Rotary unions & winding technology

Rotary unions can be used to transfer media and information between rotating and stationary parts. Winding technology enables materials to be coiled onto – and uncoiled from – cores in an orderly manner.

Contact us if you have any questions.

Contact us

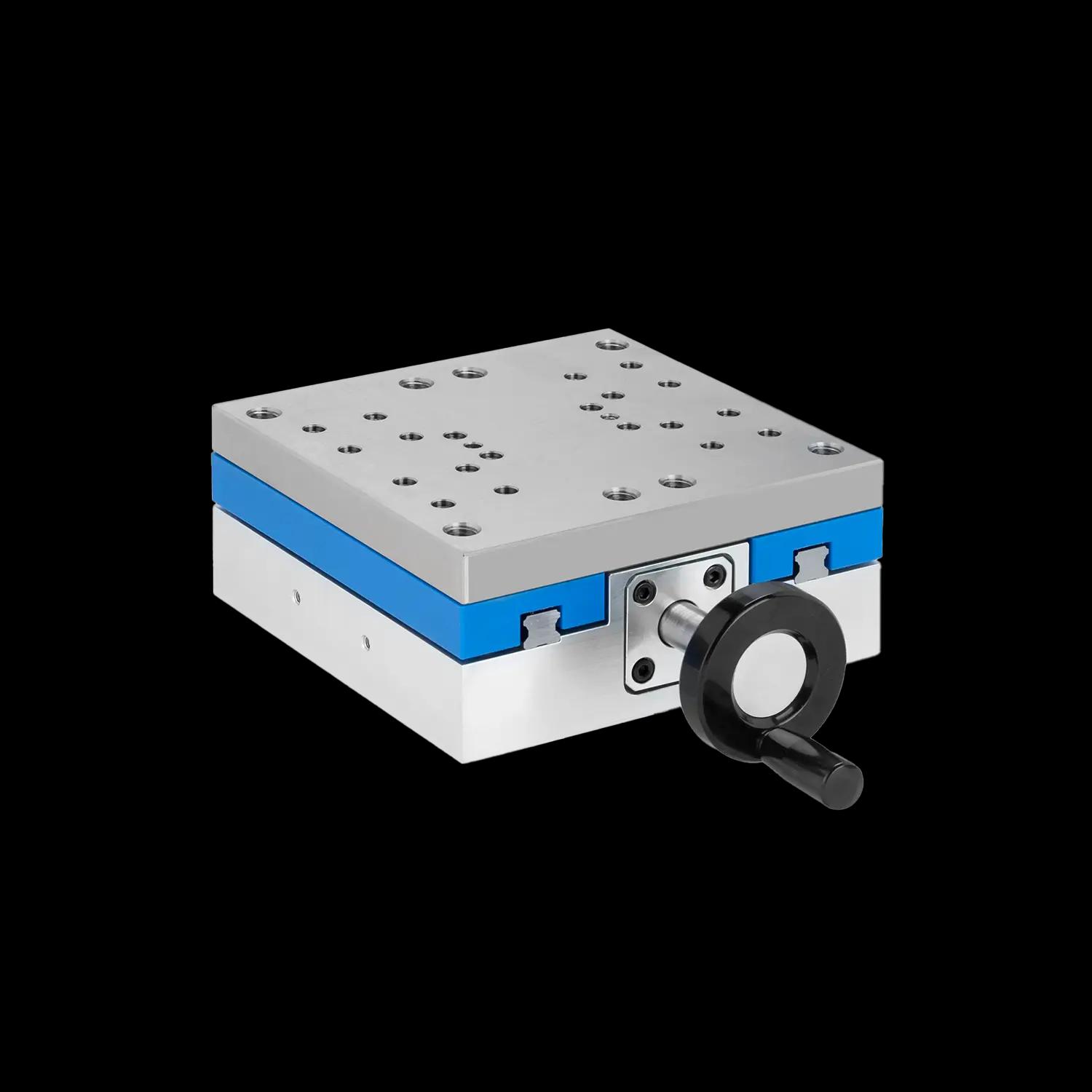

Radial and axial slides

Axial and radial slides for safety chucks and bearing flange units are available in several versions, both with and without motorised adjustment

