A solution that improves manoeuvrability and simplifies travel in tight environments.

In many industrial and logistics sectors, operators have to move trucks in narrow, technical or hard-to-reach areas. Repeated manoeuvres, in particular forced slots to orient the truck precisely, generate lost time, operational fatigue and the risk of trajectory errors. Faced with these constraints, the ability to move a trolley laterally, without additional effort or complex movement, becomes A real lever for performance and safety.

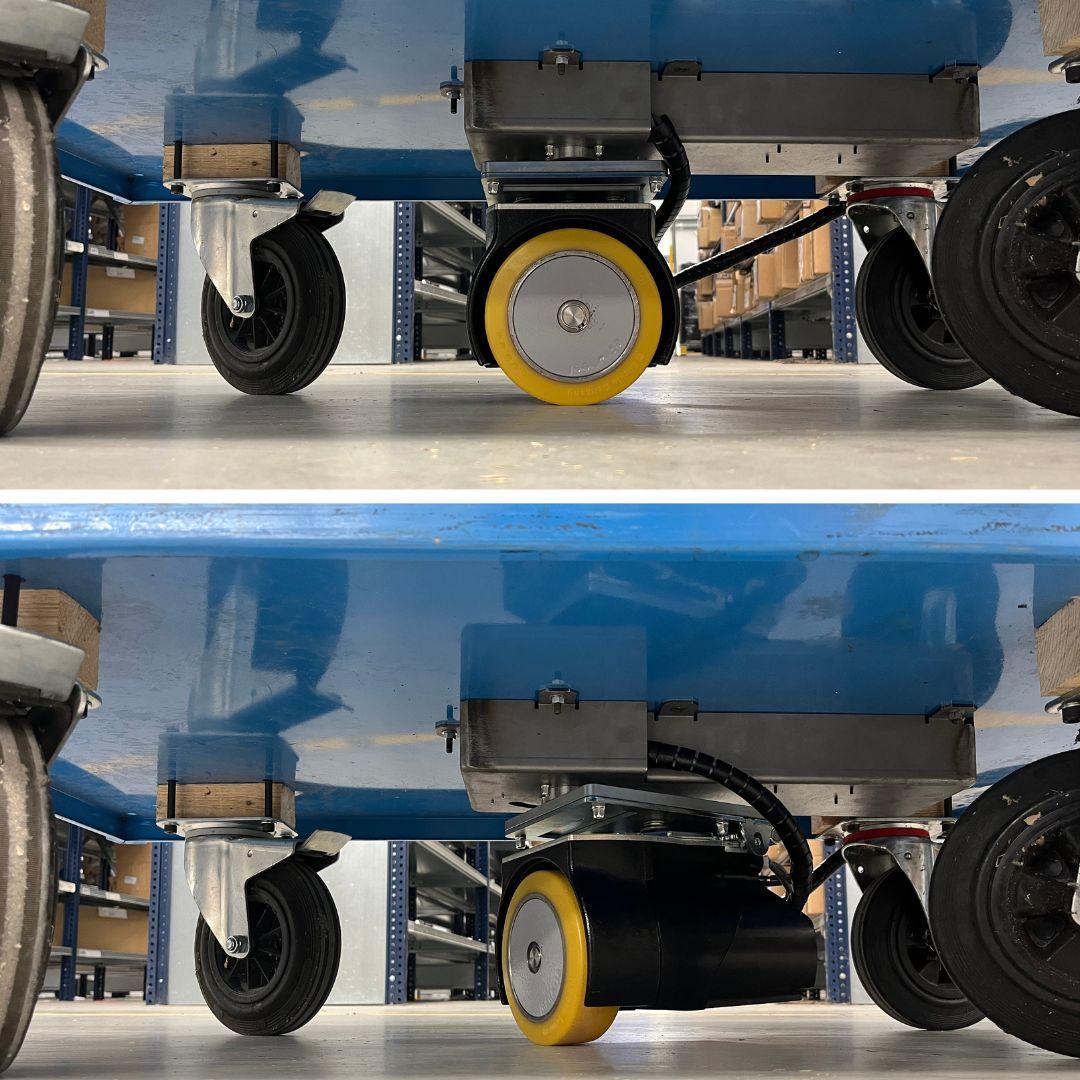

Our client, user of trolleys equipped with motorised wheels EZW150 or EZW160 with suspended screed, had a clearly identified need : Be able to perform lateral movements in cramped environments. This manoeuvre requires that the wheel can rotate 90° when the truck is stationary, in order to gain in precision, manoeuvrability and safety.

We have developed an innovative system that allows the EZW wheel150/160 to rotate 90° when the trolley is stationary. This solution significantly improves manoeuvring accuracy, flexibility of use and safety in everyday life.

We have designed a complete 90° rotation system, fully integrated and powered directly by the motorised wheel.

Actuator : one electric actuator Bansbach EEL35.

Piloting : map EEL-S2-1.

User control : remote control EEL-HS3 two-button.

Mechanical and electrical integration developed in-house by BIBUS FRANCE.

We have thus brought Our technical expertise on the mechanical design, wiring, integration and functional safety of the project.

Our design office produces 3D plans, validates mechanical forces and defines the system architecture.

One Close collaboration with APEM, our partner of the EZW wheel, in order to define a safe and compatible wiring that guarantees the proper functioning of the system.

The creation of a Working prototype in our workshop, including wiring cleaning.

The prototype was tested in our workshop on one of our trolleys in order to validate the robustness, safety and ergonomics of the system. A complete BIBUS Solutions study file was then produced in accordance with Our Process to industrialise our system, and ensure its monitoring and optimisation.

By removing the "slots" that were previously necessary, the customer optimises the organisation of his workspace and improves his ergonomics.