Ball screws

Why Thomson Ball Screws?

Not all precision ball screws are created equal. At Thomson, our careful attention to design, quality, materials, manufacturing and application support has set us apart from the competition and created an ideal recipe for success that has lasted for decades.

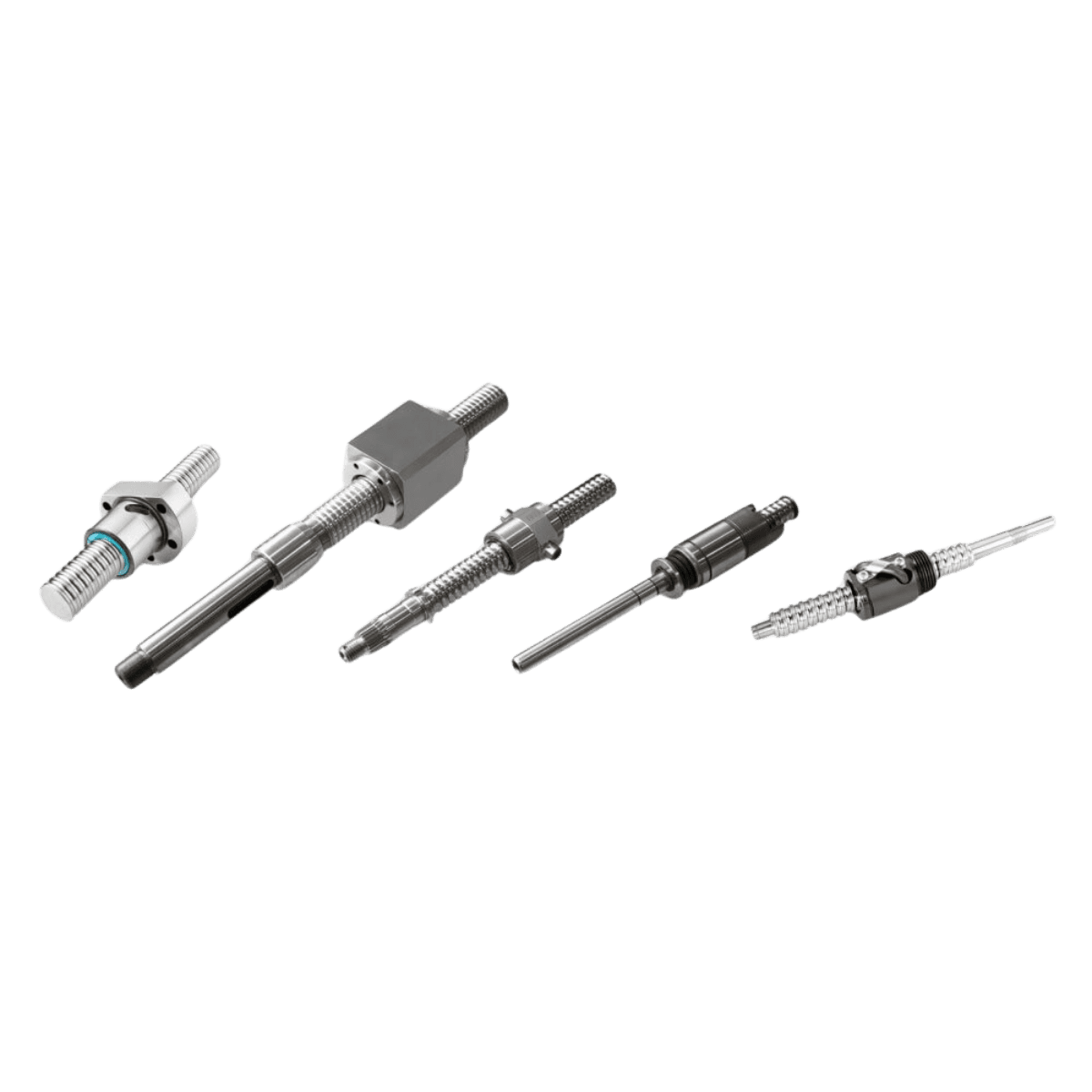

Customization Options

When standard Thomson ball screws don’t meet your exact specification requirements, our engineering experts can help customize a solution for your application. Whether it’s one or a large quantity, a simple component modification or complex assembly, our custom capabilities can meet your needs and improve your machine’s performance.