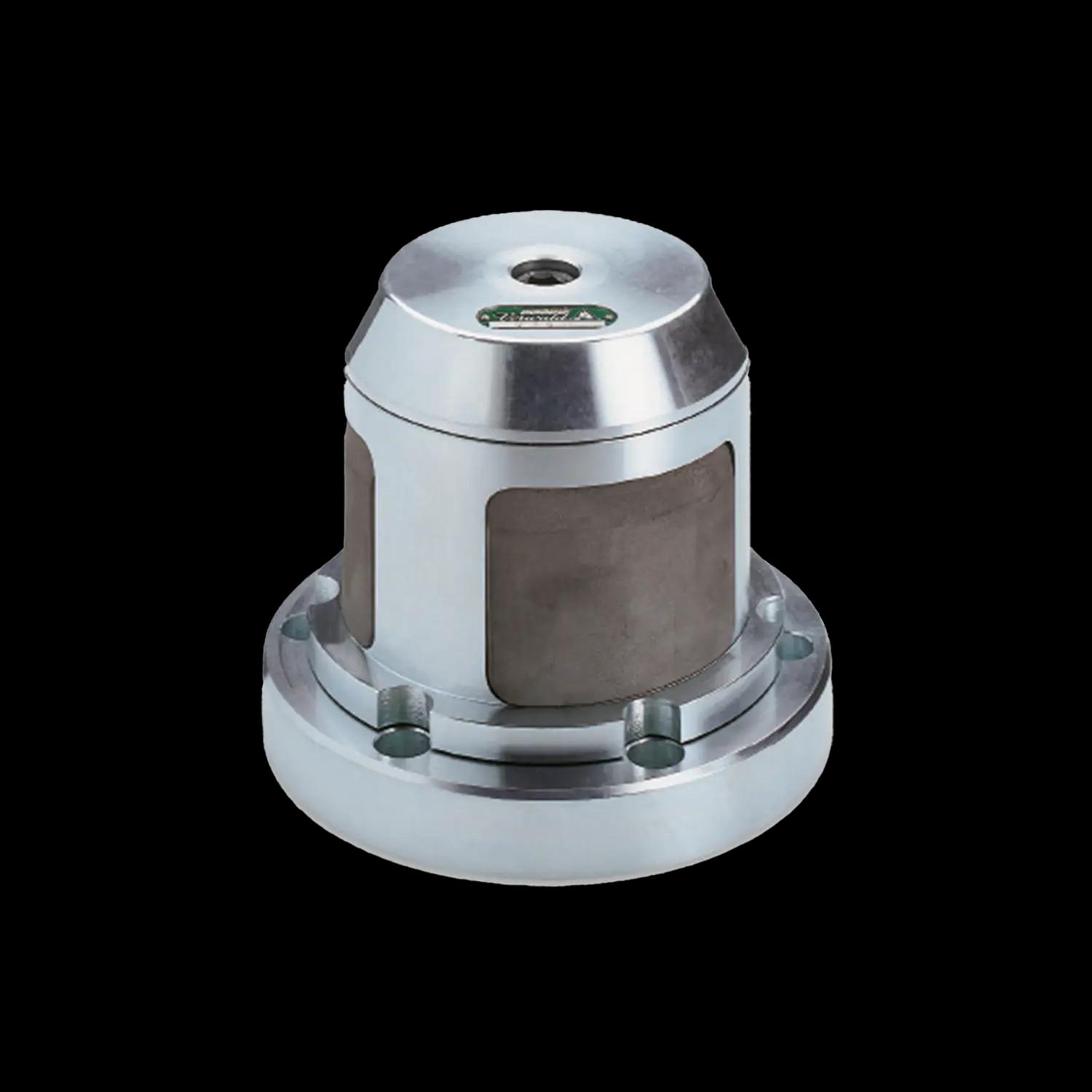

Clamping cones

The cone enables torque to be transferred to the core when used on straightforward shafts and spindles.

Filling gun

Whether you need a version with or without a pressure indicator and spiral hose, we will be happy to help.

