Stopper/Separating stops

Wörner Stopper/Separating stops

Essential for efficient stop-and-go operation in production and assembly lines

If you're looking to decelerate, stop, or precisely position workpiece carriers, explore our new range of pallet stoppers from our partner Wörner—also referred to as pallet dampers or separating stops. These components ensure smooth and controlled carrier flow in your production line.

A pallet is a mechanical carrier used in automated assembly lines to transport products like gearboxes, battery packs, or smartphones along belt or roller conveyors. Efficient handling of each carrier involves guiding and stopping it precisely—whether at assembly stations or accumulation zones.

At each workstation, whether manual or automated, Wörner stoppers hold the pallet firmly while the conveyor continues to run.

Wörner offers one of the most comprehensive product ranges on the market, including:

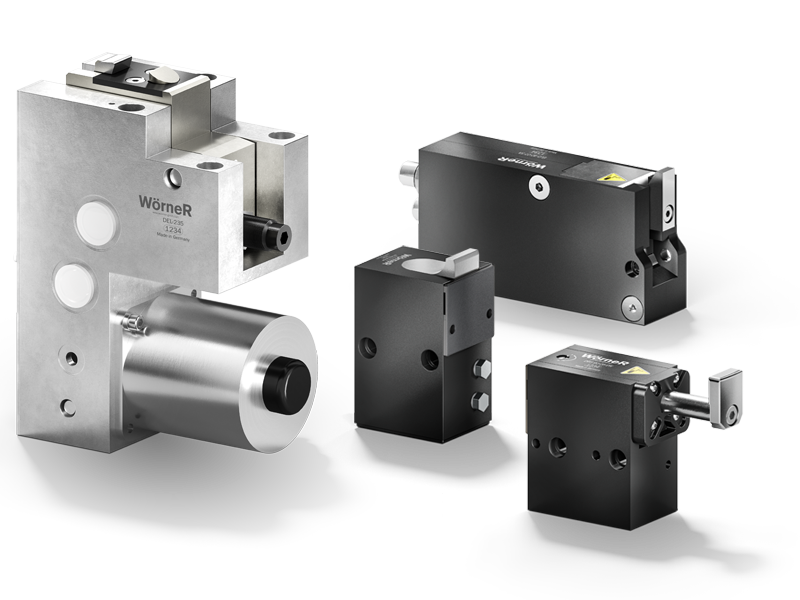

- Stopper/Separating Stops

Reliable stopping and precise positioning of one or more workpiece carriers at a defined stop point. Designed for seamless integration into modern conveyor systems, these units are available in variants featuring integrated damping technology for smooth, vibration-free stopping. The workpiece carrier is released for further transport by lowering the stop plate. Pneumatically or electrically driven.

All pneumatic stoppers

All electric stoppers - Stopper for Roller systems

Featuring a slim design, for use in roller conveyor systems. This stopper is ideal for seamless integration into roller conveyor systems. Its compact construction eliminates the need to remove or omit rollers, ensuring the efficient operation of your system. Perfect for applications in automated production.

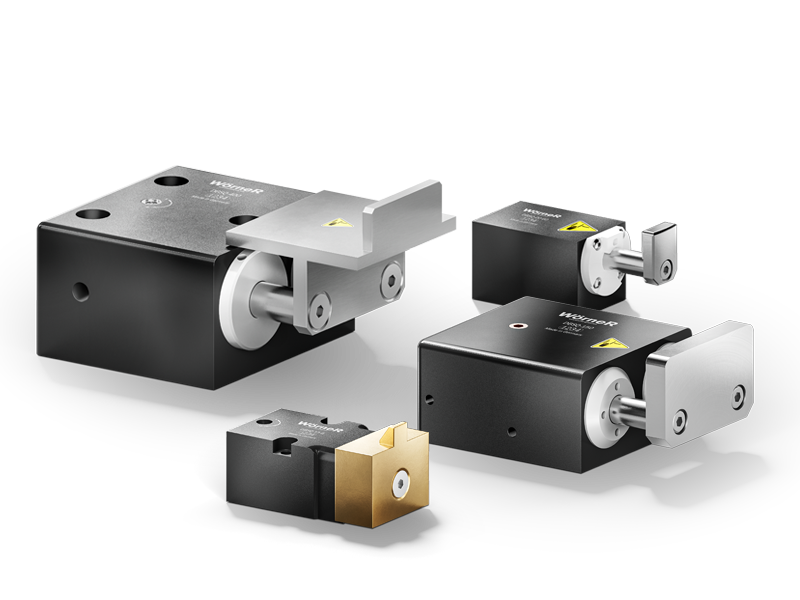

All stoppers for roller systems - Angle dampers

The angle damper enables smooth stopping and precise positioning of a workpiece carrier at a defined stop point, in conjunction with a change of direction or at the end of a stitch section in conveyor systems. Operating without a lowering mechanism, this compact unit provides an efficient and reliable solution for precision material handling and optimized conveyor flow.

