Shaft couplings

Our high-quality shaft couplings – with a proven track record in mechanical and plant engineering – are the key to creating flexible, rigid and torsionally rigid shaft connections that meet a multitude of requirements.

Contact us if you have any questions.

Contact us

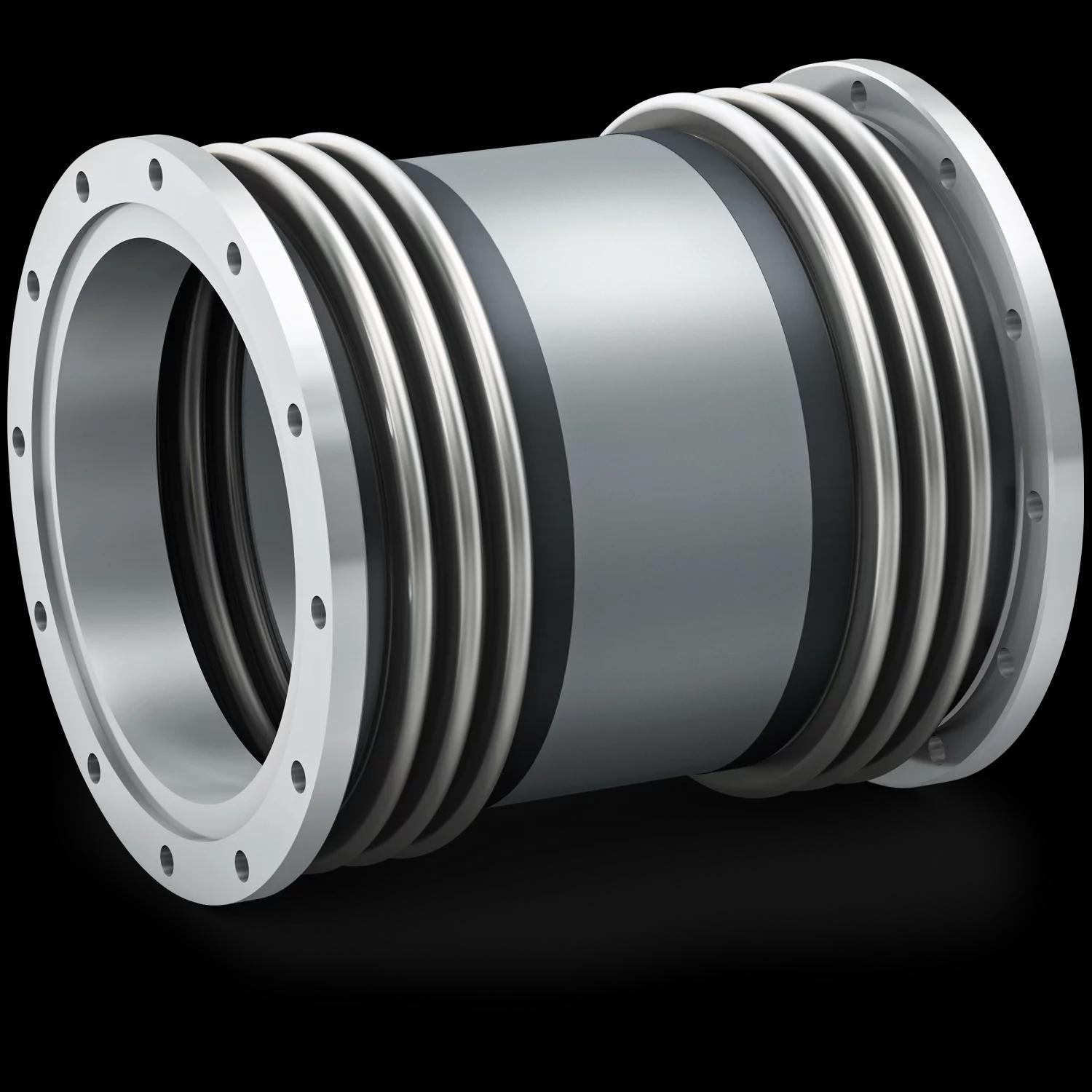

ZA series line shaft couplings

Spanning longer distances: Line shaft couplings from R+W

BX series high torque metal bellows couplings