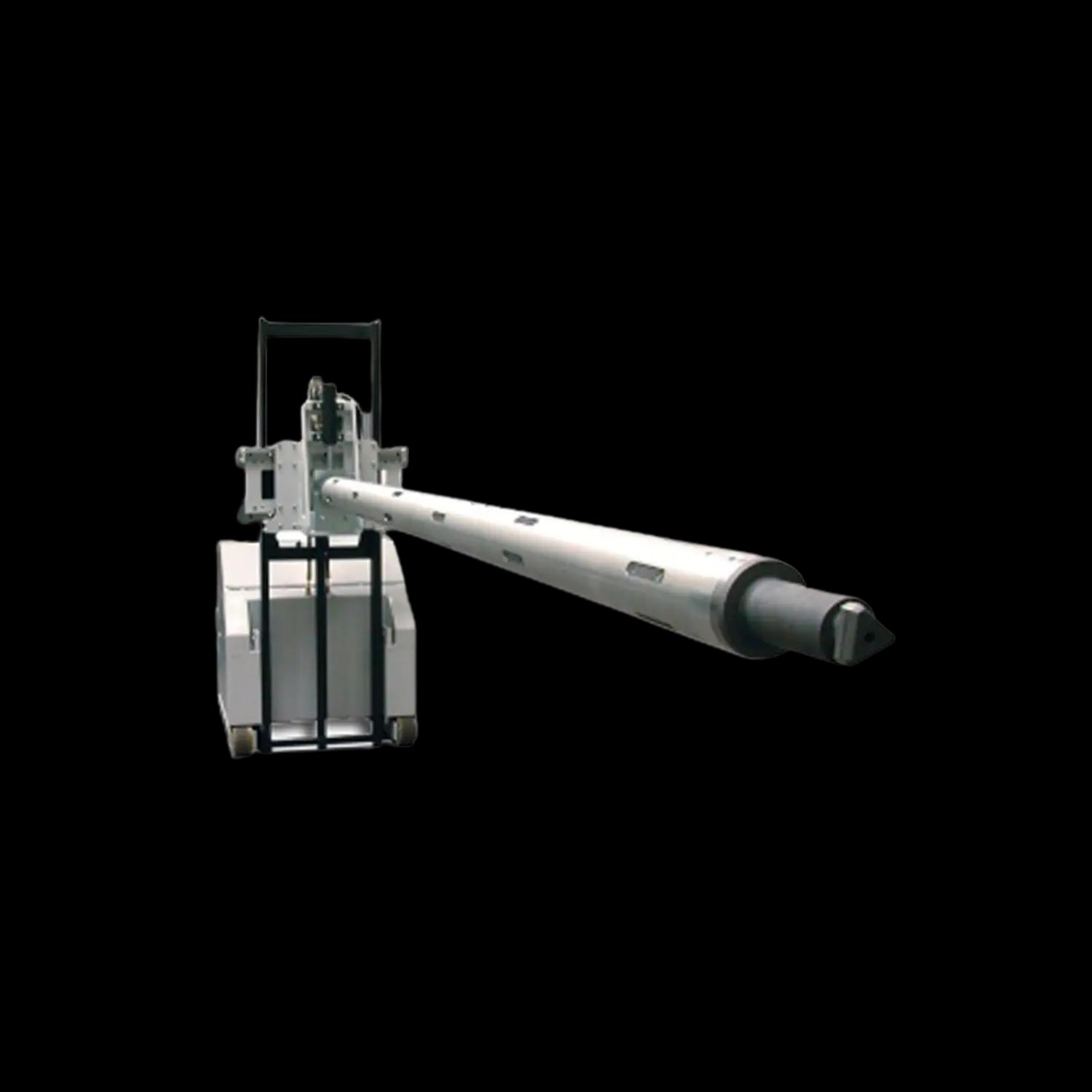

Mobile shaft puller

These shaft transport carriages are used to extract the expansion shafts from the finished roll and insert them into the core

