Products

Contact us if you have any questions.

Contact us

ORL2-40T-2PS6

CAPTRON ORL2-40T-2PS6 – Optical Sensor for Precise TCP Calibration

easyE-35i actuator

Intelligent inline actuator solution

MOSAIC M1S COM

The new Mosaic M1S COM master unit integrates 2 RJ45 network connectors for connections to the field bus and / or to the network for remote control.

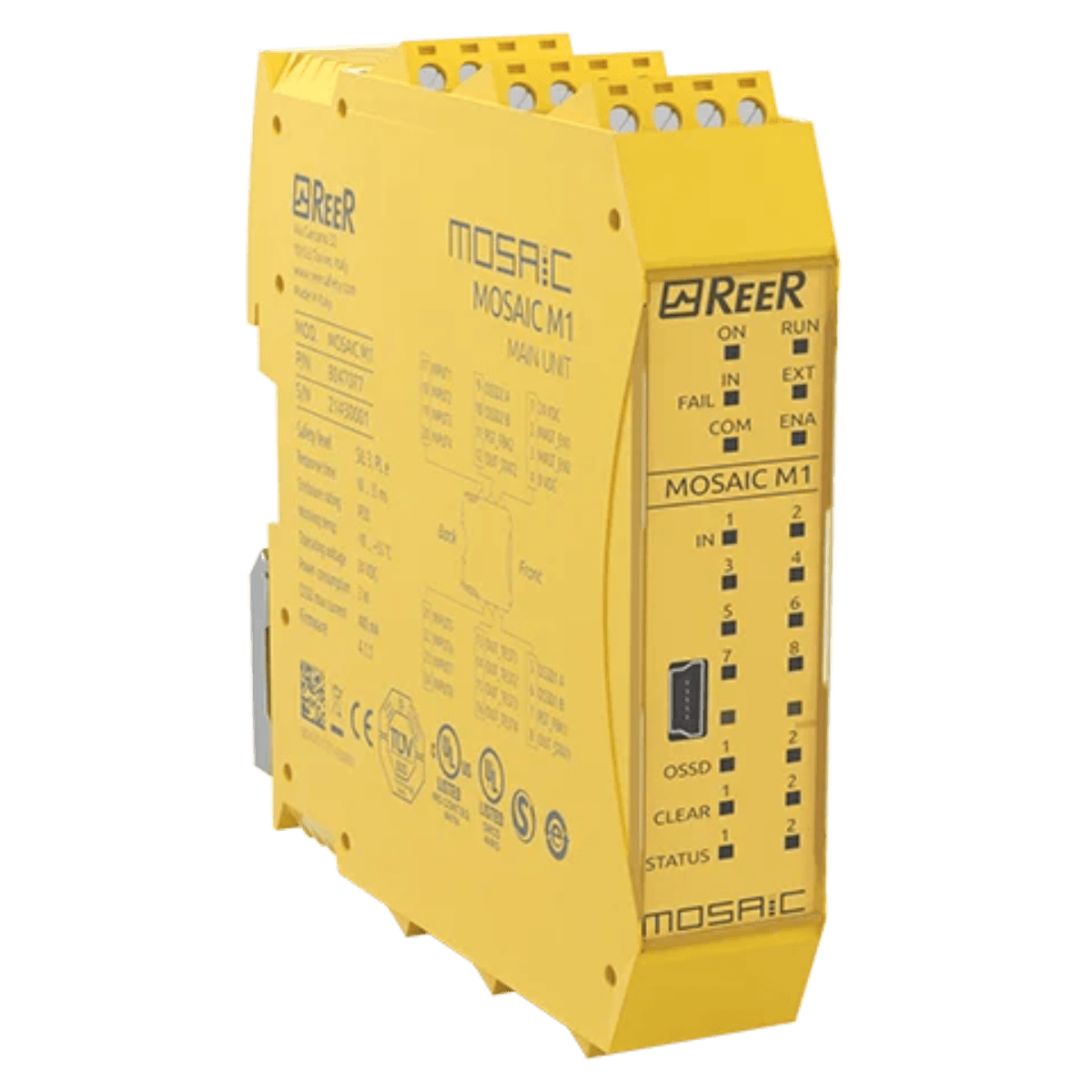

MOSAIC M1

M1 Master module: programmable, 8 inputs, 2 OSSD output pairs, 2 inputs for manual start / reset and EDM supervision, 4 test outputs for sensor monitoring, 2 digital outputs, USB interface.

