“Our verifier is the judge”

Precision above all: why opt for standardized verifiers? In the world of traceability, where every code must guarantee perfect readability at every stage of the supply chain, it's essential to use reliable, standardized metrology tools.

Isabelle Peuzet Prud’hon

Product Manager for MICROSCAN & OMRON Verifiers

In the world of traceability, where every code must be perfectly readable at every stage of the supply chain it's essential to use reliable, standards-compliant metrology tools.

Unlike a simple scanner, which can be affected by external factors, a certified verifier like those offered by BIBUS France acts as a truly impartial judge. It assigns a “grade” to each code, ensuring its quality and compliance throughout the supply chain. Isabelle Peuzet Prud’hon, an expert in barcode verifiers, explains why these tools are critical to ensuring reliable and secure traceability.

Why is it essential to use a certified verifier rather than a simple scanner?

“I would say our verifiers are like calibration tools they're the ‘judges’. They determine, right after production, whether a product meets quality standards for barcode readability. This ensures that codes will be correctly read throughout the supply chain, regardless of the applications being used. Unlike scanners, which are subjective, our verifiers are entirely objective. They are based on metrology tools that comply with ISO standards.”

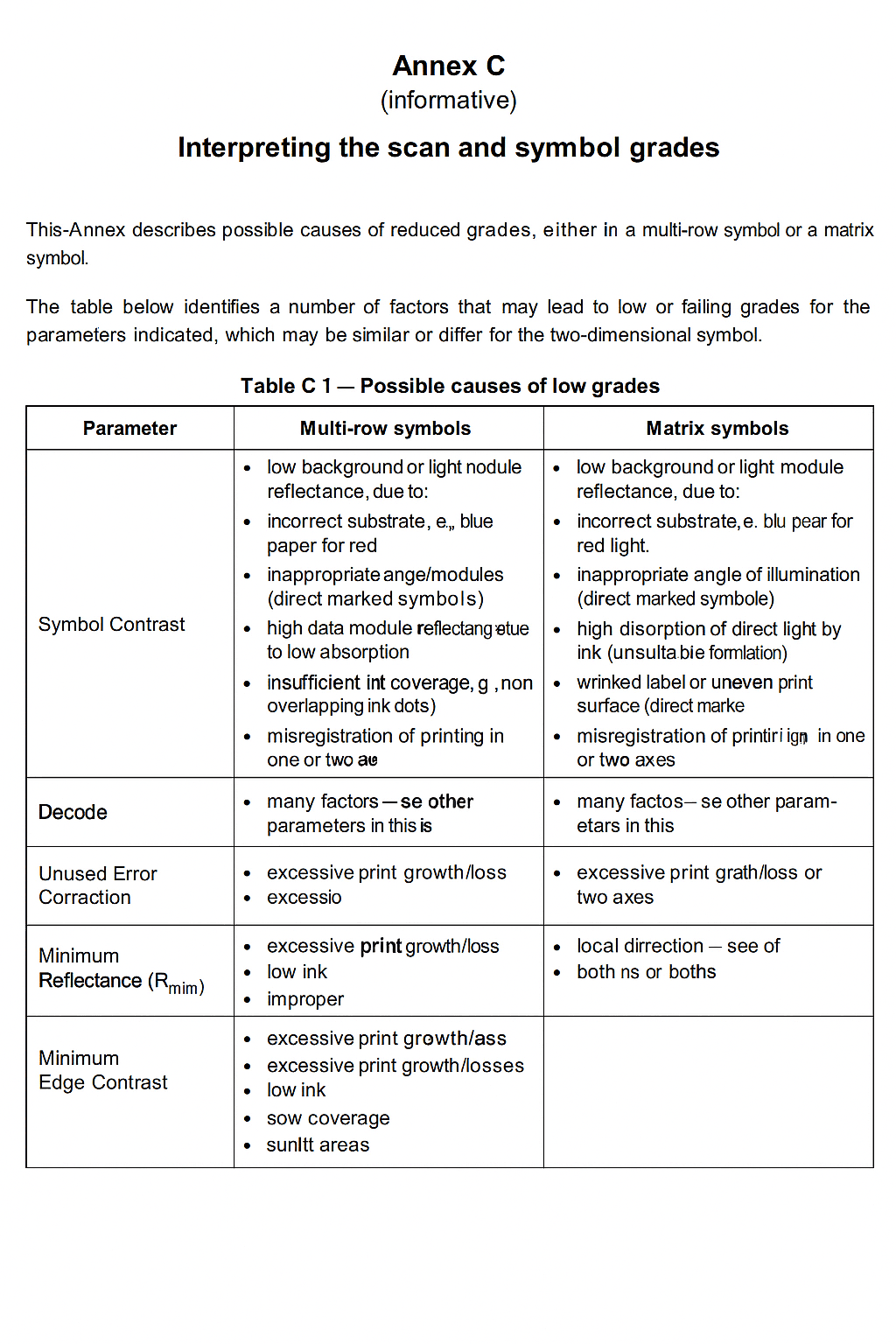

Below is an excerpt from ISO standard 15415, which outlines the criteria used by our range of verifiers to assess print quality.

"There is no room for interpretation."

When there is a drop in quality, the goal isn’t to punish, but to prevent a product with a potentially unreadable code from reaching the market.

It also allows for adjustments to be made to printing machine settings.

We step in to support teams whether they’re printers, manufacturers, or freight forwarders to ensure optimal quality. The verifier’s camera provides a precise view of the situation, detecting potential anomalies and assessing whether a code may become unreadable over time.

If a risk is detected, everything is stopped immediately. We investigate different hypotheses: Is it a conveyor speed issue? A print speed problem? Clogged nozzles? A laser issue? A wrinkled ribbon?

Thanks to the device and the analysis it provides, we can pinpoint where the problem lies and take preventive measures. What I always say is that a verifier enables predictive preventive maintenance.

For example, if after six months we know that a client’s laser is likely to become misaligned, we can anticipate this. When that time comes, we measure all the parameters of the printing machine to avoid drifting into a failure state.

Because that failure could mean non-compliance and potentially scrapping an entire batch of products.