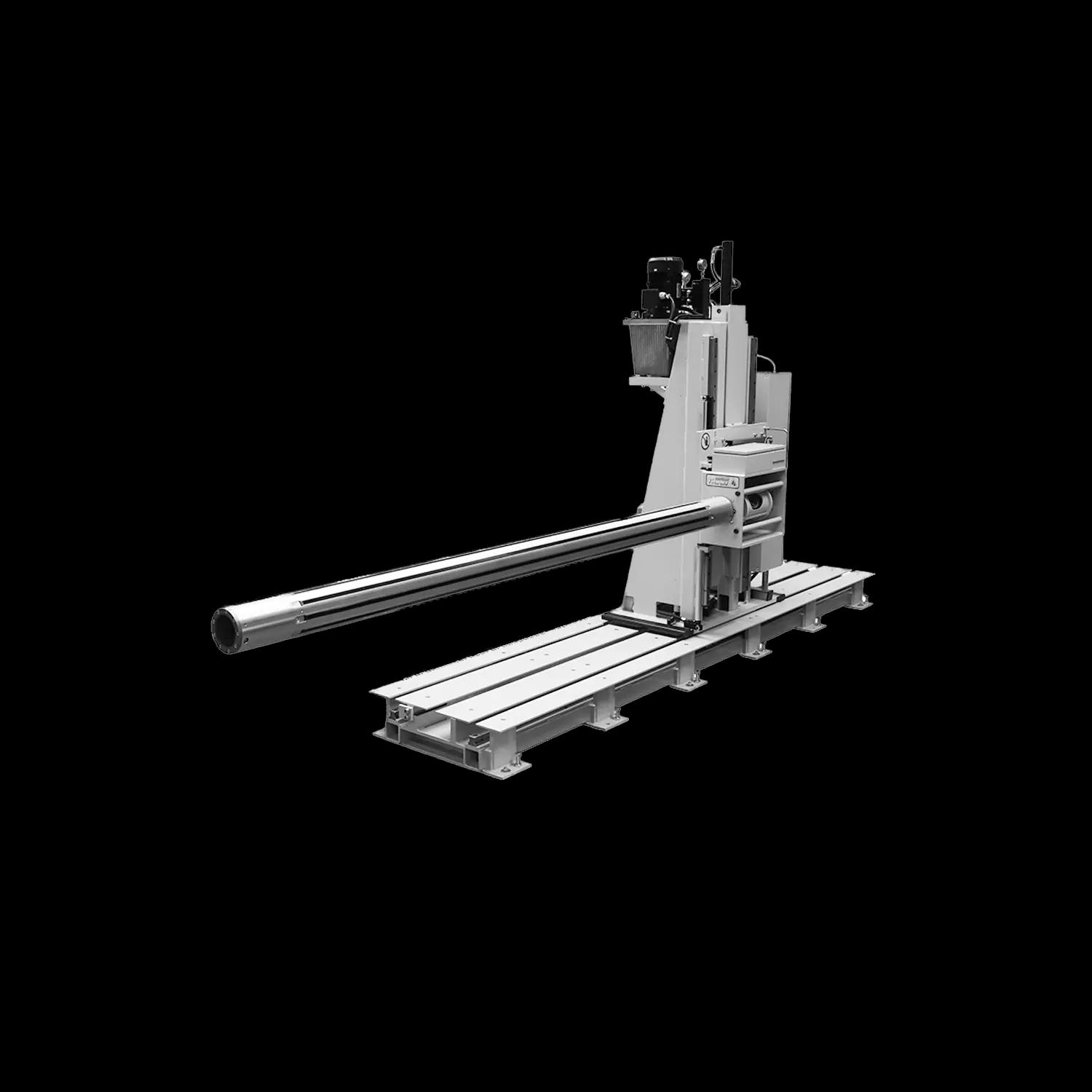

Stationary shaft puller

Capable of handling everything from small and lightweight expansion shafts/drums right through to those weighing several tonnes

Series 409 flat hose shaft

Series 409 pneumatic expansion shafts enable rolls of any width to be clamped securely by means of expanding ledges, offer high torques and load capacity, and can be flexibly customised for various applications.

Sliding chuck

The Boschert sliding chuck makes light work of basic radial settings and winding length compensation.