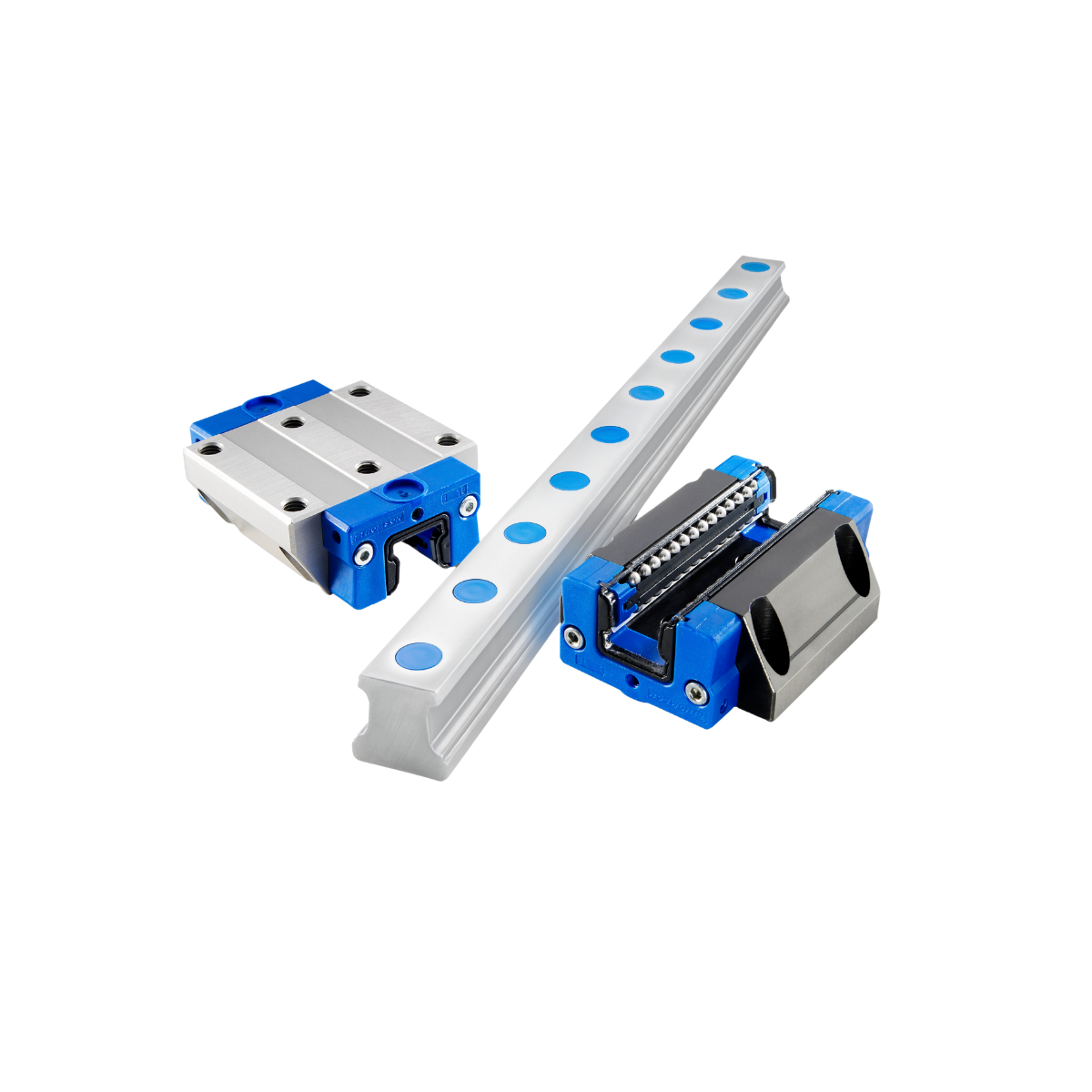

Legacy Profile Rail Linear Guides

Proven profile rail linear guide solutions for compact and precision applications

