ACE Controls - Choosing the right MC shock absorber

From the most delicate miniature machines to extreme temperature requirements, this comprehensive product line promises to meet the challenges of motion control with finesse.

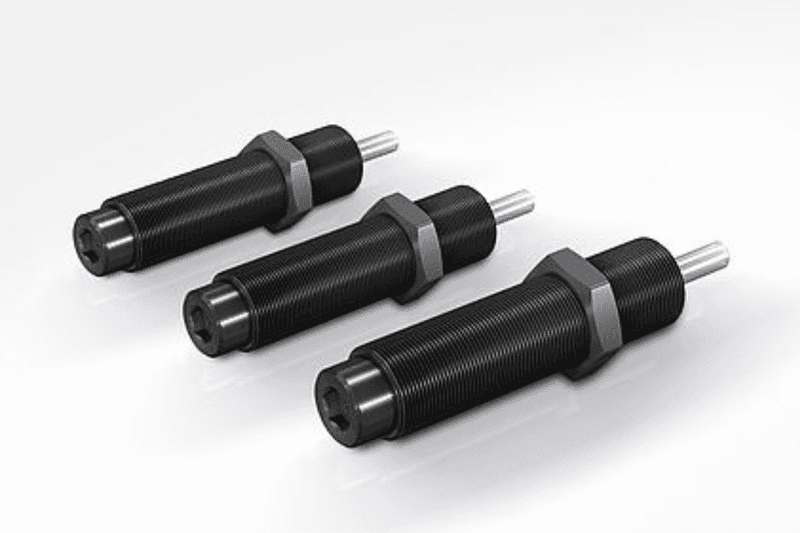

The MC range from ACE Controls presents a wide repertoire of dampers designed to deliver unrivalled performance in a variety of applications. From the most delicate miniature machines to extreme temperature requirements, this comprehensive range of products promises to meet the challenges of motion control with finesse.

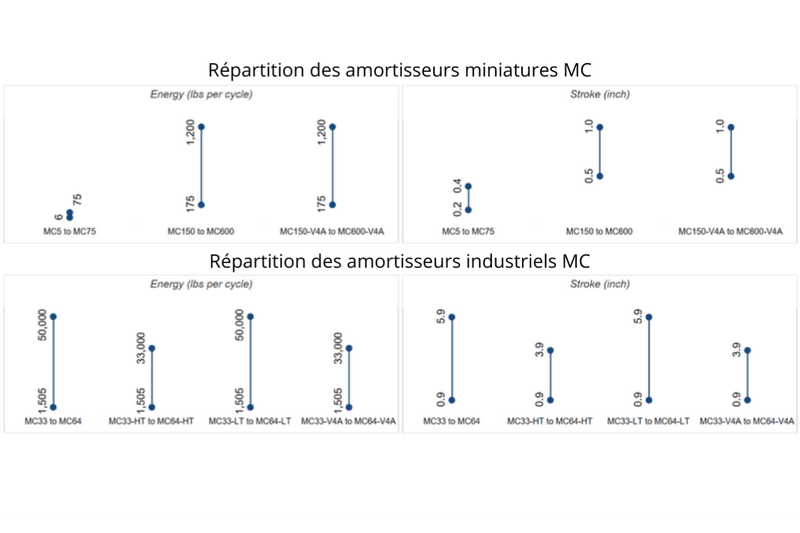

Thanks to the following tables, you can choose the ideal MC range damper to meet your exact requirements.

I. Miniature Shock Absorbers

Miniature Shock Absorbers

MC5 to MC75 Range

The MC5 to MC75 miniature shock absorbers from our partner ACE are ideal for compact designs.

These maintenance-free hydraulic machine elements feature a continuous external thread, an integrated positive stop, and temperature-stable oil, allowing them to absorb a wide range of energy.

Their versatility makes them well-suited to various applications, including rotary actuators, automation, material handling, robotics, and more, in sectors such as:

- electronics

- medical

- light industry

MC150 to MC600 Range

ACE's MC150 to MC600 shock absorbers offer exceptional durability and the lowest reset force. Their sealed rolling diaphragm technology allows for a service life of up to 25 million cycles.

These maintenance-free, ready-to-install shock absorbers feature progressive energy capacities and are compatible with impact angles up to 25° when a side-load adapter is installed. This makes them suitable for a variety of applications:

- material handling equipment,

- packaging equipment,

- medium-sized robotics,

- machine tools

They can also be installed inside a cylinder for end-of-stroke cushioning in pneumatic systems.

MC150-V4A to MC600-V4A Series

The MC150-V4A to MC600-V4A miniature shock absorbers are made of stainless steel and offer high performance, durability, and corrosion protection.

Based on the MC150 to MC600 product series, these self-compensating shock absorbers provide perfectly progressive energy absorption.

Thanks to their stainless steel construction (AISI 316L) and a complete range of stainless steel accessories, they are ideal for medical, electrical, marine, packaging, and chemical applications.

They can also be filled with food-grade oil for food processing applications.

II. Industrial Shock Absorbers

Industrial Shock Absorbers

MC33 to MC64 Range

The MAGNUM range of shock absorbers, MC33 to MC64, offers high energy absorption and a robust design. They feature the latest shock absorber technology with self-compensating capabilities, providing a longer service life and a wide damping range, making them highly advantageous for various industrial automation and machine engineering applications.

MC33-V4A to MC64-V4A Range

The MAGNUM range of shock absorbers, MC33-V4A to MC64-V4A, offers optimal corrosion protection thanks to their stainless steel construction (AISI 316L) and a special oil suitable for the food industry.