All angle dampers - Index cylinders

Designed for highly accurate positioning and lifting of workpiece carriers from the conveyor, index cylinder is a cost-effective and user-friendly alternative to conventional lifting and positioning units. Its compact design and ease of integration make it an ideal choice for efficient and precise automation systems.

All index cylinders - Anti-bounce stops

Anti-bounce stops hold the workpiece carrier at the stop point with pinpoint accuracy and zero rebound. Mainly used in conjunction with undamped stoppers and for conveyors with a low coefficient of friction. Also, ideal for blocking the material flow against the intended conveying direction, such as manual workstations or lifts. Optionally with lowering of the pawl to enable reverse operation.

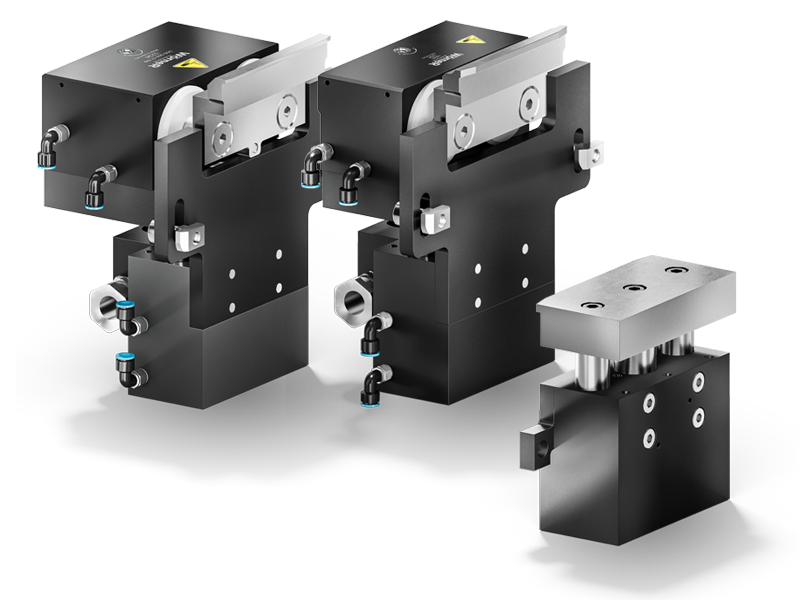

All anti-bounce stops - Acceleration Units

Quickly accelerate the workpiece carrier to match conveyor speed immediately after the work cycle is completed, enabling a significant reduction in overall cycle time. This efficient acceleration enhances throughput and optimizes production flow in automated conveyor systems.

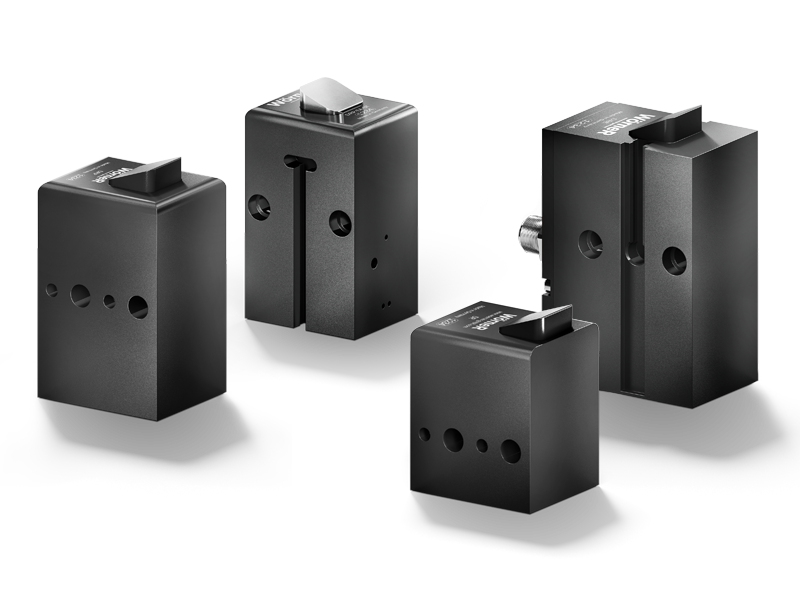

All acceleration units - Displacement Stops

Efficiently control material flow at conveyor crossings, enabling smooth transitions between longitudinal and transverse transport directions. The narrow design fits perfectly between two parallel longitudinal sections, allowing individual control of all positions for maximum flexibility in complex conveyor systems.

All Displacement Stops

All technical details, data sheets, and available variants can be found by clicking the link below

Contact us if you have any questions.

Contact us