Easy Wind

The plug-and-play web tension control

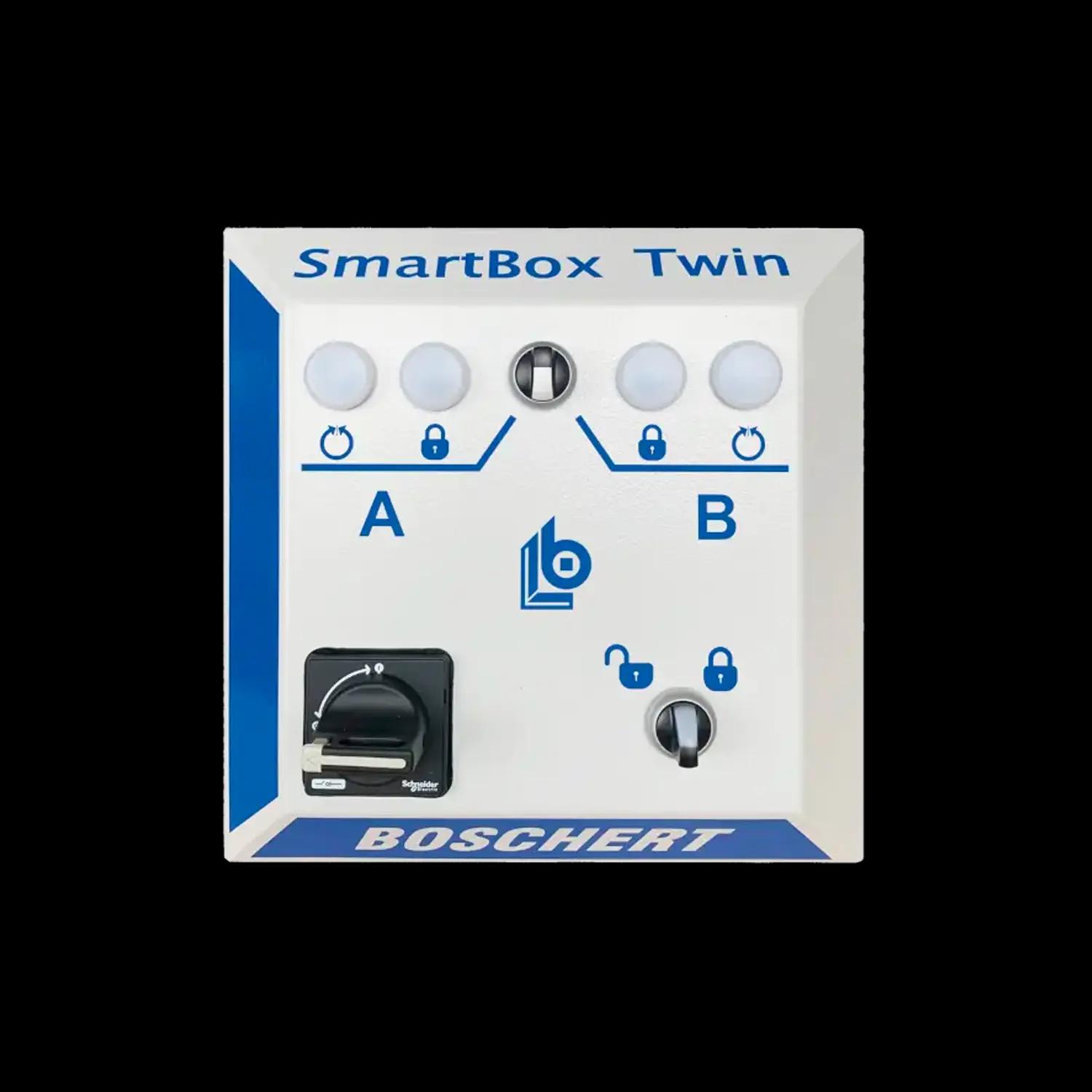

Smart Box

Easy control of pneumatic and electric bearings

Multi-brake

Precise tension in the winding industry: Boschert’s versatile brake solutions for optimum unwinding

Series DSB double disc brake

Type DSB double disc brakes

Series ESB single disc brake

Manual and pneumatic single disc brakes and single disc brakes with membrane cylinders for the winding industry

