Coupling technology

R+W Couplings – Precision, Reliability, Flexibility

For over 30 years, R+W Antriebselemente GmbH has been developing and manufacturing state-of-the-art shaft couplings for precision and industrial drive technology. Headquartered in Germany, R+W has become a global player offering solutions for machinery manufacturing, robotics, automation, medical technology, and many other industries.

Product Categories

• Precision couplings: bellows, elastomer, and miniature versions, torque limiters, disc couplings, and drive shafts – covering a torque range from 0.05 to 25,000 Nm. These couplings are characterized by completely backlash-free operation and a maintenance-free design.

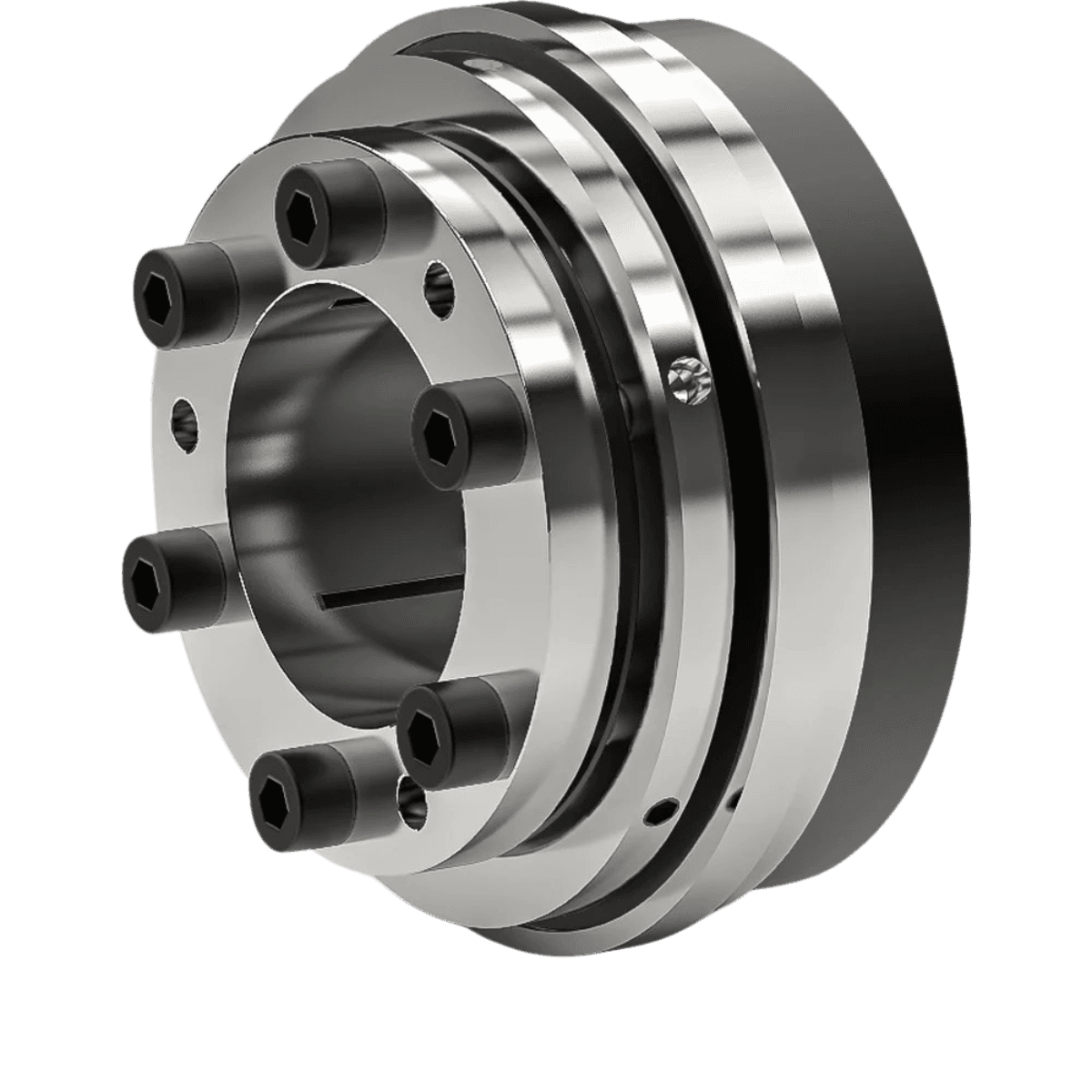

• Industrial couplings: high-torque, robust designs (200 to 2,080,000 Nm) such as gear couplings, disc pack couplings, and flange types – capable of compensating for shaft misalignment and withstanding extreme industrial loads.

Key Advantages

• Backlash-free – for precise torque transmission and excellent positioning accuracy

• Wear-free, long-lasting construction

• Modular and customizable – adaptable designs and sizes tailored to specific requirements

R+W couplings offer a reliable solution for any application where precise torque transmission, durable machine elements, and system efficiency are critical.

Let me know if you’d like a more technical, marketing-focused, or shorter version as well.

Contact us if you have any questions.