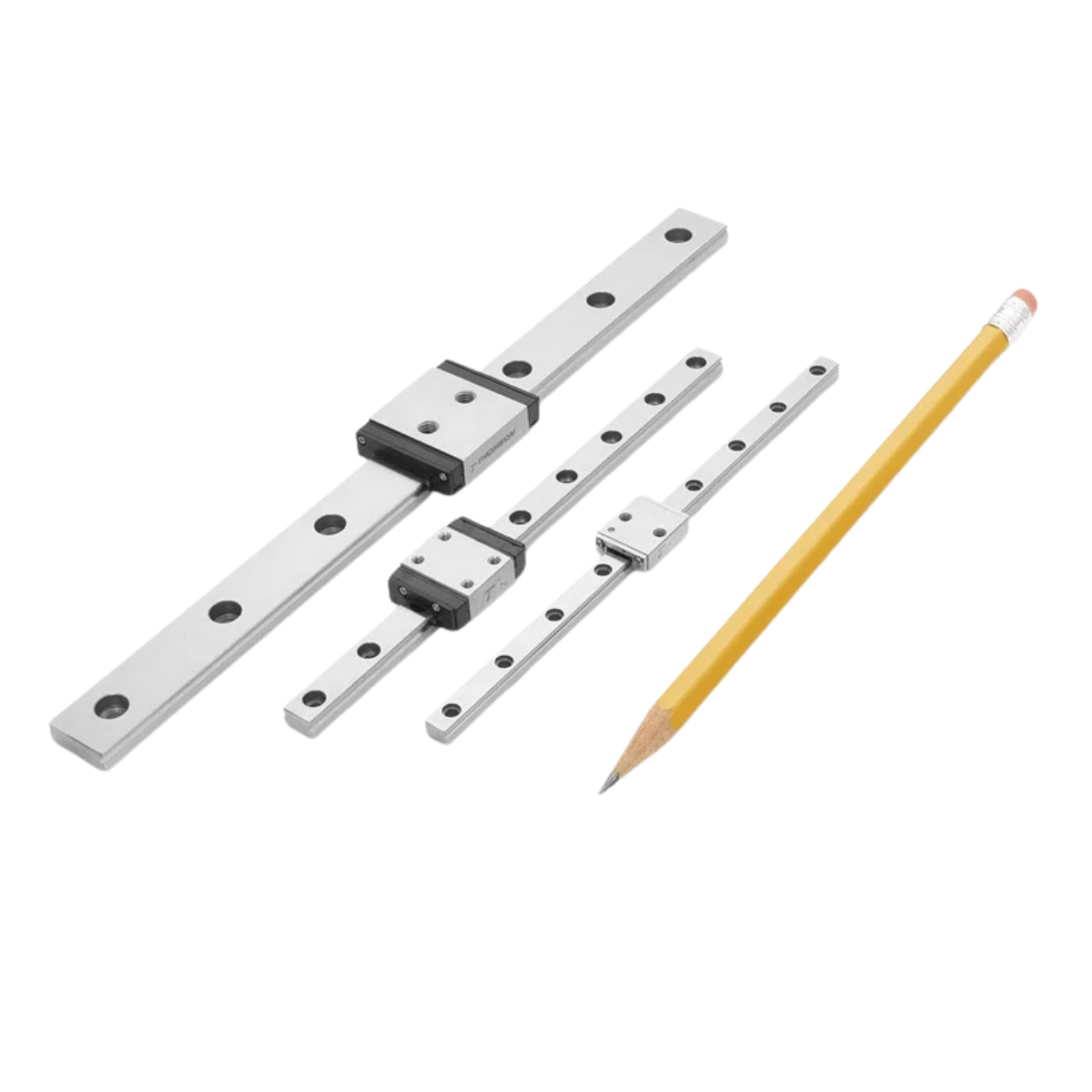

MicroGuide® Linear Guides

Ultra-compact profile rail linear guides for precision motion

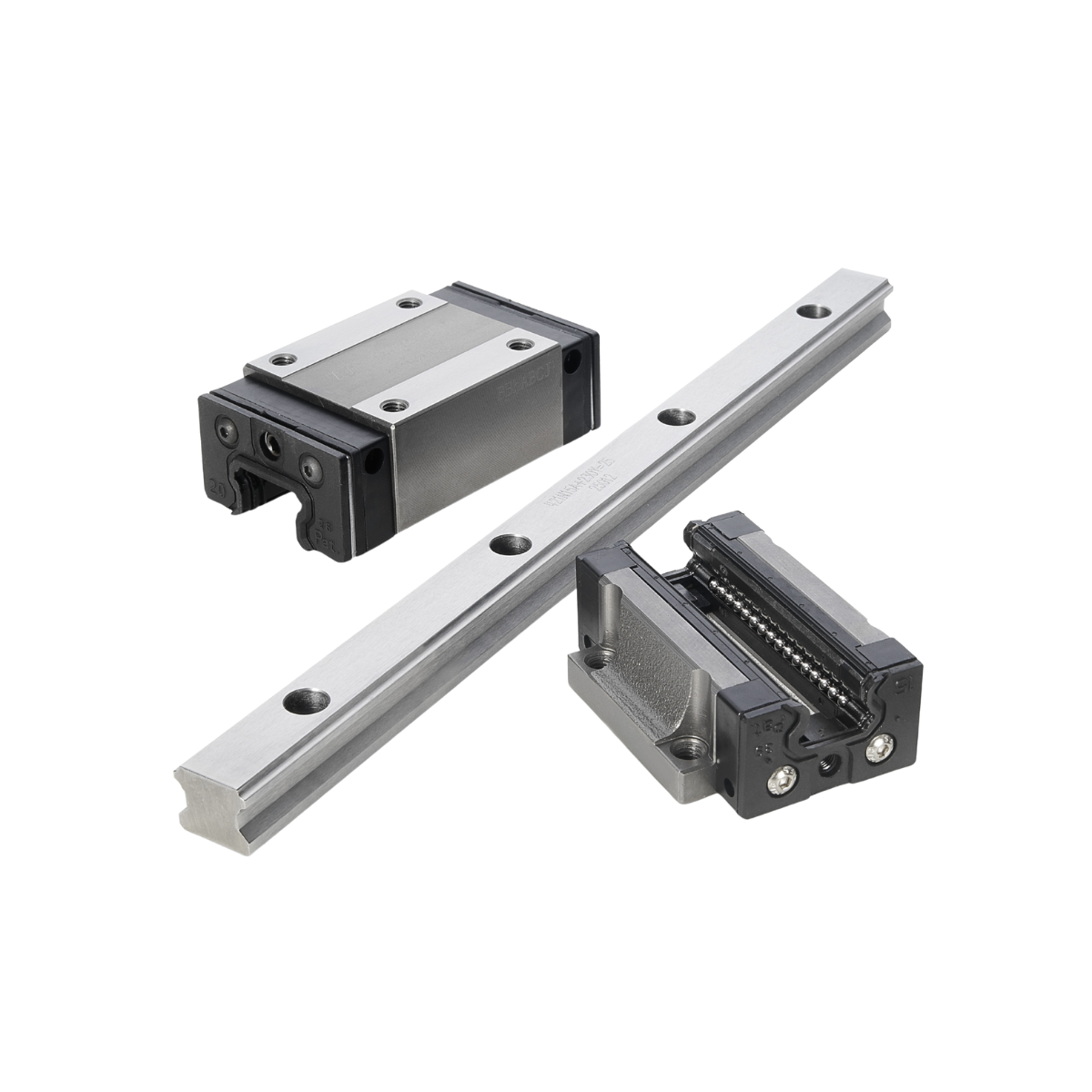

400 Series Profile Rail Linear Guides

Compact and precise profile rail linear guides for space-efficient designs

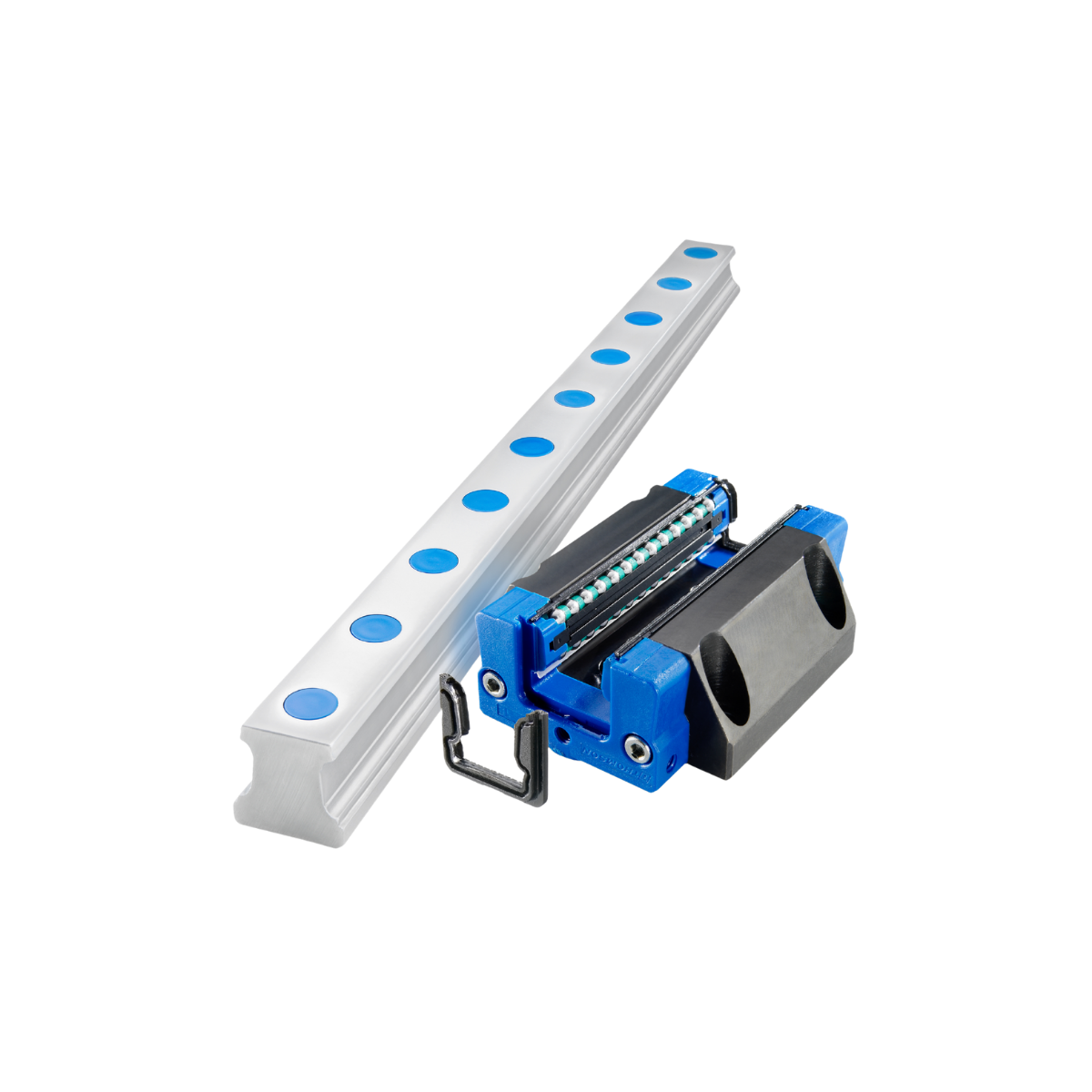

500 Series Roller Linear Guides

