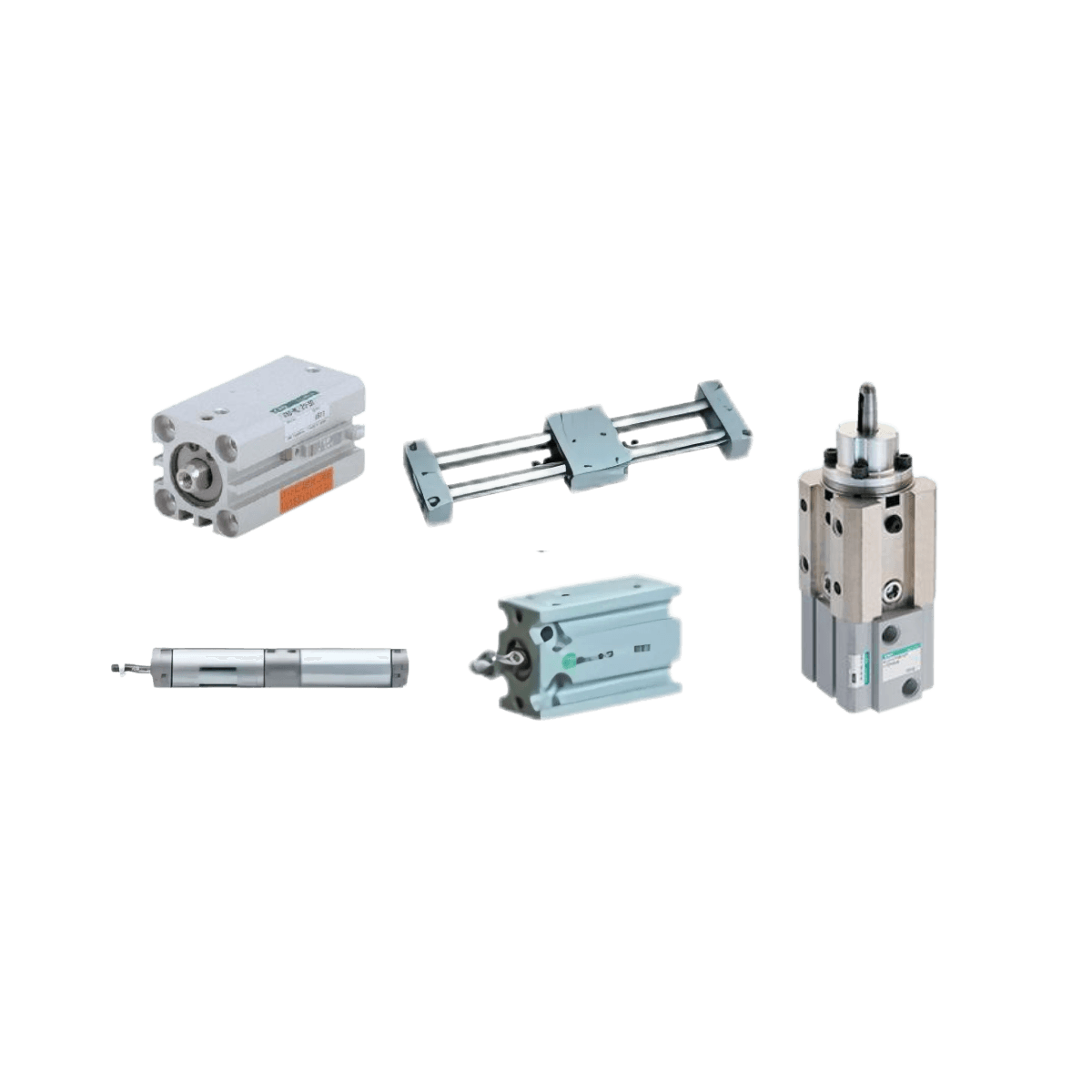

Pneumatic cylinders

- Standard Cylinders

These include pencil, micro, round, and standard cylinders, available in various sizes. These cylinders are generally used for general-purpose applications and are manufactured in Japan, ensuring long-lasting and reliable performance - Compact Cylinders

Compact-designed cylinders, such as the SSD2 and SMG models, are ideal for applications in confined spaces. These cylinders can be easily integrated into various systems.