Contact us if you have any questions.

Contact us

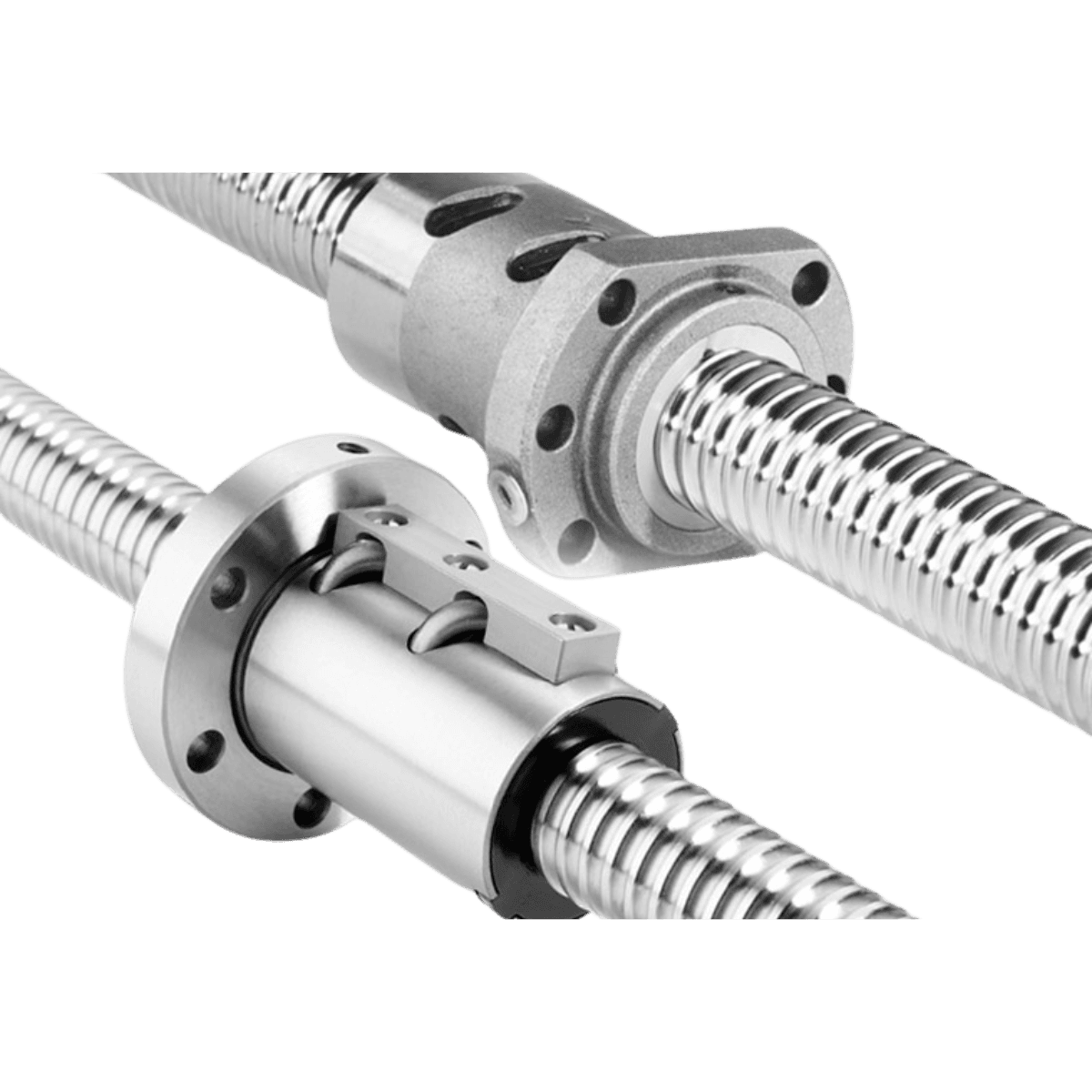

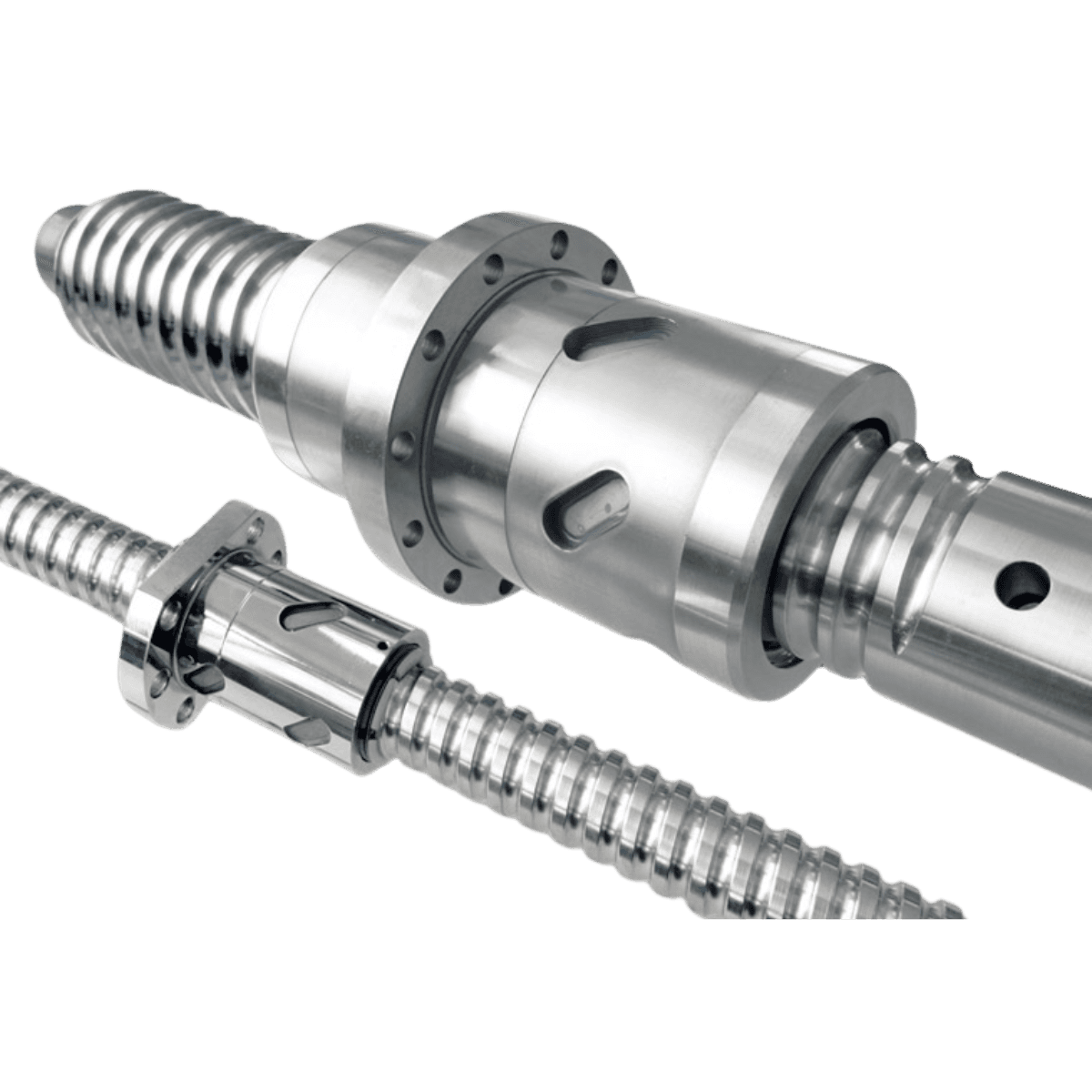

Precision Plus Ground Metric Ball Screws

The highest precision product available, with standard lead accuracies of ±6µm/300mm.