High-rigidity roller guide systems for heavy-duty linear motion

500 Series Ball Linear Guides

High-precision ball guide systems for smooth and accurate linear motion

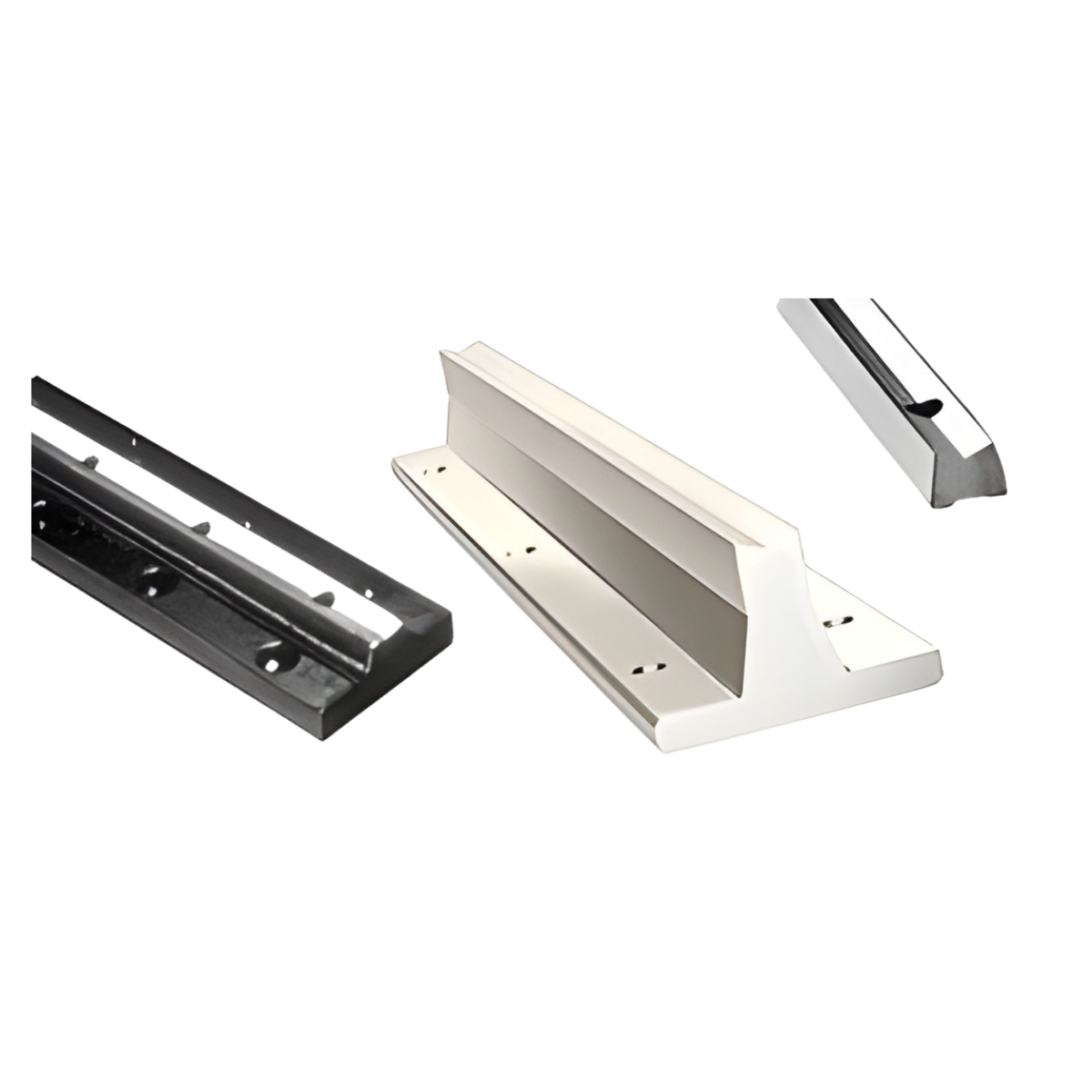

Legacy Shafting

Proven round shaft linear guide solutions for long-term industrial use

Shaft Rail Assemblies

Pre-assembled linear guide systems for fast and precise installation

