Intervention robotics: when extreme conditions dictate mechanics

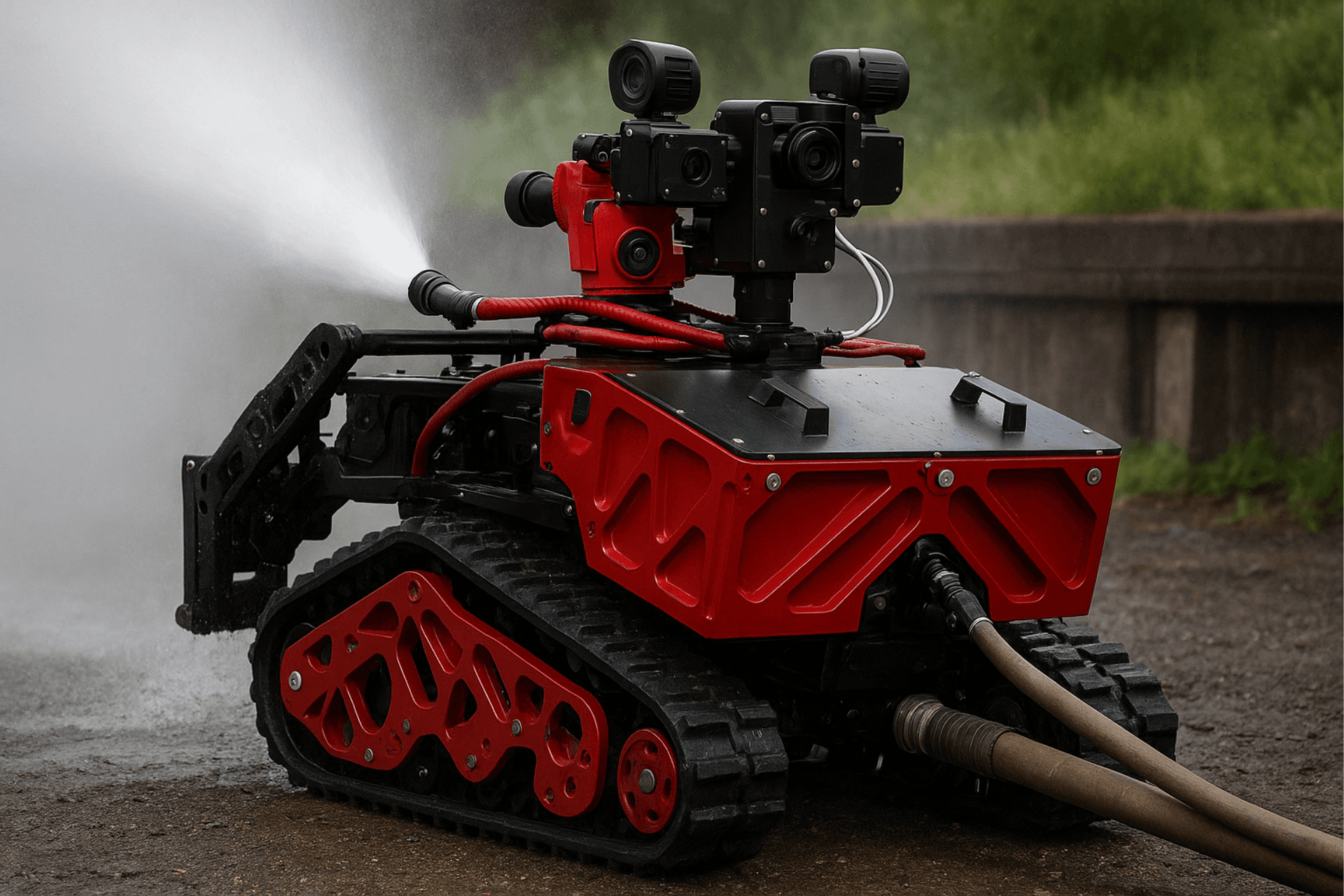

In urban or industrial fires, on polluted sites, or in dismantled power plants, there are zones where every second counts and every meter covered is a risk.

