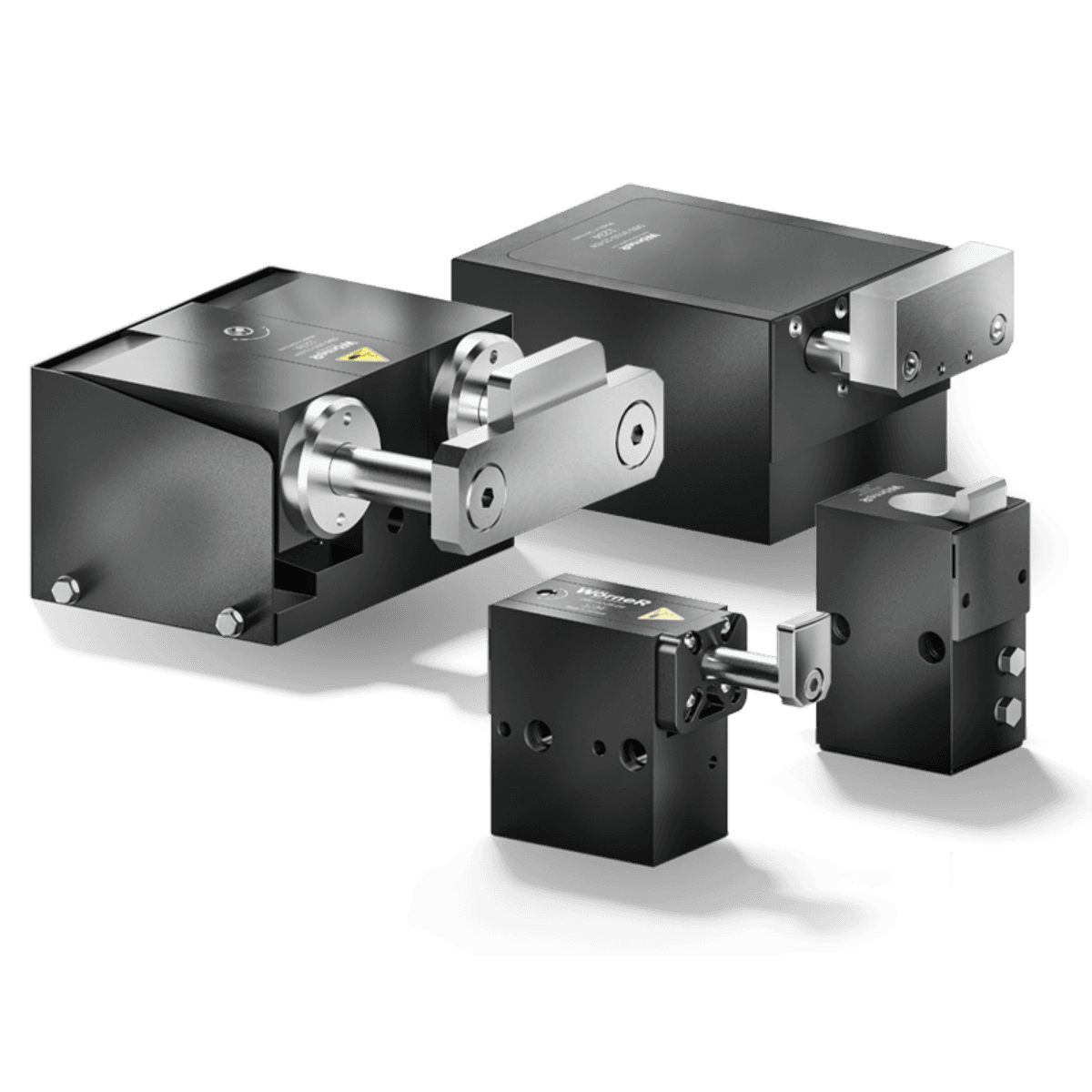

Damped stoppers, electrically driven

- High efficiency and low operating costs due to electromechanical drive - Air damping system -Short cycle times

Undamped stoppers, electrically driven

- High efficiency and low operating costs due to electromechanical drive - Low noise - Short cycle times