Shaft Support Rails

Rigid support rails for increased accuracy and load capacity

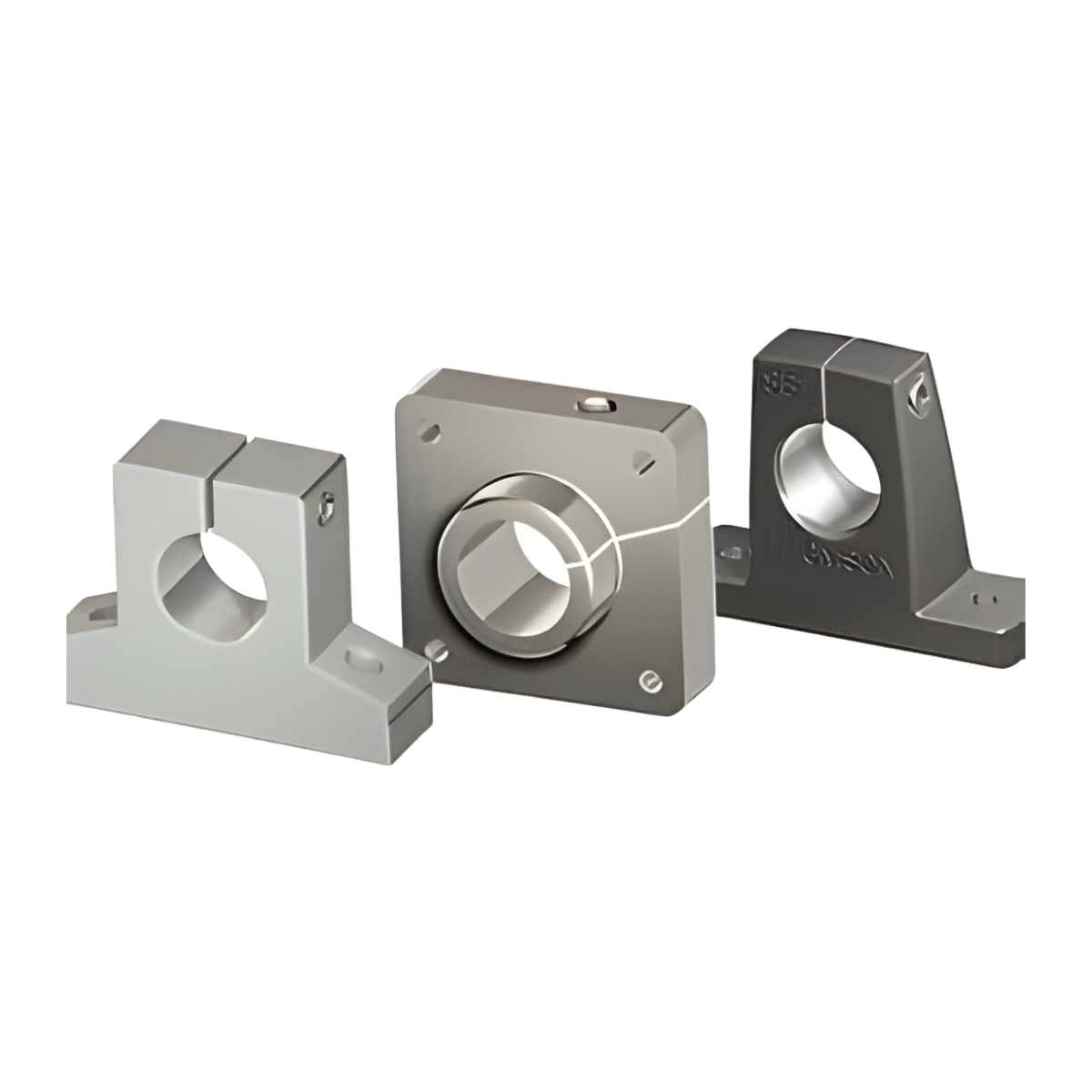

Shaft Support Blocks

Stable support solutions for round shaft linear guide systems

60 Case Quick Shafting

Fast-to-install round shaft linear guides for flexible machine design

60 Case Standard Shafting

High-load, wear-resistant shafts for demanding linear motion