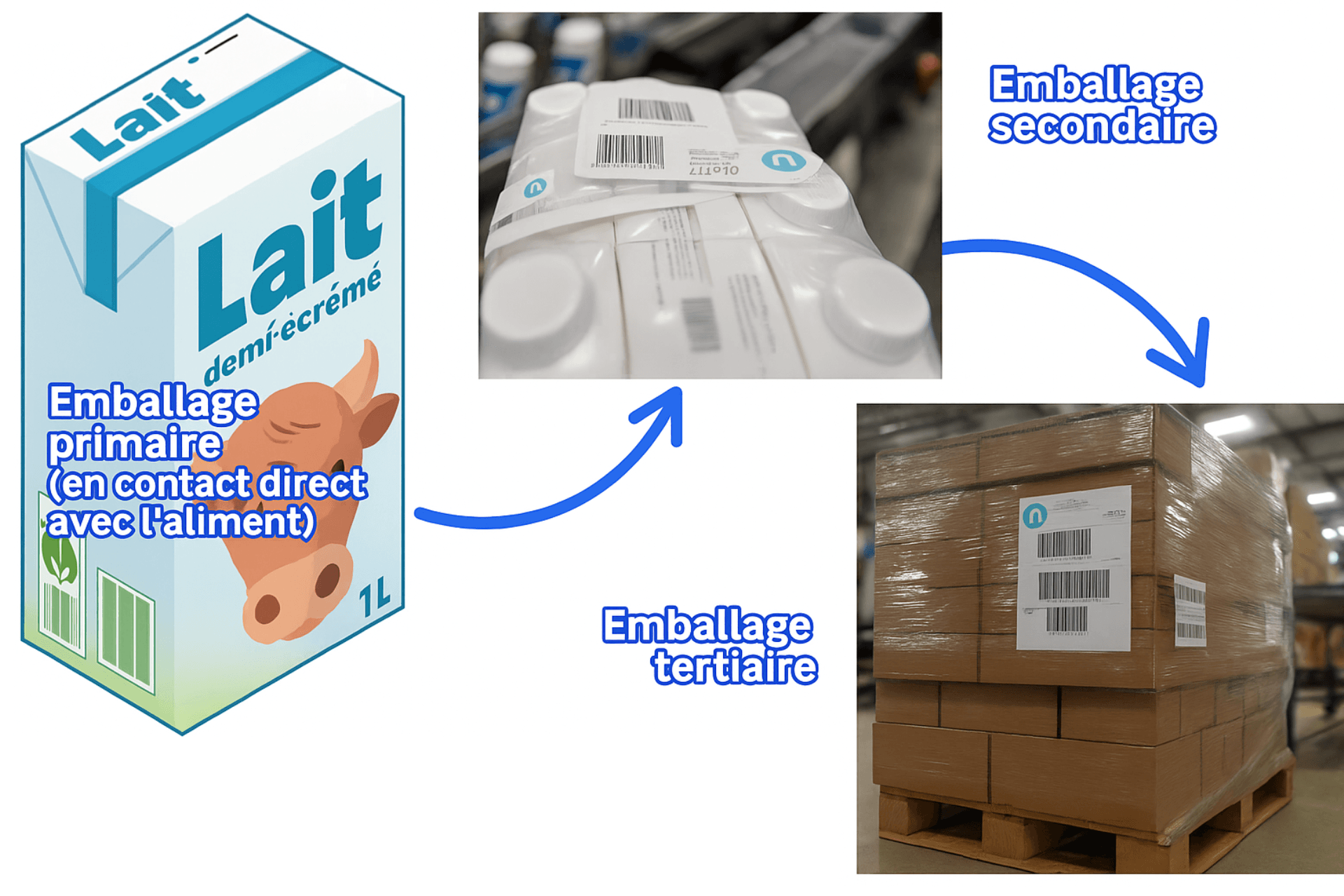

Is print quality measurement possible on all types of packaging?

Yes. On a carton, a titanium part, a plastic component, an automotive part, a perfume box, a label, a shipping carton, or even a pallet. In other words, from primary products to tertiary packaging.

How do grading and compliance with ISO standards influence the release of products throughout the supply chain, from the factory to final distribution?

