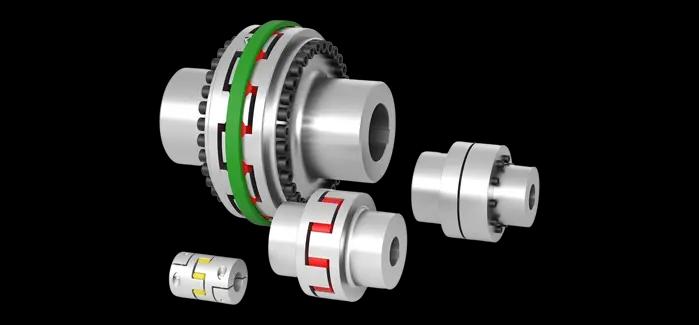

Shaft couplings

Our high-quality shaft couplings – with a proven track record in mechanical and plant engineering – are the key to creating flexible, rigid and torsionally rigid shaft connections that meet a multitude of requirements.

Contact us if you have any questions.

Contact us

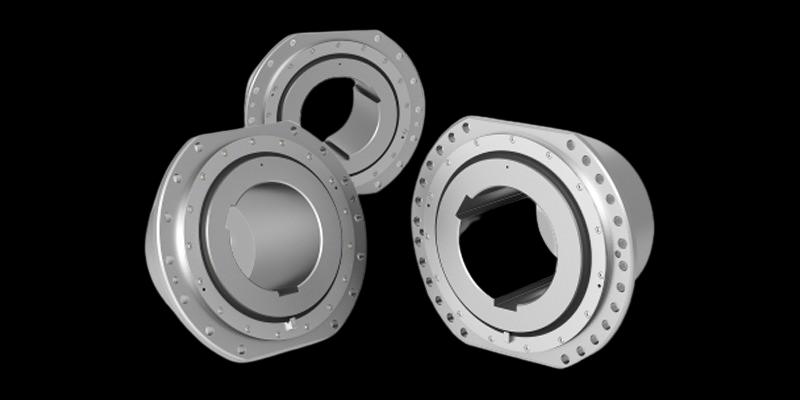