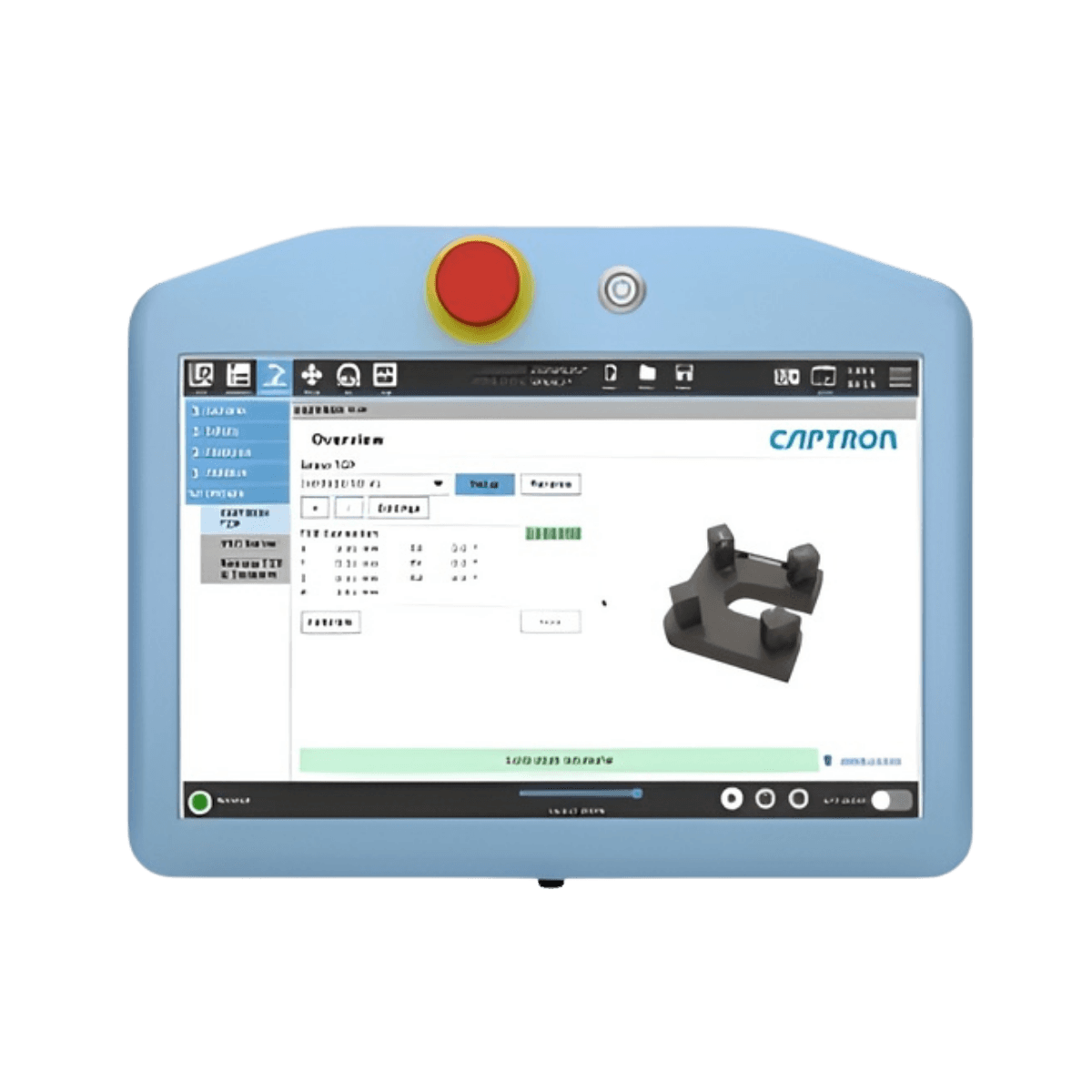

Software URCap (TCP Calibration)

CAPTRON Software URCap – TCP Calibration Software for Universal Robots

OGLW2-70T4-2PS6

CAPTRON OGLW2-70T4-2PS6 – Optical Sensor for Precise TCP Calibration

OGLW2-70T5-2PS6 (with slave connector)

CAPTRON OGLW2-70T5-2PS6 – Optical Sensor for Precise TCP Calibration with Slave Connection