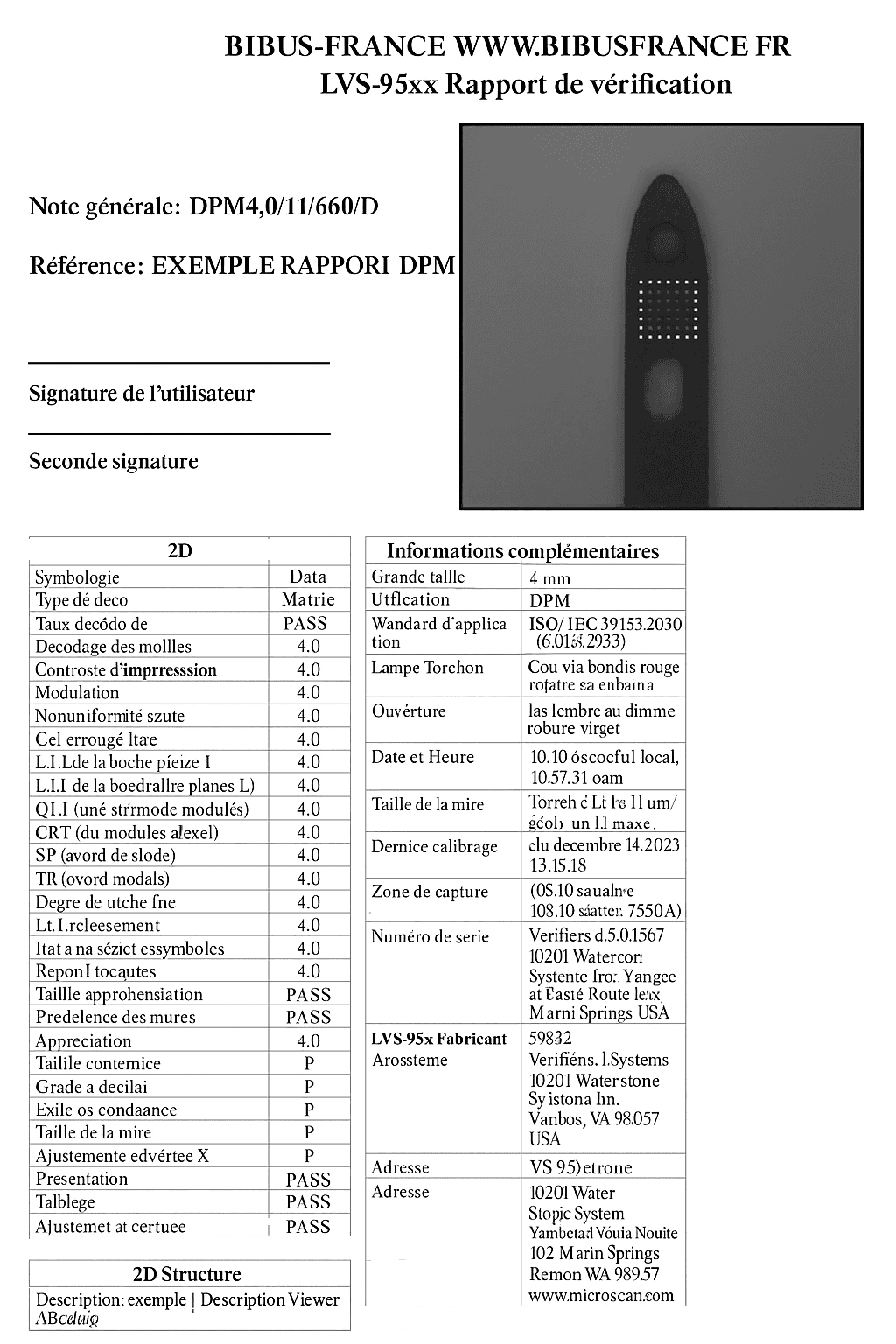

At BIBUS France, our added value lies in our ability to ensure barcode quality by precisely measuring it, through an evaluation we refer to as a “GRADE.” This grade is an overall score, assessed on a scale from 0 to 4, which determines whether a product can be released to the market.

The grade must be equal to or higher than the minimum required score, which is defined either by a specific ISO standard (such as ISO 15415/15416 for printed codes or DPM 29158:2020 for direct part markings like engraved or dot-peened codes), by an application standard (such as GS1, HIBCC, IFA, etc.), or by the customer’s specifications.

Our measuring device the verifier, whether mobile or integrated into a printer ensures compliance with these quality standards. It generates an objective report with a score based on various quality criteria.

This measurement process is not just a formalityit ensures that the code remains readable at every stage of the supply chain, whether in a hospital, a supermarket, a logistics warehouse, or a pharmacy. This way, we guarantee that the code fulfills its function throughout the entire supply chain, from the manufacturer to the end consumer.

Application examples:

- Automated production line

- Warehouse

- Supermarket self-checkout

- Pharmacy barcode scanner

How does your work contribute to the circular economy, a growing priority?

Traceability is essential to supporting the circular economy, as it ensures that products can go through multiple life cycles. In industries such as automotive or electronics, components can be reused or recycled provided they are clearly identified. This allows each part to be tracked from production through to recycling.