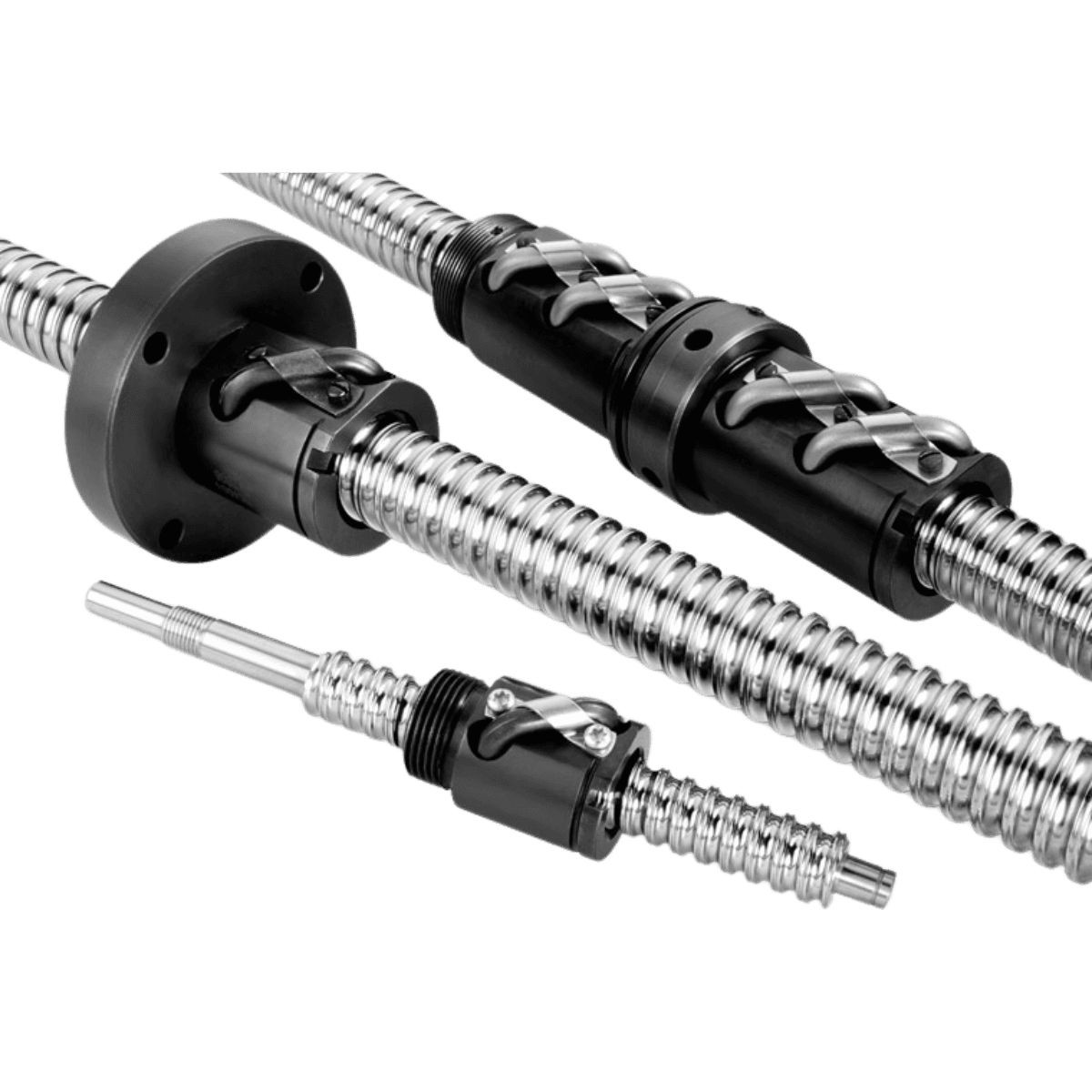

Precision Rolled Metric Ball Screws

Provide quiet, smooth running, efficient performance.