Torsionally stiff bellows couplings

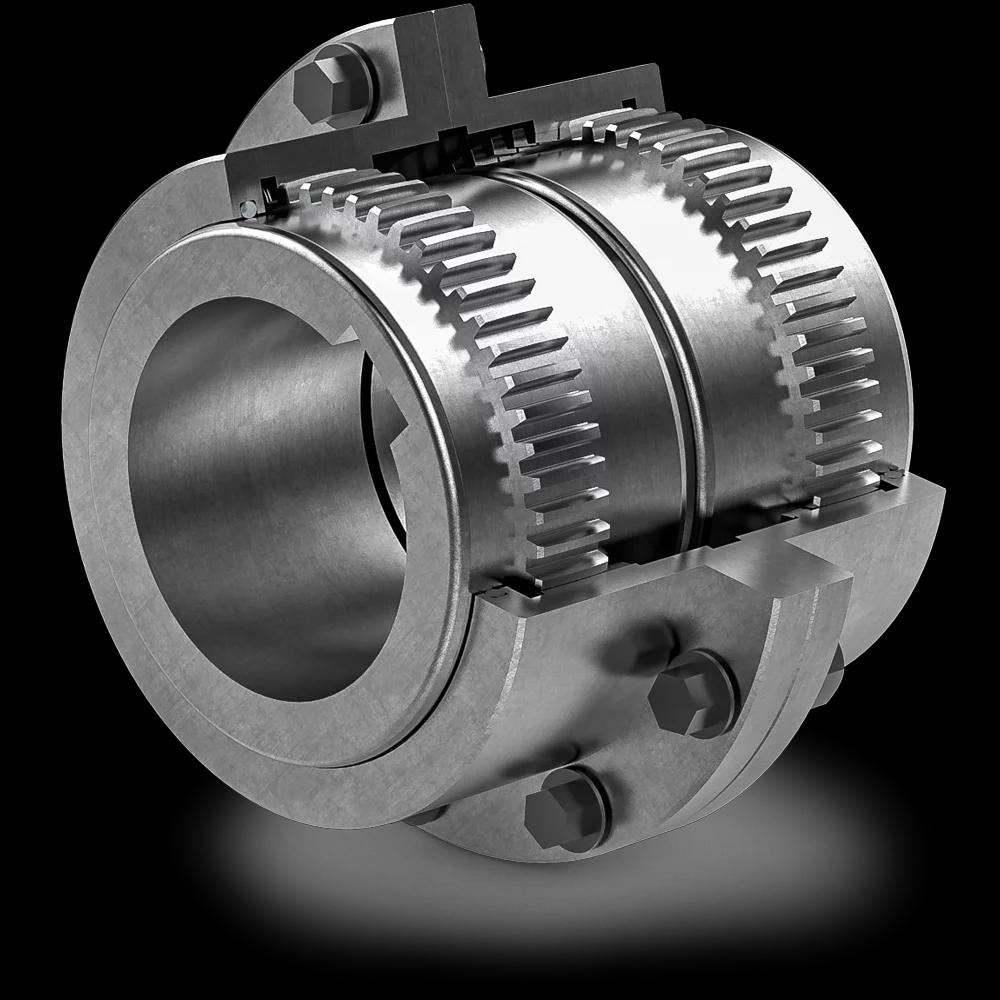

BZ series gear couplings

Flexible gear couplings

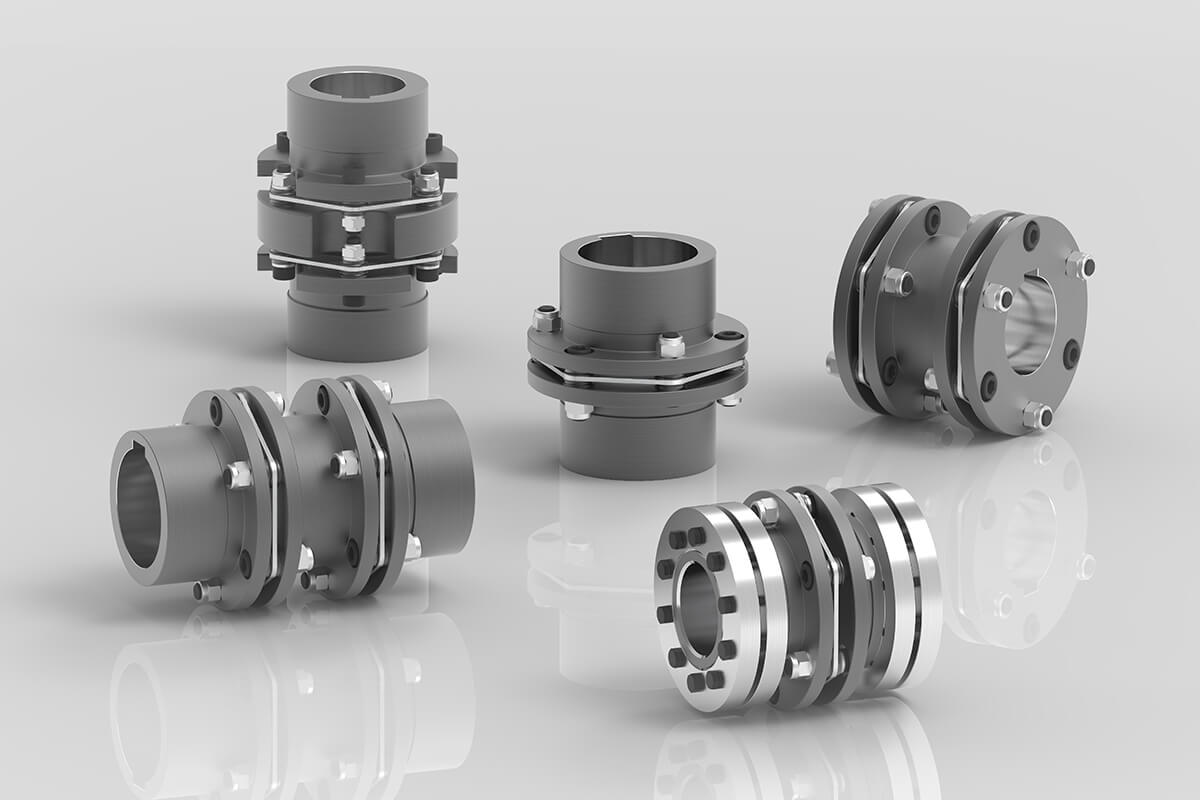

LP series metal disc couplings

High strength disc pack coupling

ST series safety couplings

TORQSET® Safety couplings

SK series torque limiters

Backlash free torque limiters

MK series miniature bellows couplings

Zero backlash, torsionally stiff and highly accurate - Precision couplings from R+W