Another relevant example is the use of enhanced QR codes, which facilitate product traceability in reuse or recycling contexts. When properly applied and verified, these codes ensure that each product can be tracked throughout the various stages of its life cycle, thus promoting a sustainable and controlled approach to supply chain management.

Is sustainability a priority at BIBUS France?

Yes. Our solutions are not just technical tools they embody a true commitment to excellence, reliability, and compliance with ISO standards. With our tools, we ensure that every step of the supply chain runs smoothly, contributing not only to safety but also to promoting a more sustainable and responsible approach with a long-term vision.

Thank you, Isabelle Peuzet Prud’hon.

Isabelle Peuzet Prud’hon

Product Manager, LVS

Tel. +33 2 32 32 58 23

Mobile +33 7 61 63 19 45

Related articles

Since 8 December 2023, the wine and spirits industry has had to conform to current French and European regulations.

In a world where traceability is a guarantee of safety for consumers and patients, barcodes play a decisive role.

Designed to check the legibility and conformity of engraved or printed barcodes, barcode verifiers check various types of linear, two-dimensional and stacked linear combinations.

Les codes-barres linéaires que nous connaissons depuis plus de cinquante ans sont voués à disparaître. De plus en plus obsolètes, de nouveaux usages de consommation et de nouvelles réglementations les remplacent au profit des Flashcodes.