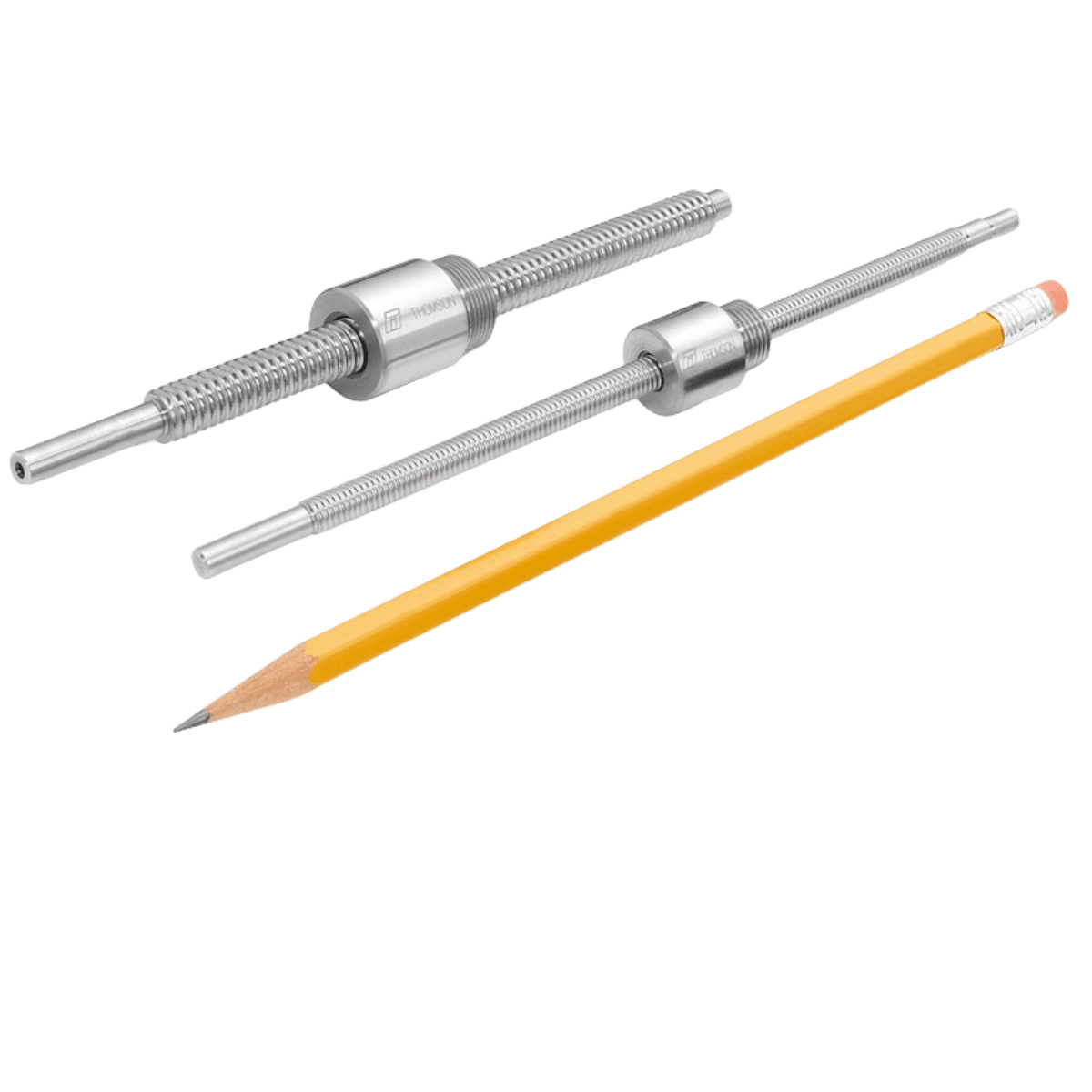

Miniature Metric Precision Ball Screws

efficient and cost-effective solution in a small envelope, ideal for use in small spaces

Special Customized Ball Screws

Optimize your design with a custom ball screw solution.