Where humans cannot go, machines must go… and return.

In urban or industrial fires, on polluted sites, or in dismantled power plants, there are zones where every second counts and every meter covered is a risk.

Firefighters know these zones all too well.

Smoke inhalation, sudden surges in temperature, or what firefighters call a “roll-out” when smoke ignites and the heat jumps from 600 °C to 1,000 °C in an instant can kill in seconds.

In these conditions, sending a human first is no longer an option.

The robot as a safety scout

This is where heavy-duty assistance robots, also called service robots, come into play.

They are tactical allies that enter the zone first, spray water to cool the area, reduce the average temperature, secure the ground, and open the way for human teams.

But for these critical missions to succeed, their motors must meet challenges that very few players know how to tackle.

That was precisely the issue raised by one of our clients, who turned to our design office, BIBUS Solutions.

A no-compromise set of requirements

The project team listed demands that are rare in mobile robotics:

- Extreme mobility: navigating debris, obstacles, and steep ramps

- Maximum compactness: delivering high power in a very limited space to preserve the overall robot design

- Absolute reliability: no risk of failure during missions, zero tolerance for defects

- Firefighter safety: mechanical disengagement without tools, operable even with thick gloves, and usable in emergencies

Why standard solutions were not enough

The market offers decent drives for crop robots or flat-surface vehicles. But in extreme situations, these motors max out.

Low-cost solutions fail as soon as slopes or obstacles multiply.

That’s the difference between rolling on flat ground… and saving a life in a critical zone.

