Shaft couplings

Our high-quality shaft couplings – with a proven track record in mechanical and plant engineering – are the key to creating flexible, rigid and torsionally rigid shaft connections that meet a multitude of requirements.

Kontakt os, hvis du har spørgsmål.

Kontakt os

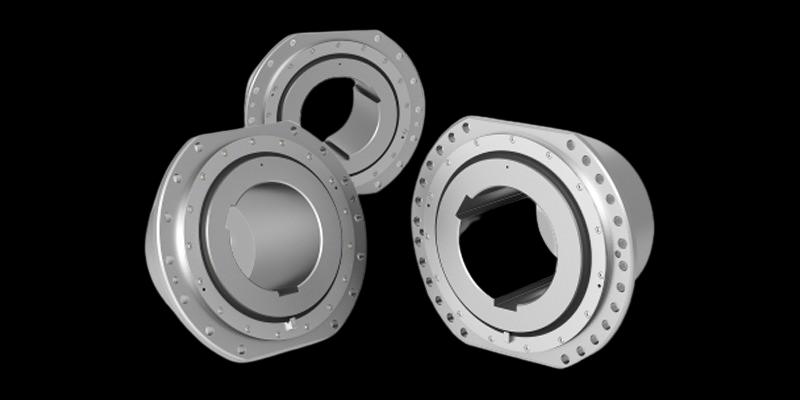

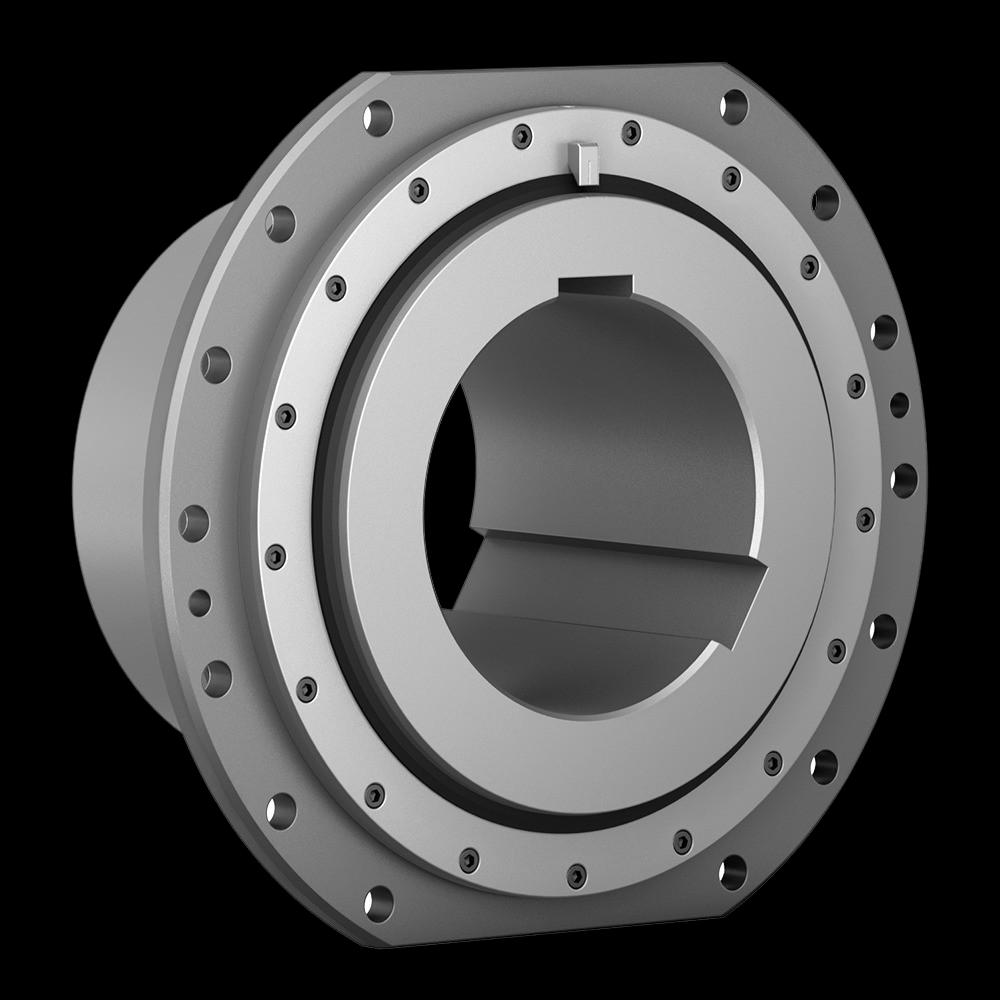

