Industrial Automation: Stabilus innovates with ACE and DESTACO for a new collaborative gripping solution

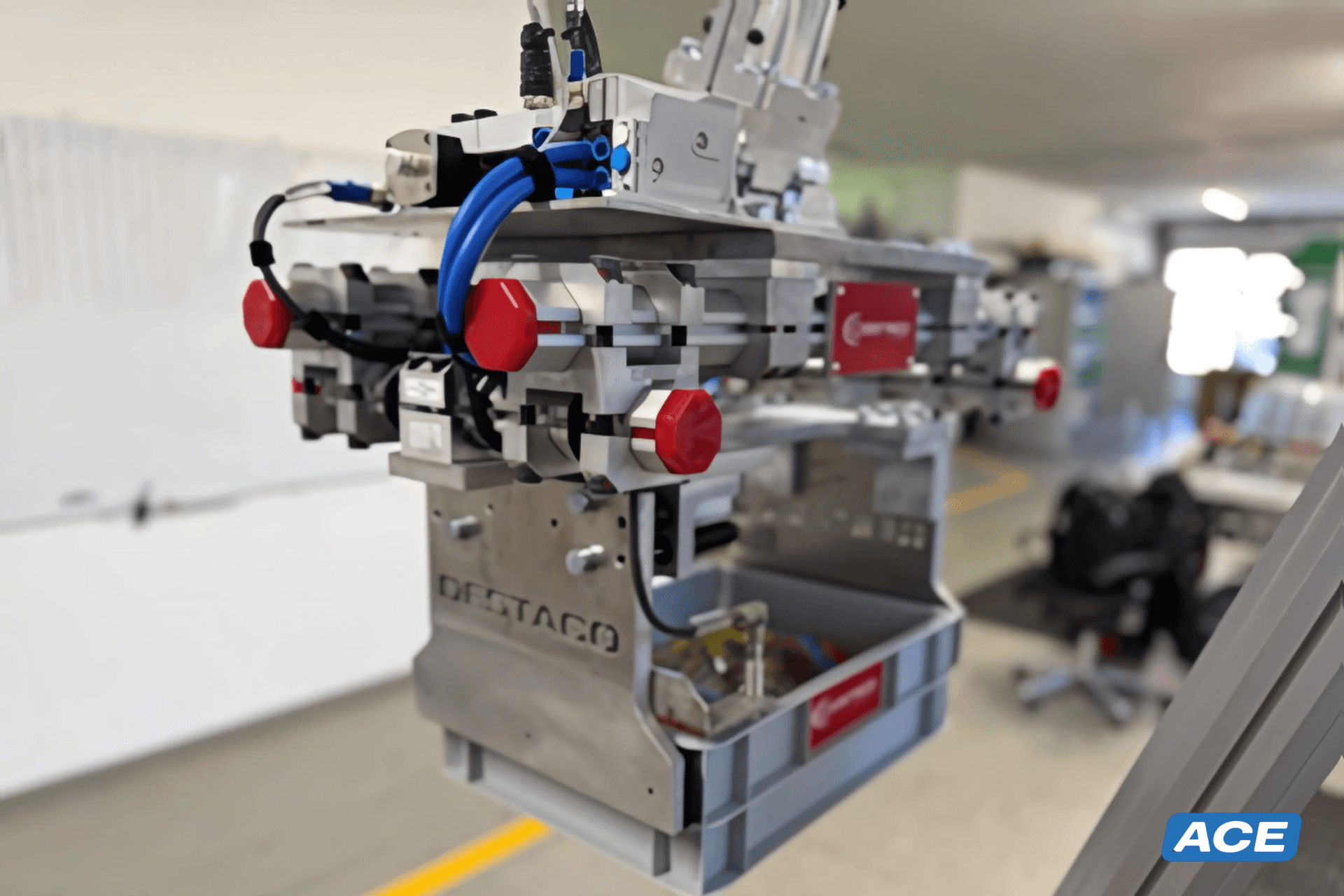

By integrating ACE's precision industrial shock absorbers into DESTACO’s modular gripping systems, Stabilus offers an intelligent, reliable automation solution, perfectly suited to modern industrial cycle rates.

At the Automatica 2025 trade fair in Munich, Stabilus Group introduced a major advancement in its Stabilus4Automation strategy. By combining DESTACO’s expertise in robotic grippers with ACE’s leadership in industrial damping solutions, Stabilus has delivered an innovative collaborative handling solution tailored to a real customer need in automated palletizing.

By integrating ACE's precision industrial shock absorbers into DESTACO’s modular gripping systems, Stabilus offers an intelligent, reliable automation solution, perfectly suited to modern industrial cycle rates. It’s not theoretical, it was designed based on a concrete need in a live palletizing application.