OGLW2-40T-2PS6

CAPTRON OGLW2-40T-2PS6 – Optical Sensor for Precise TCP Calibration

Essentials™ Motion Systems

Optimized features at an exceptional value

Essentials™ Servo Drive

Optimized for Flexibility and Setup Speed

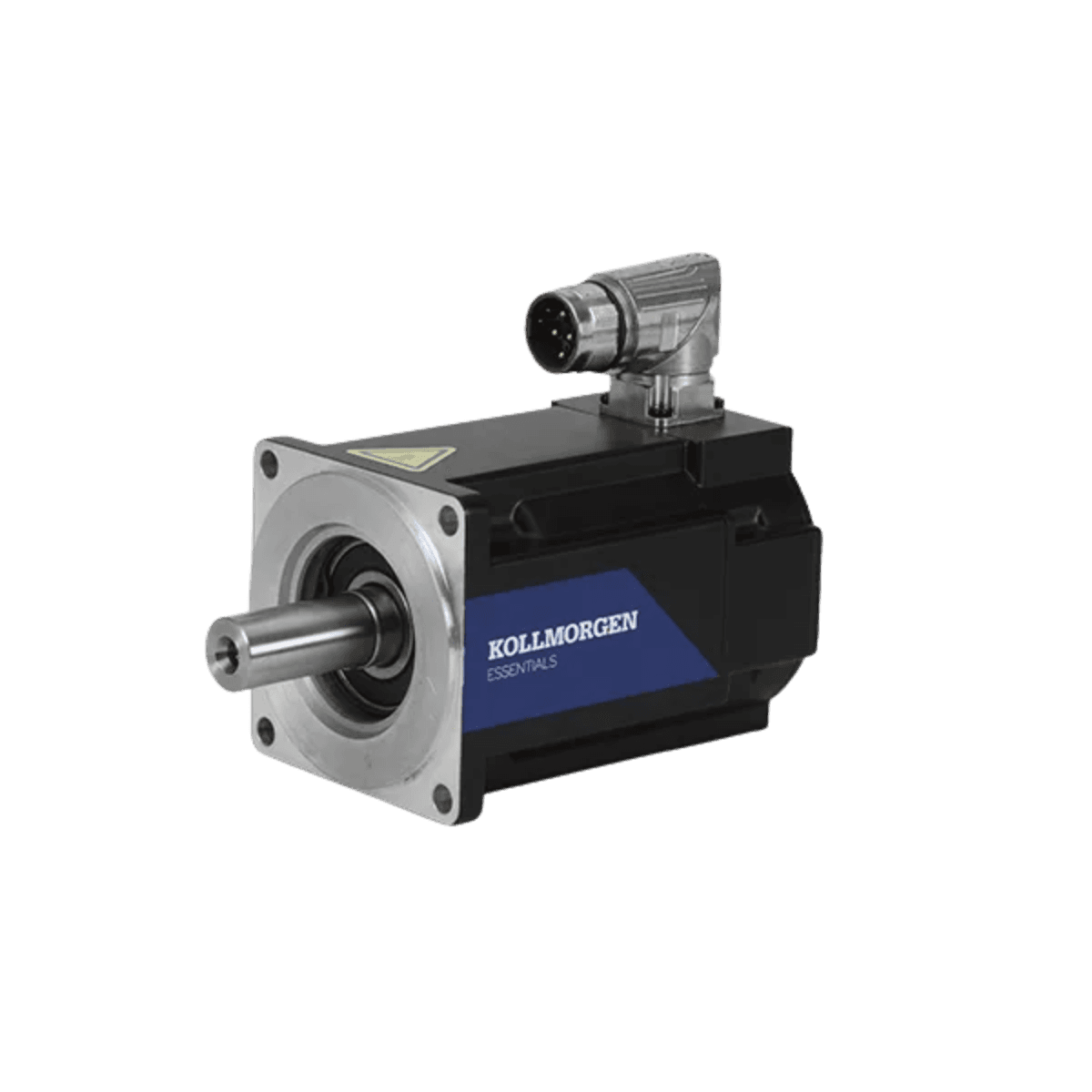

Essentials™ Servo Motors

Flexible Options. Value-Added Features.