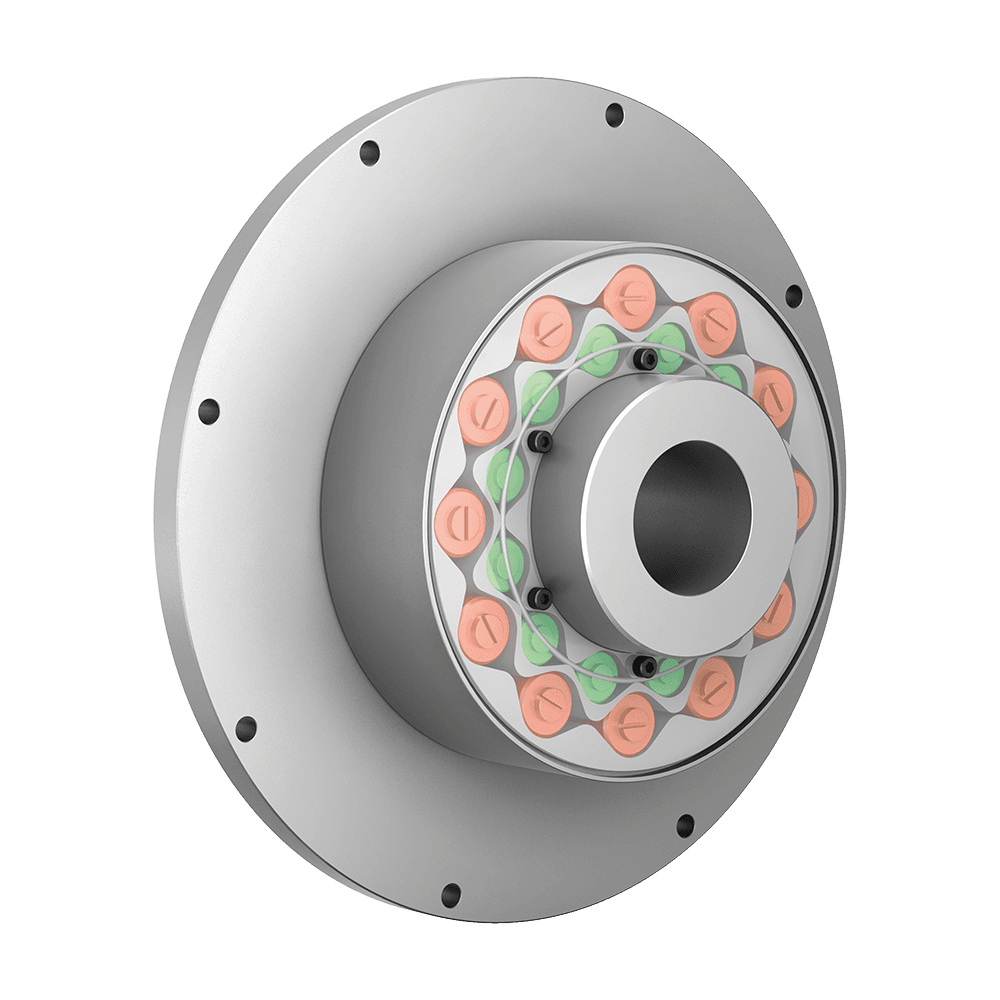

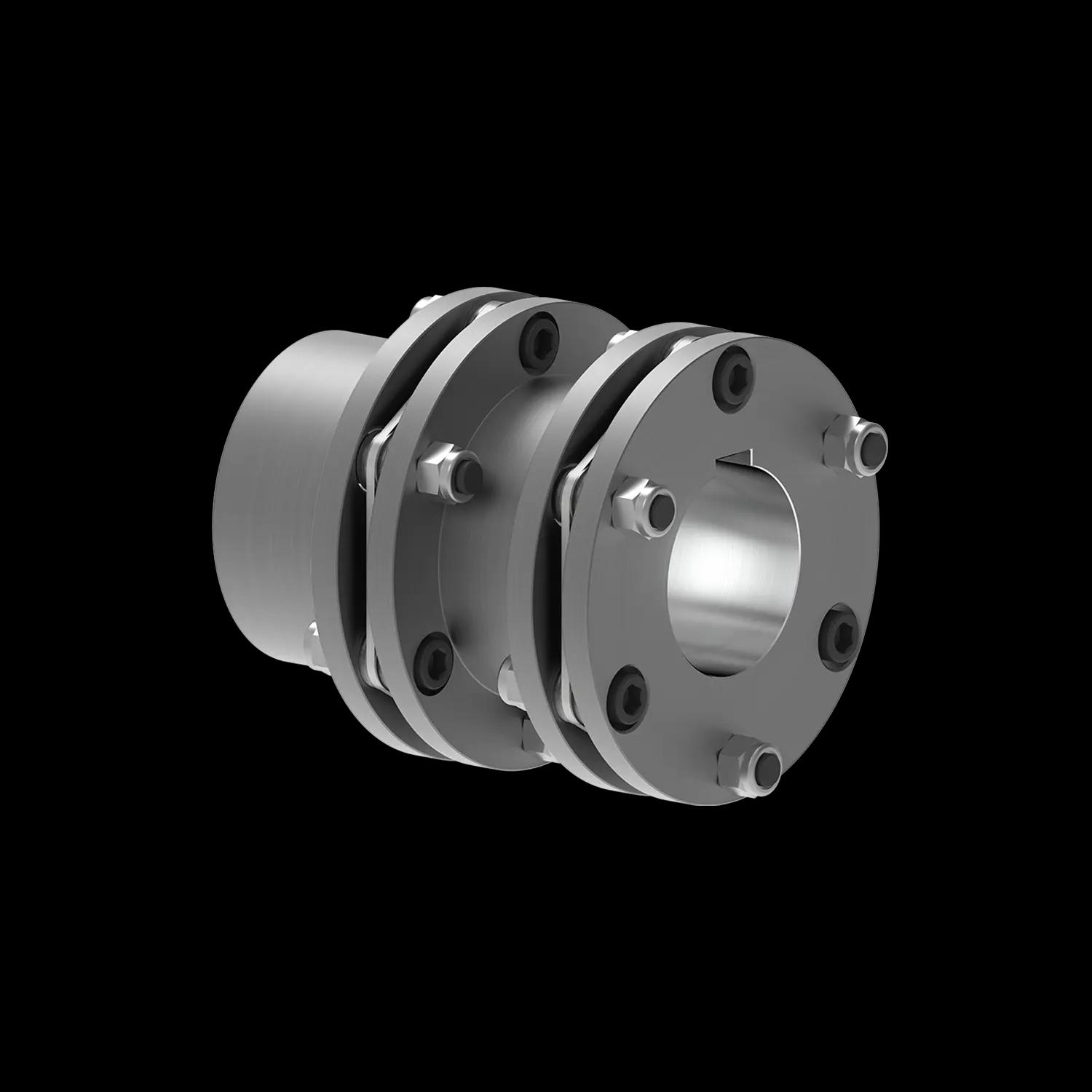

TNF 5571-B

Version B contains shrink discs that are pushed onto the flange hub and then tightened with screws from inside the flange hub.

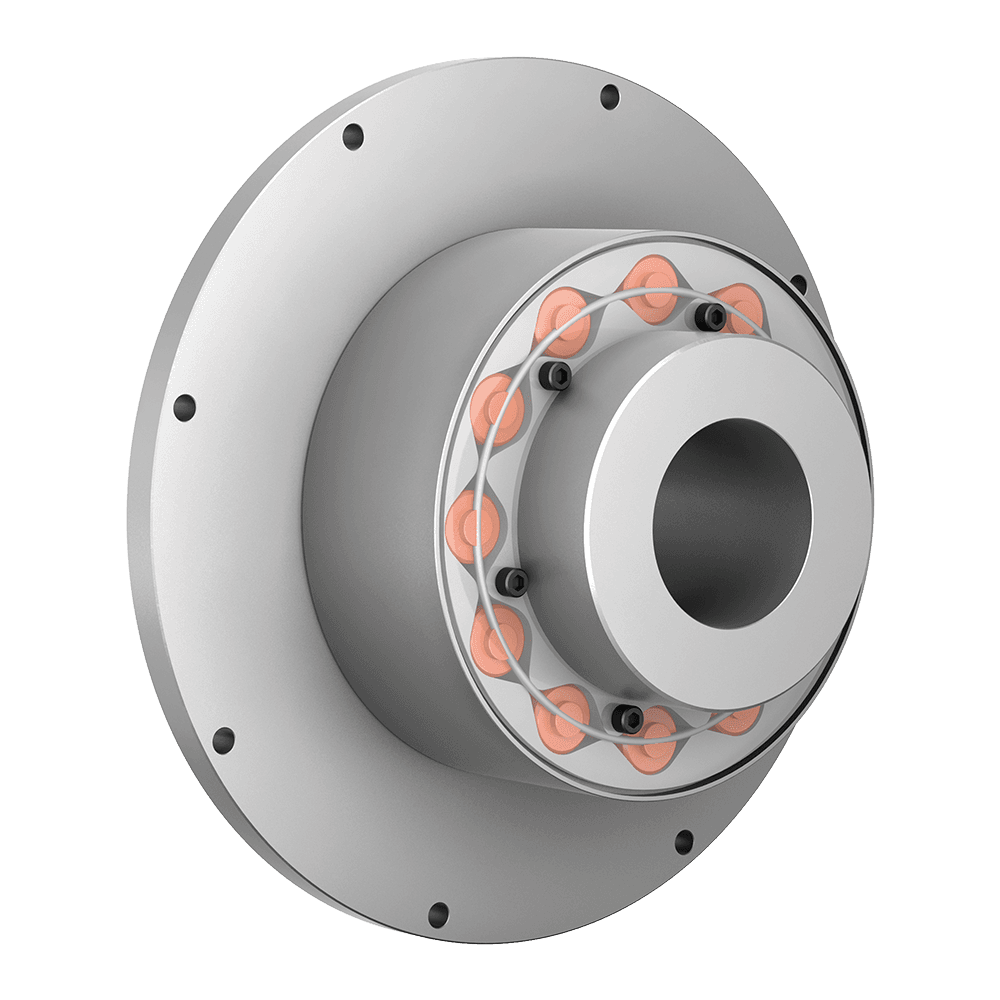

TNF 5571-A

Version A contains standard shrink discs. These are pushed fully onto the flange hub.