Contact usOur quality brands

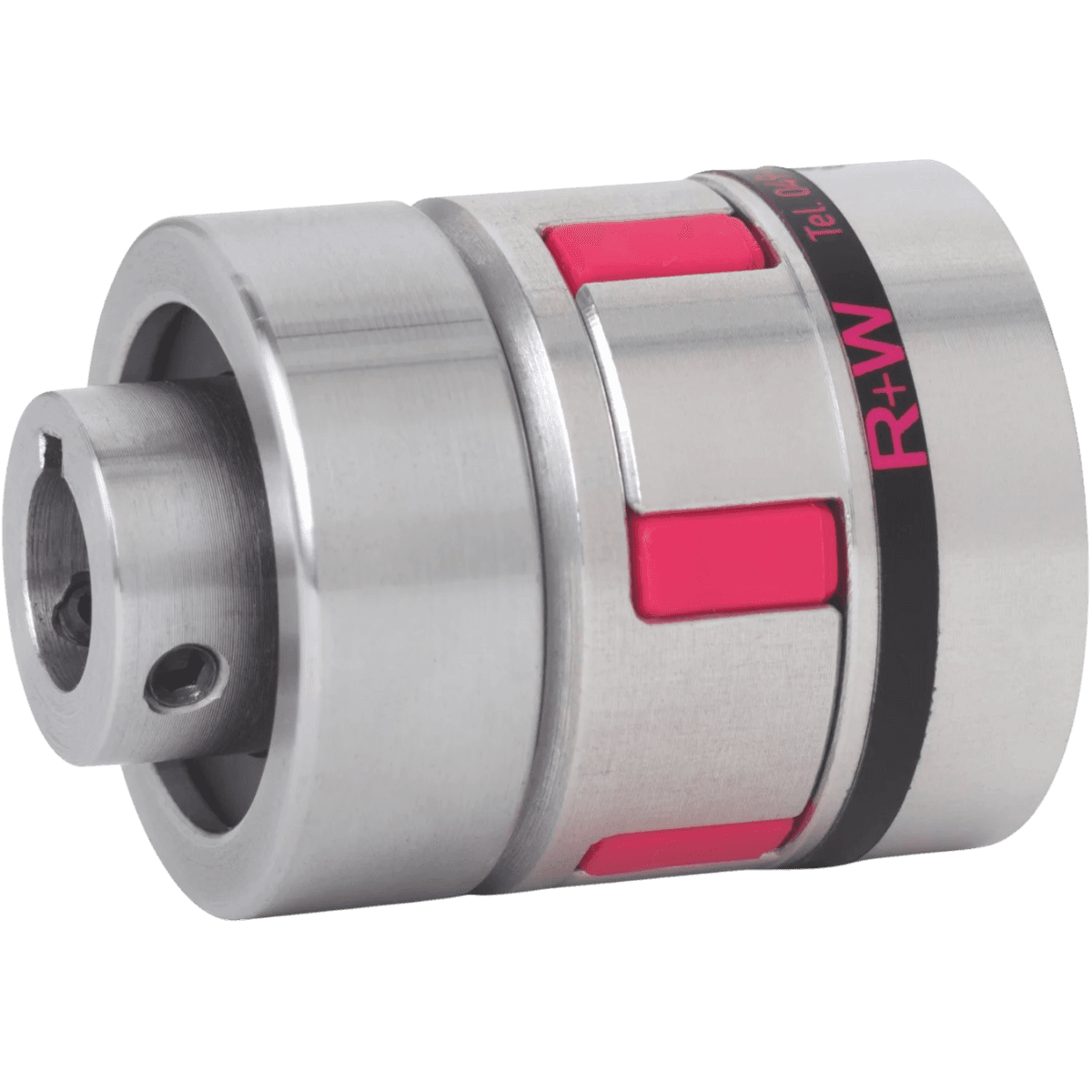

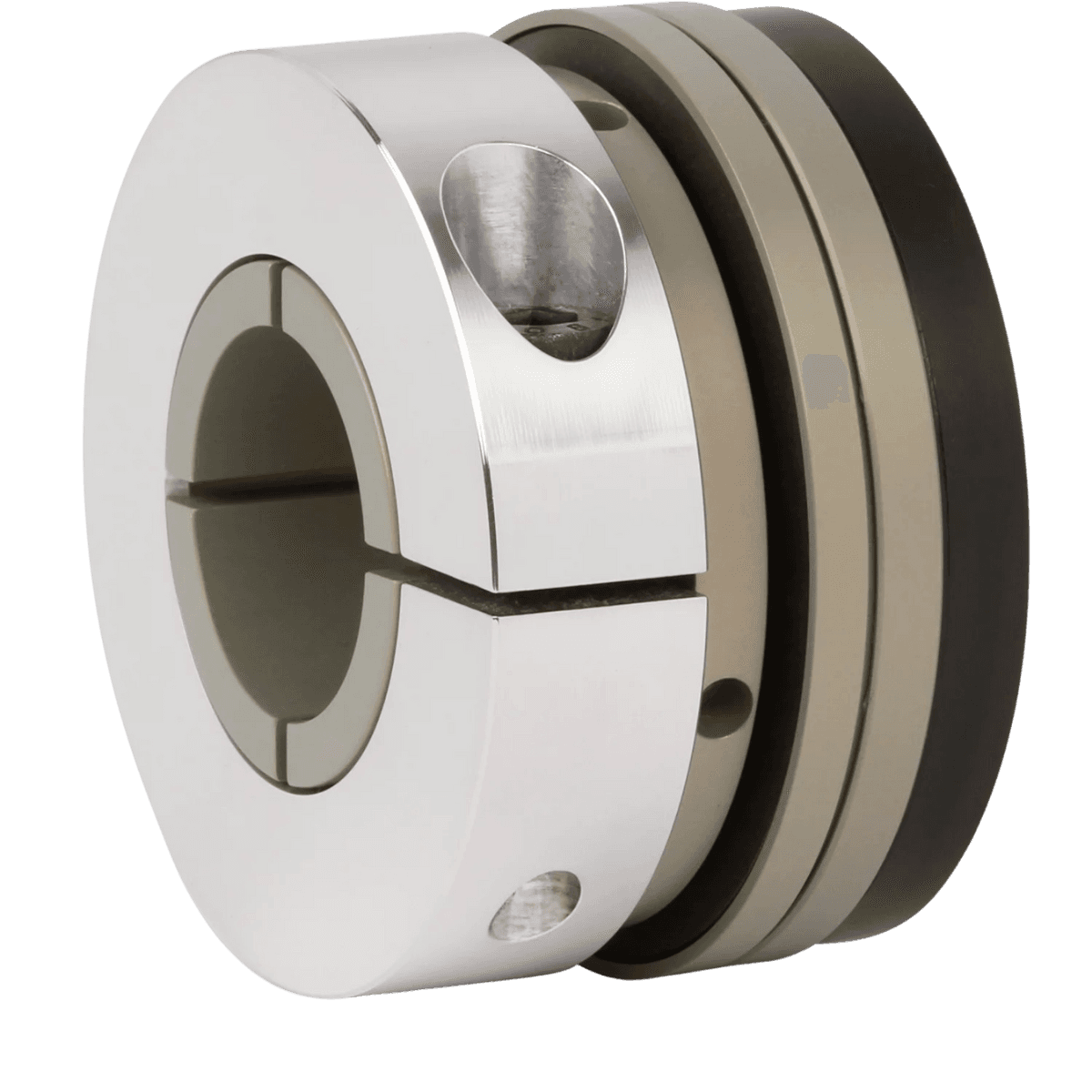

ESL – Torque limiter

Two hubs, each with keyway, Safety system is integrated into one of the hubs

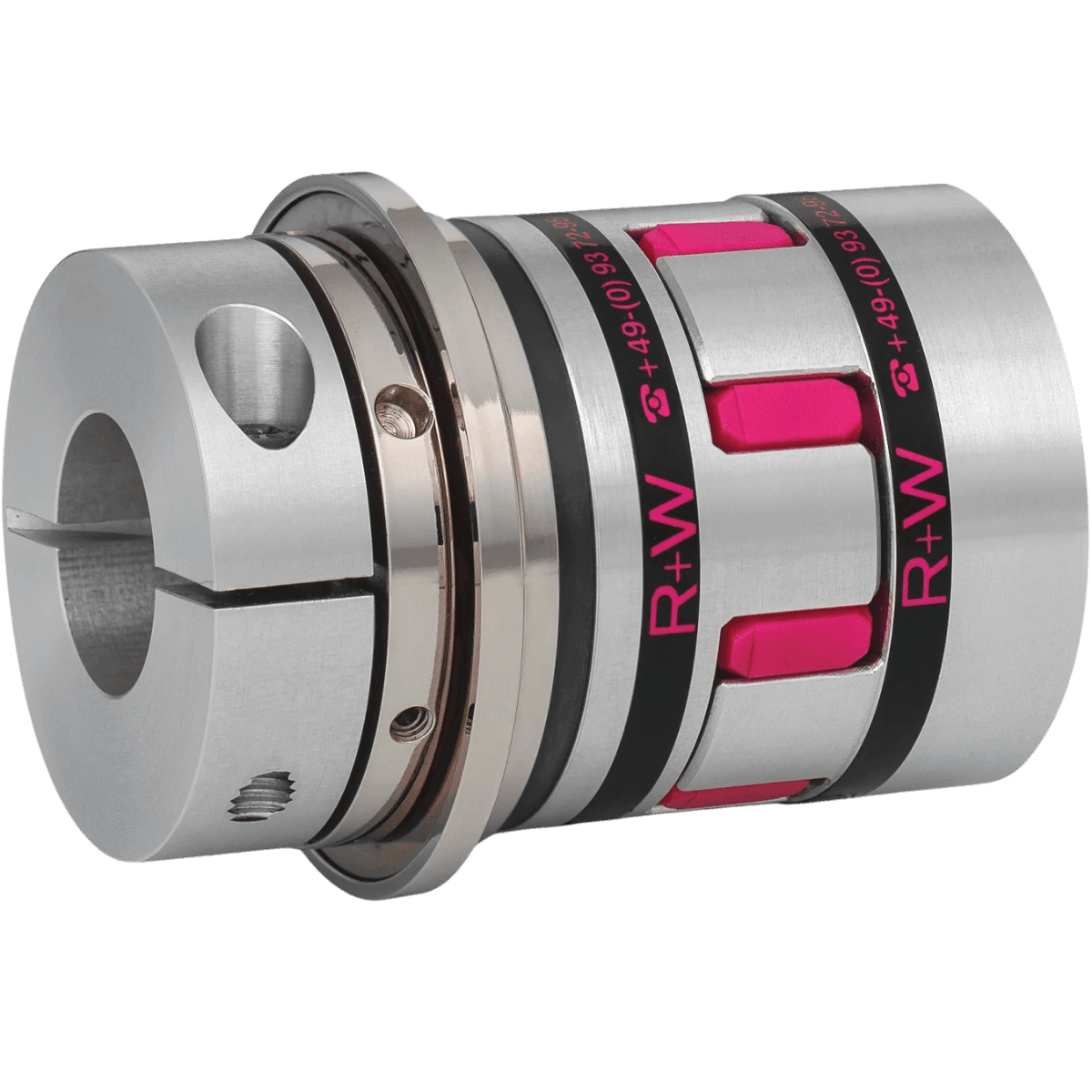

SLE – Torque limiter

Clamping collar with clamping screw, Clamping hub with concave driving jaws and clamping screw, Safety system: spring loaded ball-detent principle

SL2 – Torque limiter

Clamping collar / clamping hub with one clamping screw each, Safety system: spring loaded ball-detent principle

SLP – Torque limiter

With DIN 6885 or ANSI B17.1 keyway, Safety system: spring loaded ball-detent principle

SLN – Torque limiter

With clamping collar and a single clamping screw, Safety system: spring loaded ball-detent principle

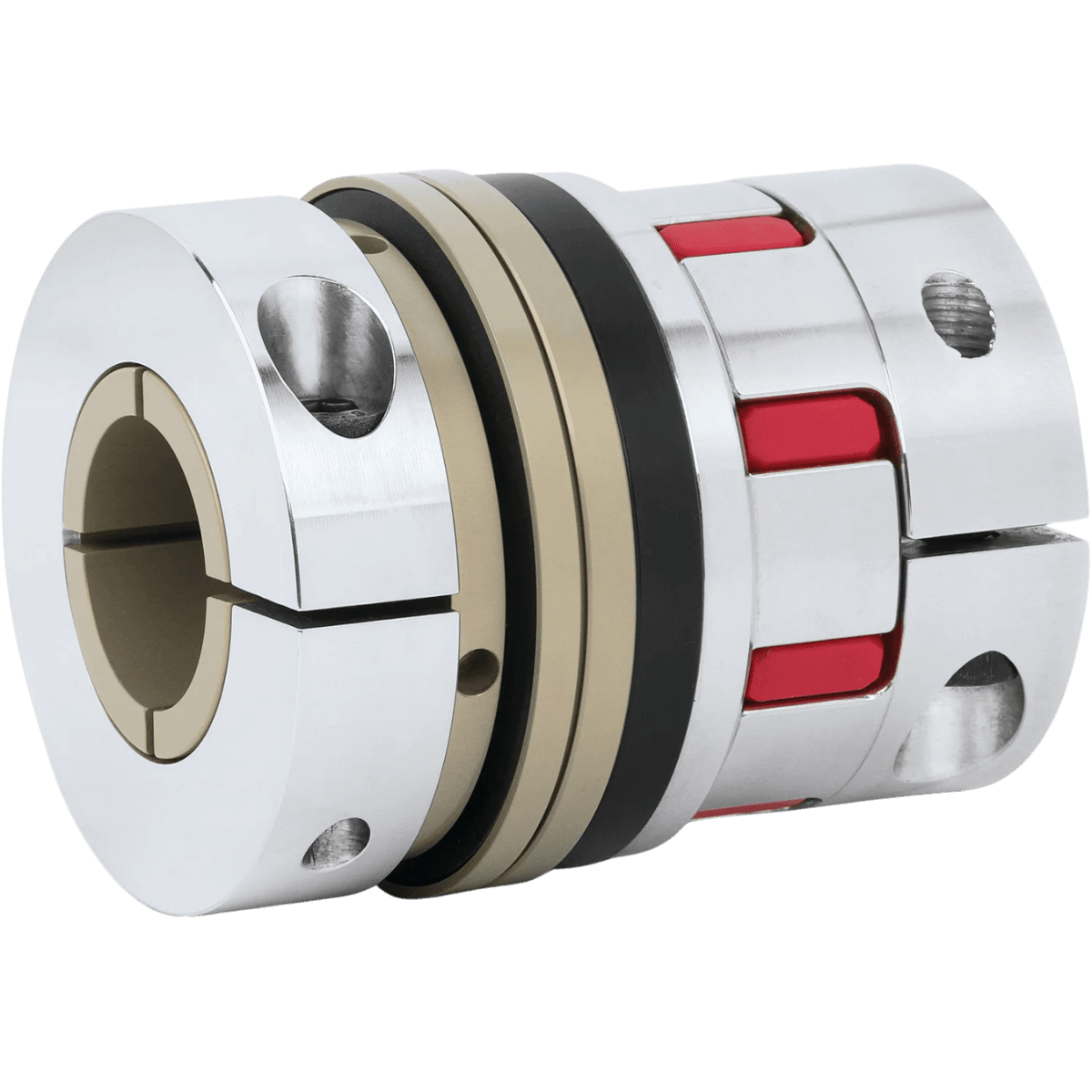

ES2 – Torque limiter

Two clamping hubs with one clamping screw each and concave driving jaws, Safety system: spring loaded ball-detent principle

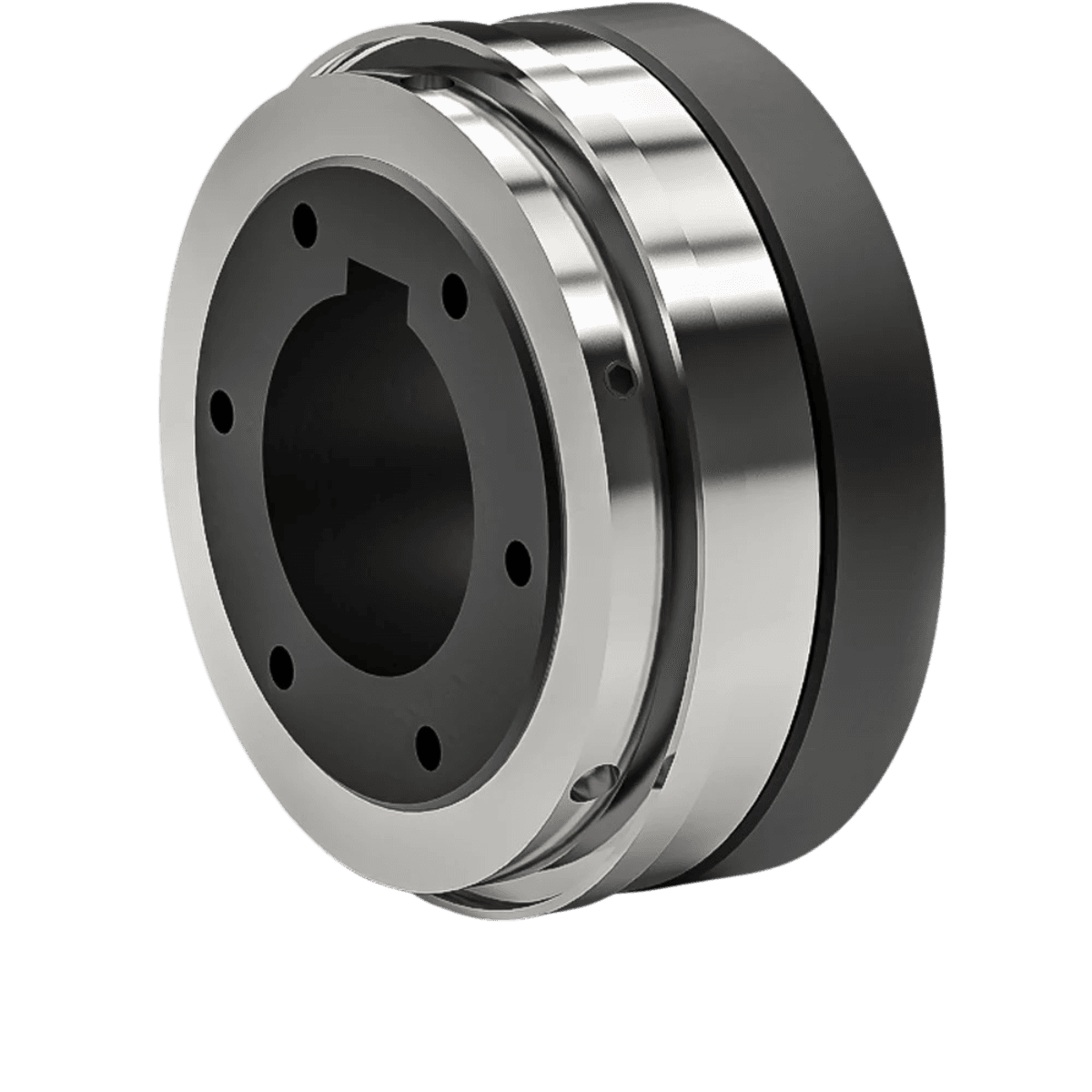

SK5 – Torque limiter

Two clamping hubs with one clamping screw each, and one of the clamping hubs with tapered male segment, Safety system: spring loaded ball-detent principle