The BIBUS Solutions contribution

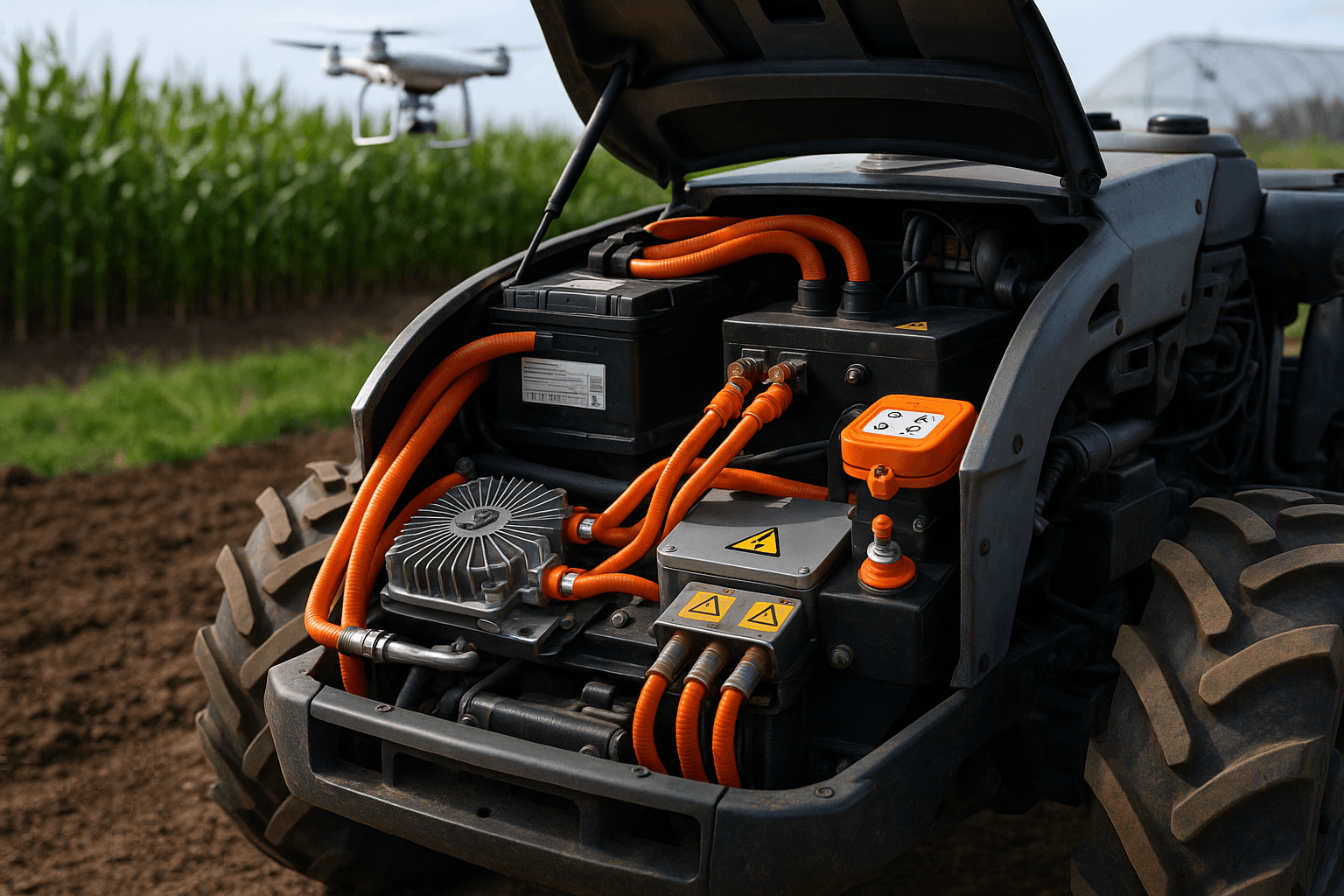

Our design office developed and integrated a turnkey solution:

- 2 I&W Engineering wheel gearmotors: compact, powerful, and sized for the mission’s demands

- DMC SUPERSIGMA drive control: ensuring compatibility, energy optimization, and precise control

- Custom mechanical disengagement system, designed in-house, tested to withstand field constraints, and operable with a single safe gesture in real conditions

- On-site commissioning with a single technical contact to minimize interfaces and reduce the risk of information loss

Our system allows:

- Maximizing compactness while increasing available power

- Reducing technical interfaces, lowering friction points

- Ensuring field reactivity: smooth integration, operational prototype in record time

- Securing missions: robots that complete their task without blockage or overheating

Beyond firefighting: agriculture and industry in the extreme

The same logic applies in other environments:

- Vineyard robots for steep slopes

- Intervention robots for underground parking with tight ramps

- Tactical vehicles operating in contaminated or rugged zones

Once again, the value lies not in the lowest price, but in full functionality tested and validated.

Why we don’t do salad-picking robots

At BIBUS France, we could make crop robots. You know, the little machines that help farmers harvest lettuce. Flat ground, no big stakes, cheapest possible.

We don’t. Why? Because we’d be twice as expensive as the market, and competitors already do that job well.

Instead, we design, integrate, and validate systems that turn demanding specifications into operational reality.

Because where failure is not an option:

- The mechanics must be flawless

- Every component must be built for extremes

- And “low-cost” has no place

We always choose the solution that guarantees functional and operational safety, along with long-term performance.

That is our commitment and what sets us apart.

Choose a reliable and sustainable solution. Contact us today to discuss

Related articles

DMC motor controllers are the brain of electrification systems. BIBUS France offers a complete range of high-performance controllers, perfectly suited to I&W Engineering hub motors and the most demanding industrial applications.

The electric wheel motors developed by I&W Engineering and distributed by BIBUS France represent a major advancement in the field of special vehicle electrification. Discover how this patented technology is transforming the industry by offering a solution that is 40% more compact.

Bibus France electrification solutions transform industrial and agricultural vehicles to meet current environmental challenges. Find out how our electric engine and our integrated "plug & drive" integrated systems can propel your business to a more sustainable and more efficient future.