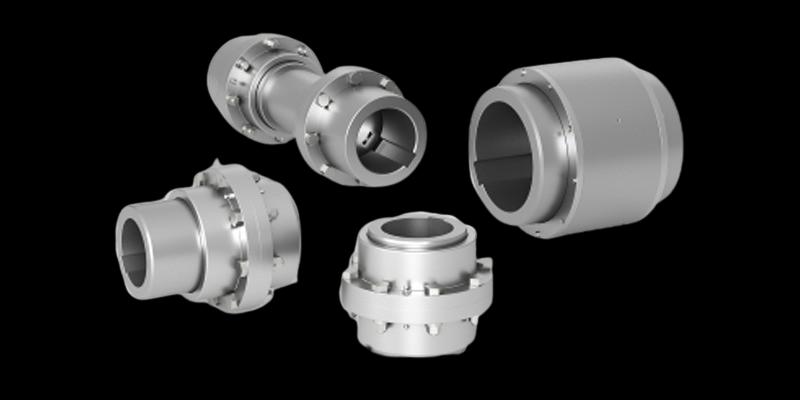

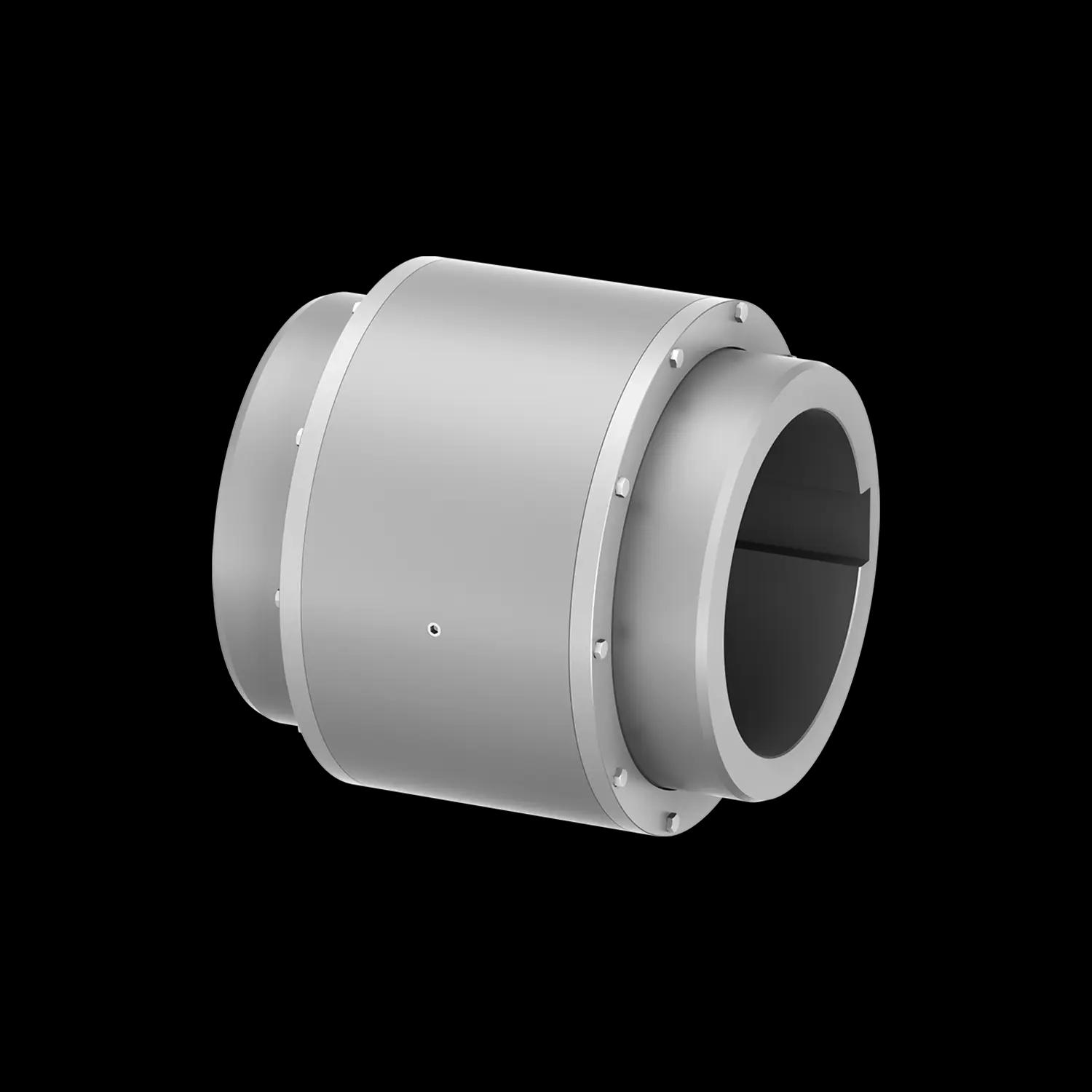

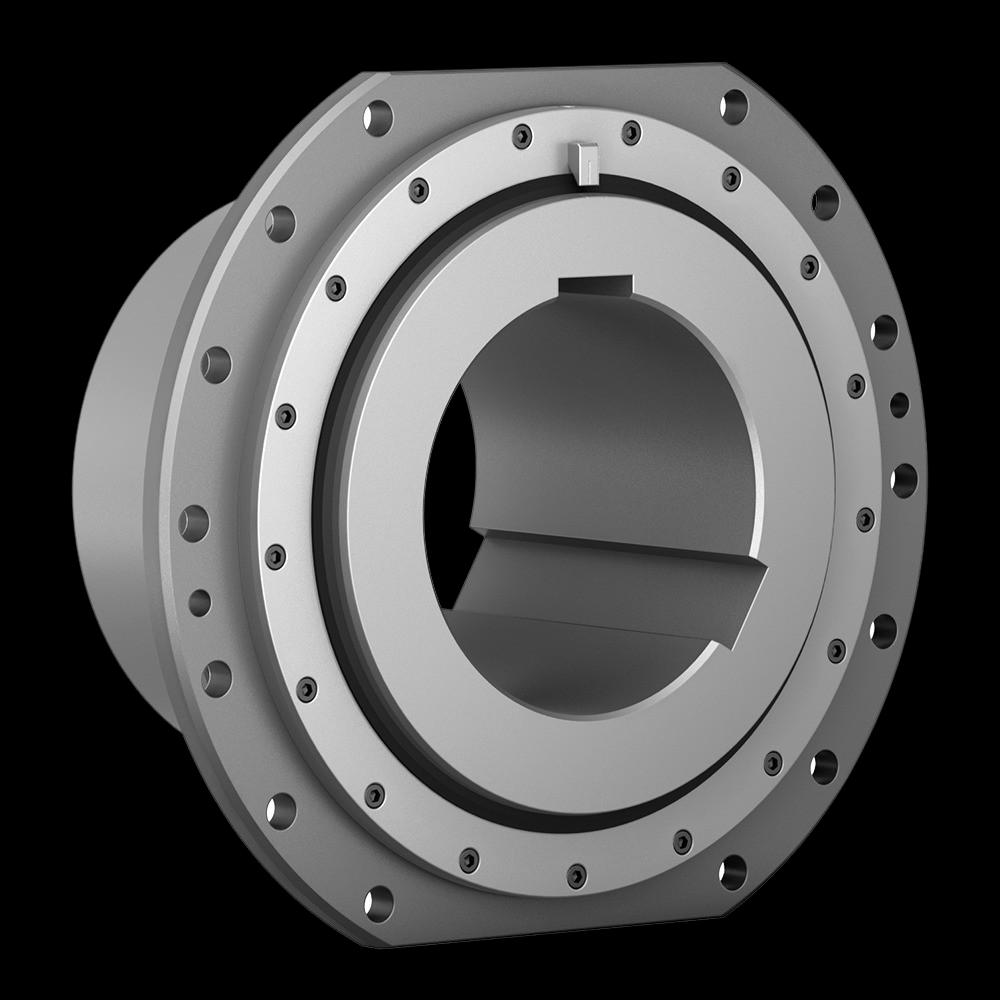

TNC TKVO

The RINGFEDER TNK TKVO is a highly rigid barrel coupling, with both the hub and the housing made from high-strength material.

TNZ ZCH

The RINGFEDER TNZ ZCH is a coupling unit that consists of a one-piece casing with O-ring supports on both sides.

TNZ ZCAZ and ZCBZ

The RINGFEDER TNZ ZCAZ is supplemented by a spacer, which is installed between the casings of a TNZ ZCA with the aid of fitted bolts.

TNZ ZCAF and ZCBF

The RINGFEDER TNZ ZCAF type is constructed from the coupling halves of the TNZ ZCA, which are supplemented with an intermediate shaft and two rigid counter flanges.

TNZ ZCAV and ZCBV

Version for vertical installation

ECT 6418

The ECT 6418 curved tooth gear coupling is available in two different hub versions.