These self-compensating industrial shock absorbers offer high energy absorption capacity, a wide damping range, and a robust design, making them ideal for various industries: food, medical, electronics, offshore, etc.

MC33-HT to MC64-HT Range

The MC33-HT to MC64-HT shock absorbers in the MAGNUM range are specially designed for high-temperature and high-cycle applications.

Thanks to special seals and fluids, they can operate reliably at temperatures ranging from 0°C to 150°C, offering a wide damping range and high energy absorption in a compact design.

These self-compensating industrial shock absorbers are well-suited to harsh conditions and find applications in factories, industrial automation, and machine engineering.

MC33-LT to MC64-LT Range

The MC33-LT to MC64-LT shock absorbers in the MAGNUM range are designed for applications in extreme low temperatures, with the ability to operate reliably in temperatures ranging from -50°C to 66°C.

These self-compensating industrial shock absorbers offer a wide damping range, high energy absorption in a compact design, and robust sealing technology, making them well-suited for various industrial, automation, and machine engineering applications, even in adverse conditions.

Related articles

ACE, world leader in damping technology in terms of quality and service, offers a complete range of innovative solutions to make your production processes more efficient and sustainable.

Emergency stop systems are essential safety mechanisms designed to stop machines rapidly in dangerous situations, to prevent accidents and protect your employees.

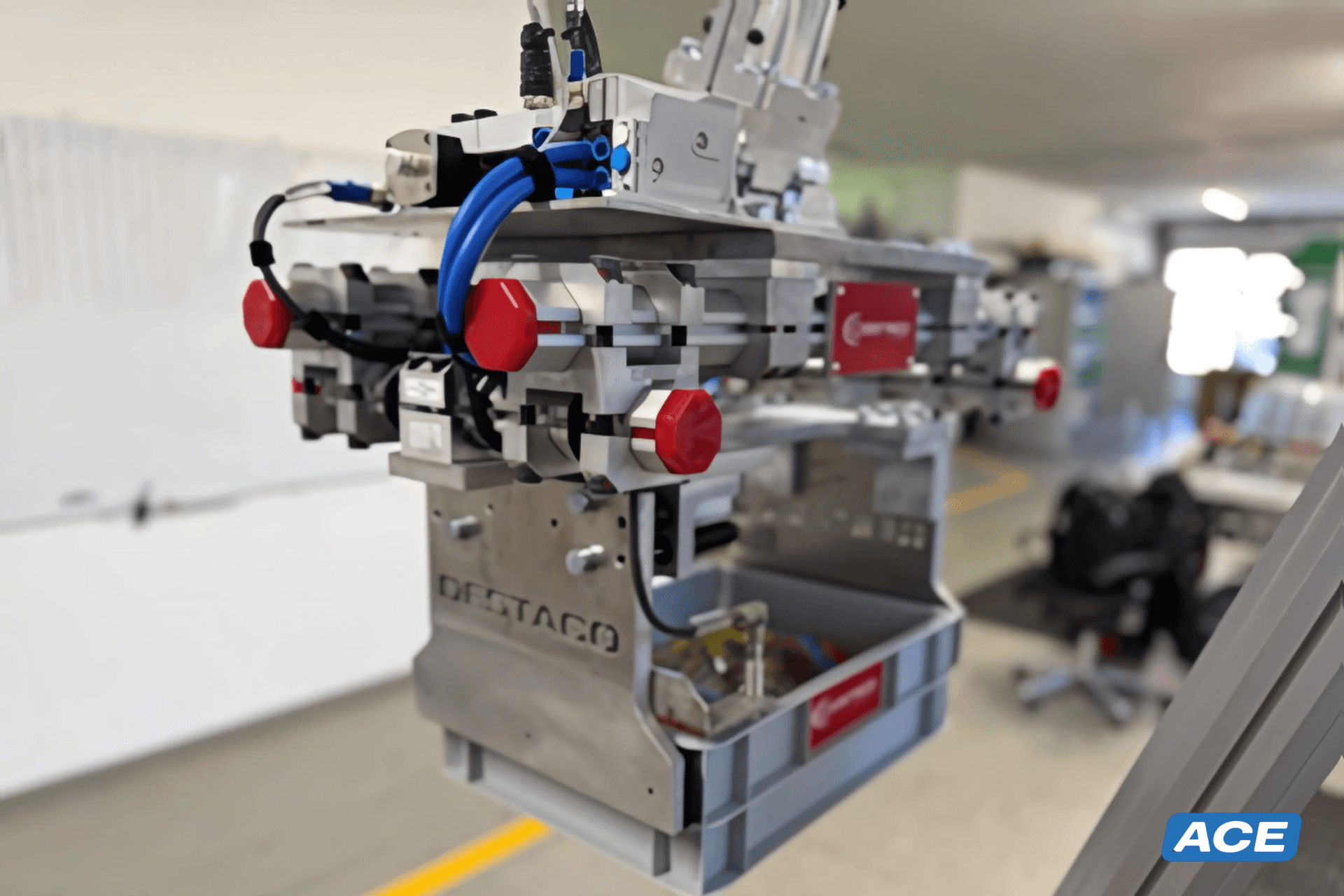

By integrating ACE's precision industrial shock absorbers into DESTACO’s modular gripping systems, Stabilus offers an intelligent, reliable automation solution, perfectly suited to modern industrial cycle rates.

By integrating ACE's precision industrial shock absorbers into DESTACO’s modular gripping systems, Stabilus offers an intelligent, reliable automation solution, perfectly suited to modern industrial cycle rates.