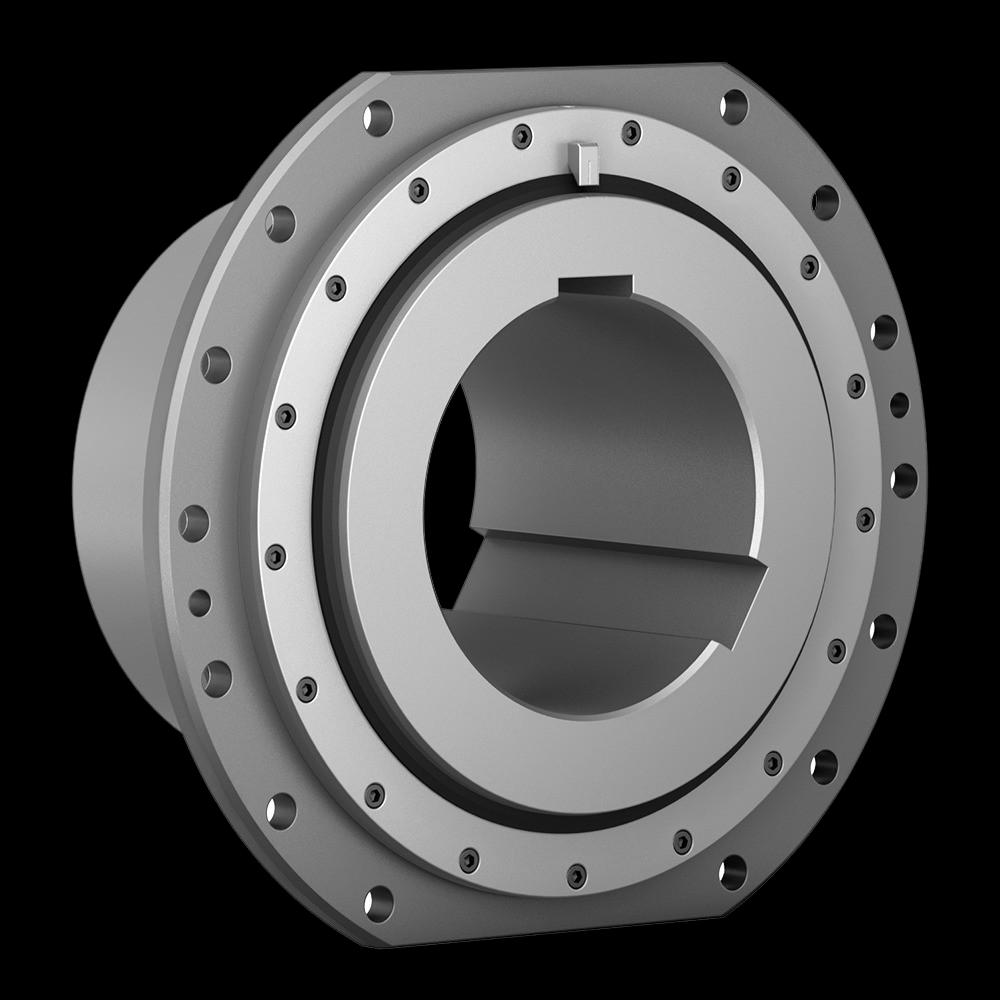

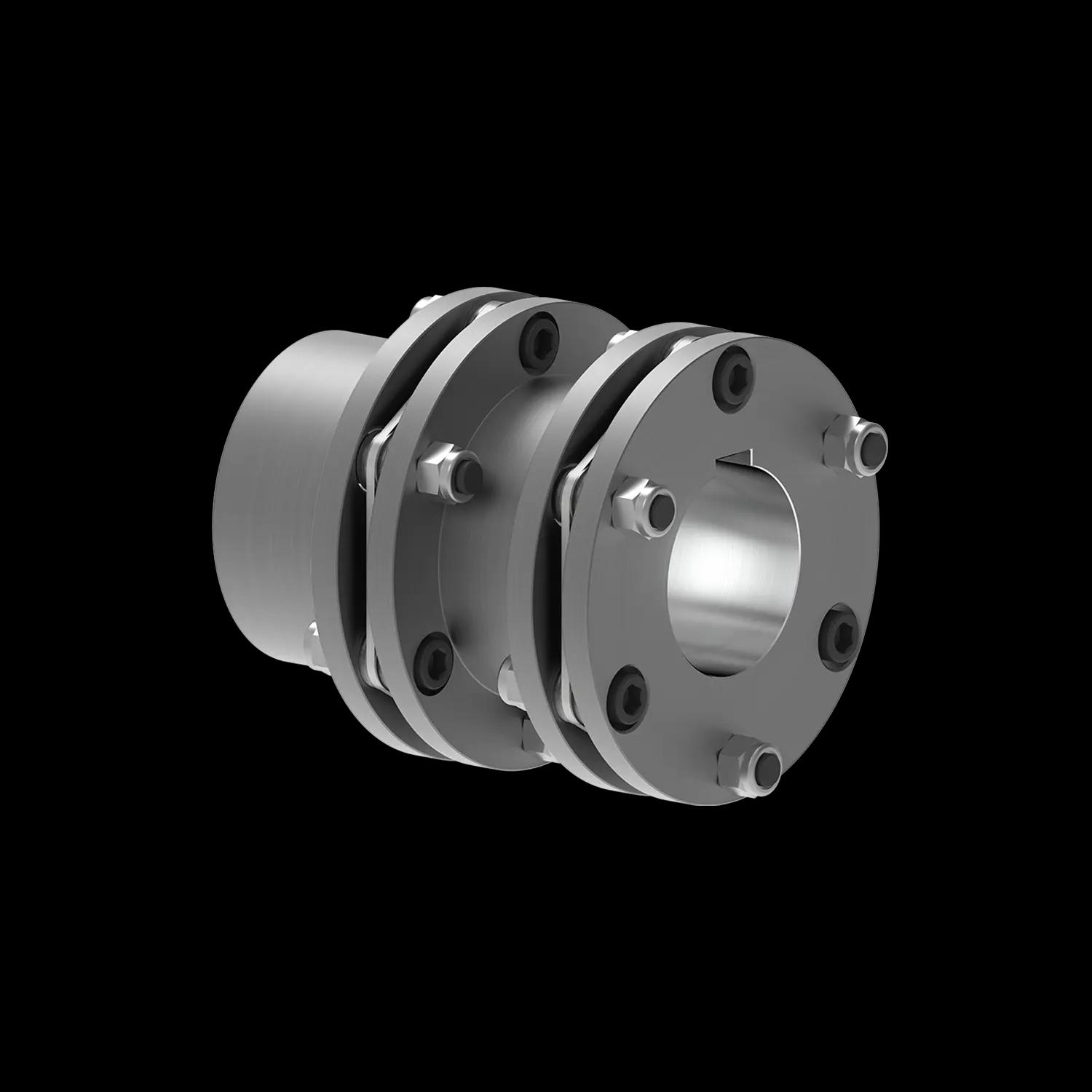

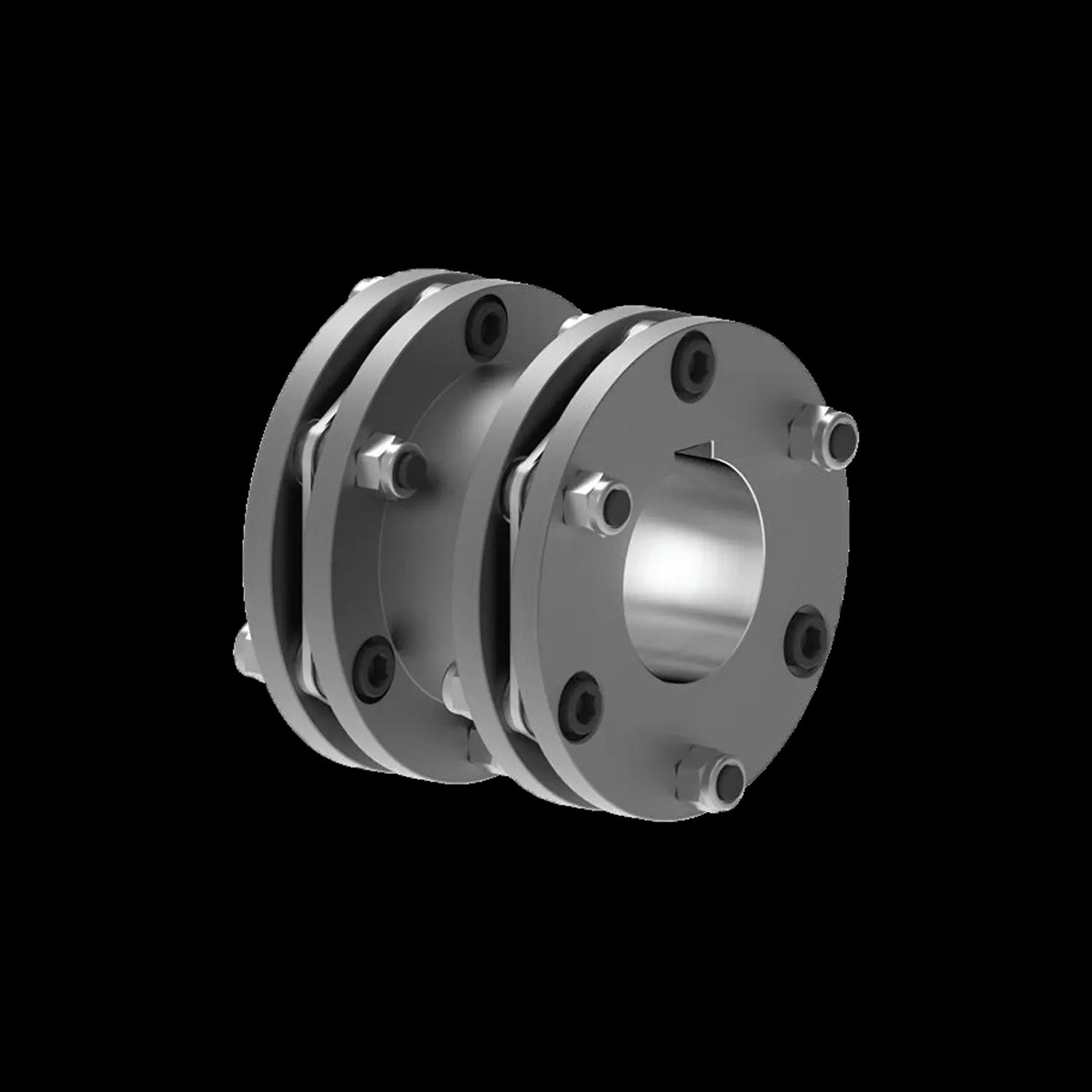

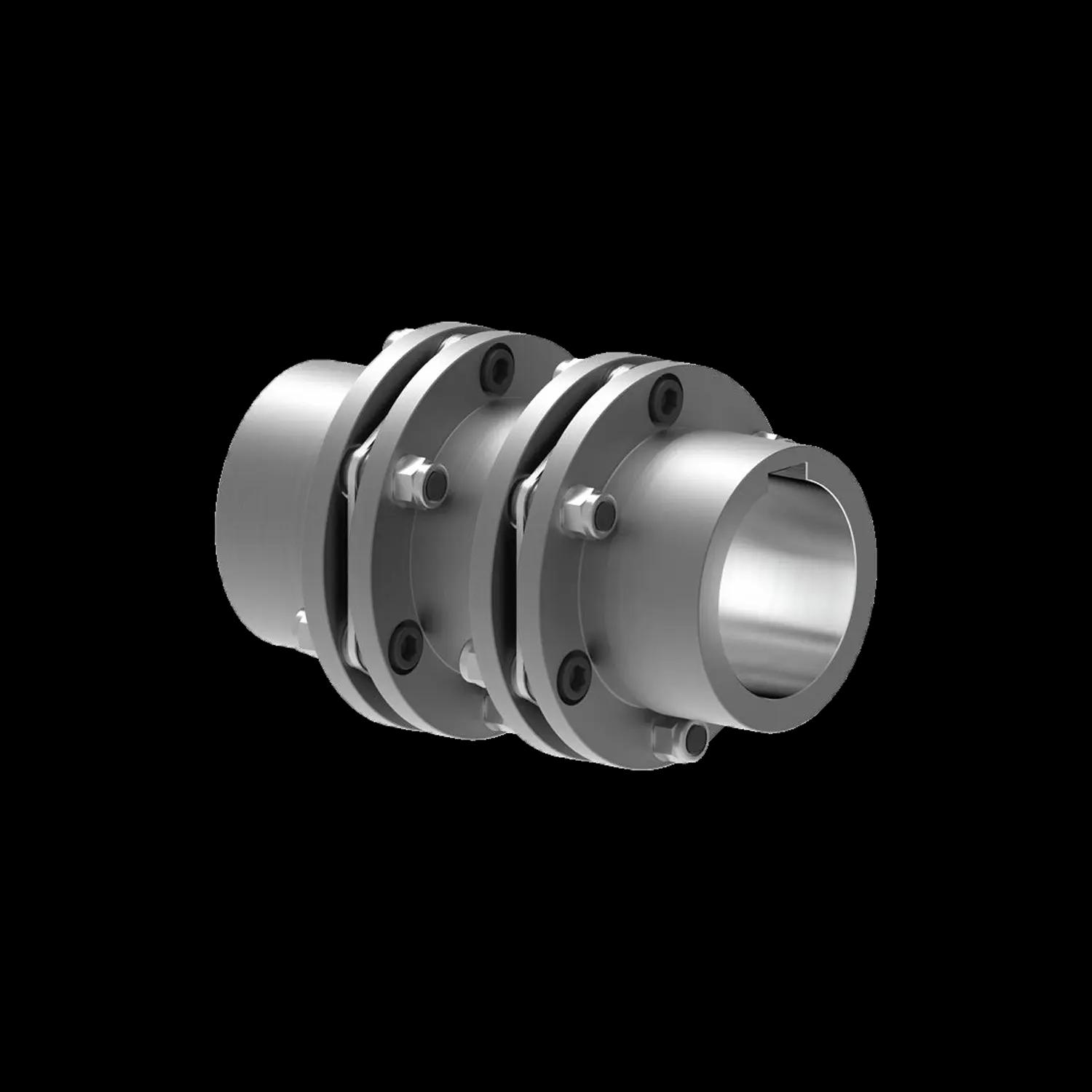