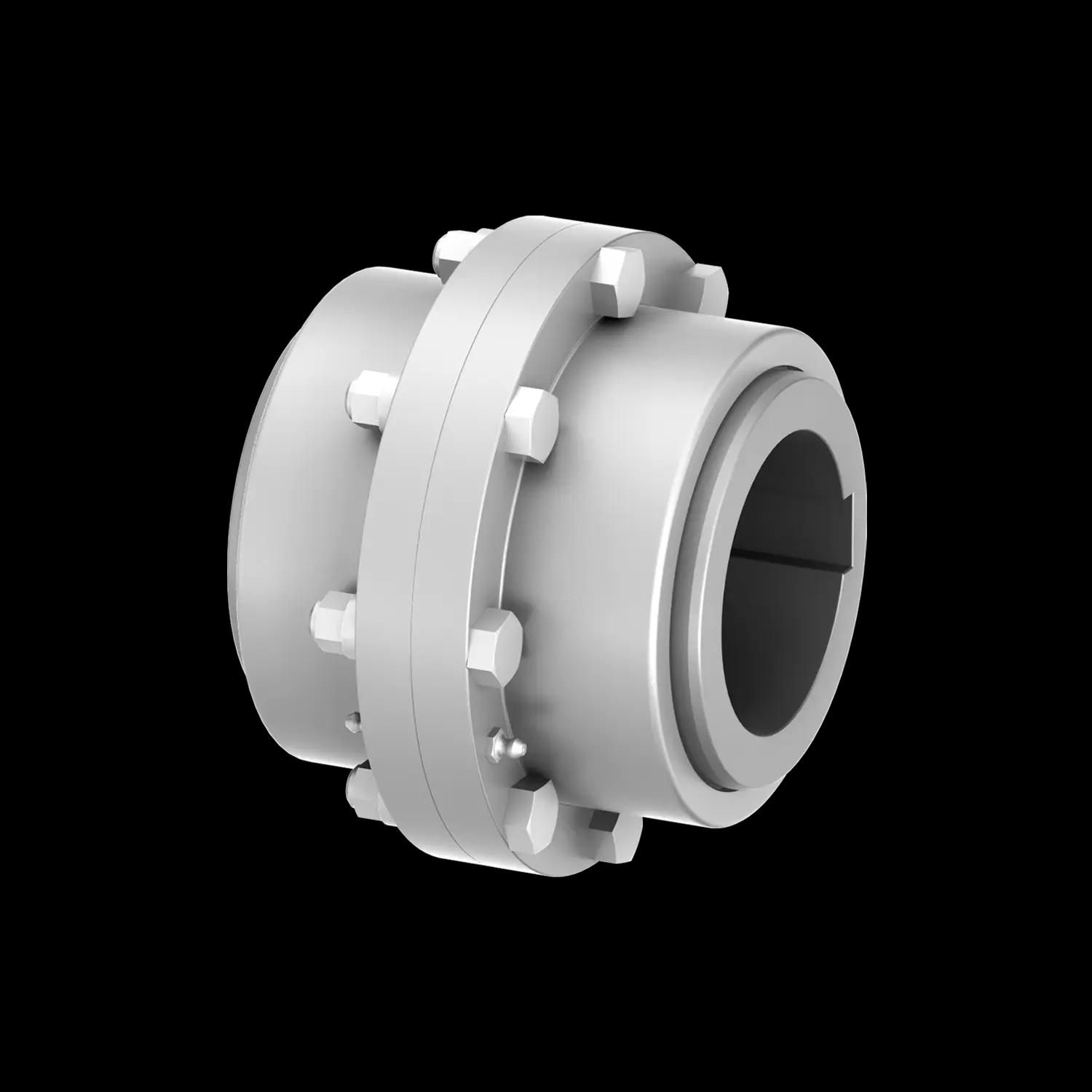

TNZ ZCAUU and ZCBUU

The RINGFEDER TNZ ZCAUU is a type of universal hub that has two longer hubs compared to the TNZ ZCA. These hubs can be customised according to the specific requirements of the system.

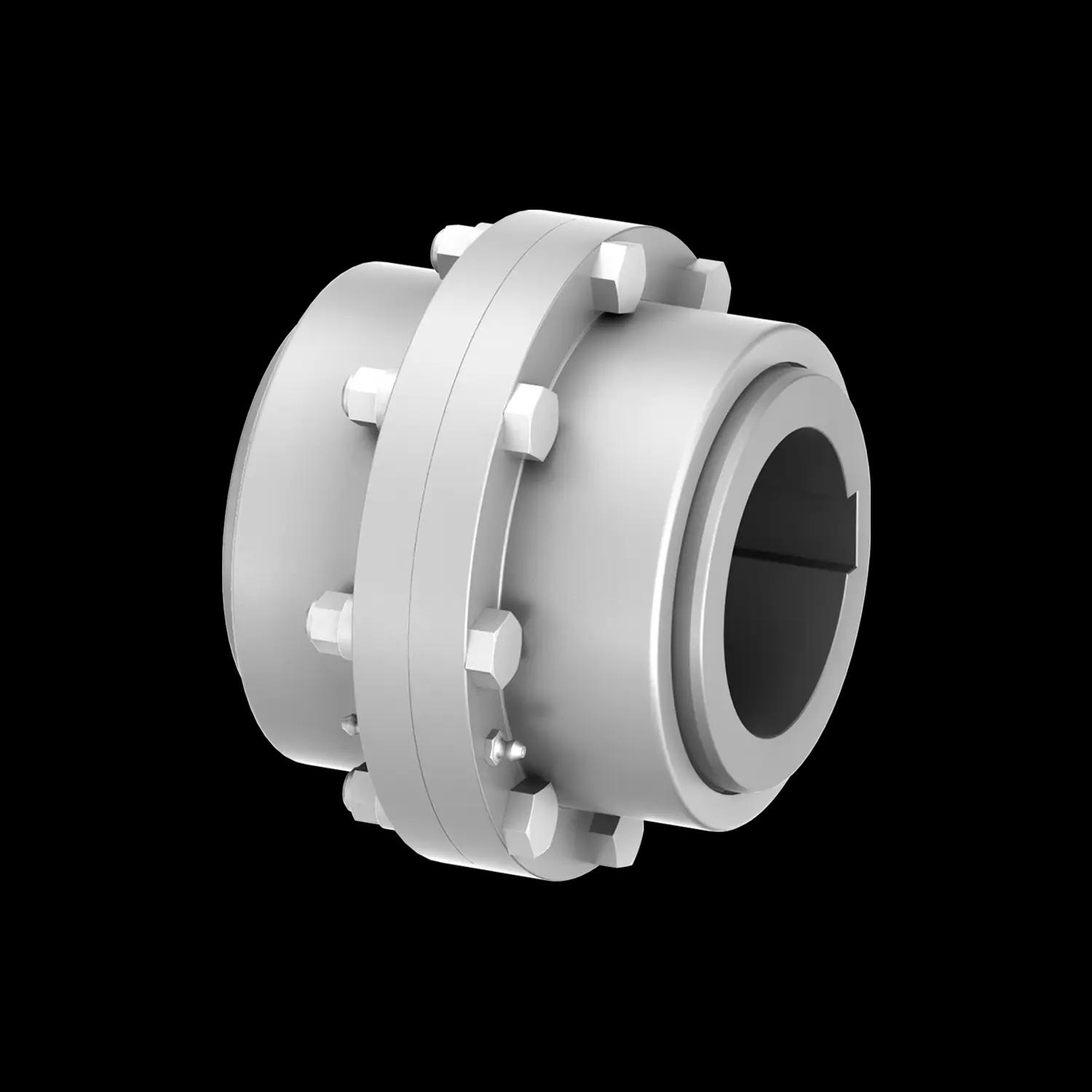

TNZ ZCAU and ZCBU

Compared to the TNZ ZCA, the RINGFEDER TNZ ZCAU has a longer hub. The length of this can be adapted to suit the system requirements.

TNZ ZCAK and ZCBK

The RINGFEDER TNZ ZCAK and TNZ ZCBK are special versions of the TNZ ZCA and TNZ ZCB couplings with limitation of the end float.

