Underwater motion in industrial environments places far greater demands on mechanical systems than operation on the surface. Constant hydrostatic pressure, corrosion and limited maintenance options mean that solutions proven in dry conditions often fail when used underwater. Selecting an actuator specifically designed for underwater operation is therefore a critical decision already at the design stage, directly influencing reliability, accuracy and long-term system performance.

Designing underwater motion systems often turns out to be far more complex than expected at the beginning of a project. In many cases, a system works on paper, yet within the first few months of operation problems appear: inaccurate positioning, unstable operation, premature failure, or control issues that are difficult to diagnose.

In most cases, the root cause is not the control system or the mechanical design itself, but the fact that the effects of the underwater environment are underestimated during the design phase.

A linear actuator that performs reliably in a dry environment is exposed to completely different loads underwater. Hydrostatic pressure increases proportionally with depth, placing continuous stress on the housing, seals and internal mechanics. This is further compounded by the risk of corrosion, especially in industrial or marine environments.

A common mistake is confusing the term “water-resistant” with an actuator that is suitable for long-term underwater operation. A general-purpose industrial solution is usually not capable of handling constant pressure and the mechanical loads present in a sealed underwater environment over time.

Many underwater applications require precise, controlled motion, such as positioning a sensor head, fine adjustment of a mechanism, or regulating an automated system.

When an actuator lacks reliable position feedback, control becomes uncertain. This not only reduces accuracy, but over time can also lead to overload and accelerated wear.

One of the biggest challenges of underwater systems is maintenance. Replacing a failed actuator is often costly and time-consuming, which is why selecting a reliable underwater actuator is a key decision already at the design stage.

Here, fast repairability is less important than long-term operational reliability.

This is no longer a general industrial solution, but an actuator specifically developed for underwater applications.