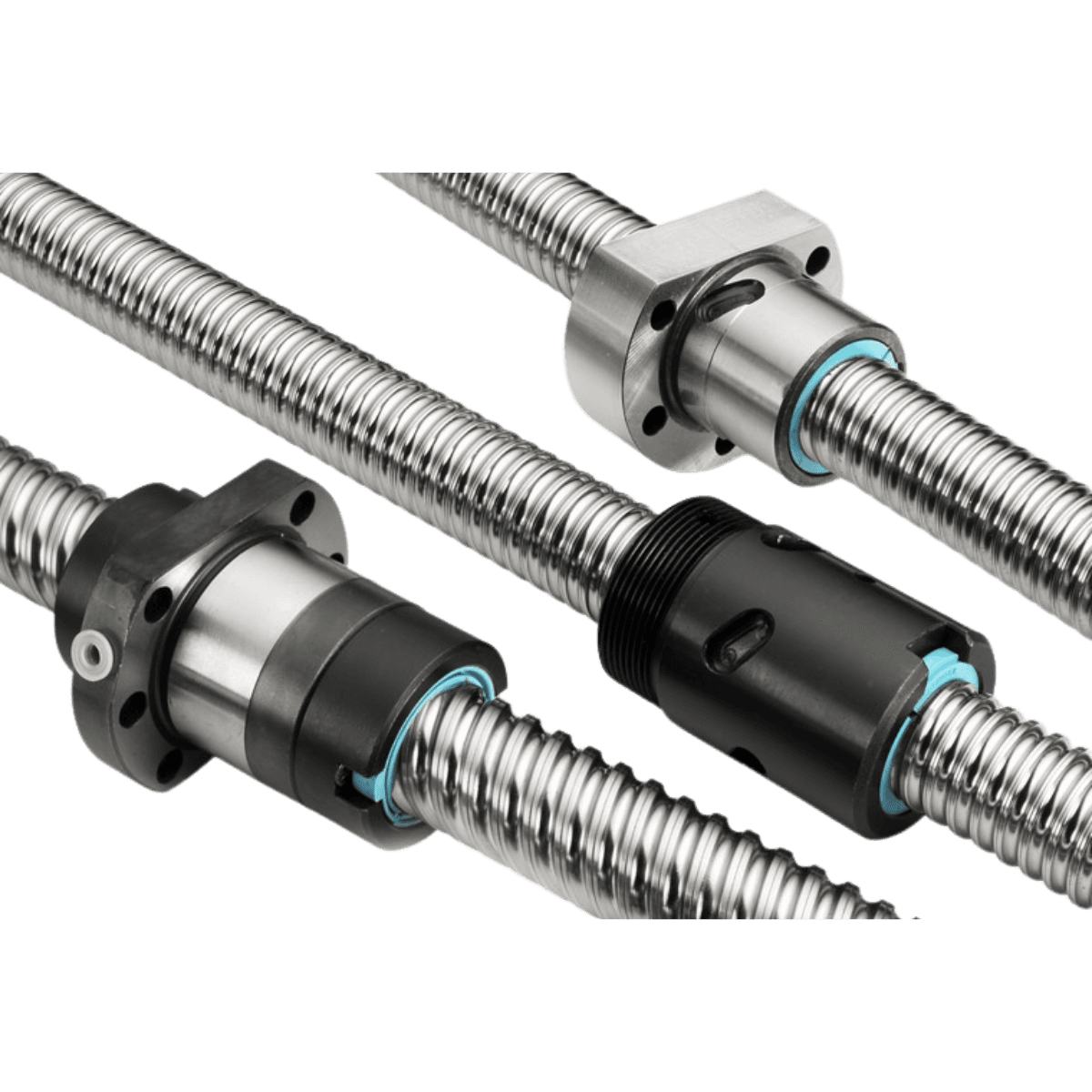

High-Load Ball Screws

Ideal for large fabrication machines in injection molding, pressing and metal fabrication.