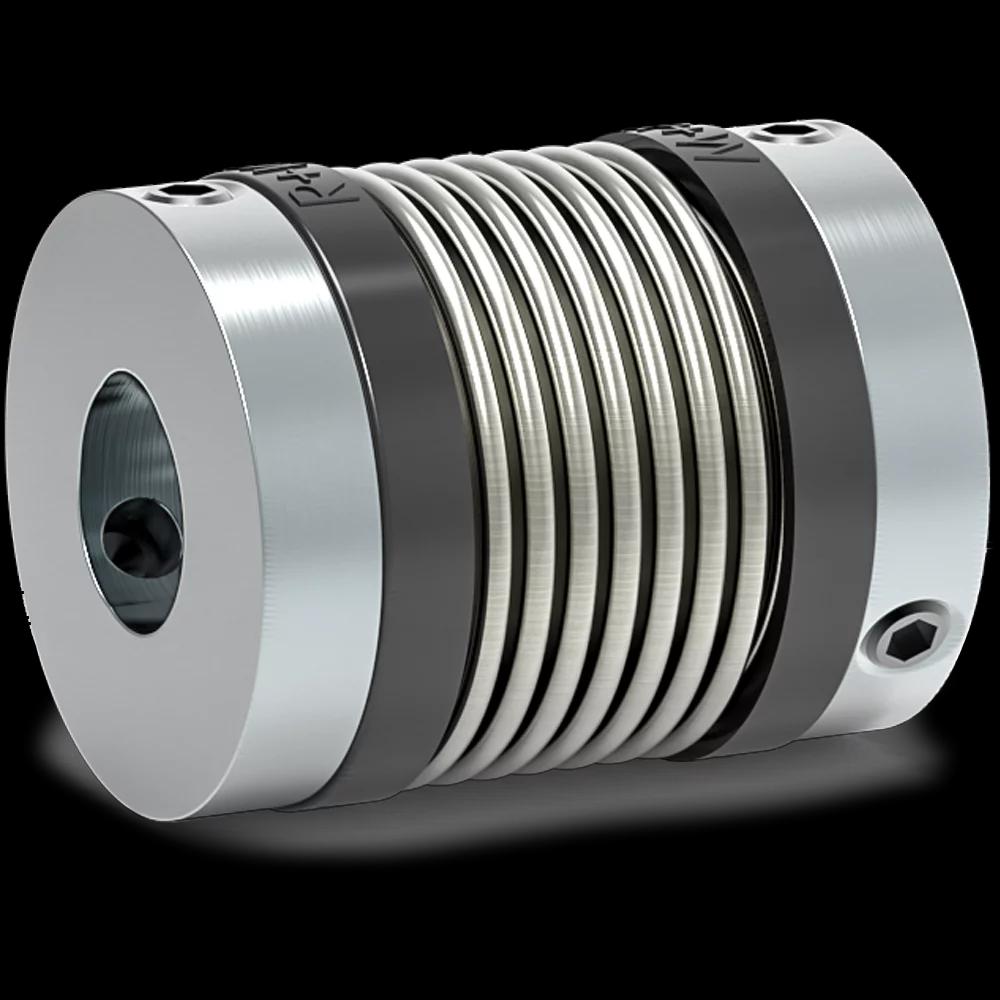

BK series bellows couplings

High precision, zero backlash and torsionally stiff: Bellows couplings from R+W

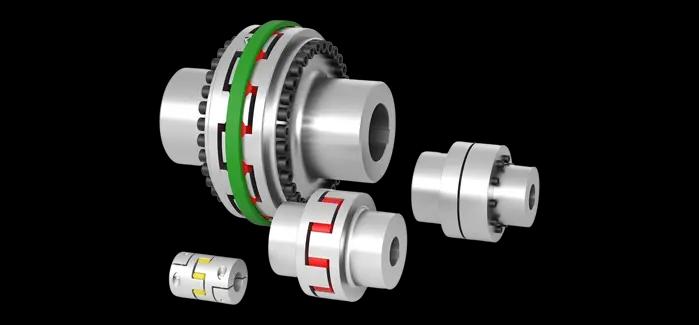

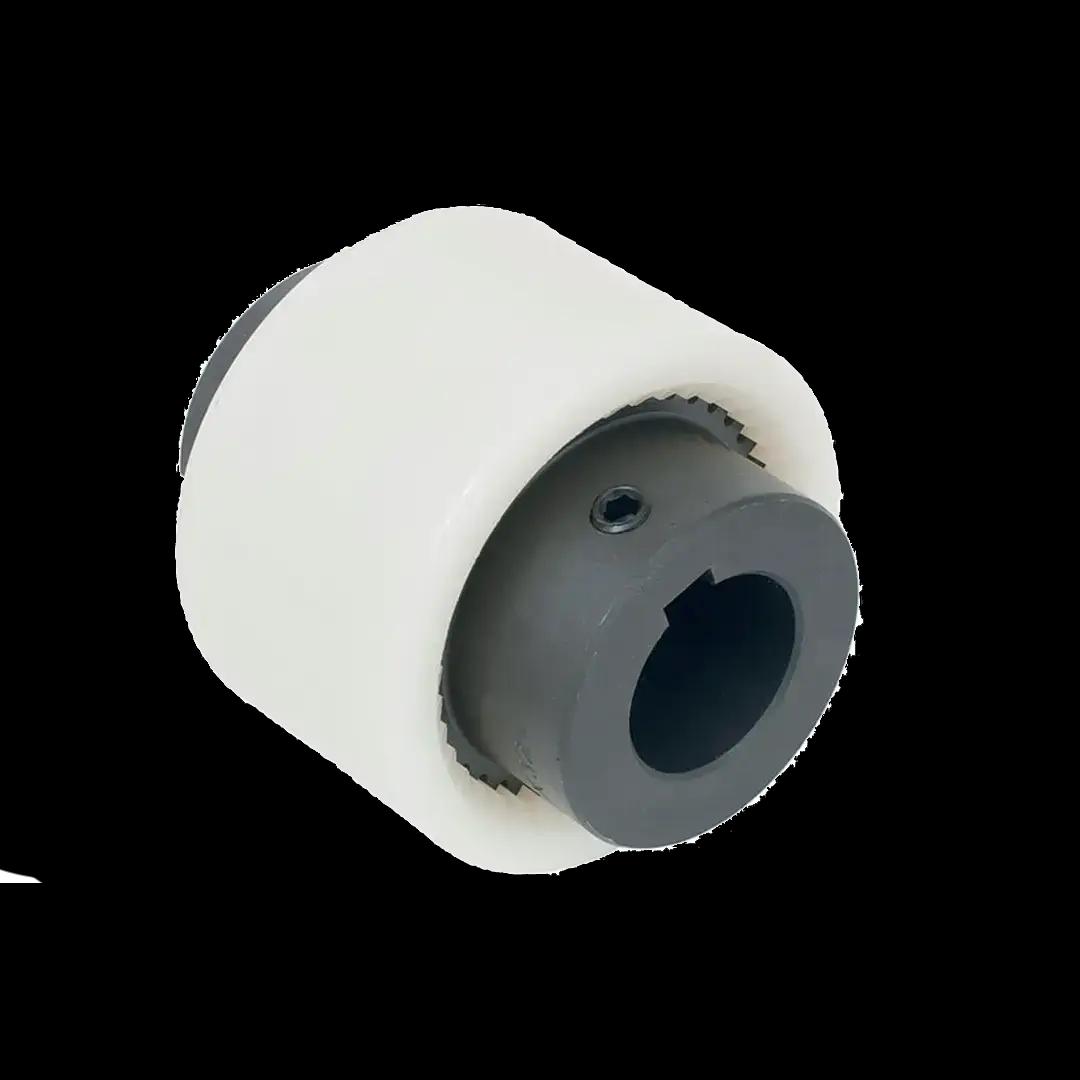

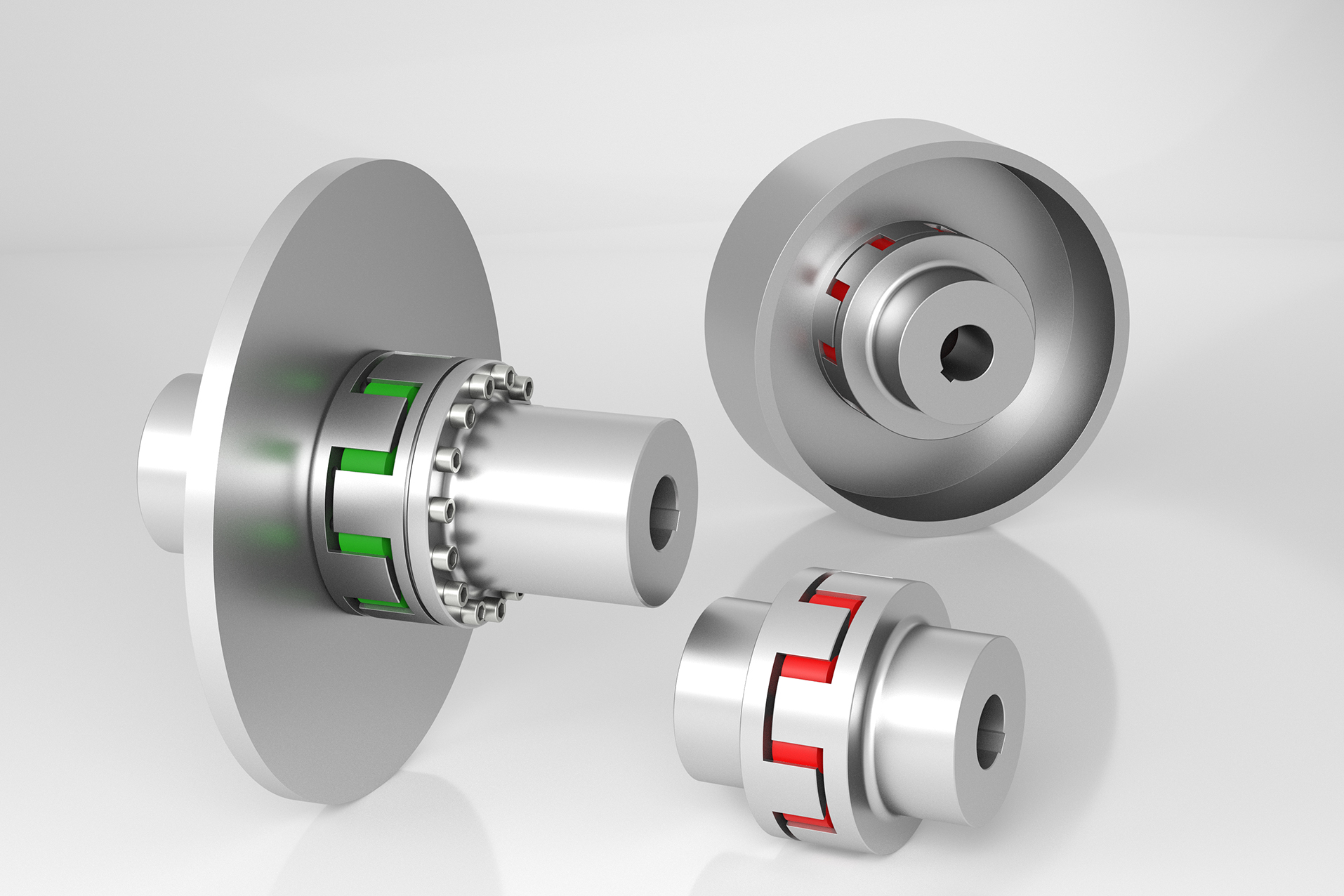

EK series zero backlash jaw coupling

Vibration damping and precise: Elastomer couplings from R+W

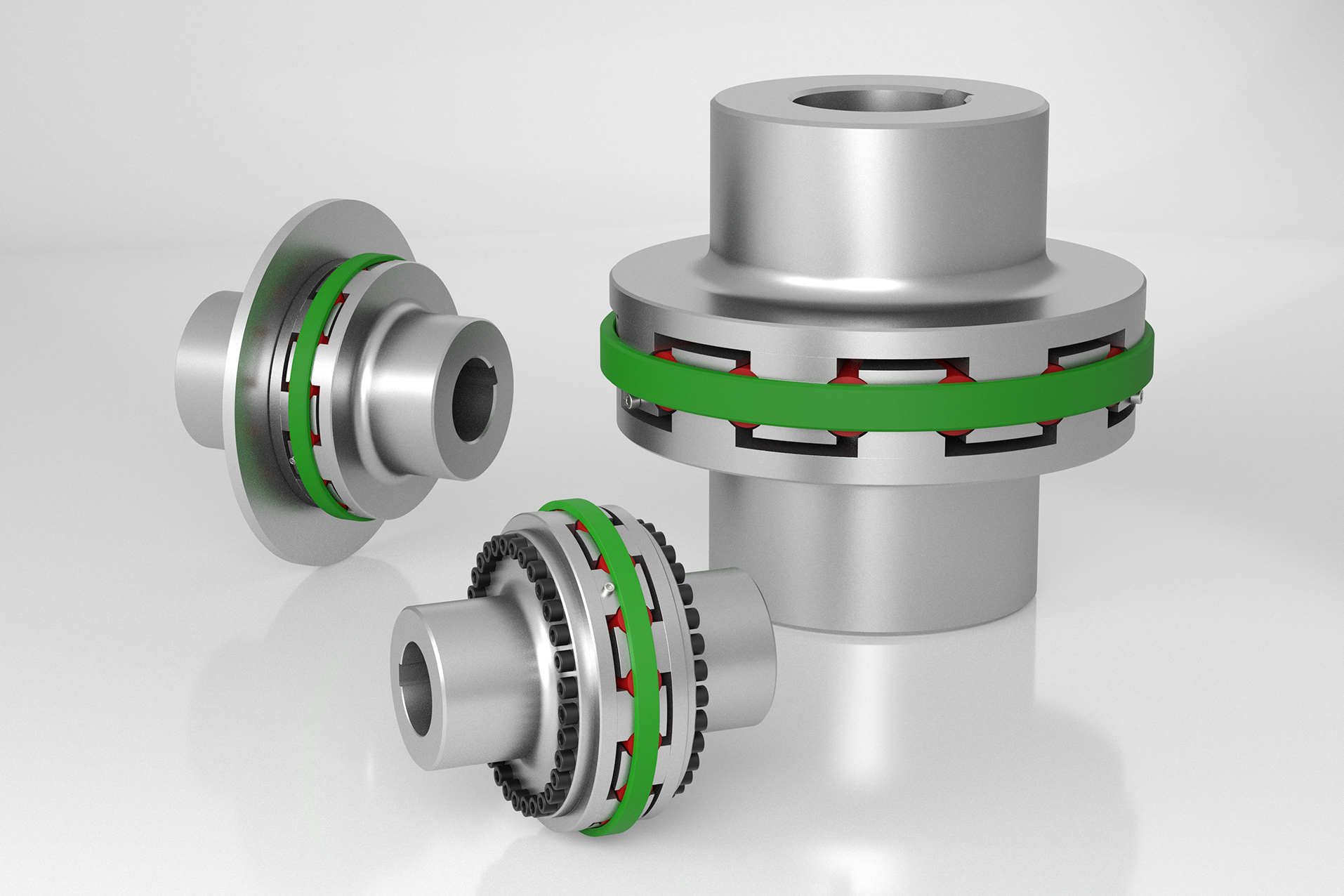

ESAPLUS elastic coupling

ESAPLUS® couplings are made of one elastic element made of pre-compressed, natural rubber, reinforced with steel to be fitted with fixing screws and a metallic band and two metallic hubs made of forged steel

TRASCO ES zero backlash jaw coupling

TRASCO® ES is our zero backlash coupling designed to compensate for misalignment and vibration dampening for indexing applications.

TRASCO jaw coupling

TRASCO® coupling is the flexible and omocinetic coupling that assures the best performance in relation to the physical space occupied in its class.

SITEX FL gear coupling with flange

The SITEX® FL couplings are designed to optimize the connections between Diesel engines and driven equipment such as hydraulic pumps.

SITEX gear coupling

SITEX® toothed couplings consist of two toothed steel hubs, which are connected with one internally toothed sleeve manufactured from stabilized 6.6 super polyamide resin.

SITEX ST steel gear coupling

SITEX® ST couplings are fully manufactured in high quality steel.

METALDRIVE steel disc coupling

METALDRIVE® disc couplings are fully made of steel and are used in all applications where high reliability, precision, and no maintenance are required.