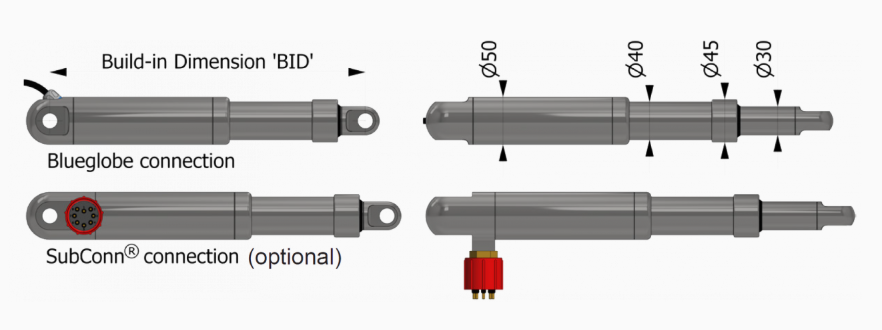

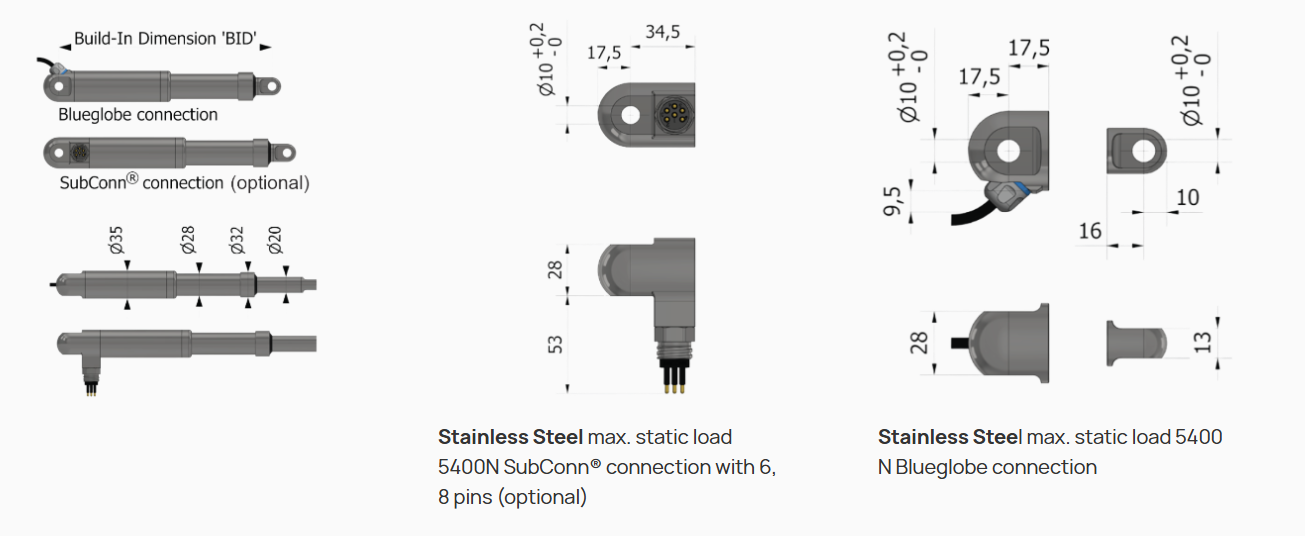

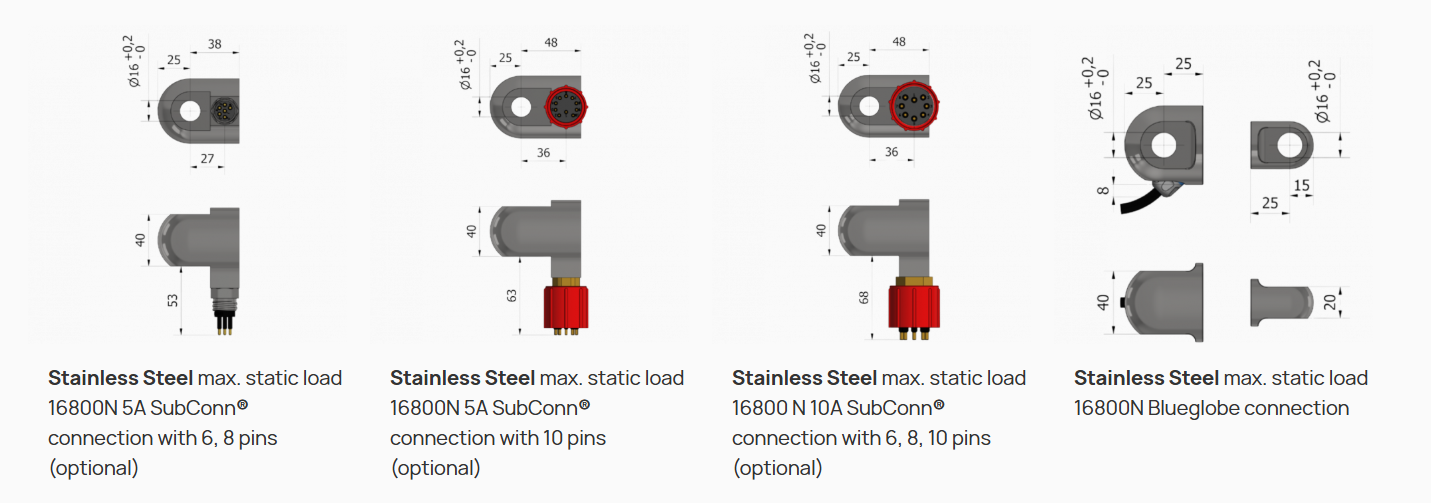

The Bansbach UW100 series was developed specifically for industrial underwater applications. It is tested for depths of up to 100 meters, features a stainless steel housing, and provides precise position feedback via an integrated Hall sensor.

Various connection options allow reliable operation even in dynamically loaded environments.

Thanks to different gear ratios, the force–speed balance of the actuator can be adapted to the specific application, which is particularly important for precise or high-load motion tasks.

Bansbach UW100 actuators are supplied as standard with a Blue Globe cable feedthrough, providing reliable protection at depths of up to 100 meters under static load. If there is a risk of dynamic cable loading, a SubConn connector version is available, further increasing operational reliability.

Selecting an unsuitable underwater actuator can lead to:

A purpose-designed solution, on the other hand, increases system lifetime and predictability.

BIBUS Kft. not only supplies Bansbach UW100 underwater actuators, but also provides technical support during the selection process. Defining the correct force, stroke, control concept and connection system at the design stage offers a clear advantage for long-term system performance.