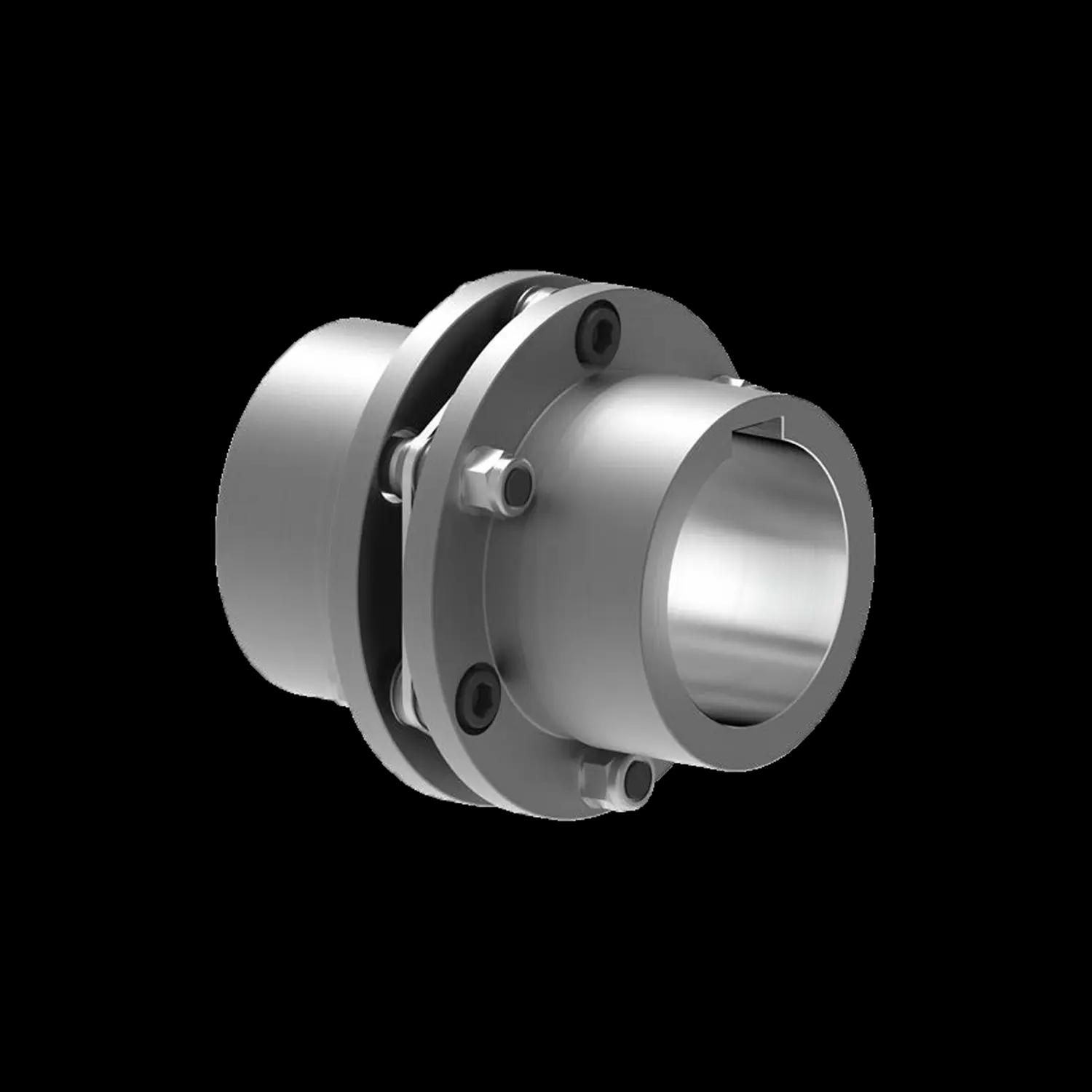

TNF 5571-B

Version B contains shrink discs that are pushed onto the flange hub and then tightened with screws from inside the flange hub.