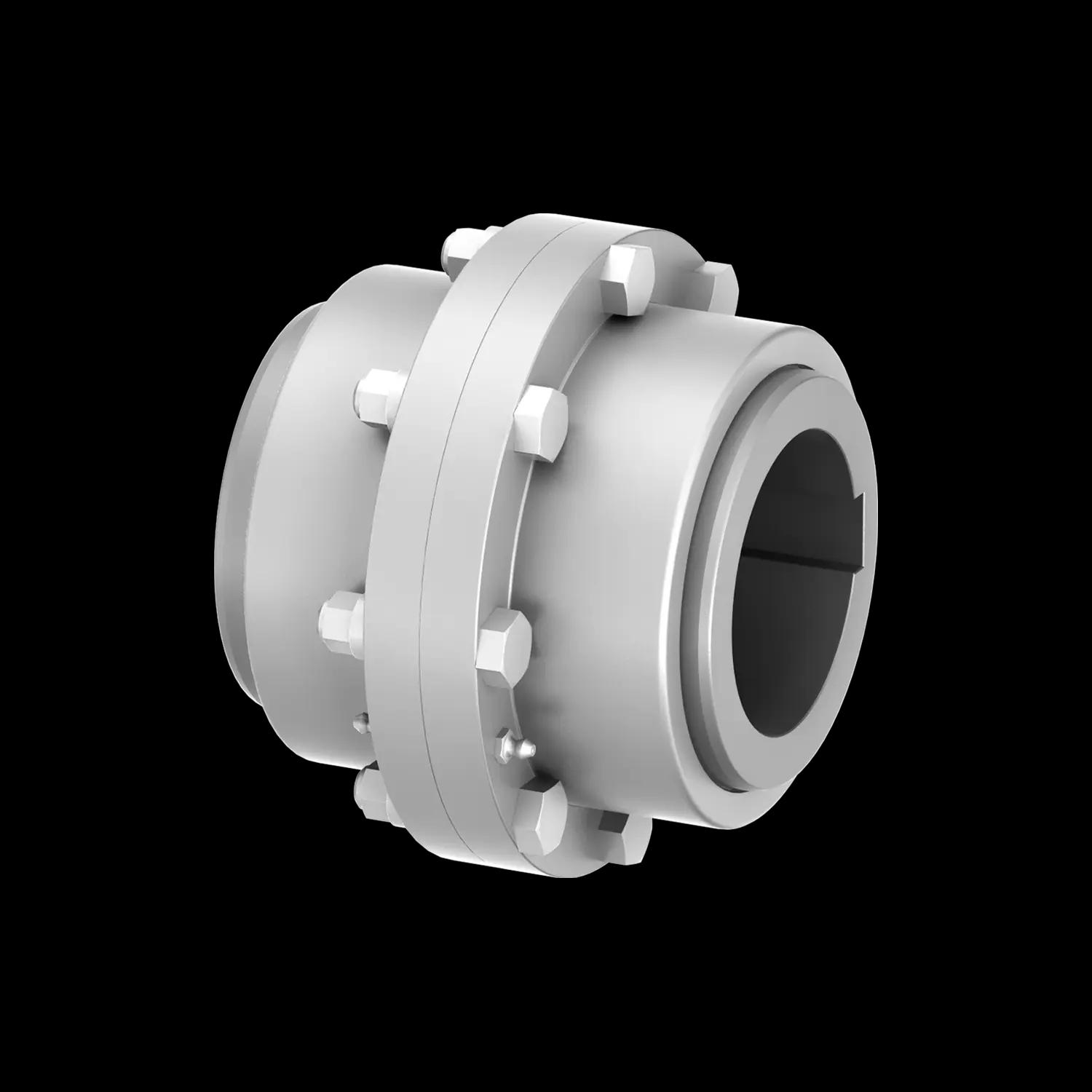

TNZ ZCA and ZCB

The RINGFEDER TNZ ZCA coupling is a gear coupling made up of two coupling halves connected by fitted bolts.

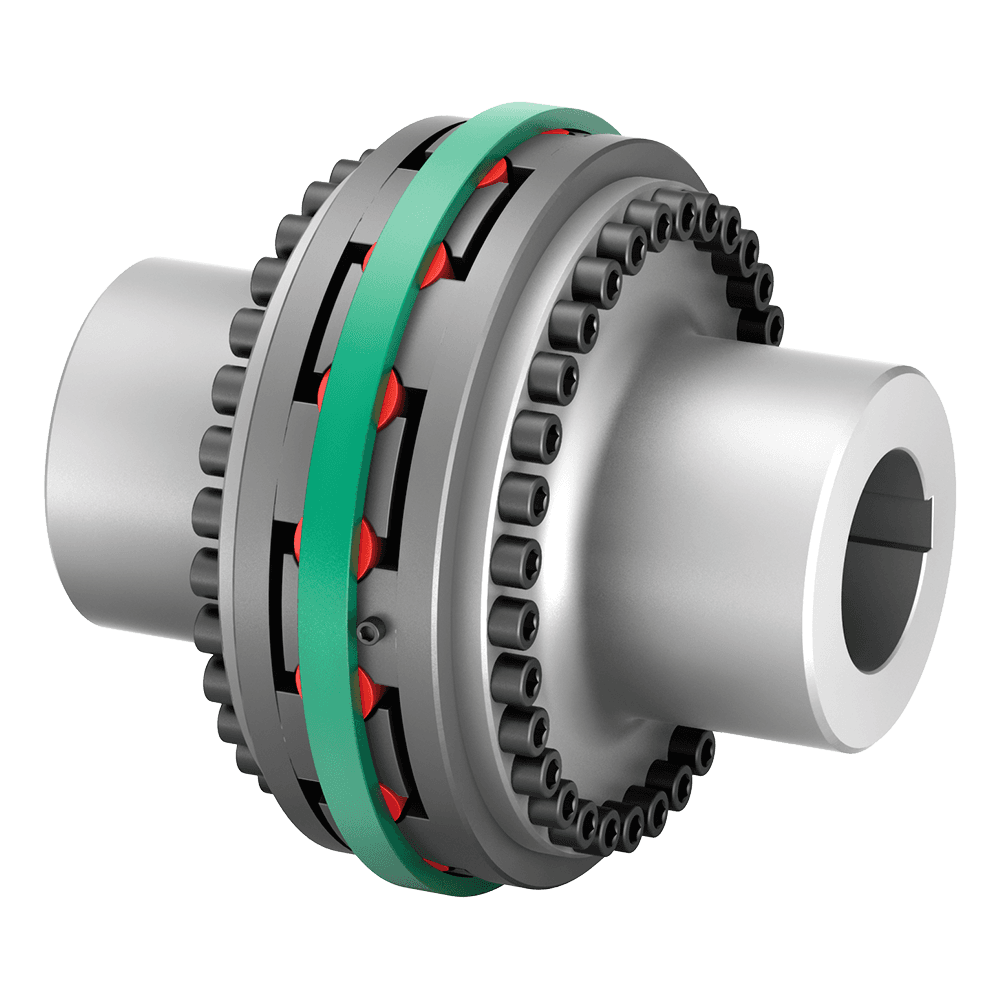

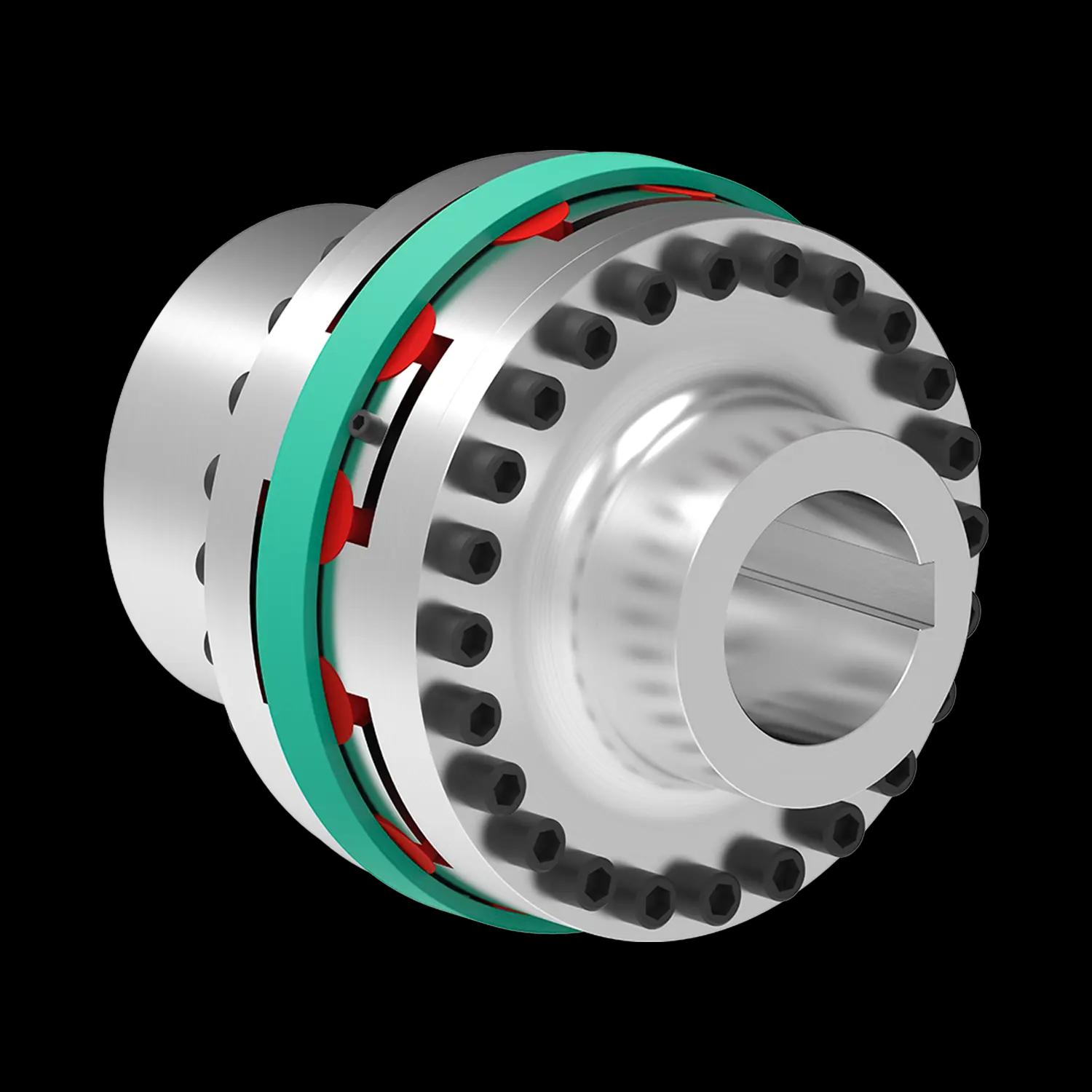

TNR 2428.2 torsional highflex coupling

Every drivetrain has its own characteristic torsional vibration behaviour. The newly developed RINGFEDER TNR provides the precise dynamic stiffness needed for each one.