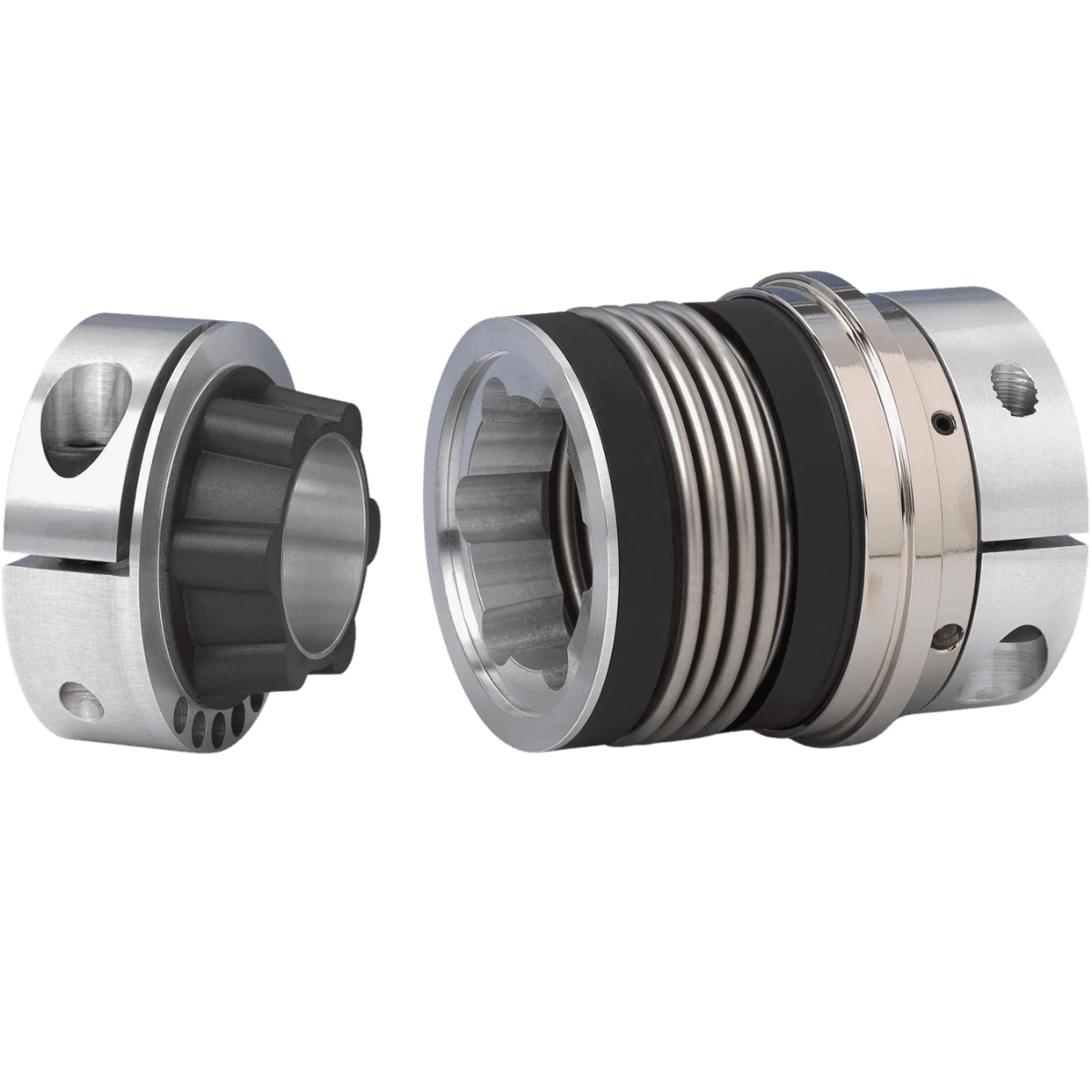

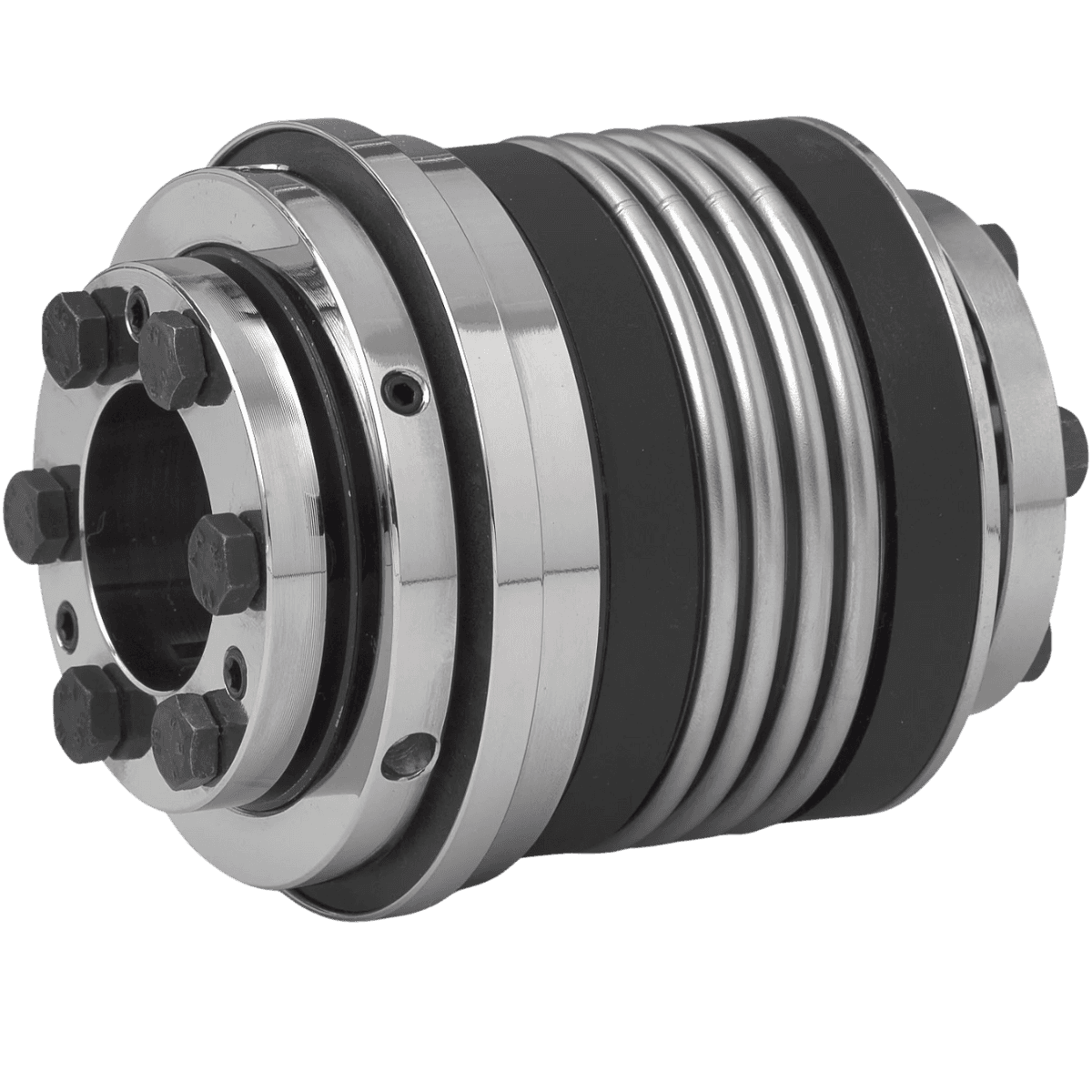

SK3 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

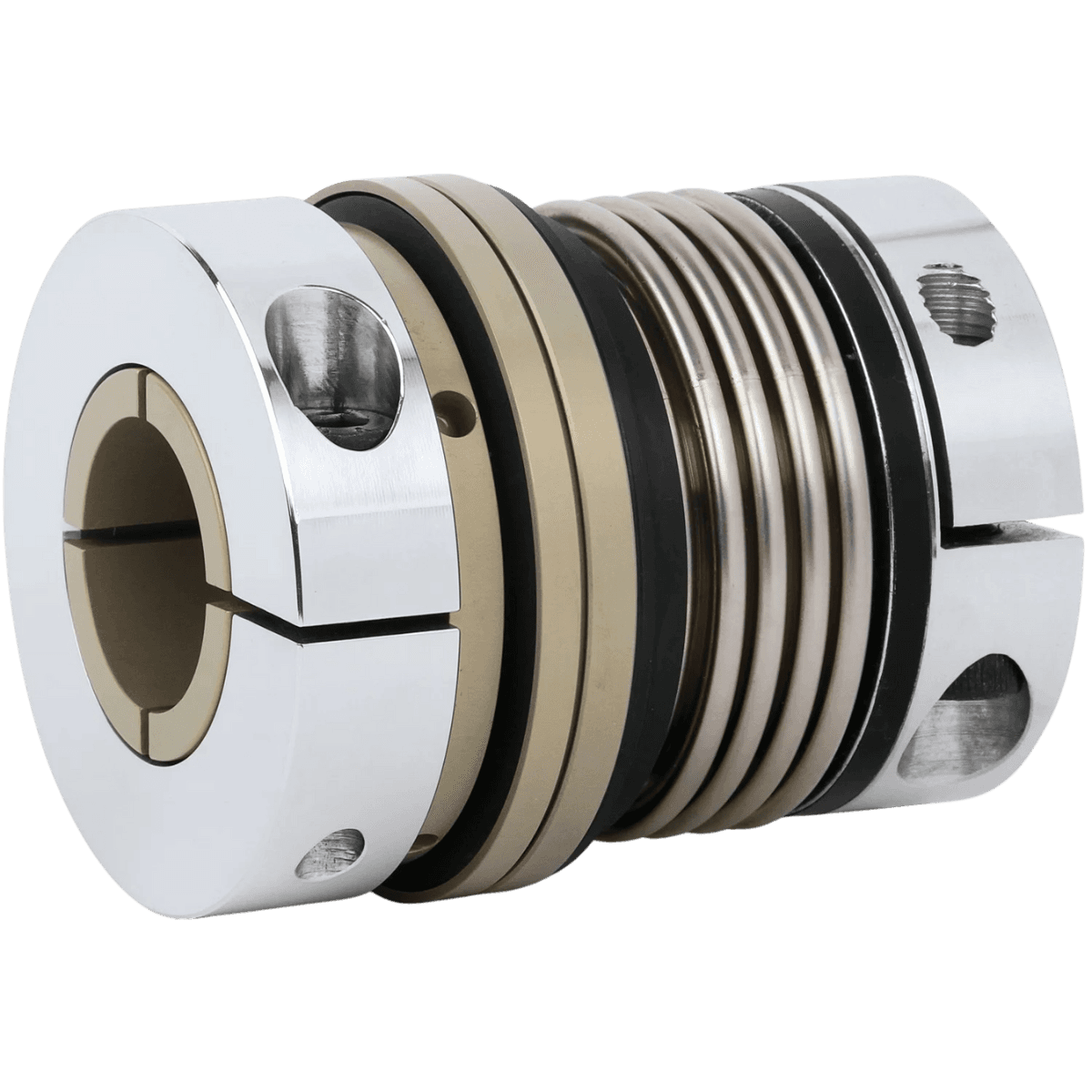

SK2 – Torque limiter

Two conical clamping assemblies with six tightening screws each, Safety system: spring loaded ball-detent principle

SKH – Torque limiter

Two clamping hubs with two clamping screw in each, Torque limiter system: spring loaded ball-detent principle