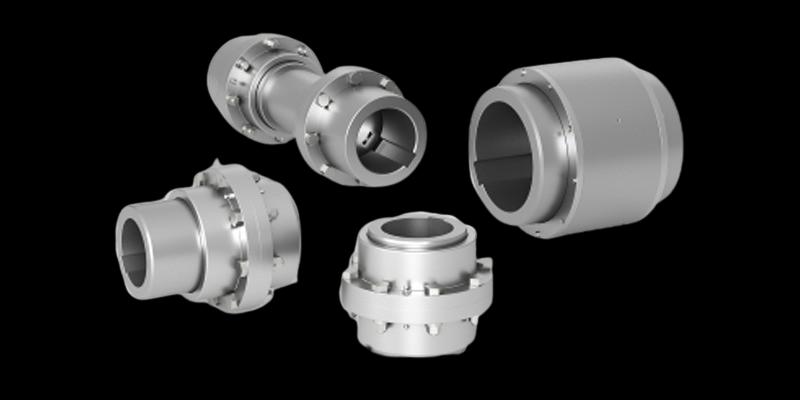

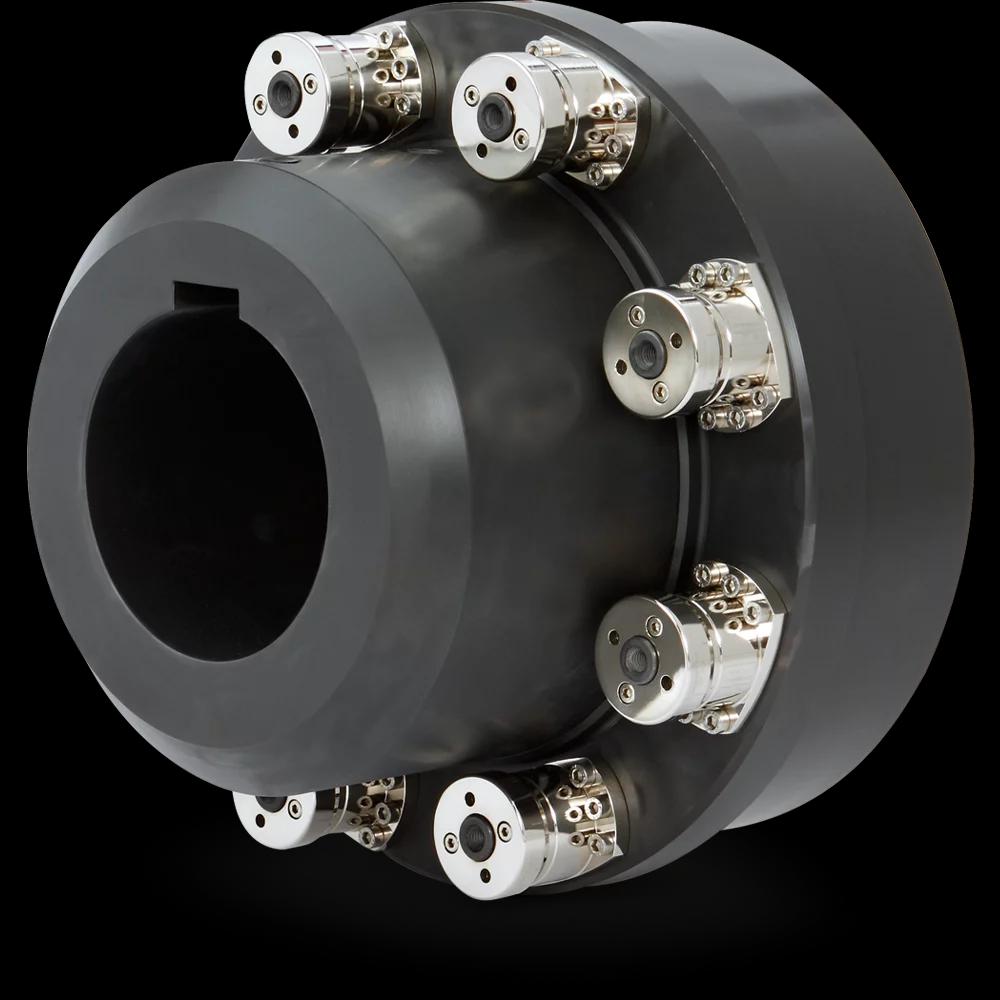

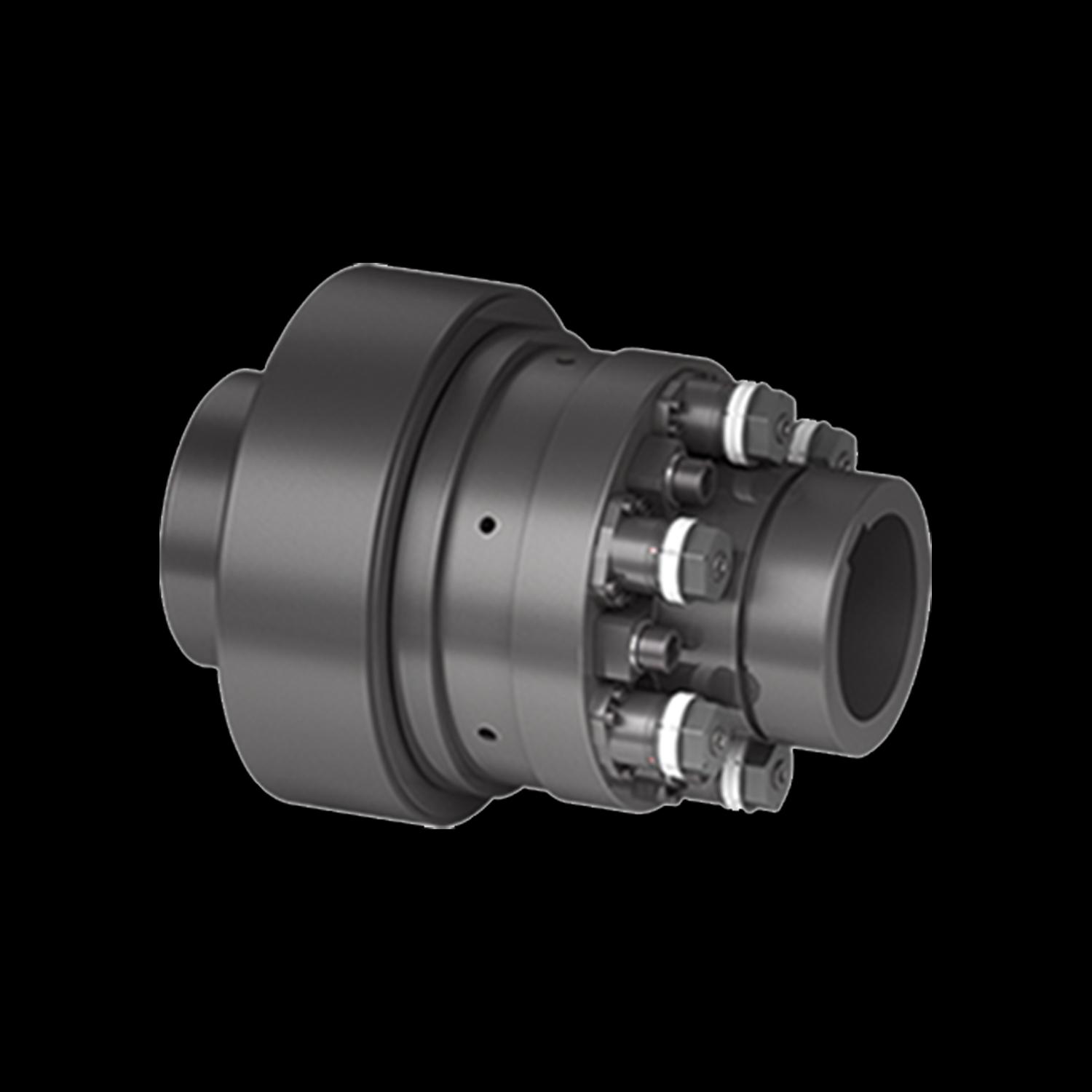

TNF 5571-A

Version A contains standard shrink discs. These are pushed fully onto the flange hub.