TNR 2428.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

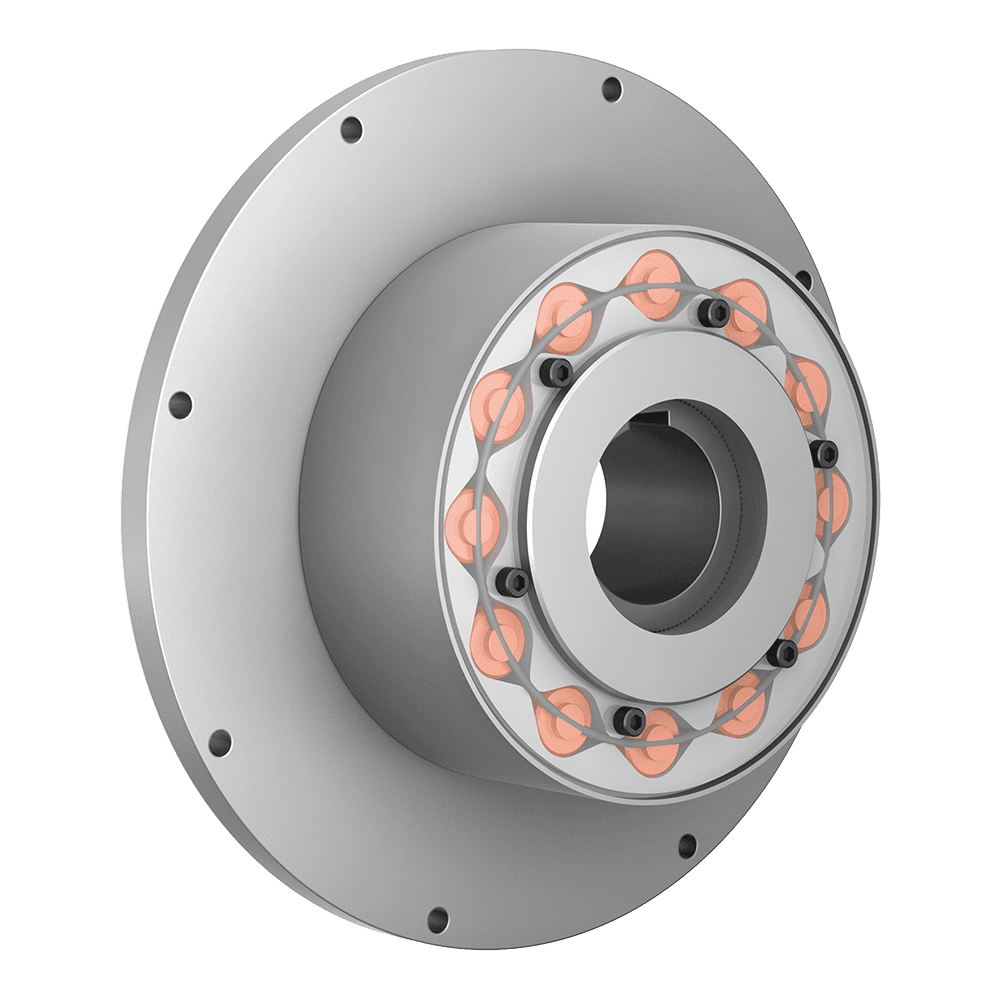

TNR 2425.2 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

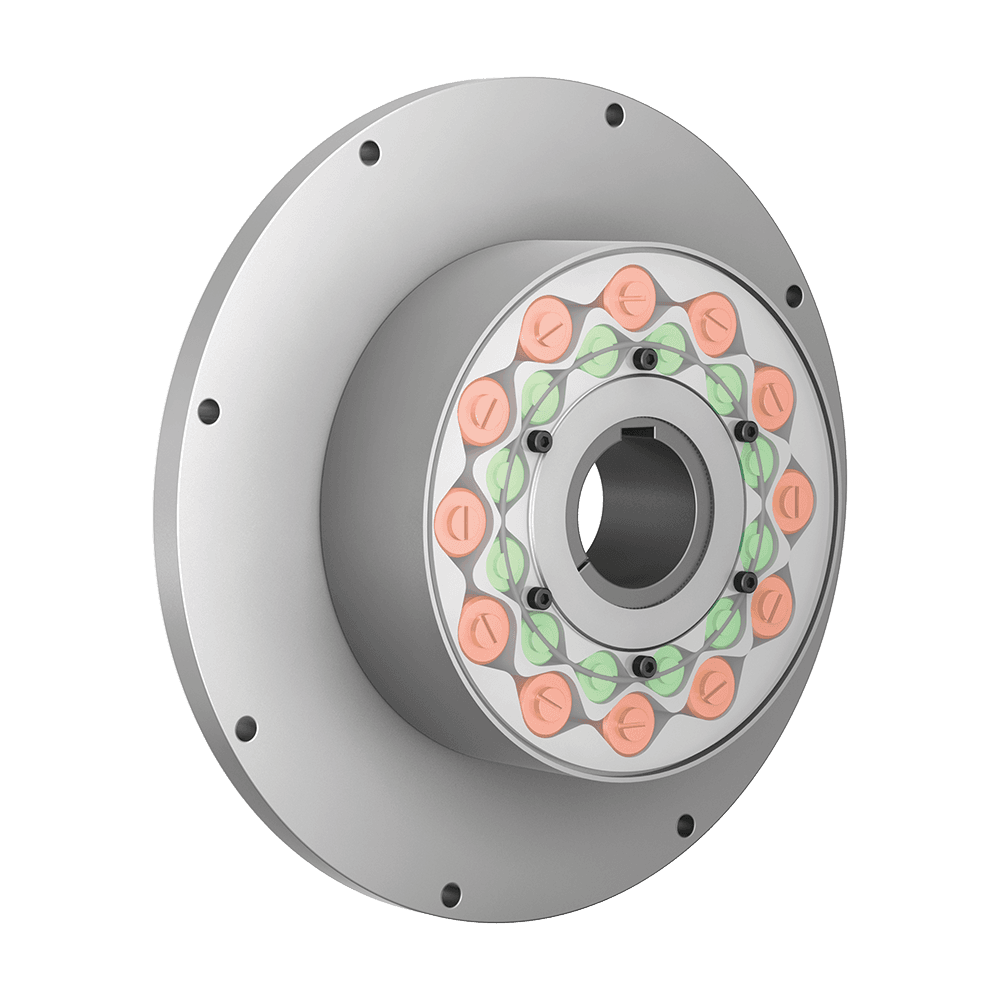

TNR 2425.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

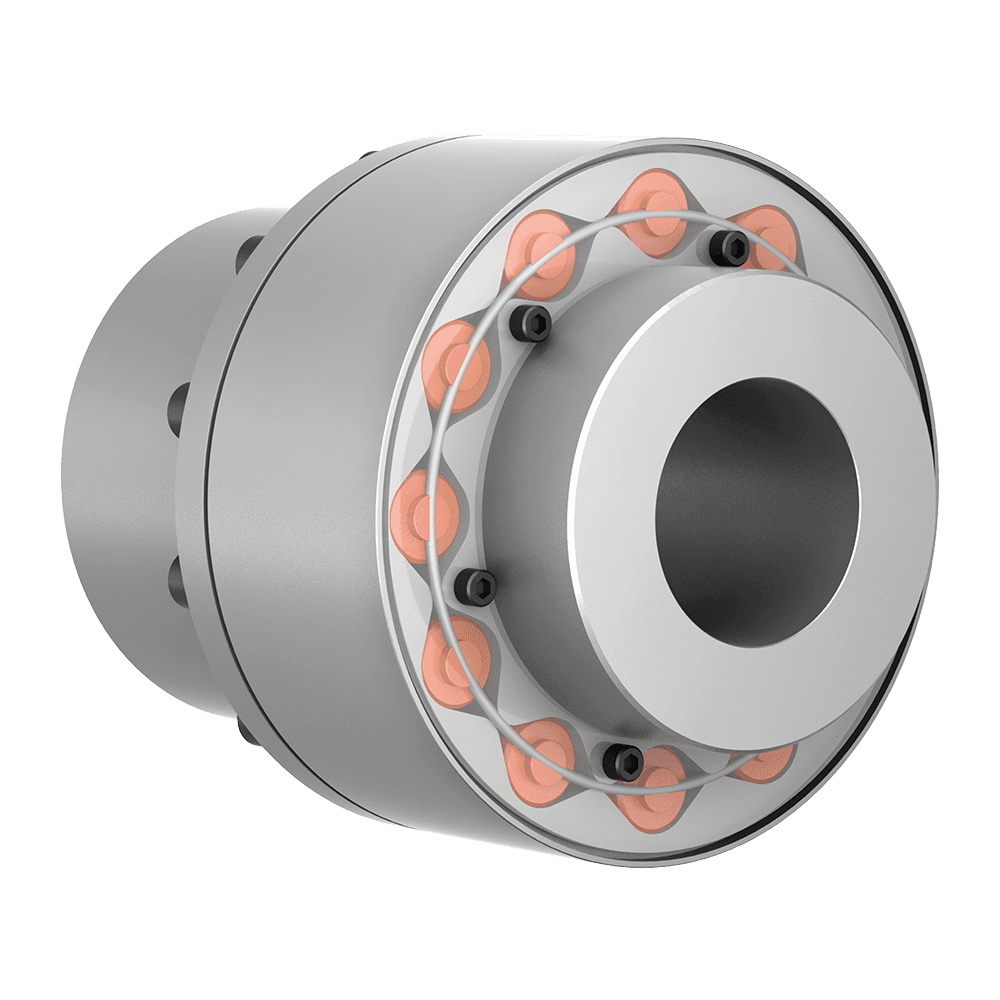