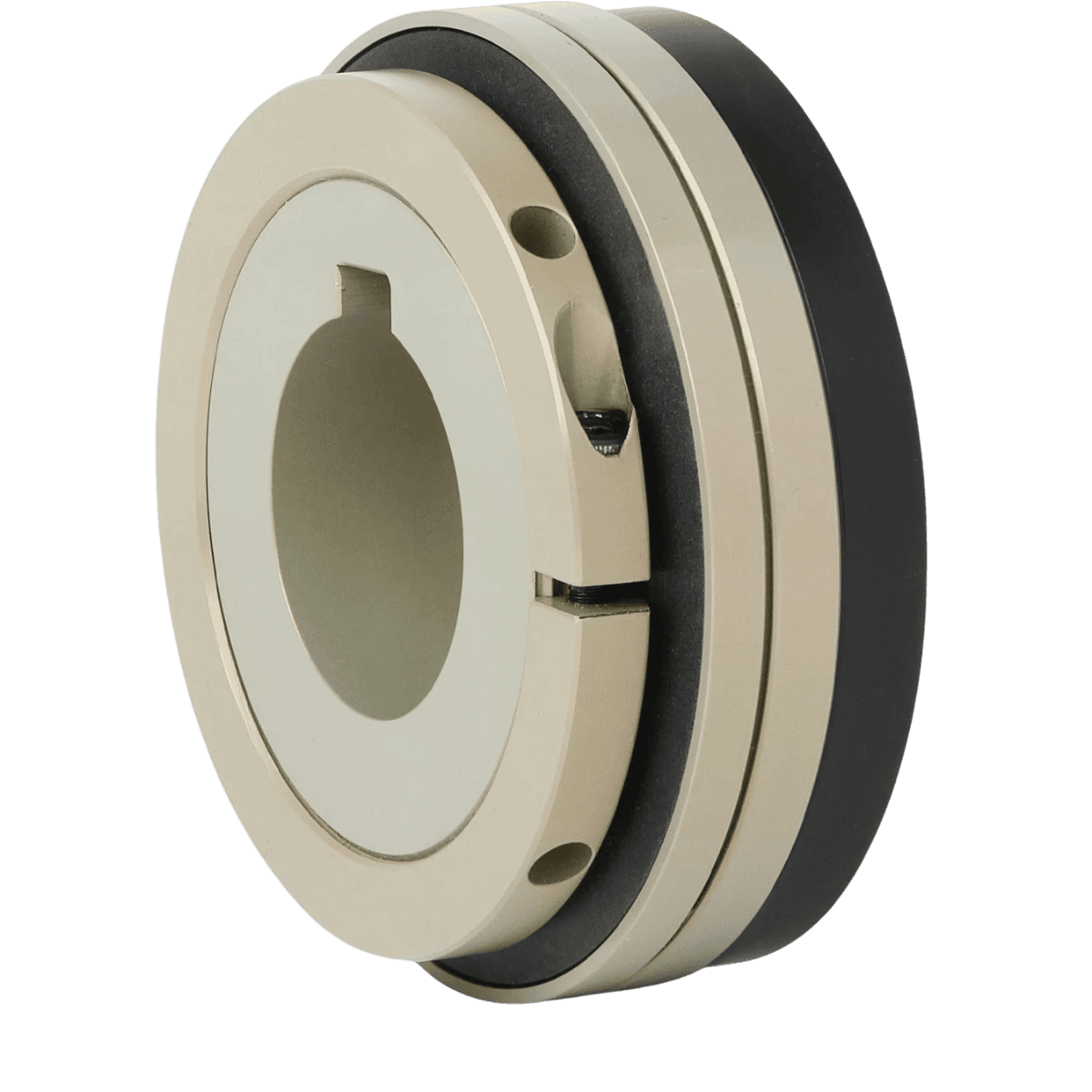

SKN –Torque limiter

With clamping ring and one clamping screw, Safety system: spring loaded ball-detent principle

SKP – Torque limiter

Safety system: hardened steel, spring loaded ball-detent principal, with simple keyway connection

SK1 – Torque limiter

Safety system: hardened steel, Clamping ring: size 1.5 – 10 aluminium, Conical clamping bushing: size 15 – 2500 steel