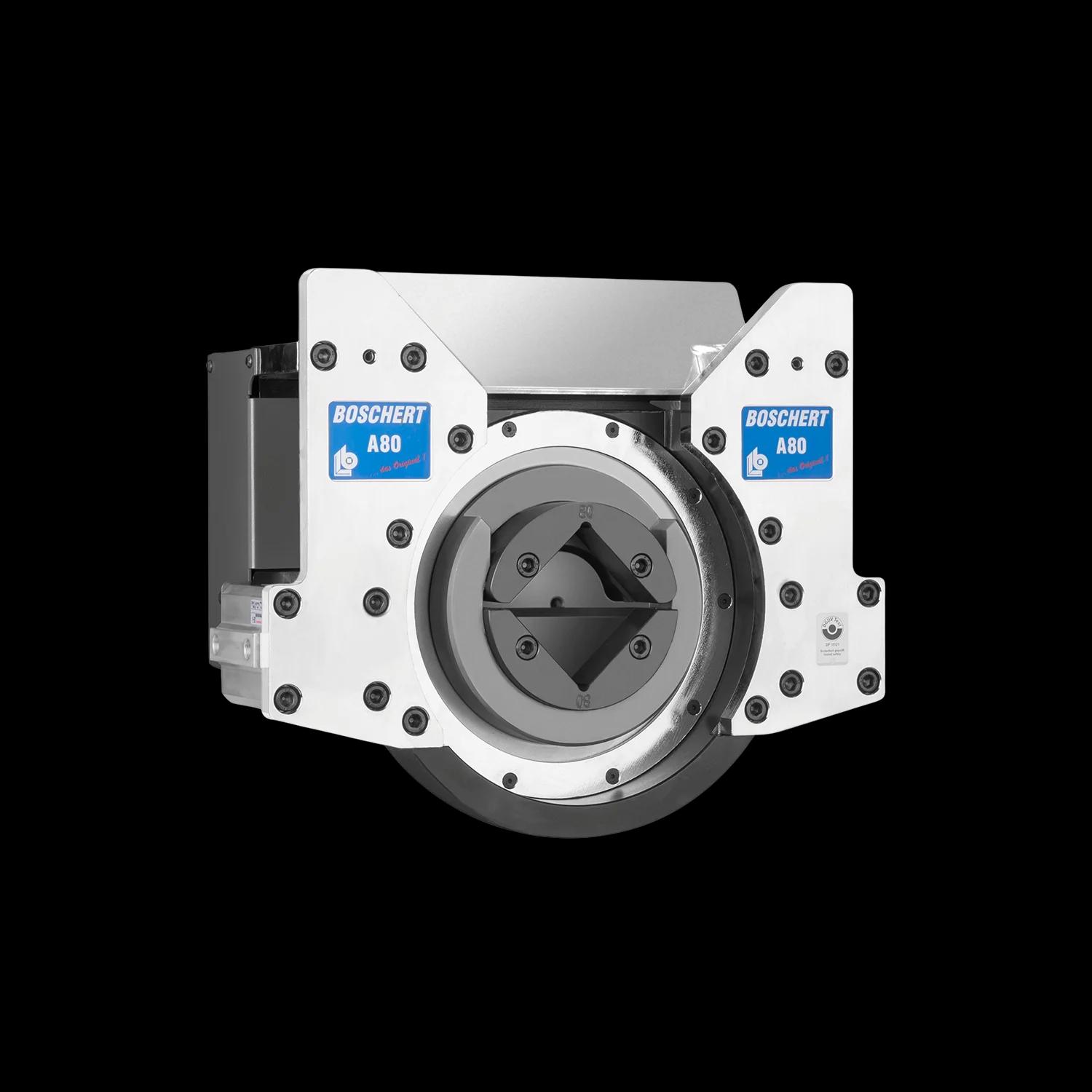

A-Chuck

The automatic chucks are interchangeable with conventional, manual safety chucks.

P-Chuck

Pneumatic chucks for pneumatic control. The automated chuck is compact and can be equipped with sensors.