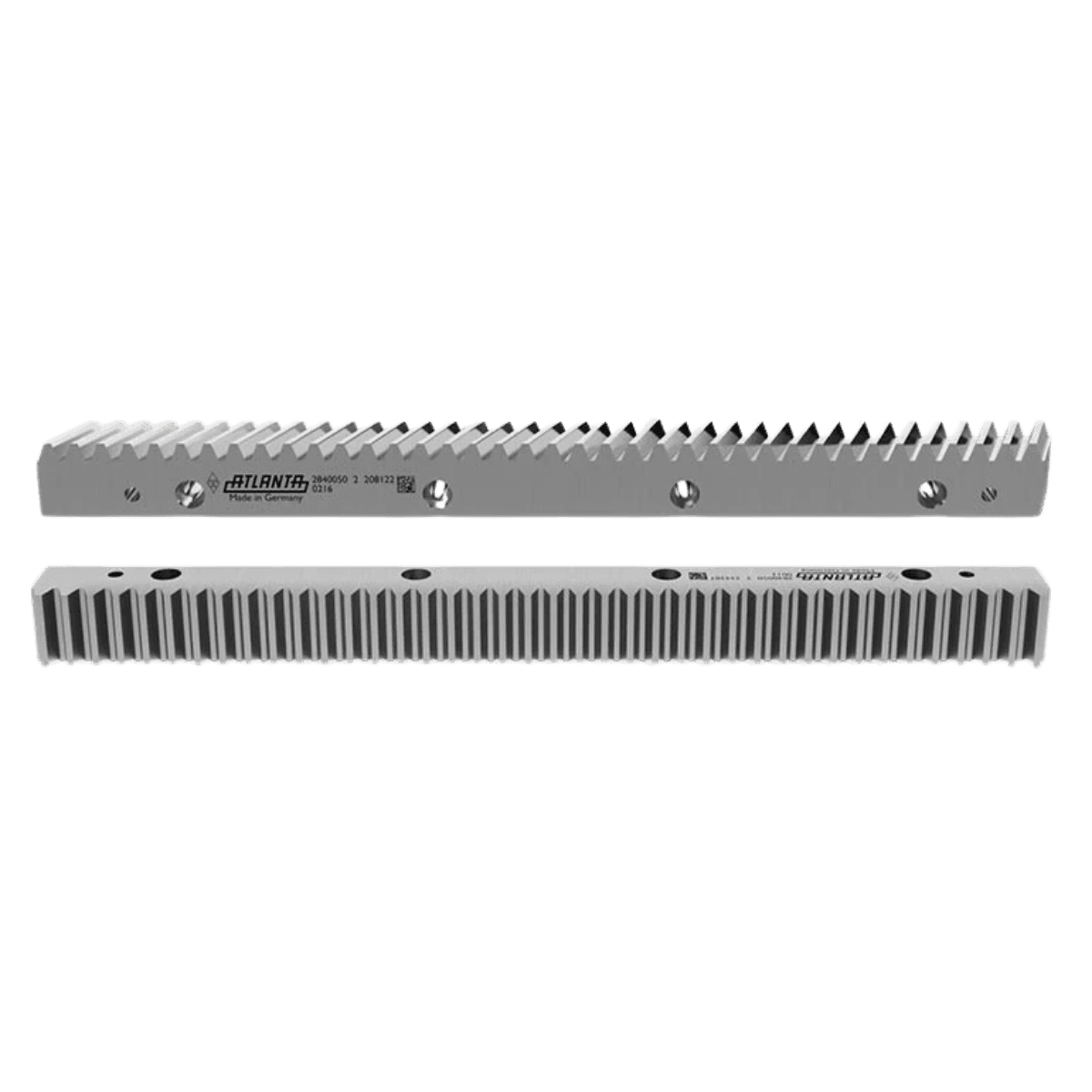

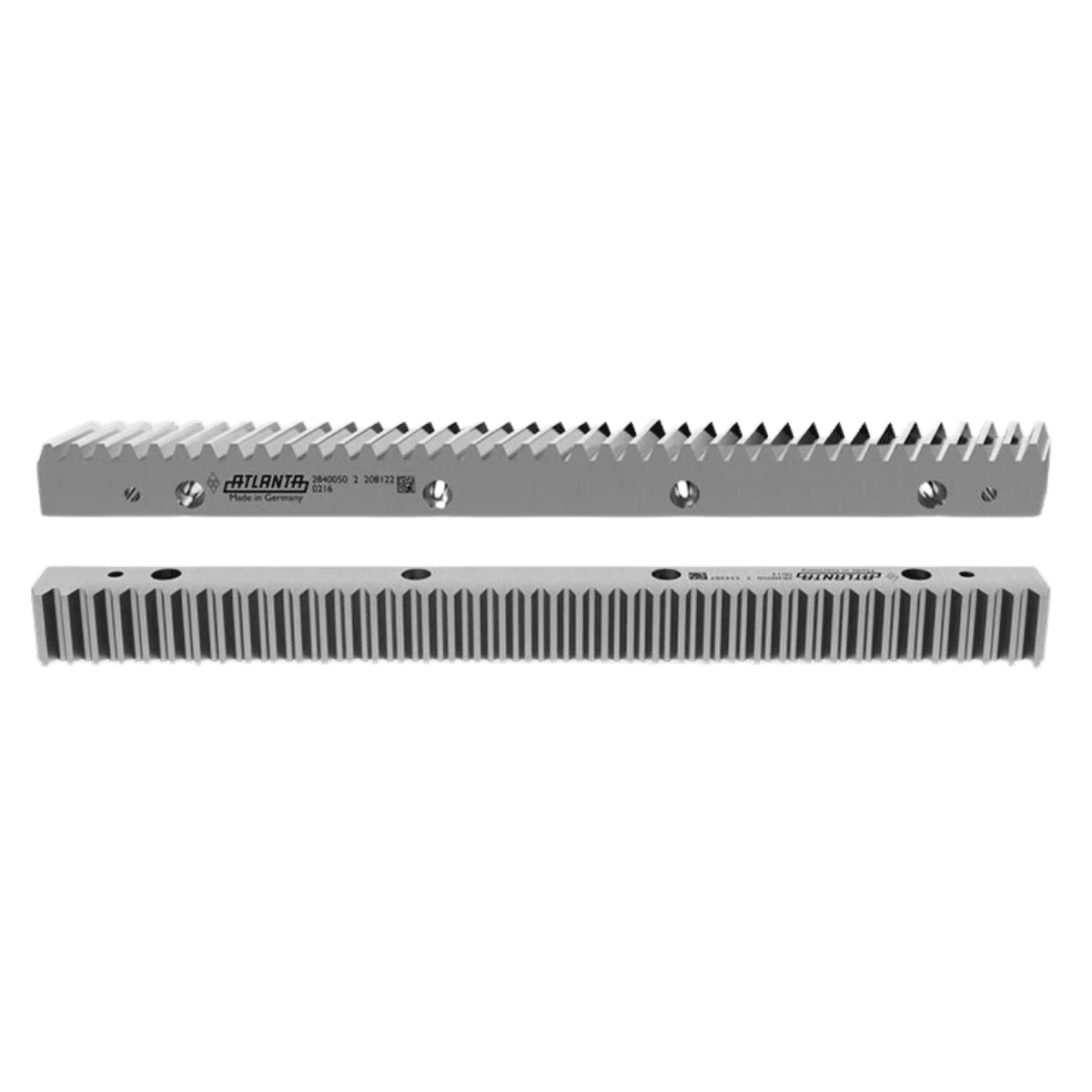

2930208 Racks Module

PR - Precision Rack

2930207 Racks Module

HPR - High Precision Rack

2930205 Racks Module

HPR - High Precision Rack