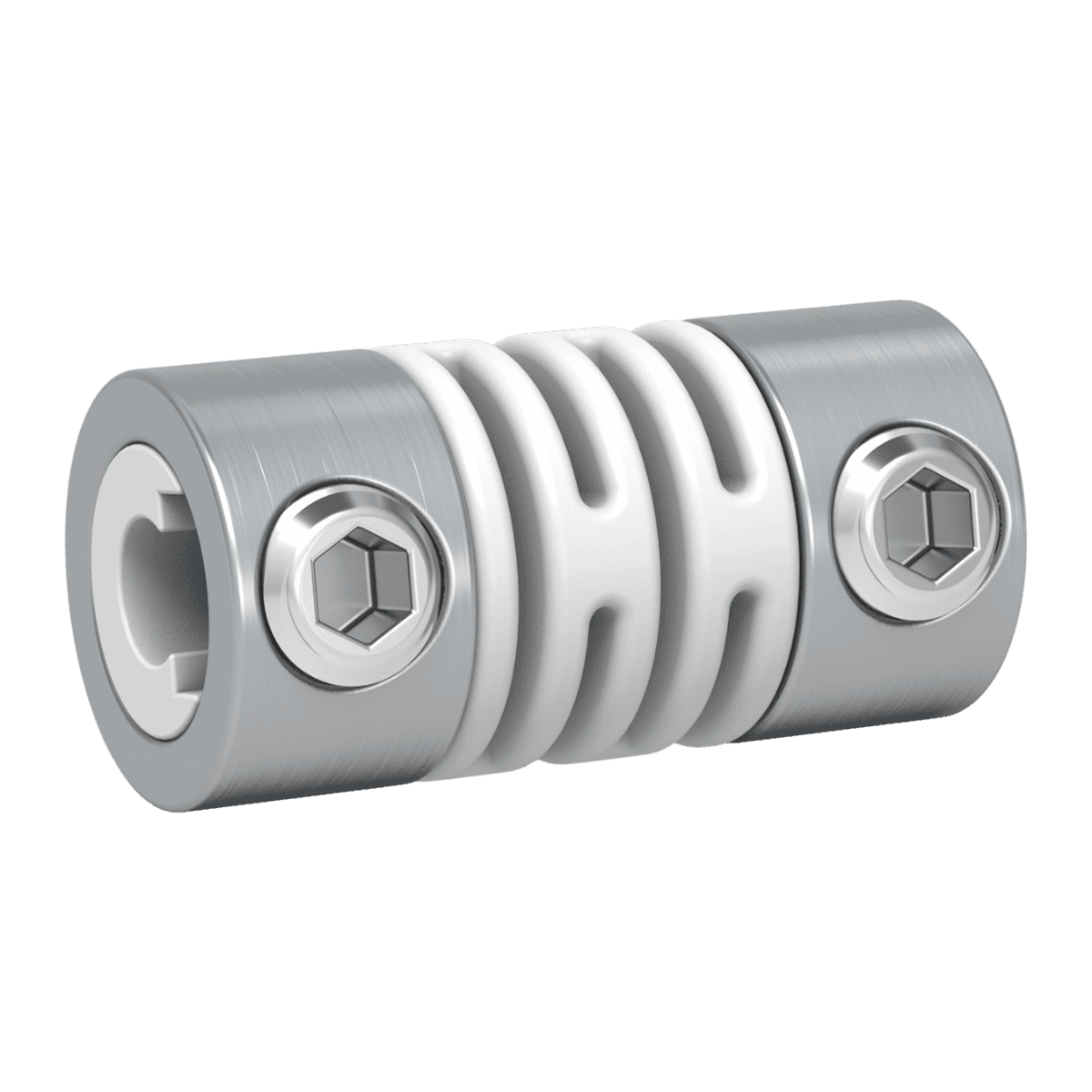

FK1 – Microflex coupling

Very small dimensions, backlash free, vibration damping

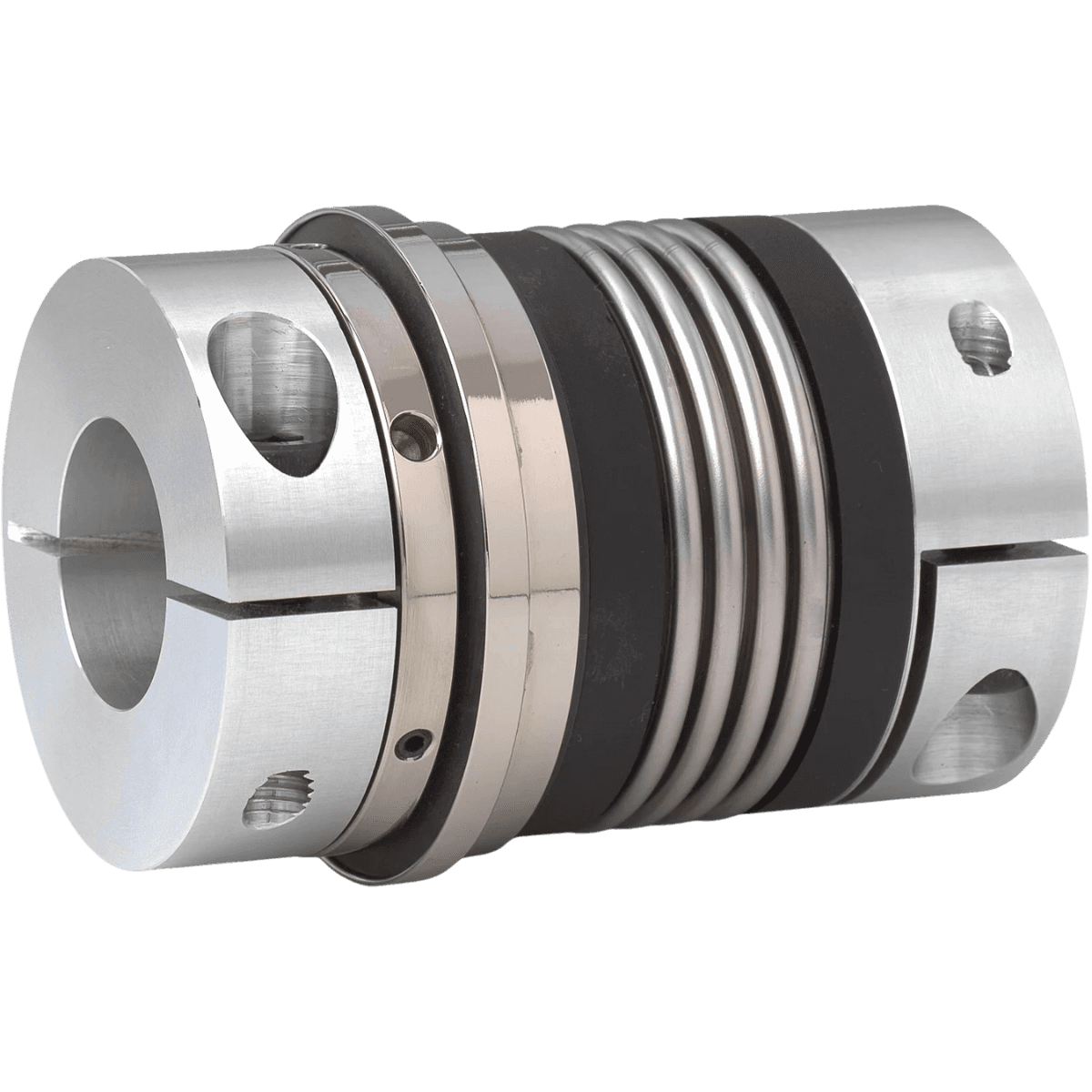

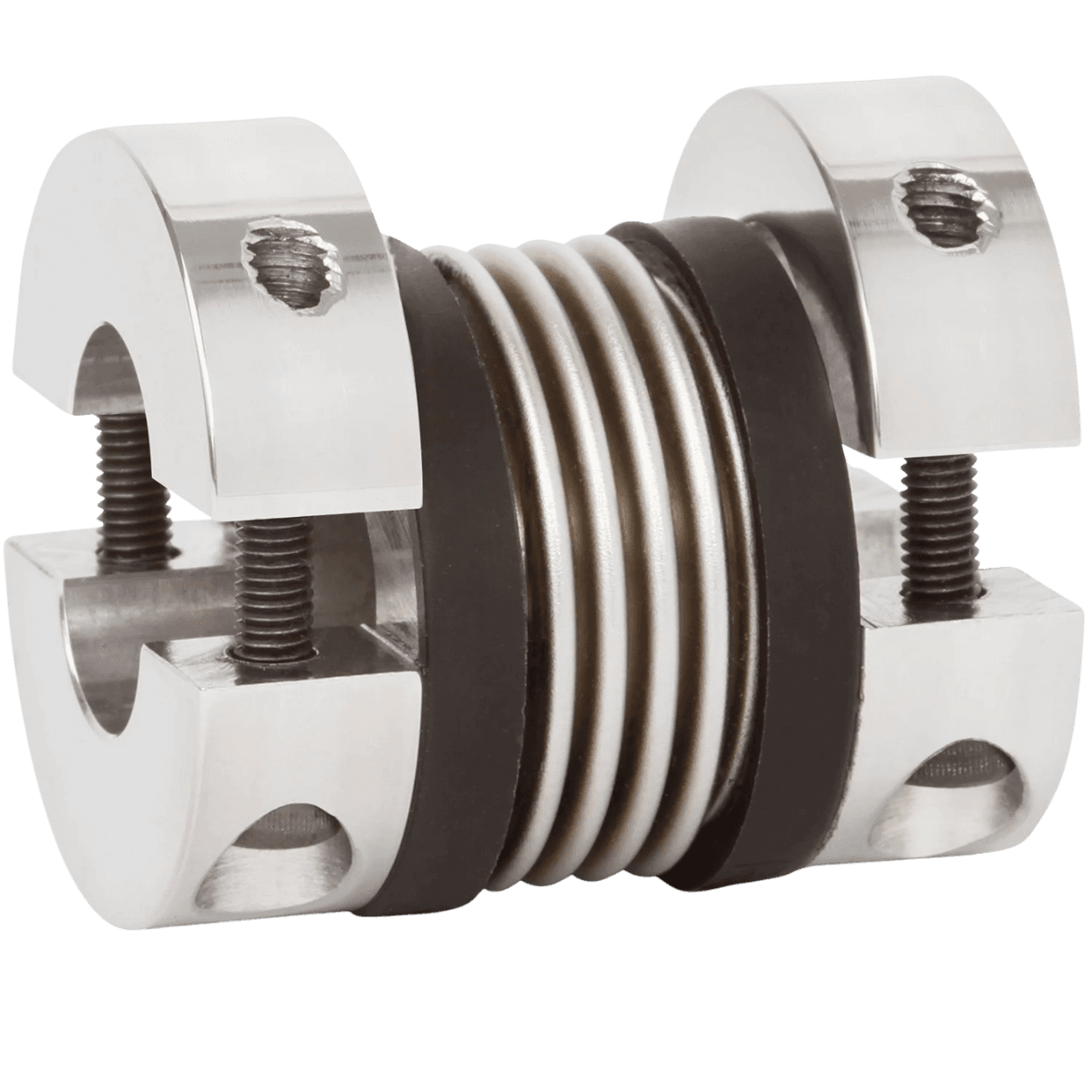

BKL Ecoflex – Miniature metal bellows coupling

Economically priced, backlash free and torsionally stiff, wear free and robust

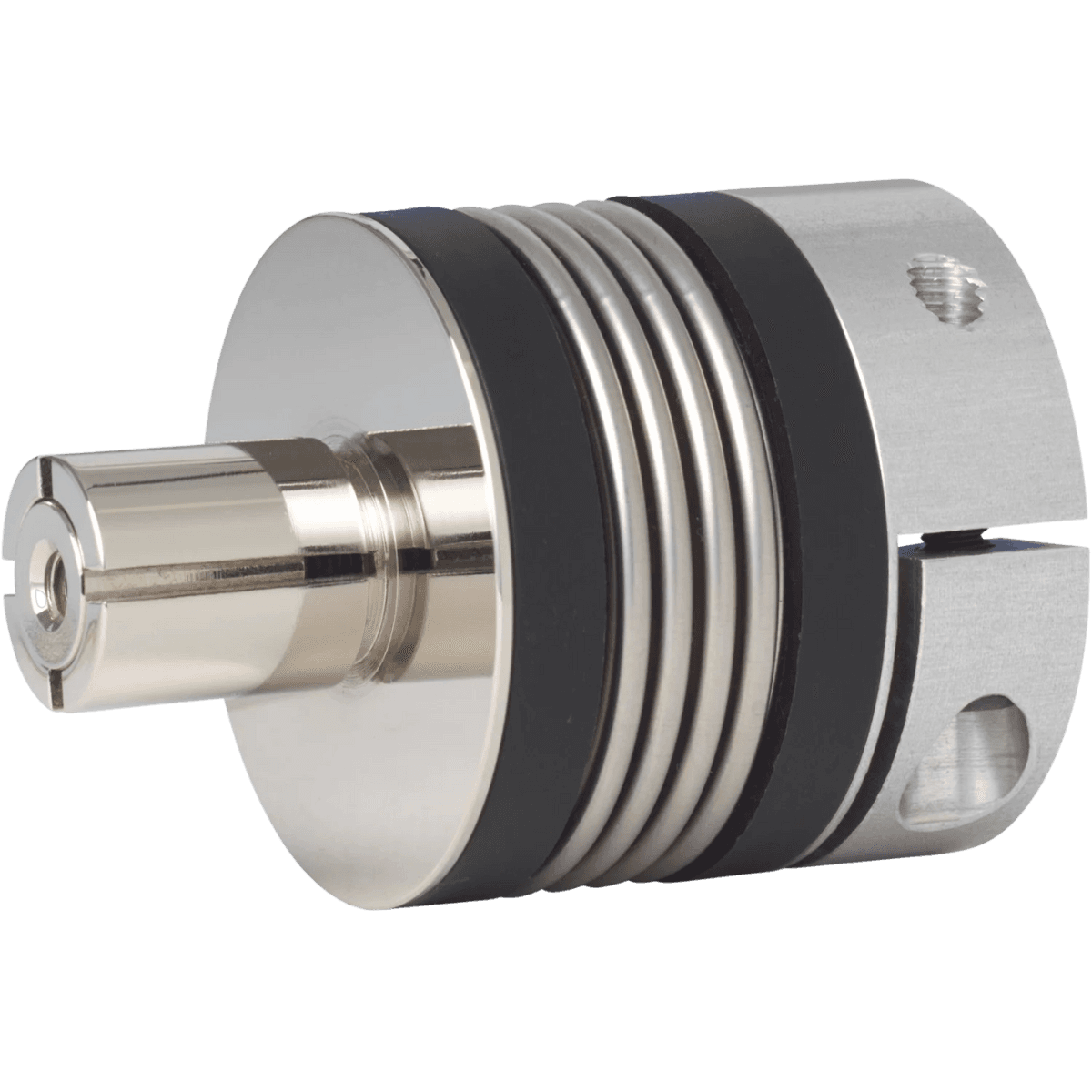

MKS – Miniature metal bellows coupling

For high speeds, force-fit self-centering conical connection, for highly dynamic applications

MK6 – Miniature metal bellows coupling

Easy installation and removal, electrically and thermally isolating, for hollow shaft mounting

MK5 – Miniature metal bellows coupling

Easy installation and removal, electrically and thermally isolating, absolutely backlash free assembly

MK4 – Miniature bellows coupling

Easy installation and removal, electrically and thermally isolating, absolutely backlash free assembly

MK3 – Miniature metal bellows coupling

For hollow shaft mounting, compact design, low moment of inertia

MKH – Miniature metal bellows coupling

Mounts laterally, easy mounting and dismounting, light weight and low moment of inertia