Swivel Connector Groove on All Four Sides

The roller switch can be mounted on the same side as the swivel connector, improving visibility and maintenance efficiency.

Threaded End Options

Two piston rod end options are available:

- Internal thread (standard)

- External thread (optional)

SMG

Simple Design – Flexible Installation

The integrated mounting block allows direct mounting from five different sides, providing maximum flexibility during installation.

Compact and Lightweight Design

Significant weight reduction and space-saving construction thanks to the integrated mounting block – ideal for installations in confined spaces.

Kompakt érzékelő elhelyezés

A helyzetérzékelő szinte teljesen a hengerházba van integrálva, így nincs tolakodó kiemelkedés, és esztétikus, biztonságos megoldást nyújt.

Easy Maintenance

Maintenance is faster and easier thanks to the newly developed mounting method, which allows servicing without stopping operation.

3. Rodless Cylinders

Rodless cylinders, such as the SRL3, SRG3, SRM3, and SRT3 models, are ideal for high-speed and precision applications. They are a good choice for handling heavy loads.

High-Speed Rodless Cylinders

The piston features a flat design and a structure that allows it to absorb external loads.

The heavy-duty design includes an anti-rotation mechanism. The piston is equipped with a seal for fast operation, optimized for high-speed performance.

Available in single-port (common port) or dual-port (standard port) versions, depending on installation space requirements.

This allows for a more compact equipment design.

The cylinder comes standard with a magnet, making it compatible with limit switches (sensors).

4. Speciális hengerek

A CKD speciális hengerek közé tartoznak a nagy teljesítményű hengerek, mint például az SHC és MCP modellek, amelyek nagy erők kifejtésére képesek. Ezek a hengerek ideálisak az olyan speciális alkalmazásokhoz, mint a préselés vagy a szegecselés.

Reduced Air Consumption

The cylinder delivers maximum force only at the end of the stroke, while operating with reduced thrust during the stroke, resulting in significant air savings.

Space-Saving Design

Compared to cylinders with the same thrust, a smaller piston diameter is sufficient, allowing for a more compact overall size.

5. Cylinders with Brake or Lock Mechanism

These cylinders, such as the JSC3 and JSG models, feature an integrated brake or locking mechanism that allows them to maintain position even in case of power failure. This is especially important for safety reasons.

Reliable Brake System Design

Position-locking mechanism for medium and large bore cylinders, offering proven reliability and operational experience.

High Stopping Accuracy: ±1.0 mm

At an unloaded rolling speed of 300 mm/s, the system achieves a stopping accuracy of ±1.0 mm, providing excellent precision for positioning applications.

Compact and Reliable Brake

The brake uses the proven mechanism from the JSC3 series, ensuring long-term reliability and durability.

Powerful Holding Force

Thanks to the patented locking mechanism, the rod holding force reaches twice the thrust force (at 0.4 MPa operating pressure), providing outstanding holding capability.

6. Guided Cylinders and Linear Guided Cylinders

Guided cylinders, such as the SSG and MSDG models, are equipped with integrated guiding mechanisms that enhance stability and precision. These cylinders are ideal for applications requiring lateral load support or high positioning accuracy.

With Built-In Guide Rod

The SSD compact cylinder series features a guide rod assembly that significantly improves lateral load capacity and stability against rotation.

Convenient Mounting Plate

Thanks to the integrated mounting plate, design and assembly are simplified — no more complicated mounting arrangements.

Compatible Mounting Hole Widths

The mounting hole pitch matches that of the SSD compact cylinder series, allowing for quick and easy replacement.

Connector Anchors Accessible from Four Sides

The cylinder connectors can be positioned on the same side as the pipe connection, improving visibility and serviceability.