Precision Rolled Inch Ball Screws

Full range of diameters, leads, and ball nut configurations, in either preloaded or non-preloaded types, all in industry-standard envelopes.

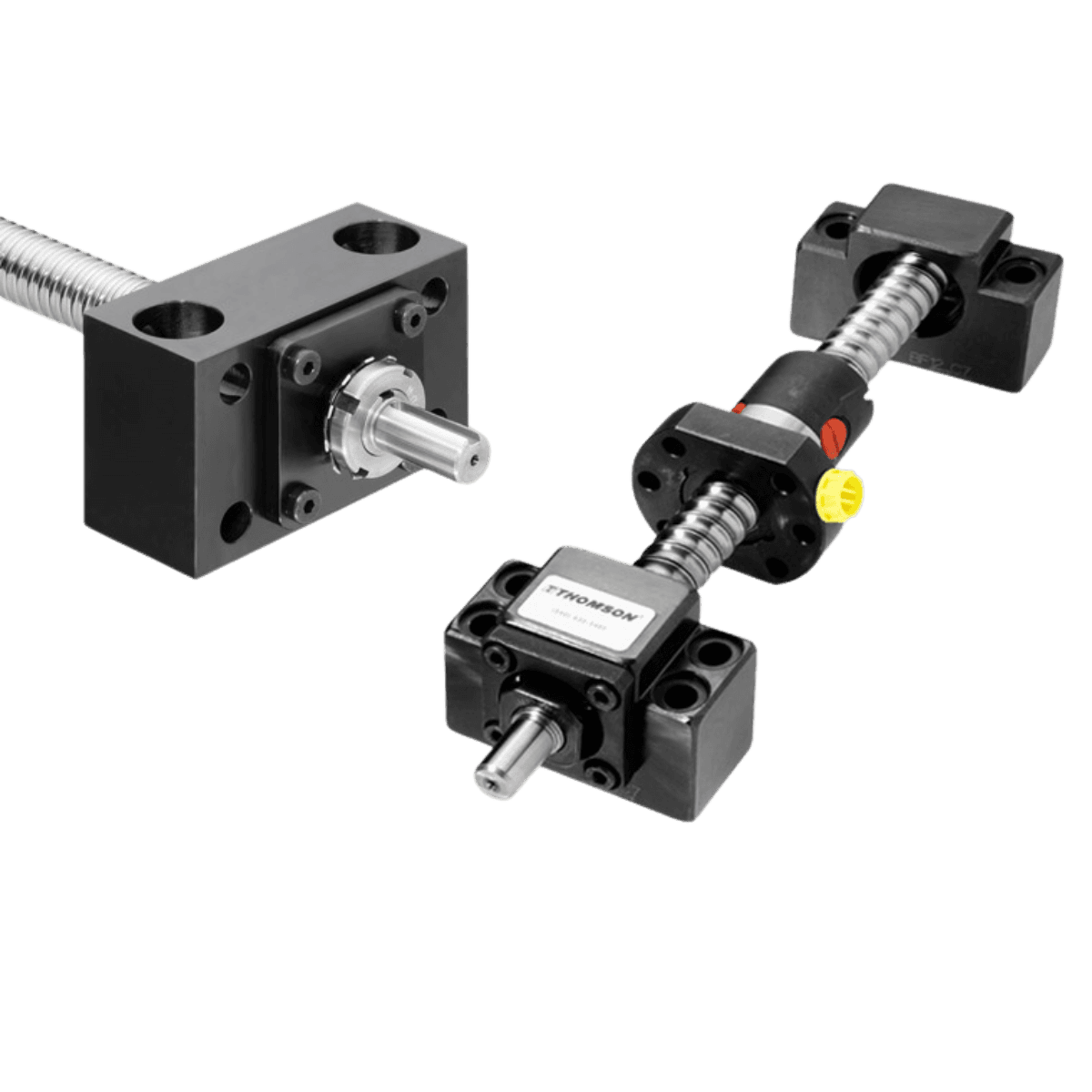

Bearing Supports

Rugged steel construction, low profile, and compact design.