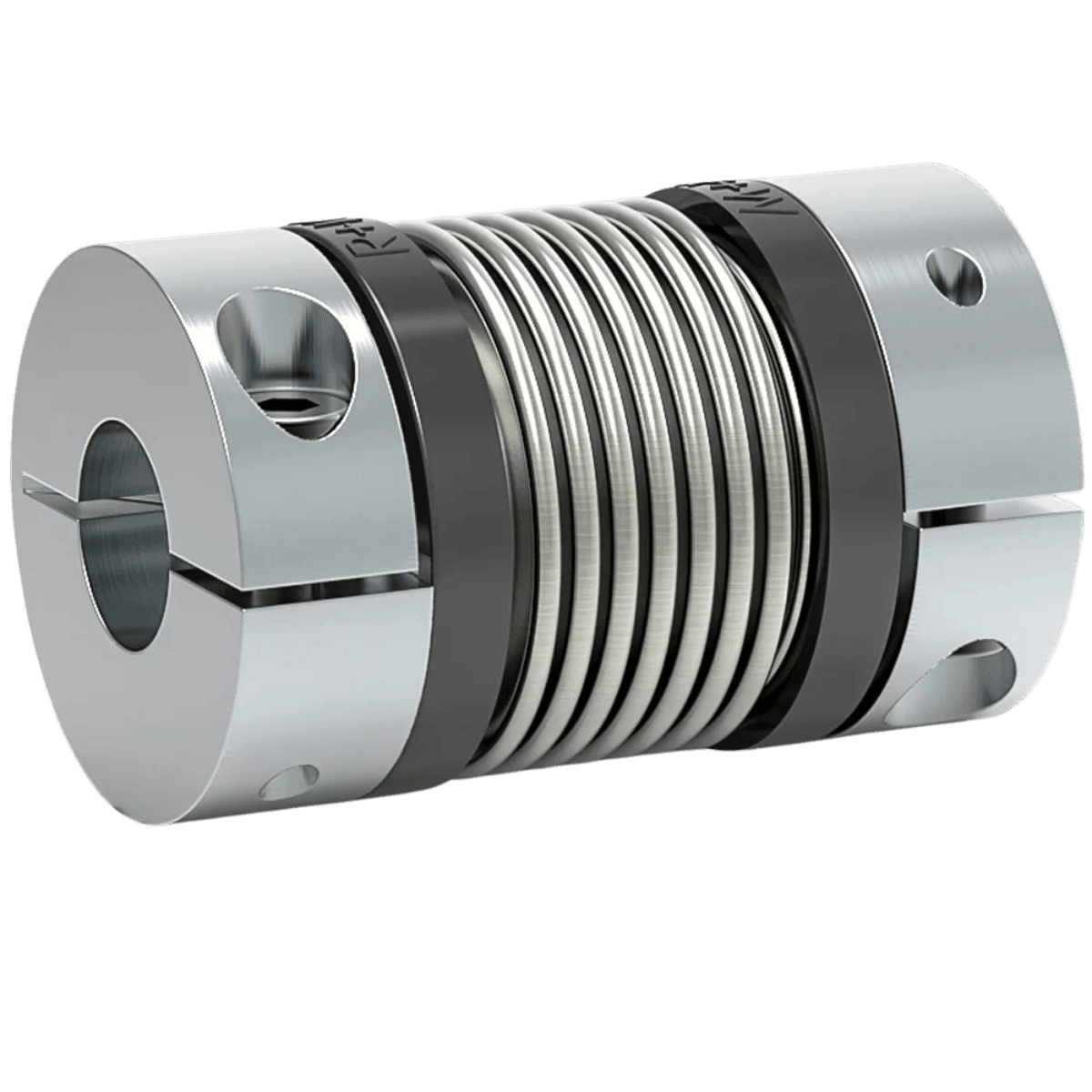

MK2 – Miniature metal bellows coupling

Frictional connection, for highly dynamic applications, low moment of inertia

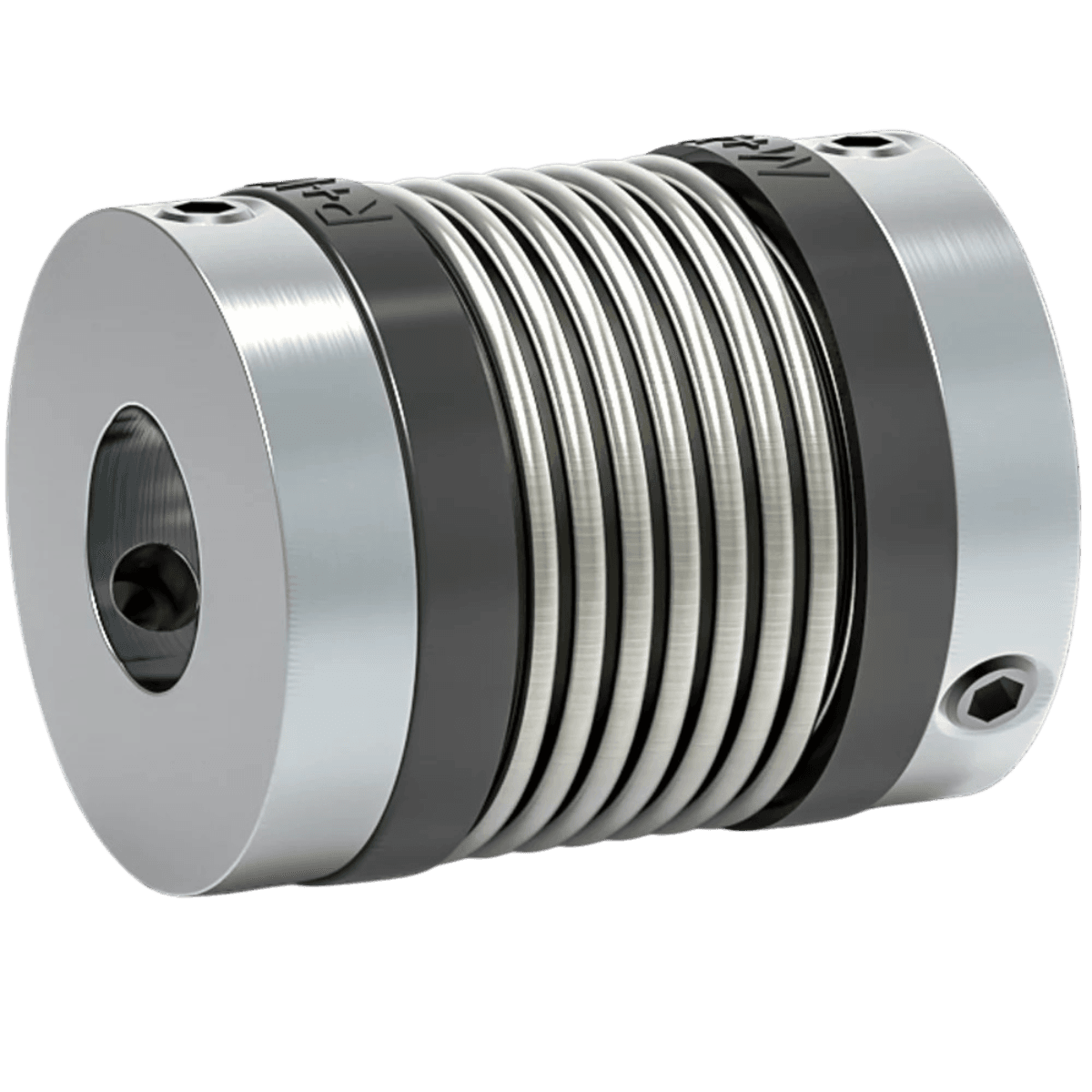

MK1 – Miniature bellows coupling

Integrated dismounting groove, low-cost design, low moment of inertia