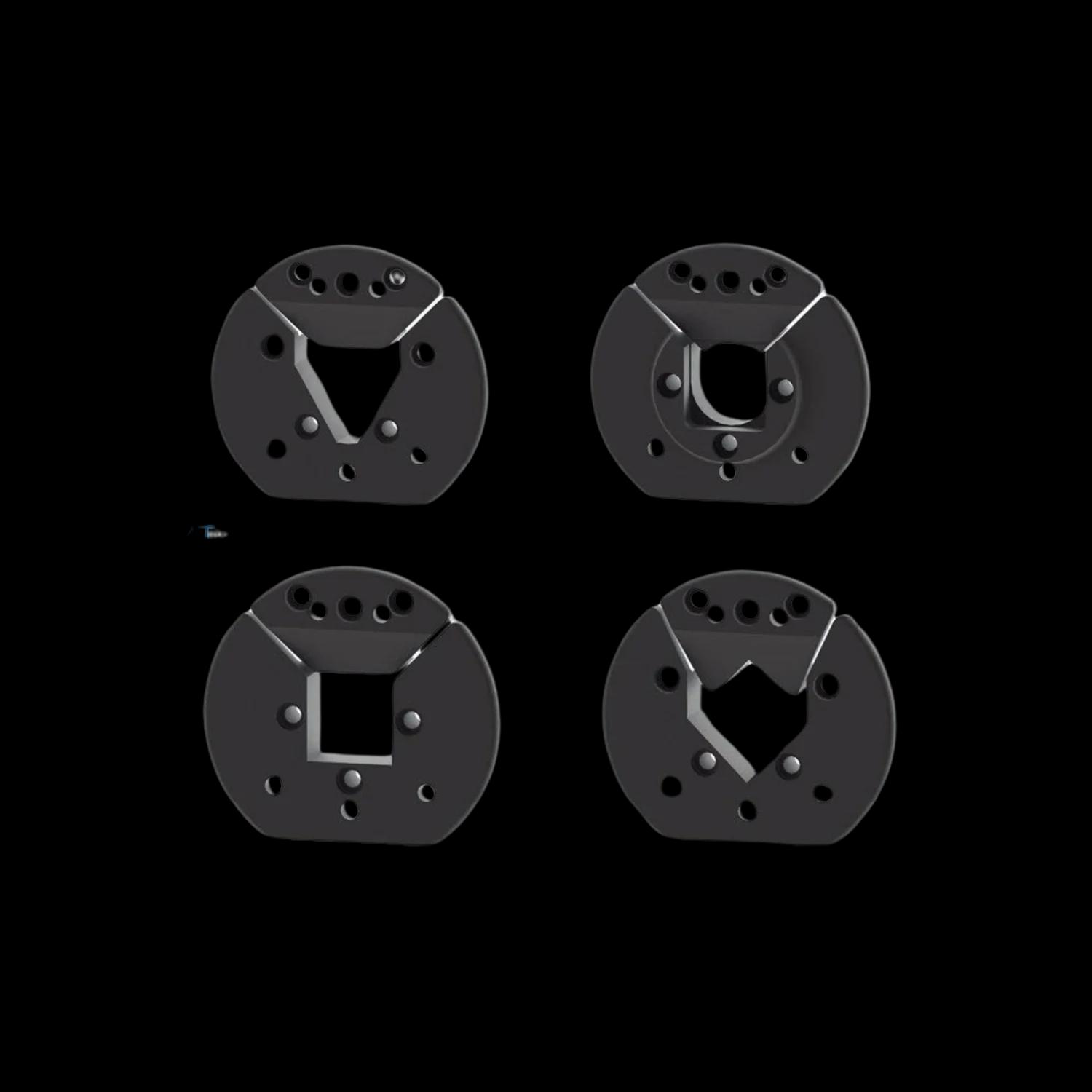

Wearing part inserts

The wearing parts (VT) can be easily replaced directly on the system.

VT-Chuck

Flexibility is the key here. One chuck for a whole host of different winding tasks.

C-Chuck

Whether required for winding or unwinding, the C-Chuck offers astounding value for money and an impressively long service life.

Bearing block/bearing unit for expansion chucks

This is a special product. Please contact our experts for more detailed information.

Series 900 adapter

The Vorwald series 900 adapter with individual expansion lugs or expansion leaves is required for applications that call for frequent changes between different core sizes.

Series 841 mechanical expansion chuck

The Vorwald series 841 expansion chuck is suitable for shaftless rewinding and winding machines with medium torques.

Series 834 Rollmatic mechanical expansion chuck

Activated by applied torque. The expansion leaves are twisted and activated by the web tension.

Series 831 mechanical expansion chuck

The axial force exerted on the core causes the expansion lugs to expand centrically.

Series 860 and series 861 expansion chucks

860 with pneumatic pressure booster, 861 with hydraulic pressure booster.

Series 811 expansion chuck

External axial actuation by a pneumatic cylinder with an external push rod.

Series 404 friction shaft

High-quality solution for applications that require precise and reliable torque transmission.

Downloads

DEUBLIN Hauptkatalog DE

DEUBLIN Hauptkatalog DE DEUBLIN Catalogue General FR

DEUBLIN Catalogue General FR