TNR 2424.2 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

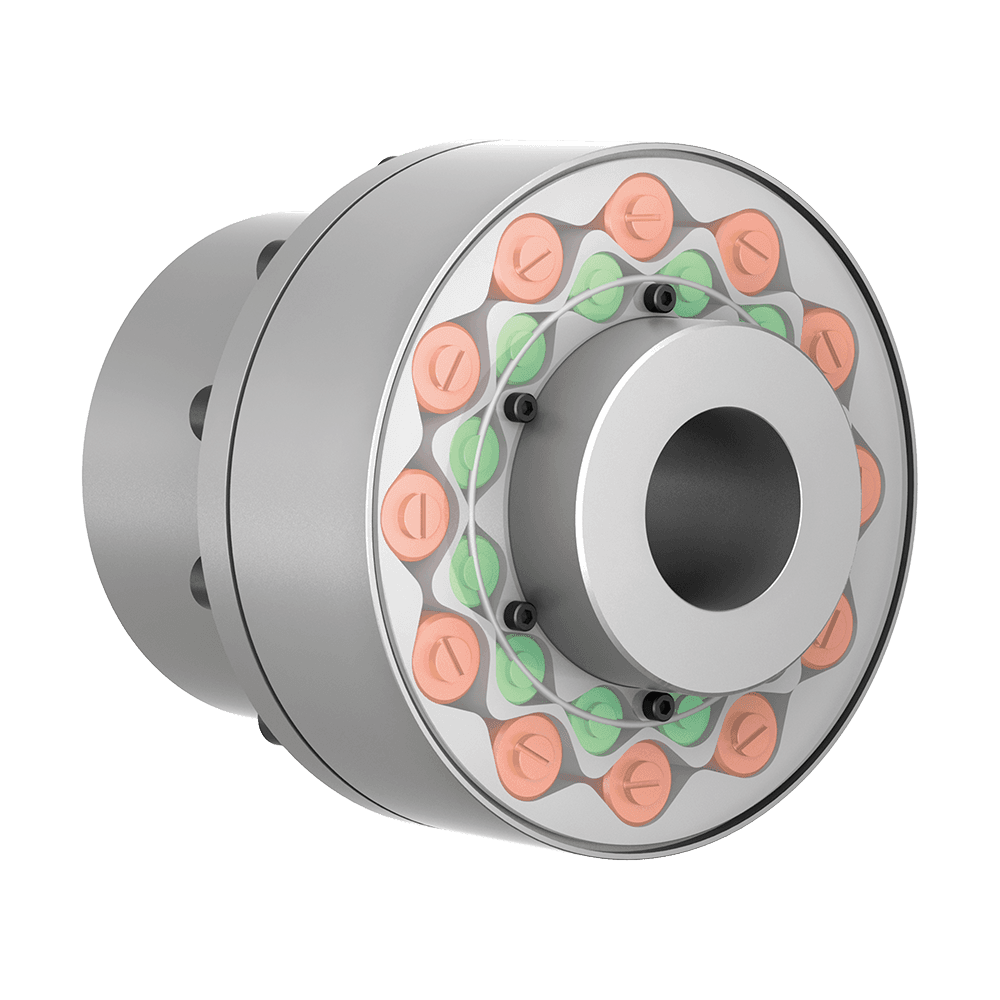

TNR 2424.1 torsional highflex coupling

Compact, plug-in construction with a choice of either a fail-safe or non-fail-safe design; high level of dynamic adjustability over a wide temperature range – the new RINGFEDER TNR.