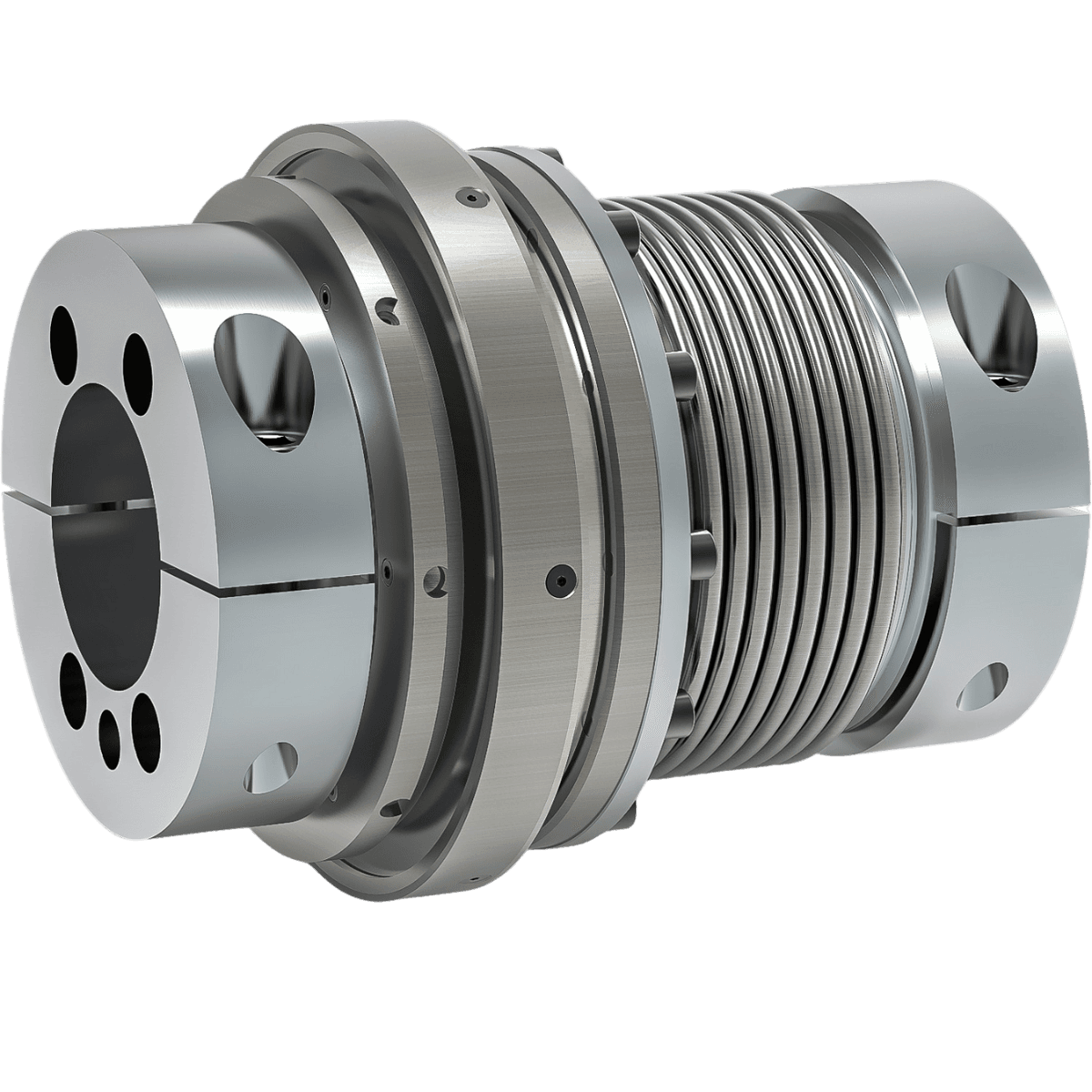

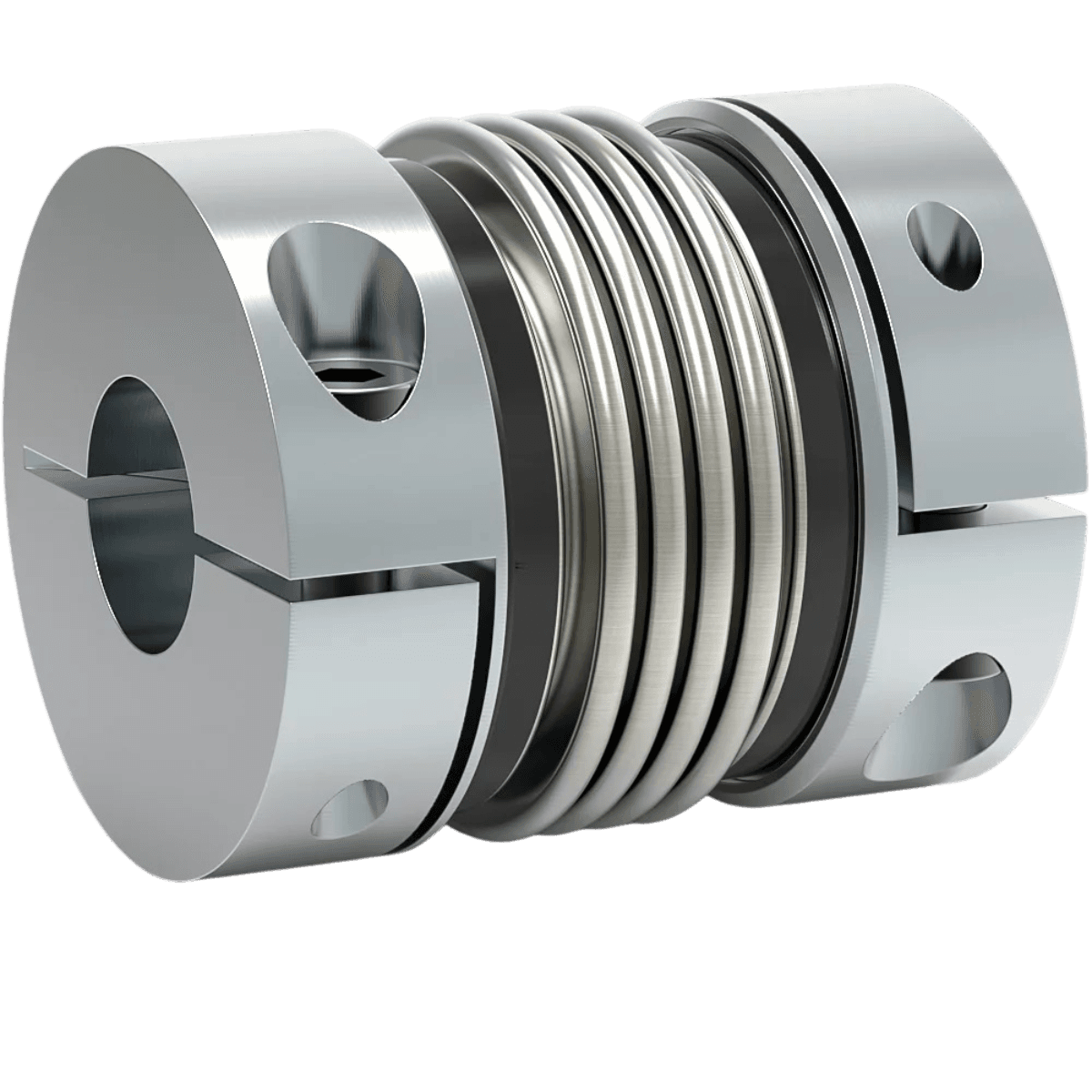

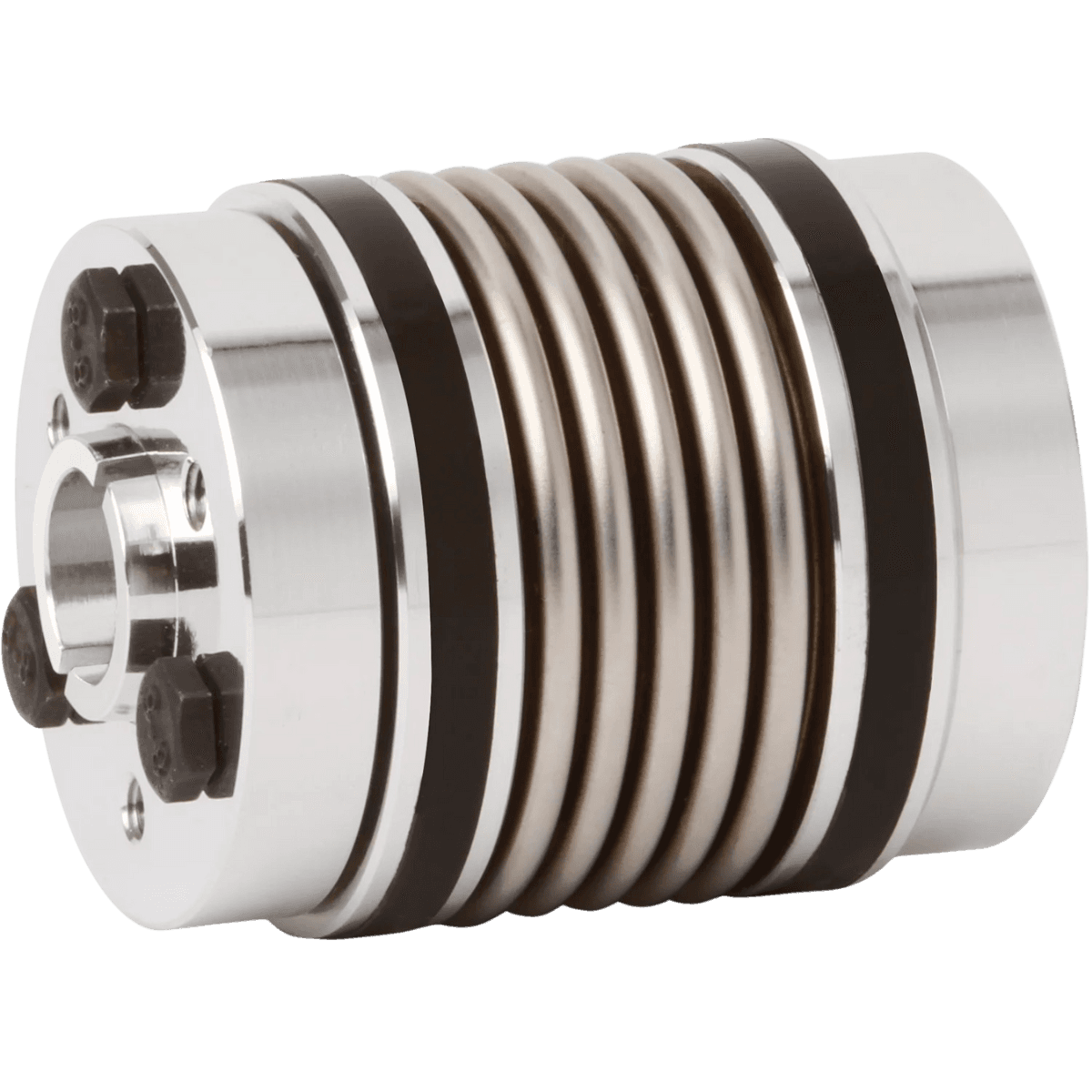

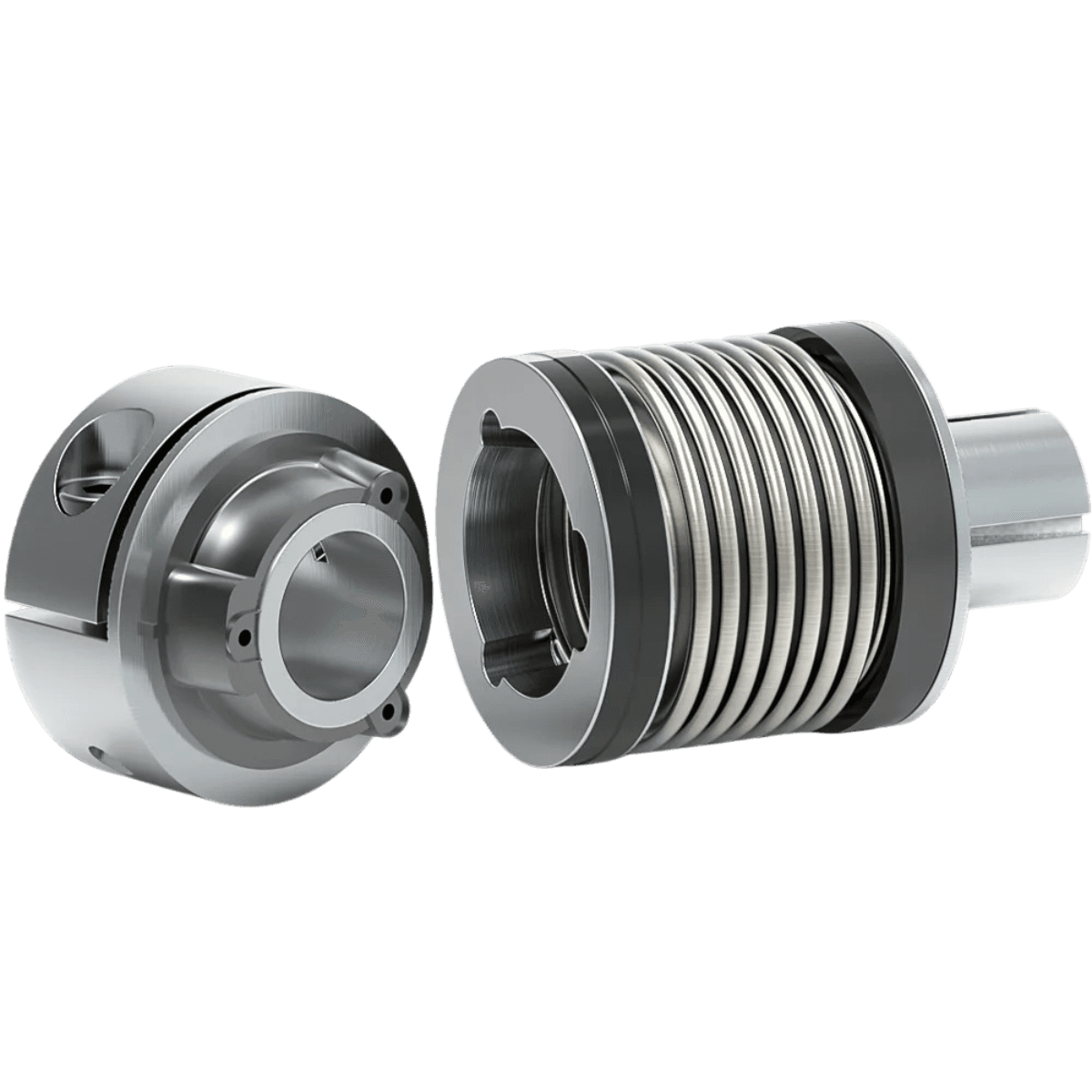

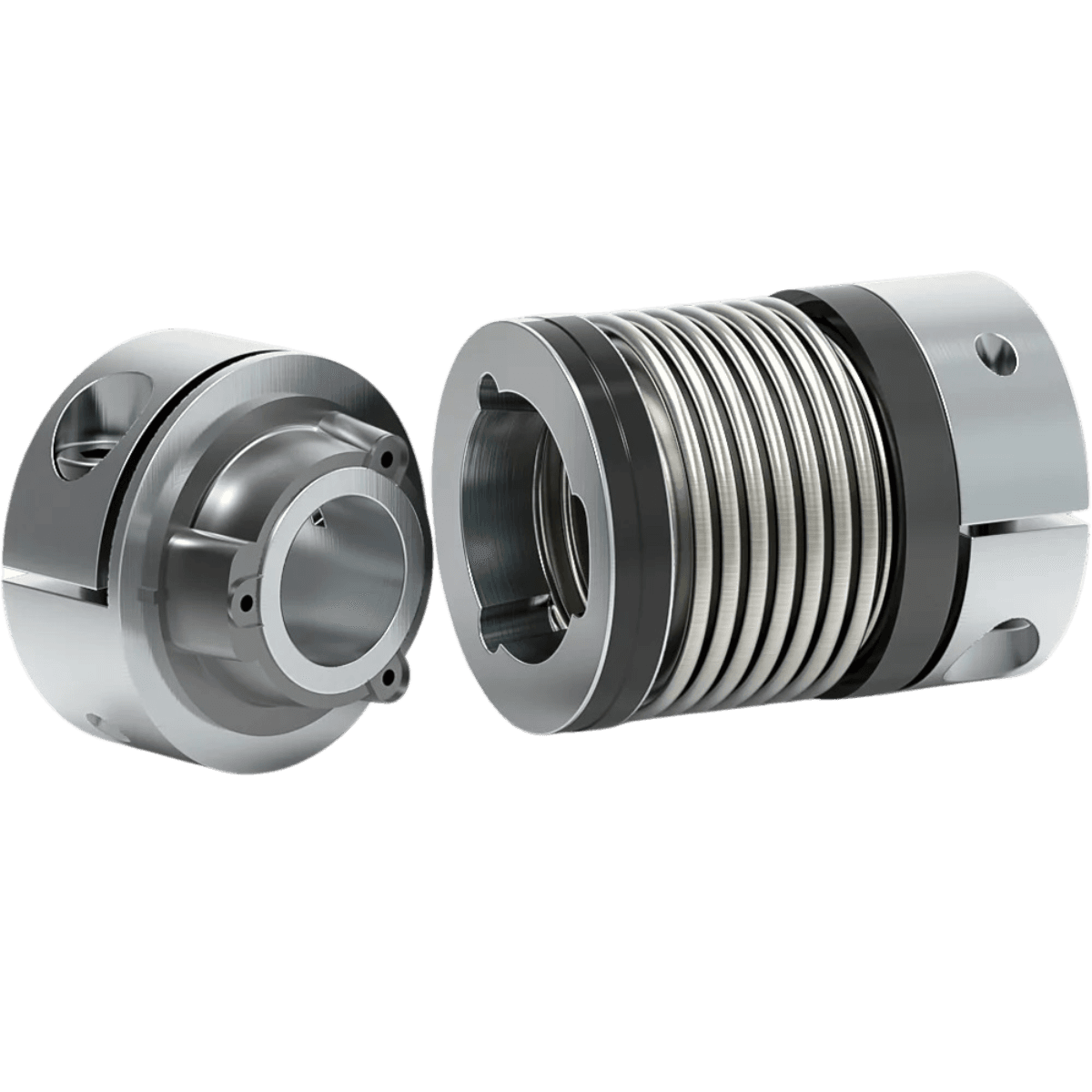

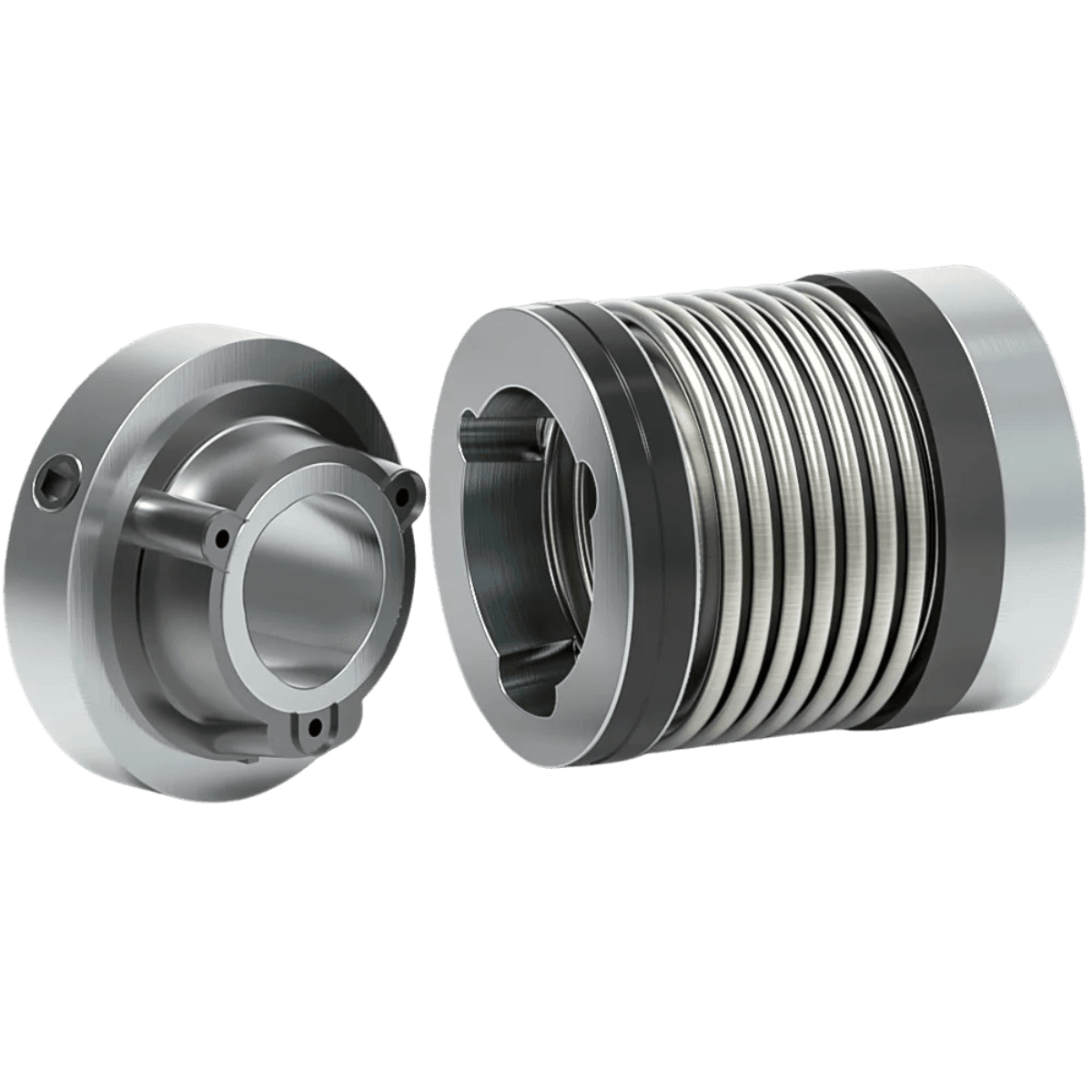

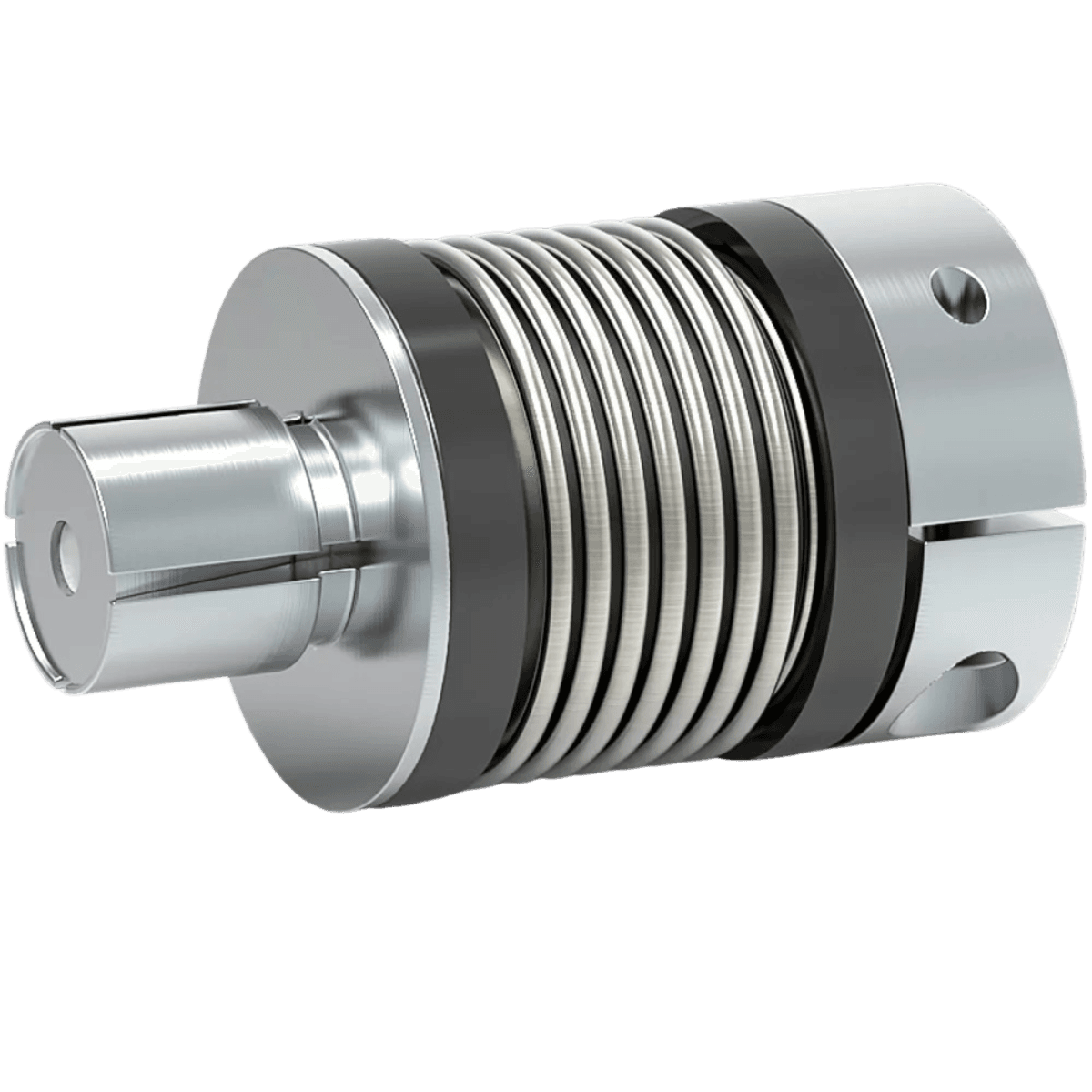