A Smarter Gripper

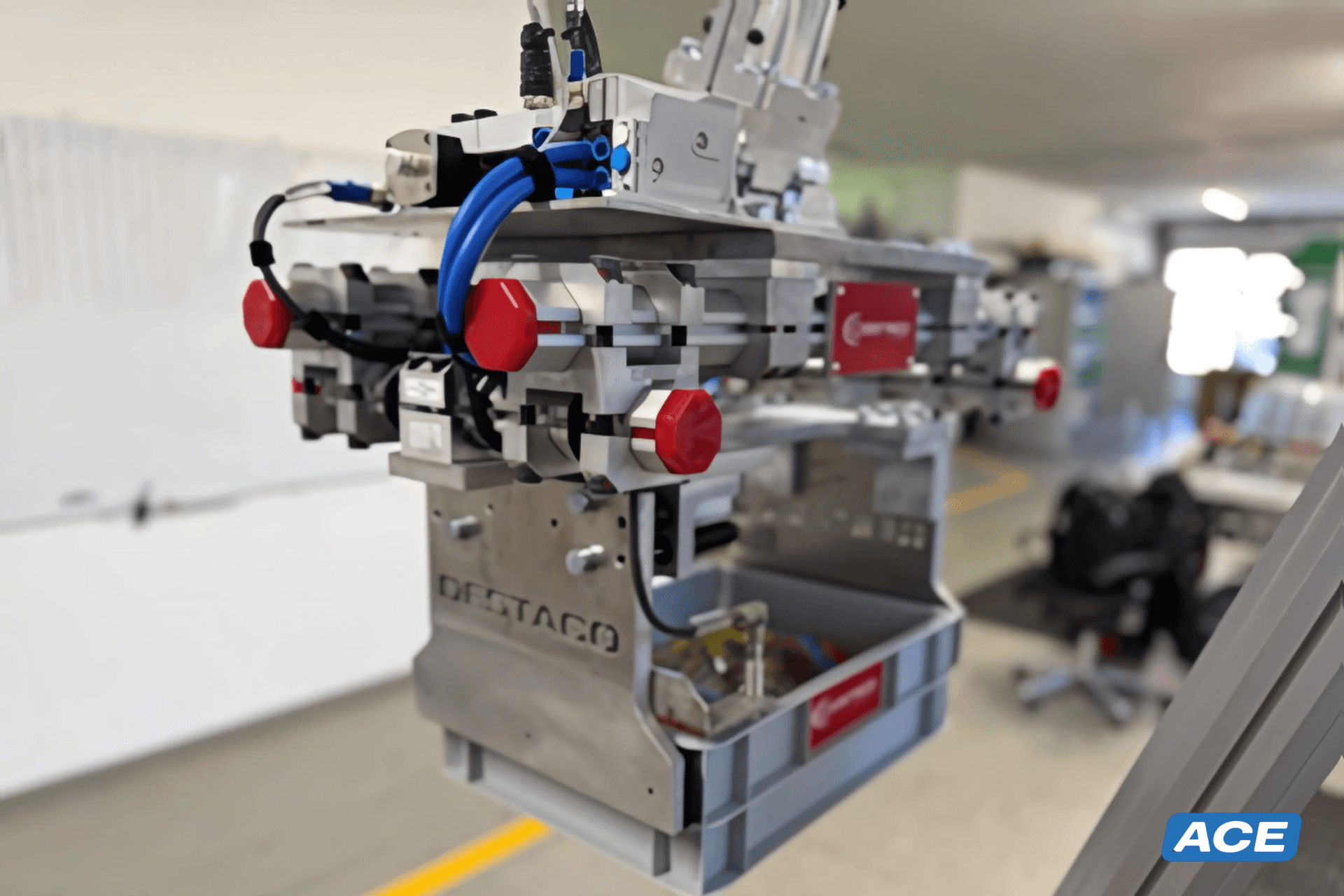

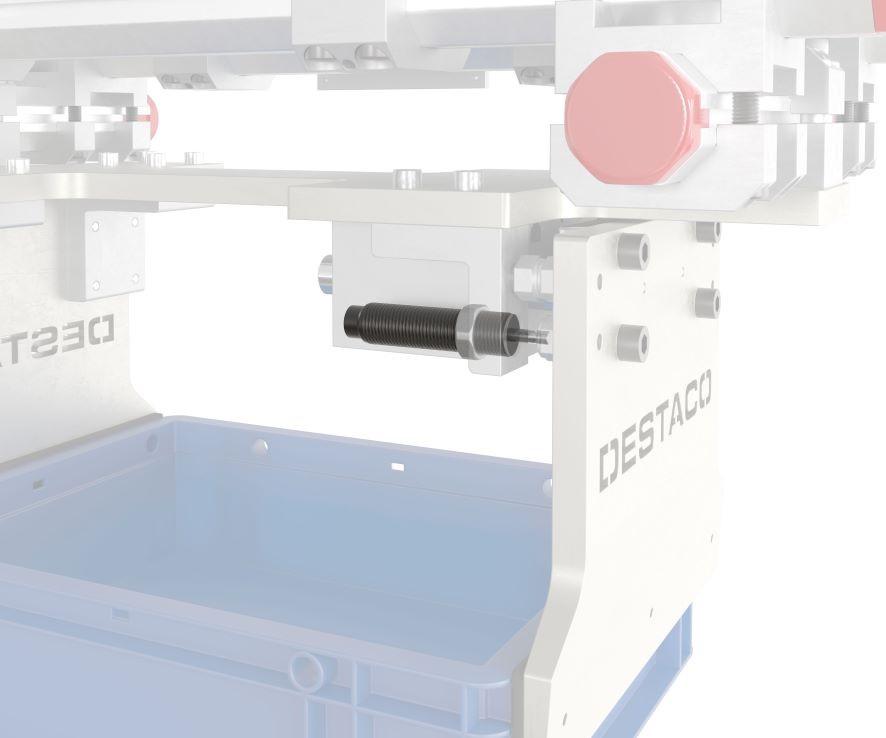

DESTACO’s DBG Series bag grippers, renowned for their speed and reliability, are now enhanced by integratingACE MC series miniature shock absorbers (MC150 to MC600), transforming them into high-performance end-of-arm tooling (EOAT):

- High cycle rate: up to 30 palletizing cycles per minute

- Enhanced versatility: precise handling of boxes, bags, cartons, and rigid or flexible containers

- Optimal safety: enclosed pneumatic toggle-lock clamp with integrated open/close detection secures items even in case of air loss

This ACE + DESTACO synergy reduces maintenance costs, improves product protection, and boosts energy efficiency. The lightweight, modular architecture of DESTACO’s DBG grippers makes them ideal for flexible integration in industries such as food & beverage, intralogistics, packaging, consumer goods, and pharmaceuticals

Want to learn more about the DBG series? Click here.

What this means for your production lines

Enhanced performance and safety

✅ Effective end-of-stroke shock absorption for optimal protection of sensitive components.

✅ Significant vibration reduction, preserving the speed and precision of your processes.

✅ Increased safety, even in the event of air supply failure, thanks to the integrated locking system.

✅ Extended machine lifespan, with controlled damping reducing wear and unexpected downtime.

Flexibility and Easy Integration

✅ Compact design, ideal for retrofitting and integration into existing lines without major modifications.

✅ Versatile use, suitable for handling boxes, bags, and other formats.

Cost Savings and Sustainability

✅ Lower energy consumption enabled by the use of smaller, more efficient pneumatic cylinders.

✅ Reduced maintenance: less wear, fewer interventions, greater availability.

✅ Reduced operating costs (electricity, compressed air), for immediate and long-term profitability.

In Summary:

Accelerated cycle times, secured products and equipment, with easy integration into existing lines. This is what we call useful automation at BIBUS France: ready-to-use, value-adding solutions that don’t disrupt your infrastructure.

A systems-level vision that makes a difference

What makes this innovation truly powerful isn’t just the quality of the components, it's the systemic vision.

ACE and DESTACO designed this solution together tested, validated, and industrialized to meet the real-world demands of production lines.

What does that mean for you, the industrial user?

- Lower integration risks with a pre-validated solution

- Faster ROI thanks to real-time savings on engineering

- Boosted overall productivity

- One single point of contact, combining components, expertise, and system engineering