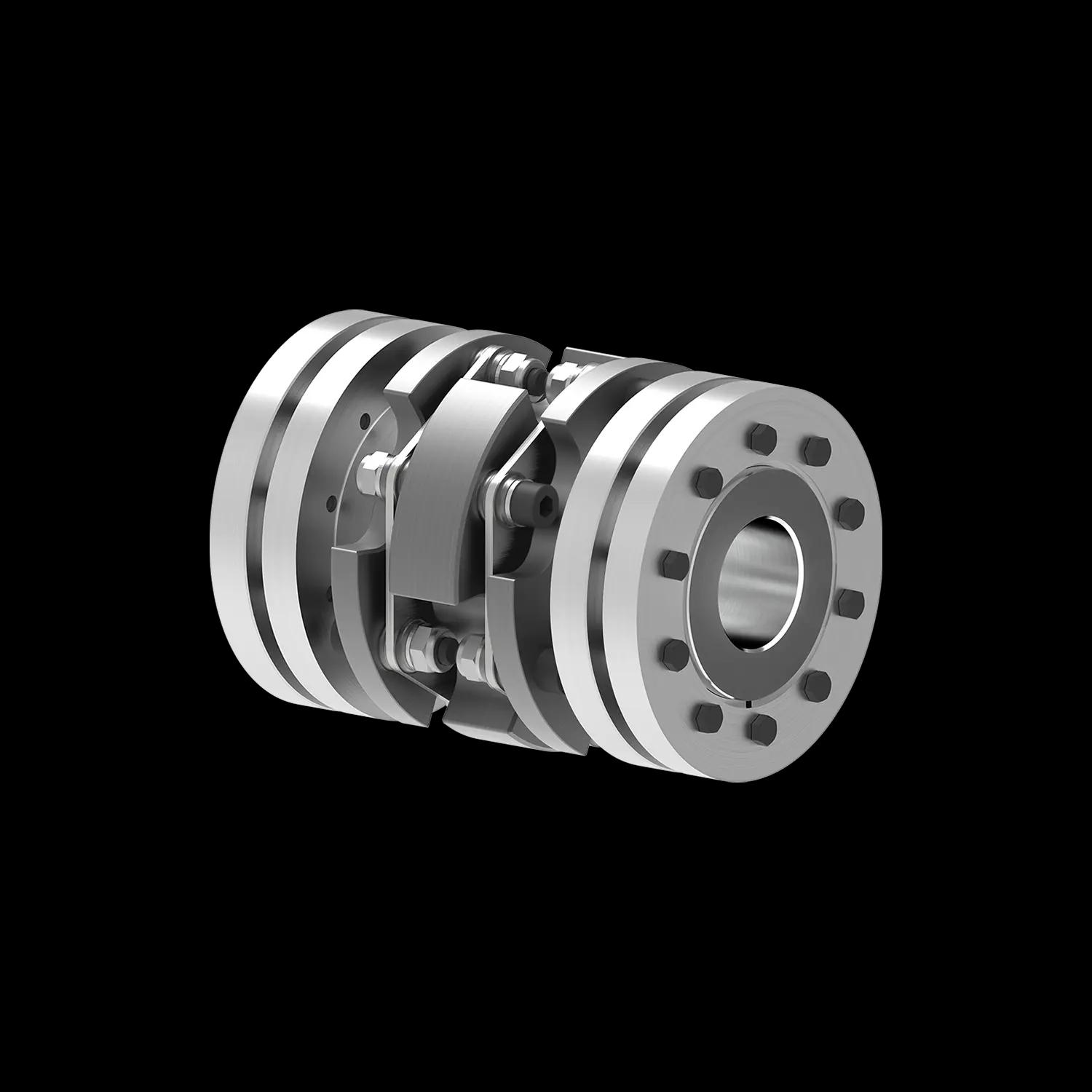

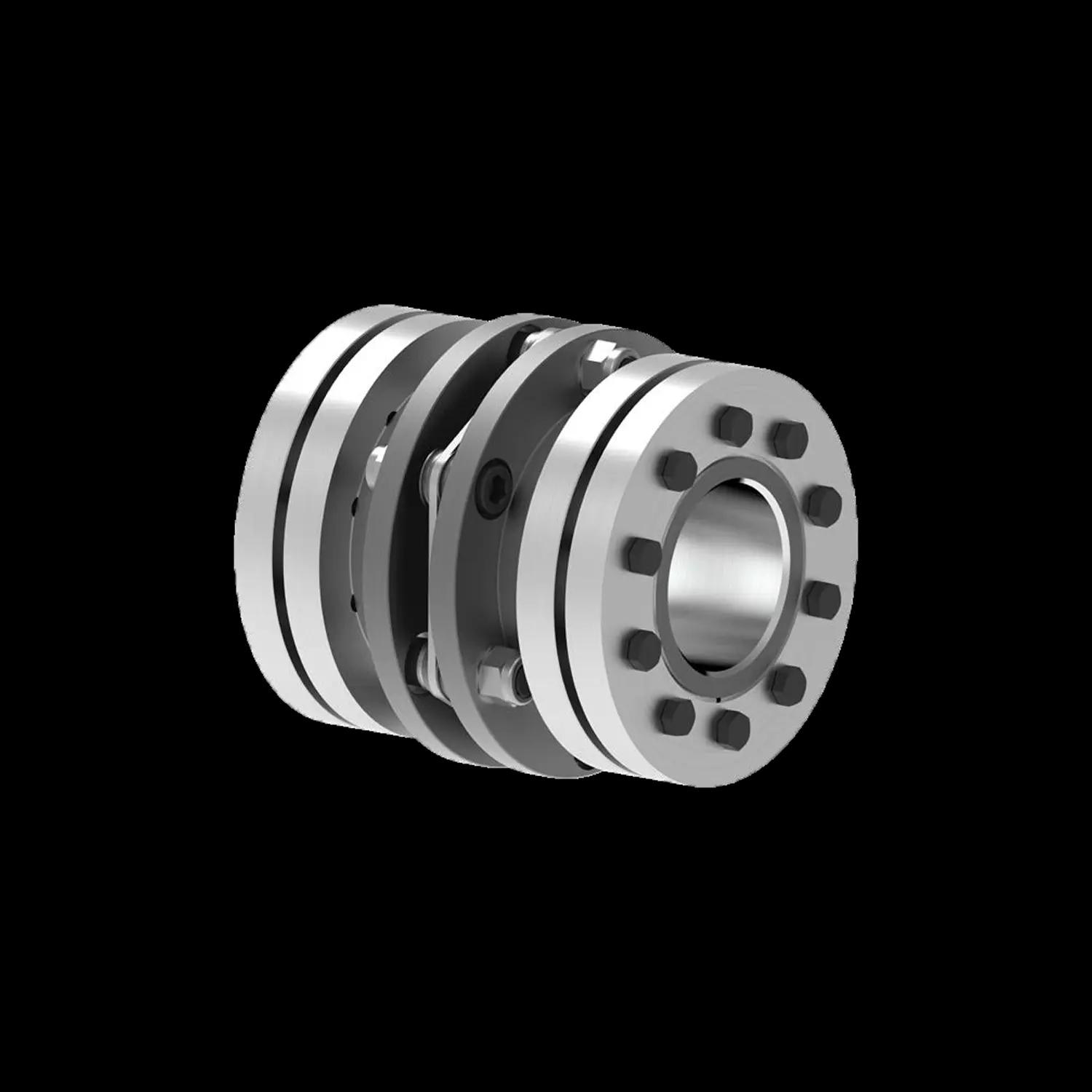

TNF 5571-A

Version A contains standard shrink discs. These are pushed fully onto the flange hub.