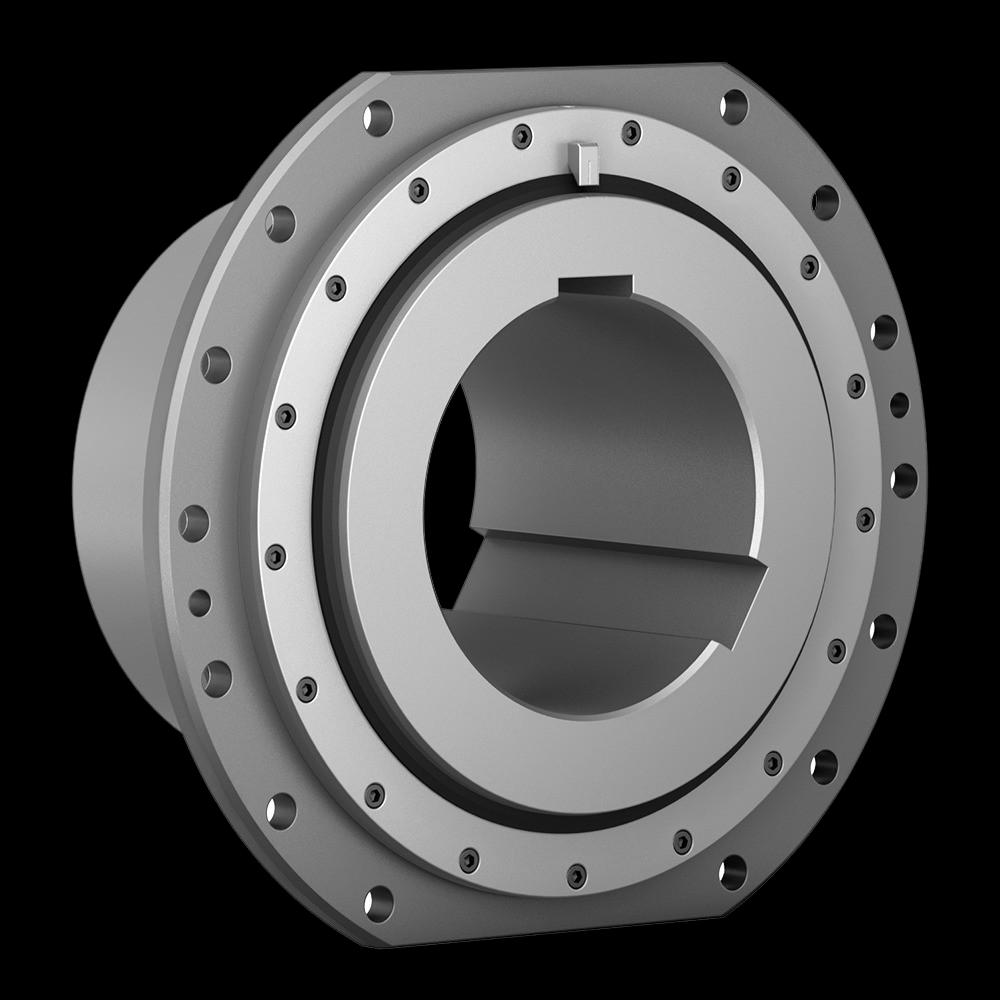

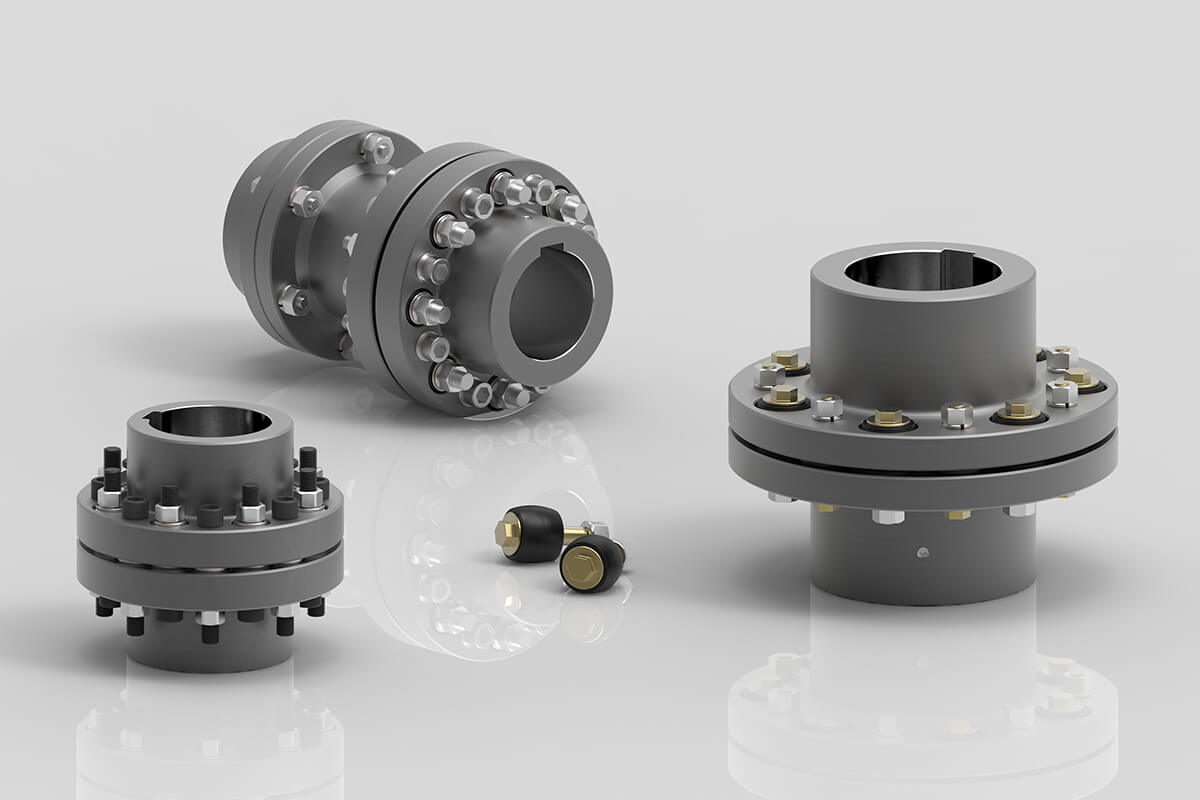

TNC TKVO

The RINGFEDER TNK TKVO is a highly rigid barrel coupling, with both the hub and the housing made from high-strength material.

TNT 2425

Safety coupling design

TNZ ZCAK and ZCBK

The RINGFEDER TNZ ZCAK and TNZ ZCBK are special versions of the TNZ ZCA and TNZ ZCB couplings with limitation of the end float.

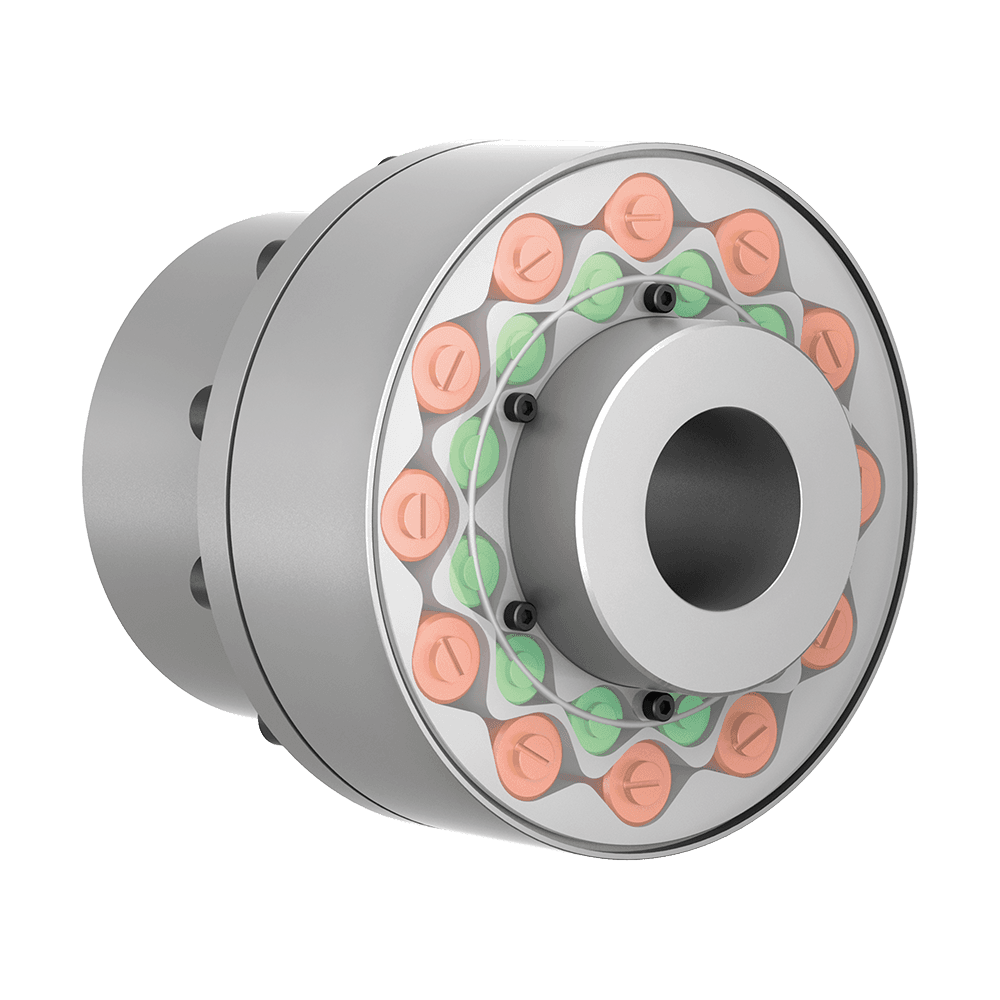

TNR 2428.2 torsional highflex coupling

Every drivetrain has its own characteristic torsional vibration behaviour. The newly developed RINGFEDER TNR provides the precise dynamic stiffness needed for each one.

TNB BH elastomer jaw coupling

The RINGFEDER TNB BH coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TND OCO

Despite its double-cardanic concept, the TND OCO is very short. The double-jointed design with two disc packs compensates for angular, axial and radial shaft misalignments with minimum axial space requirements.

TND HDH

The TND HDH is available as a connecting shaft in standardised or customised lengths.

TNS S elastomer jaw coupling

At least one coupling hub must be removed before the intermediate ring can be replaced.

Downloads

SIT - Spojke kompletni katalog.pdf

SIT - Spojke kompletni katalog.pdf R+W - Industrijske spojke.pdf

R+W - Industrijske spojke.pdf R+W - servo spojke.pdf

R+W - servo spojke.pdf