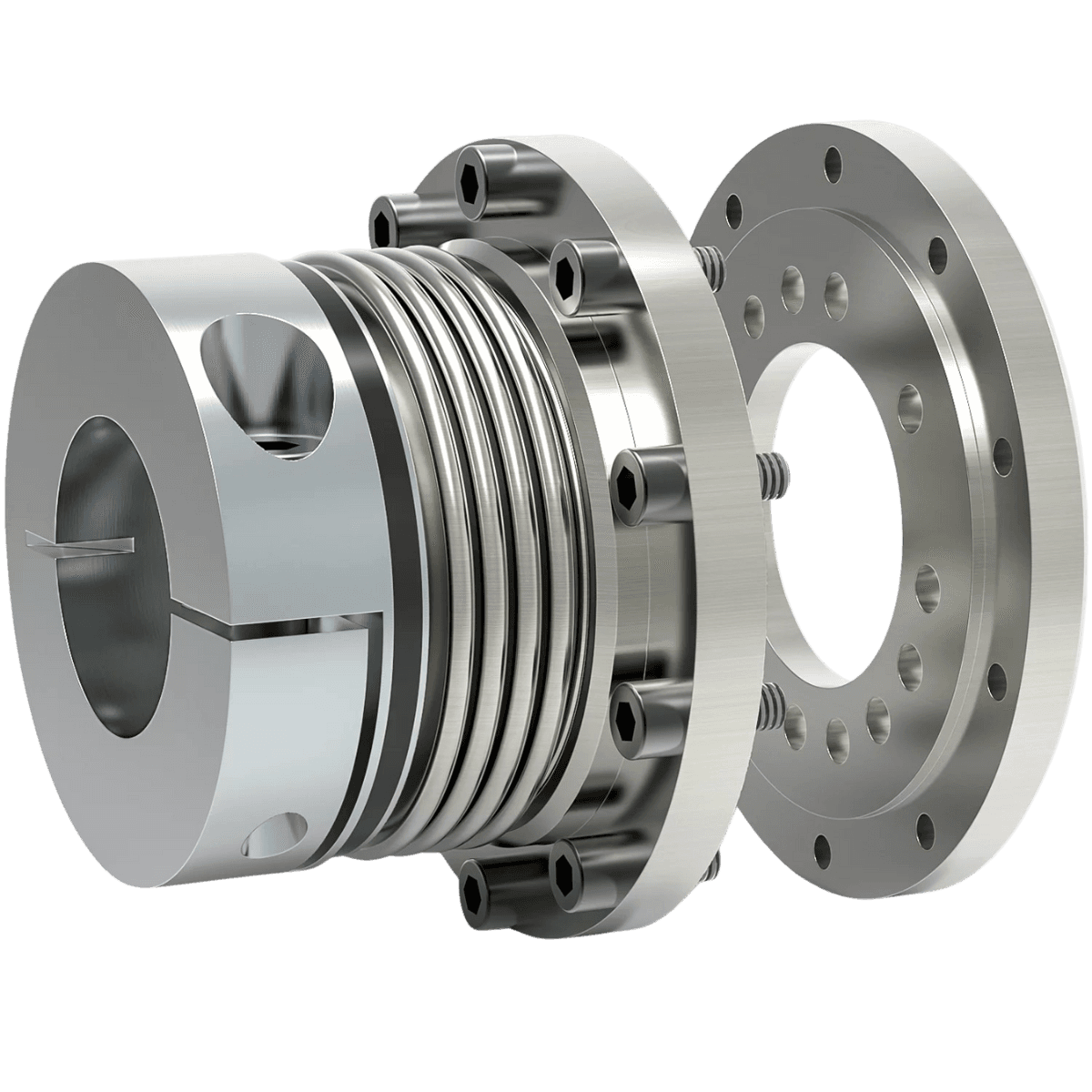

BK8 - Bellows coupling

Compact simple design, small installation space, for ISO flange output gearboxes

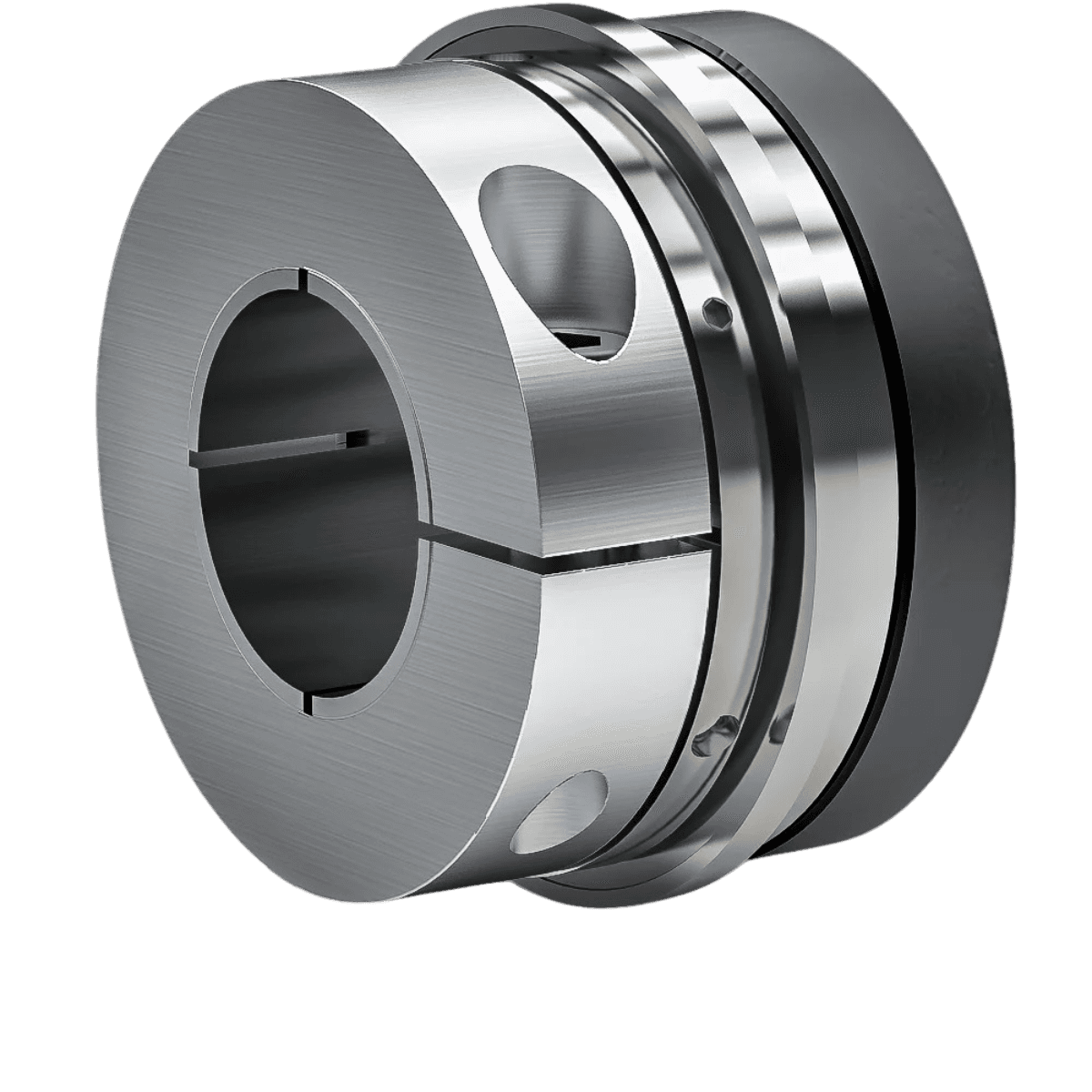

BK7 - Bellows coupling

For hollow shaft mounting, short design saves installation space, easy to mount