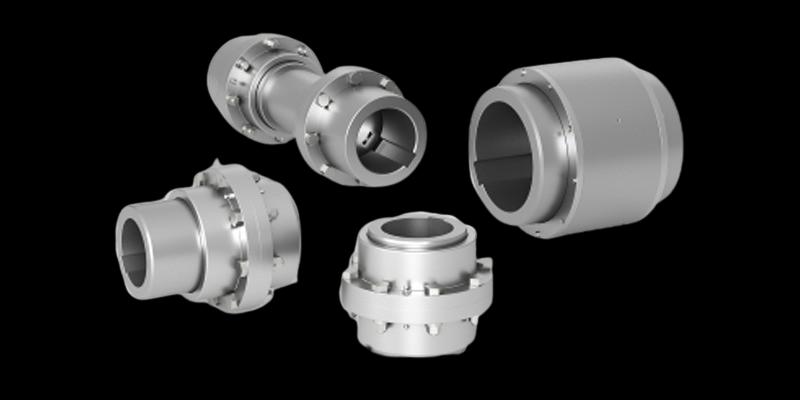

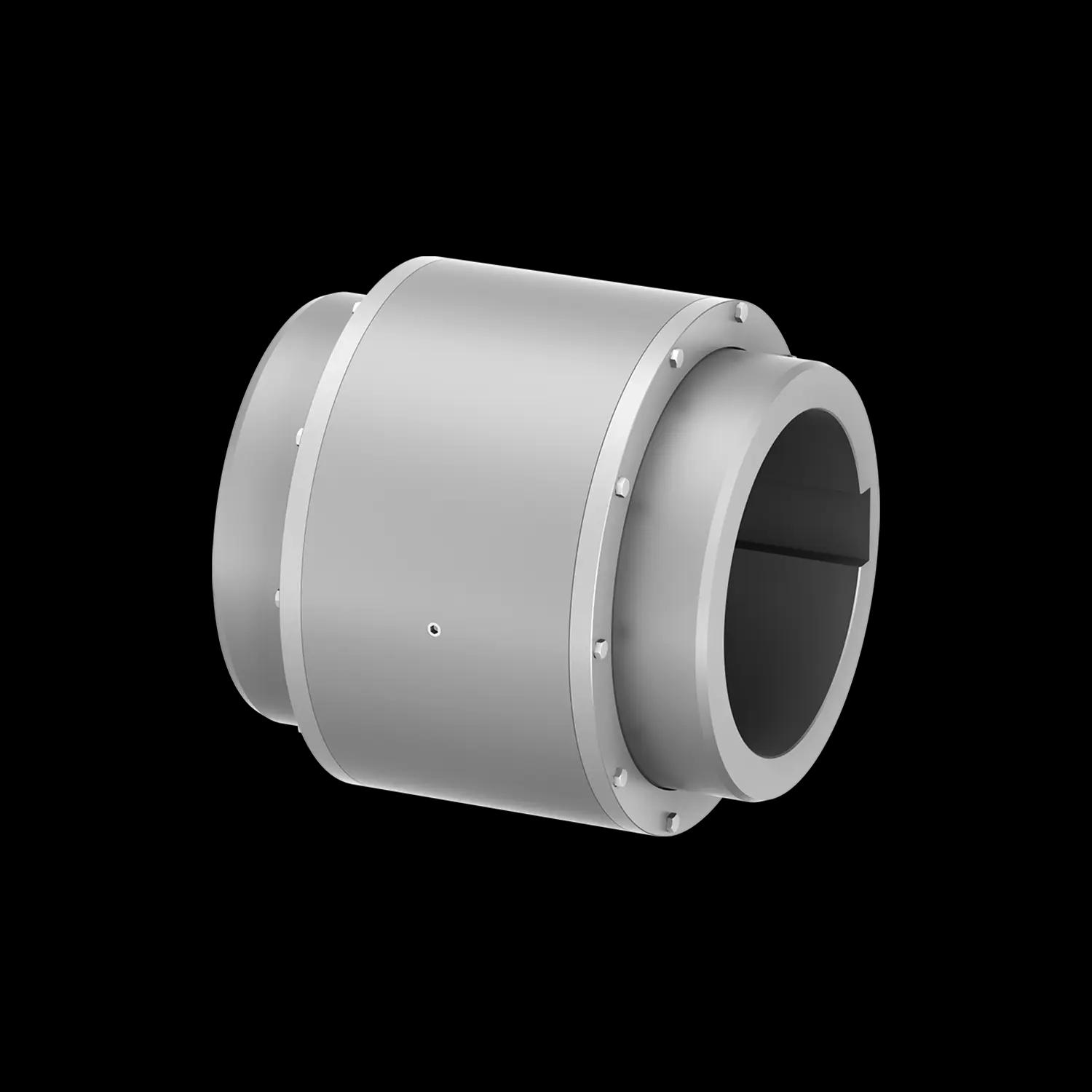

TNC TKVO

The RINGFEDER TNK TKVO is a highly rigid barrel coupling, with both the hub and the housing made from high-strength material.

ECT 6418

The ECT 6418 curved tooth gear coupling is available in two different hub versions.

TNZ ZCH

The RINGFEDER TNZ ZCH is a coupling unit that consists of a one-piece casing with O-ring supports on both sides.

TNZ ZCAZ and ZCBZ

The RINGFEDER TNZ ZCAZ is supplemented by a spacer, which is installed between the casings of a TNZ ZCA with the aid of fitted bolts.

TNZ ZCAF and ZCBF

The RINGFEDER TNZ ZCAF type is constructed from the coupling halves of the TNZ ZCA, which are supplemented with an intermediate shaft and two rigid counter flanges.

TNZ ZCAV and ZCBV

Version for vertical installation

TNZ ZCAUU and ZCBUU

The RINGFEDER TNZ ZCAUU is a type of universal hub that has two longer hubs compared to the TNZ ZCA. These hubs can be customised according to the specific requirements of the system.

TNZ ZCAU and ZCBU

Compared to the TNZ ZCA, the RINGFEDER TNZ ZCAU has a longer hub. The length of this can be adapted to suit the system requirements.

TNZ ZCAK and ZCBK

The RINGFEDER TNZ ZCAK and TNZ ZCBK are special versions of the TNZ ZCA and TNZ ZCB couplings with limitation of the end float.