Optimized Sliding Surface

The use of special wear-resistant sealing materials, high-performance grease, and optimized sealing functions ensures stable operation and long service life.

Long Service Life

By fine-tuning the sliding surfaces, a service life of over 20 million cycles can be achieved, ensuring highly reliable operation even under intensive industrial use.

Stable Operation

By optimizing the structure of the sliding surface, the initial pressure remains constant even under frequent, repetitive operation.

Since the initial pressure is stable, the operating time is predictable and consistent, ensuring reliable and uninterrupted system performance.

7. MRL

Magnetic Rodless Cylinder

Equipped with an integrated lubrication system: lubrication unit.

The sliding surfaces of the piston and the slider are fitted with grease-impregnated thread packs (lubrication units).

This solution provides long-lasting, stable lubrication, reducing wear over time.

The service life has more than doubled compared to our previous models, while operational stability has also improved.

Lubrication Unit Features (1): Lubricant Dispensing and Absorption Function

The capillary effect enables even distribution of the lubricant across the sliding surfaces via the fiber bundle, while simultaneously absorbing and retaining excess lubricant.

Note: Use a scraper and cleaning fluid to clean the tube surface.

Lubrication Unit Features (2): Dust and Contaminant Removal Function

The lubrication unit collects not only dust but also debris generated from seal wear, thereby reducing the buildup of contaminants on sliding parts.

(The conventional heavy-duty scraper remains available as an option.)

Environmentally Friendly Design

An optional rubber air spring cushion is available.

It dampens the impact noise at the end of the stroke, ensuring quieter operation and improving the production environment.

Thin Slide

Flat design with a compact, slim slide.

MRG2

Magnetic Rodless Cylinder with High-Precision Guide Rail

Linear Guide for Heavy-Duty Applications

The integrated linear guide offers 1.5 times the rated load capacity of previous models (compared to φ16 class equivalent products on the market).

The high-rigidity rail guide ensures excellent repeatability.

Alacsony asztali kialakítás

Lapos kialakítás alacsony csúszóasztal-magassággal.

Két felület használható a munkadarab rögzítésére a rugalmasabb telepítés érdekében.

Built-In Lubrication System – Lubrication Unit (Lubricator)

Lubrication Unit Features (1): Lubricant Dispensing / Absorption Function

The capillary effect ensures even distribution of lubricant across the sliding surfaces while absorbing excess grease.

Lubrication Unit Features (2): Dust Absorption Function

(A high-performance conventional scraper is also available as an option.)

7.1 Pin Clamp Cylinder – PCC

4 Positions for Arm Direction Selection

The direction of the clamp arm can be selected from 4 different positions to match the clamping side of the pin.

Two Types of Positioning Pins Available

Depending on the application, the positioning pin can be either round or diamond-shaped.

Workpiece Stop Position Adjustable by up to 2 mm

When using the spacer design, the workpiece stop position can be adjusted between 0.5 mm and 2 mm using 3 spacers per side:

- 1 spacer of 1 mm (t1)

- 2 spacers of 0.5 mm (t0.5)

A total of 6 spacers are available for adjustment.

Optional Locking Mechanism

Holds the clamp arm securely in position regardless of the workpiece thickness, preventing the workpiece from shifting or falling out in case of an emergency.

Optional Spatter-Resistant Design (SP1)

The built-in spatter protection prevents welding spatter from accumulating in the arm’s eccentric channel, thereby increasing reliability.

8. Cylinders Designed for Special Applications

CKD also offers cylinders specifically designed for special environments, such as:

- For cleanrooms: P5* / P7* series

- For battery manufacturing: P4* series

- For food industry applications: FP* series

- For outdoor use: WP series

- For high-durability applications: HP series

9. Custom Cylinder Manufacturing

In addition to CKD's standard product range, we also offer custom-made cylinders tailored to meet specific customer requirements.

These custom solutions allow for special sizes, materials, stroke lengths, or integrated functions (e.g. sensors, brakes), depending on the complexity — in some cases, delivery is possible within as little as one week.

Contact us if you have any questions.

Contact us