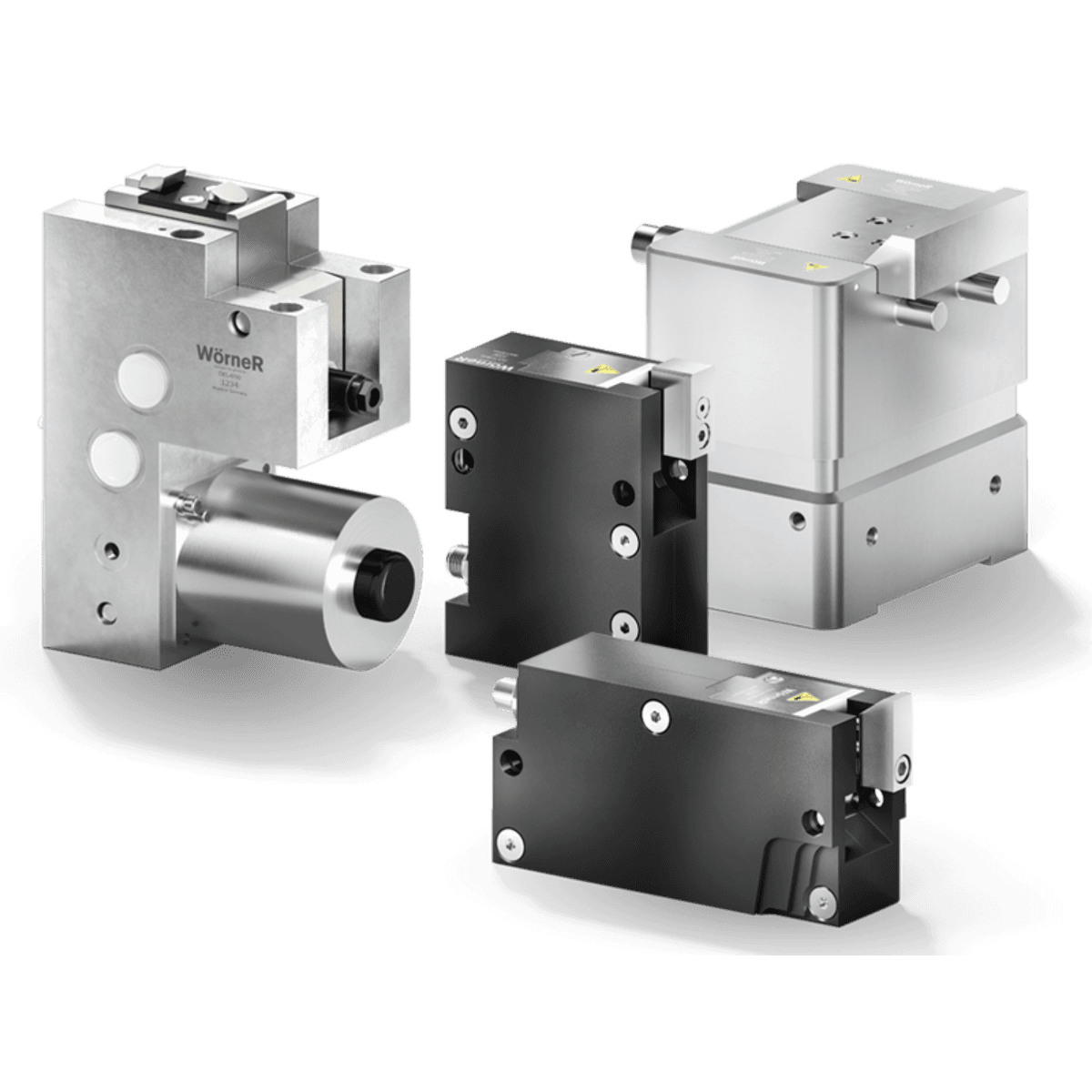

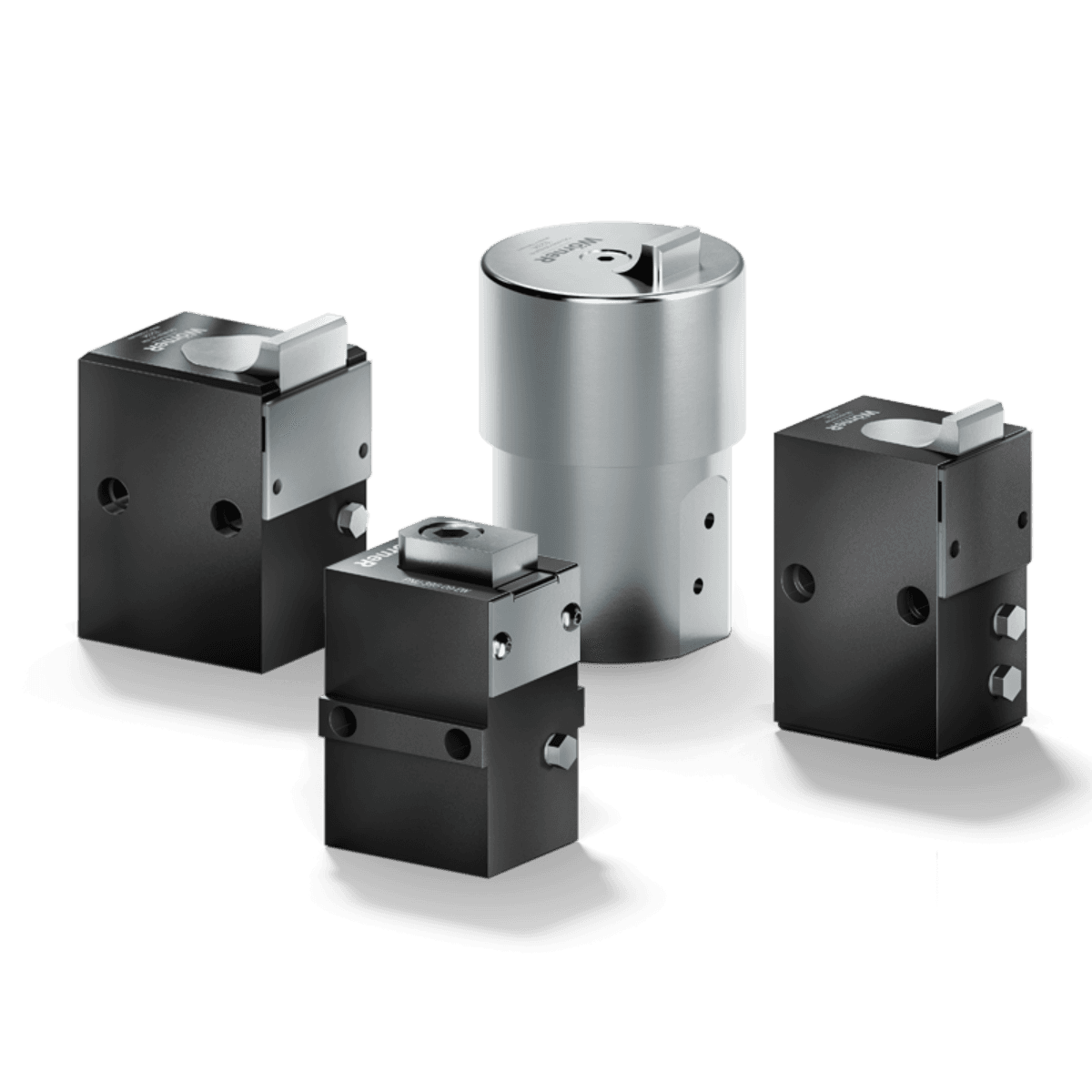

High-value stoppers

- Gentle stopping of the pallet - Single or double acting - Easy inductive or electronic sensor integration

Damped stoppers, pneumatically driven

- Gentle stopping of the pallet - Single or double acting - Easy inductive or electronic sensor integration

Undamped stoppers, pneumatically driven

- Stop one or more pallets at a defined position - Single or double acting - Easy inductive or electronic sensor integration

Downloads

Woerner-Product-Brochure-2024-2025_en.pdf

Woerner-Product-Brochure-2024-2025_en.pdf