The ACE + DESTACO solution truly embodies the spirit of Stabilus4Automation: integrated industrial automation designed to reduce cycle times, enhance equipment robustness, and elevate overall competitiveness.

At BIBUS France, we understand how critical these challenges are. Industrial customers don’t have time for siloed engineering or compatibility checks, they need intelligent, validated, integrable functional blocks that solve real business challenges, not just match technical specs.

- Results: Because every cycle gain, every millimeter shaved, every shock absorbed equals hours of maintenance avoided, better-protected products, and sustainable productivity.

- Synergy: A solution co-designed, tested, validated, and integrated equals time saved, stronger safety, and performance delivered without surprises.

Our partnership with Stabilus Group is built on a shared vision: integrated, modular, ready-to-use automation where components, engineering, and application know-how combine to accelerate industrial transformation.

See these innovations live

These revolutionary solutions are being showcased at major international automation trade fairs:

- Automatica – Munich, Germany

- AMTS – Shanghai, China

- Automate – United States

About Stabilus Group

A global leader in motion control solutions, the Stabilus Group operates across numerous sectors: mobility, healthcare, leisure, furniture, energy, construction, industrial machinery, and automation.

With over 90 years of experience and €1.3 billion in revenue in 2024, the Stabilus Group is a worldwide leader in motion control technologies for a wide range of applications.

At the heart of its innovations are systems that enable, improve, or automate safe and efficient motion: opening, closing, lifting, lowering, and adjusting.

________________________________________

Interested in seeing how this solution could fit your production lines?

Contact our BIBUS France experts

We guide you from needs analysis right through to deployment of truly useful automation.

Let’s talk!

Found this article useful? Share it and subscribe to our blog so you never miss the latest in industrial automation!

Share this article

photo gallery

Related articles

Notre service s’élargit, avec les jumeaux numériques à intégrer dans les modèles virtuels. Ce service vient s'ajouter aux logiciels de configuration et de calcul disponible online, aux plans CAO et aux solutions de simulations.

We are proud to present the MC5 to MC75 product family, miniature shock absorbers that push the limits of compactness and efficiency.

Development of a specialized orthosis to combat tremors.

From the most delicate miniature machines to extreme temperature requirements, this comprehensive product line promises to meet the challenges of motion control with finesse.