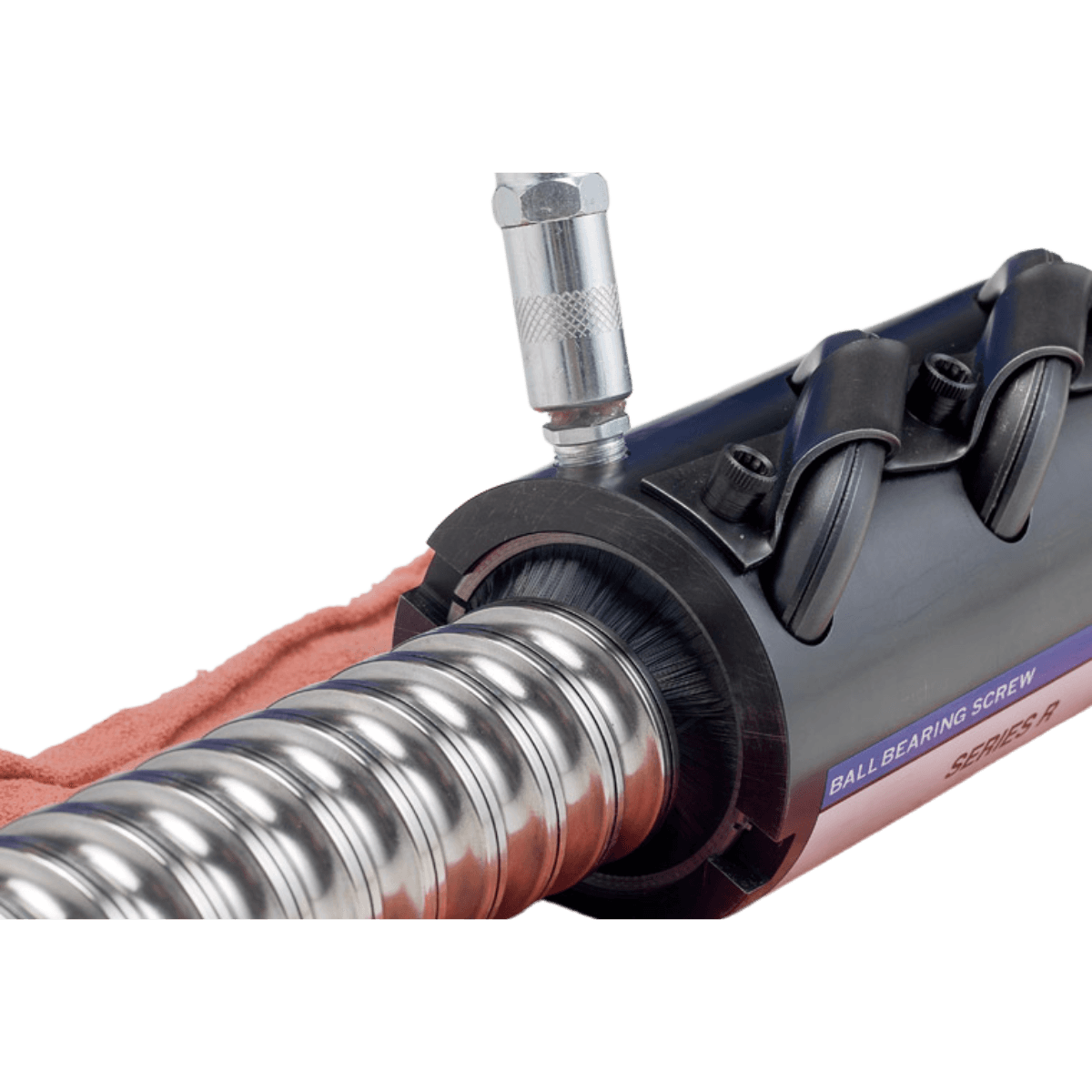

Installation, Maintenance, Lubrication, and Repair

Develop good installation process, lubrication and maintenance practices.