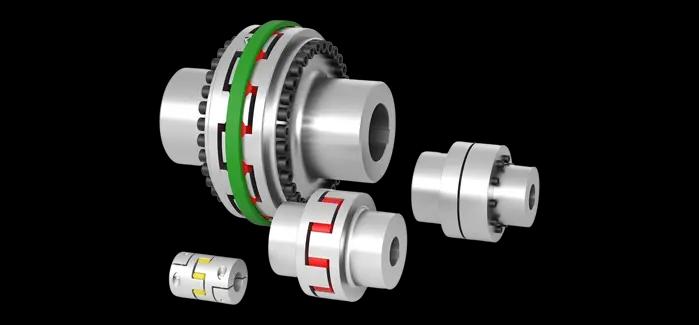

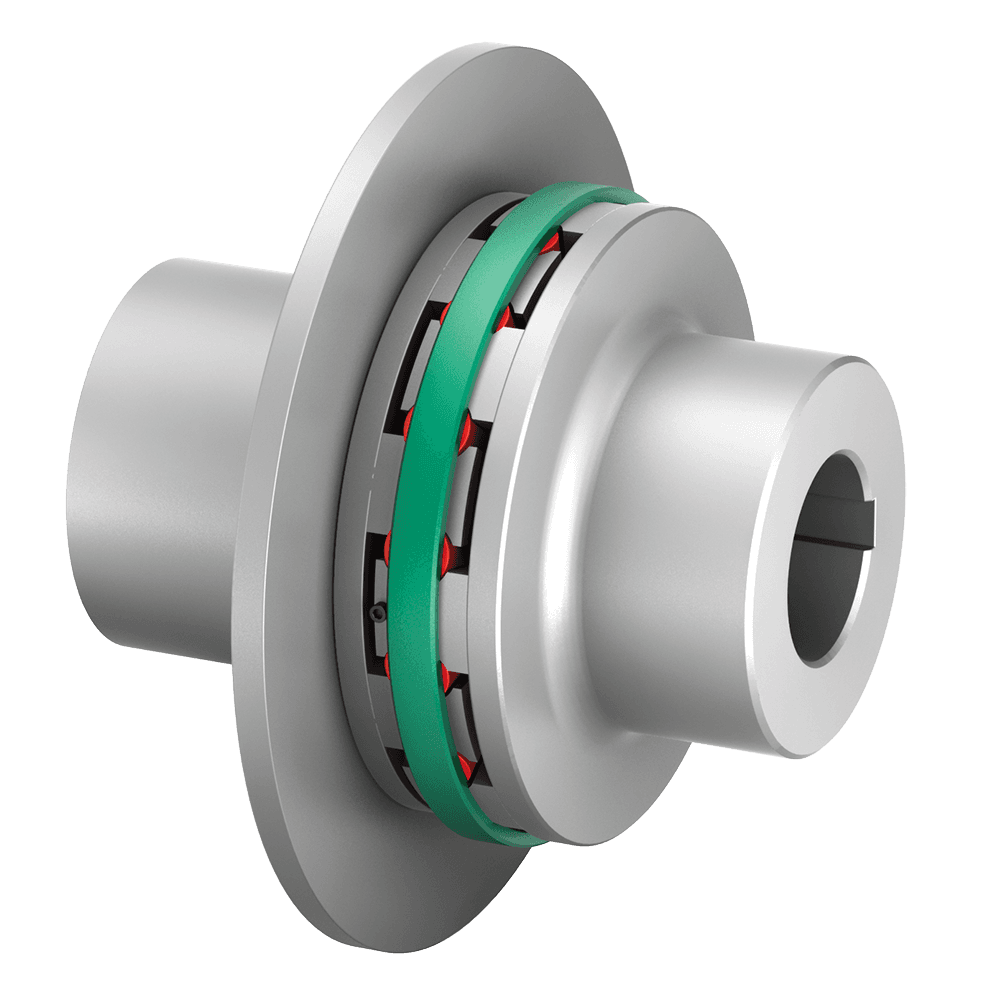

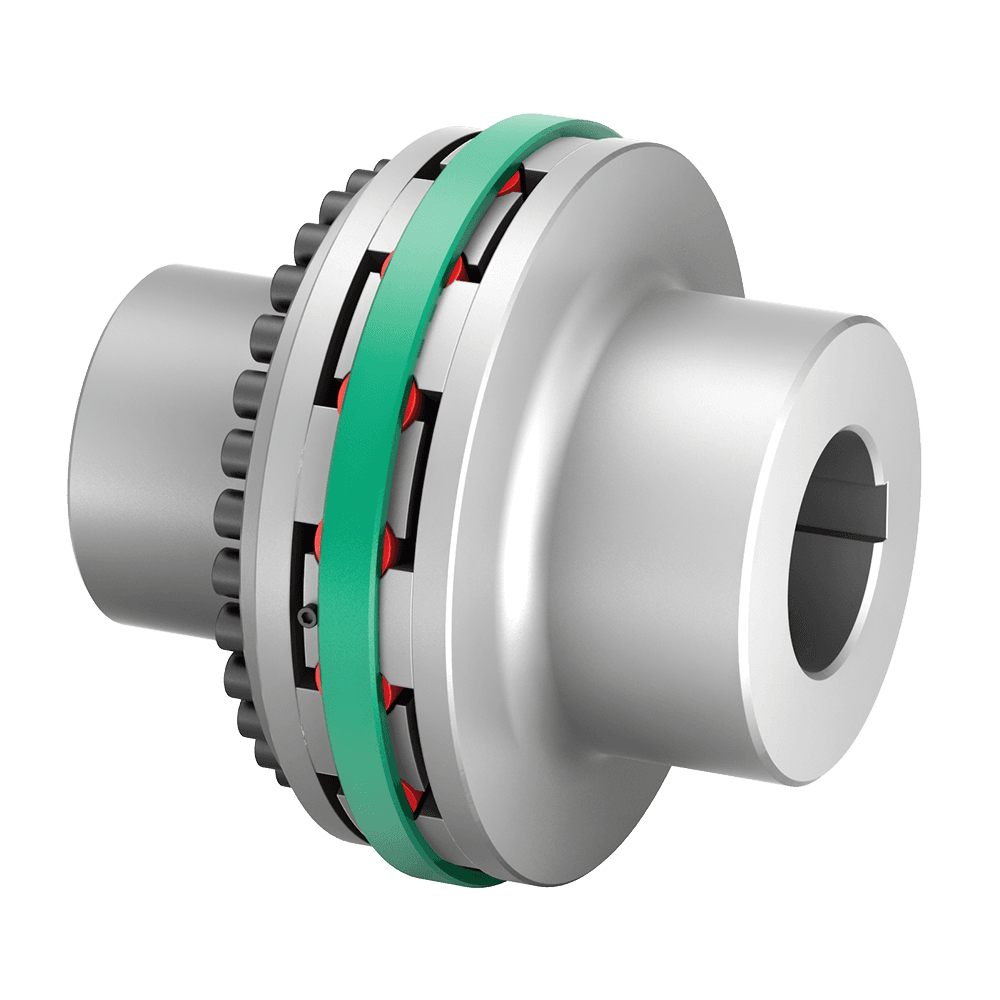

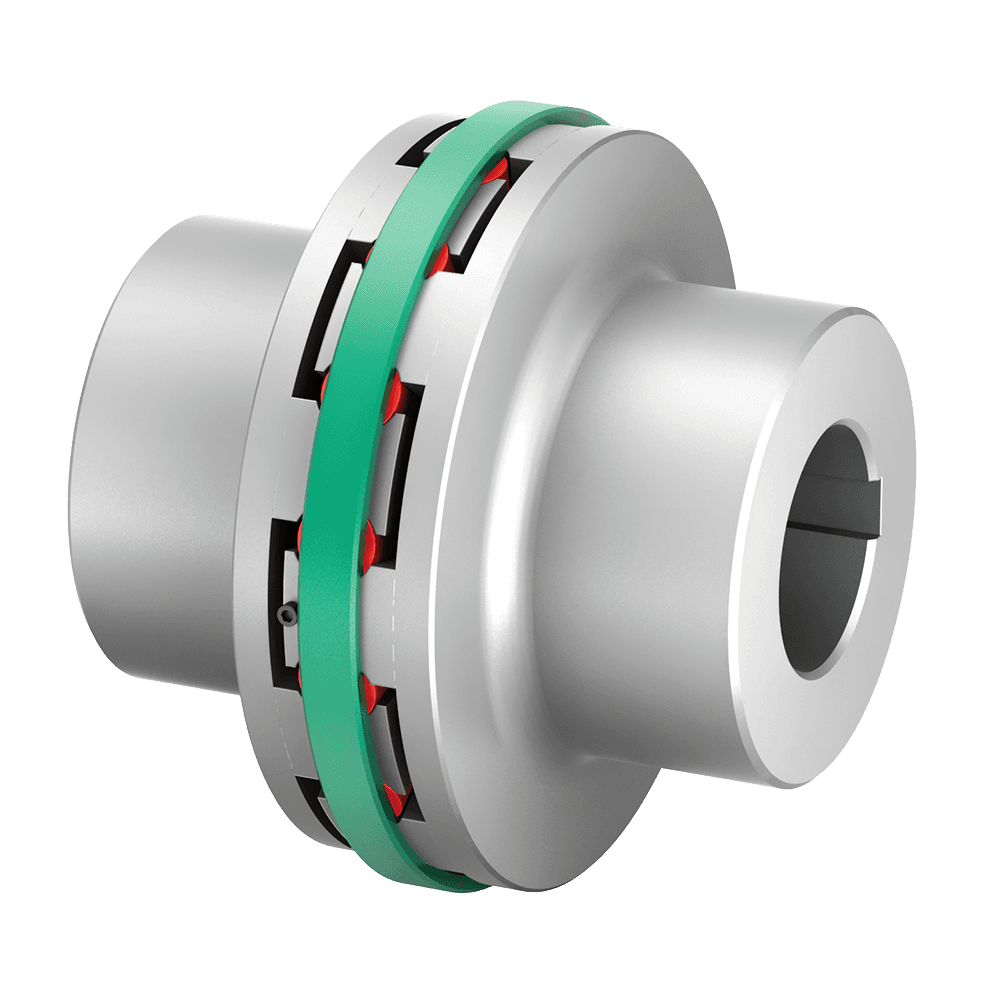

TNB BHDDV elastomer jaw coupling

The RINGFEDER TNB BHDDV coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNB BHDD elastomer jaw coupling

The RINGFEDER TNB BHDD coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNB BHD-BS elastomer jaw coupling

The RINGFEDER TNB BHD-BS coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNB BHD elastomer jaw coupling

The RINGFEDER TNB BHD coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNB BH elastomer jaw coupling

The RINGFEDER TNB BH coupling is a torsionally flexible, fail-safe jaw coupling. It compensates for angular, radial and axial shaft misalignment within defined ranges.

TNK TKV

Robust design.

TND HDV

The hub is rotated 180° and positioned internally, enabling the TND HDV to compensate for significant misalignments with its double-cardanic design.