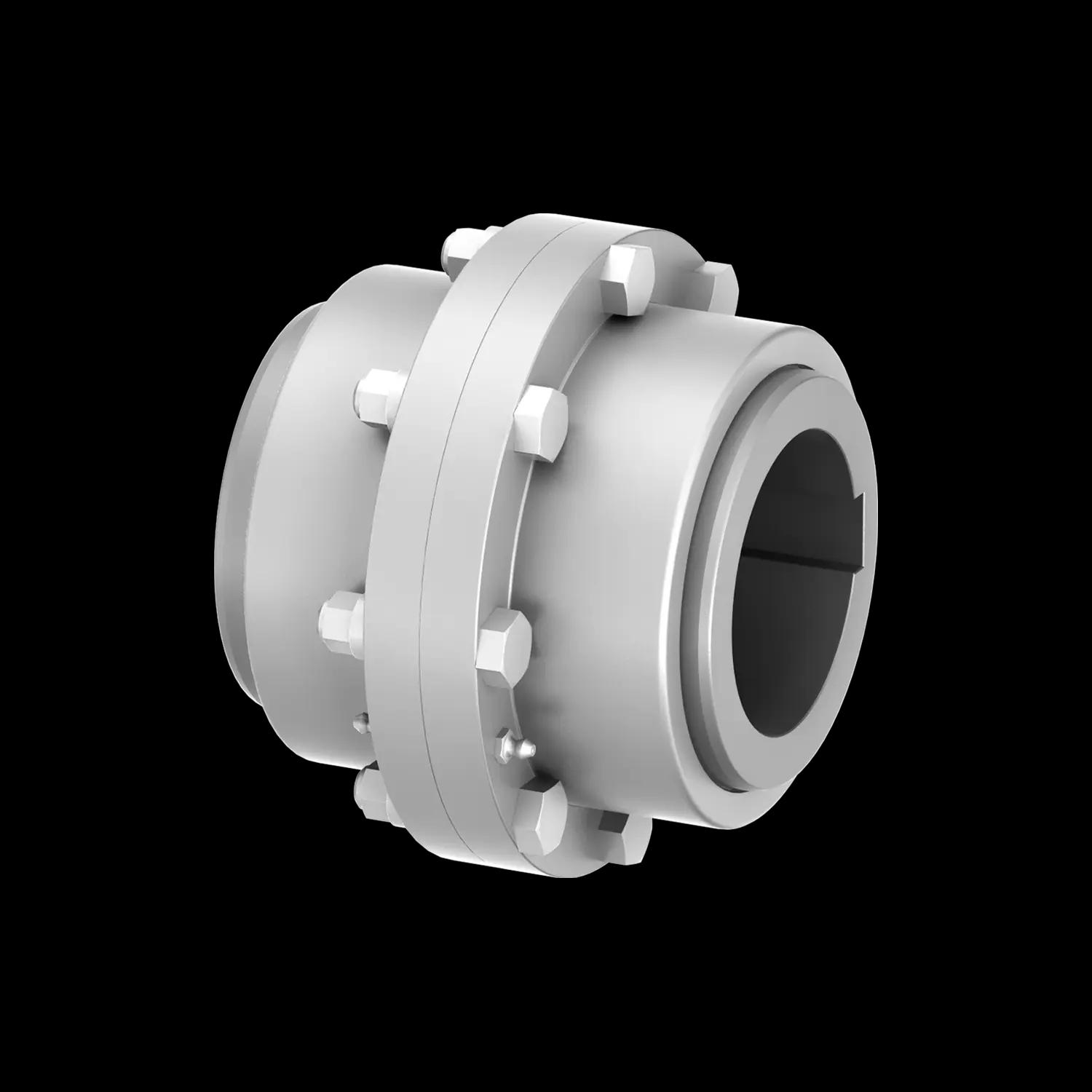

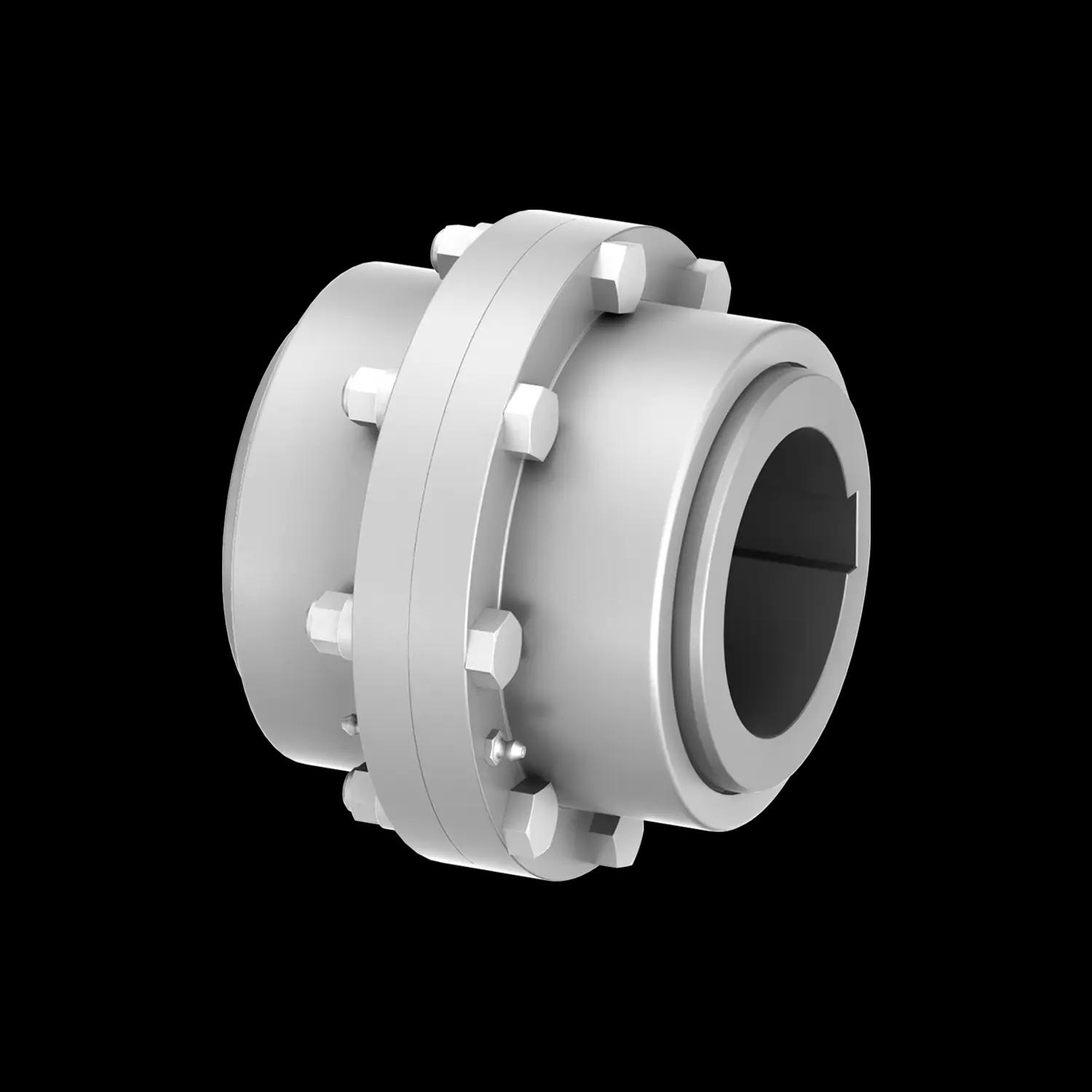

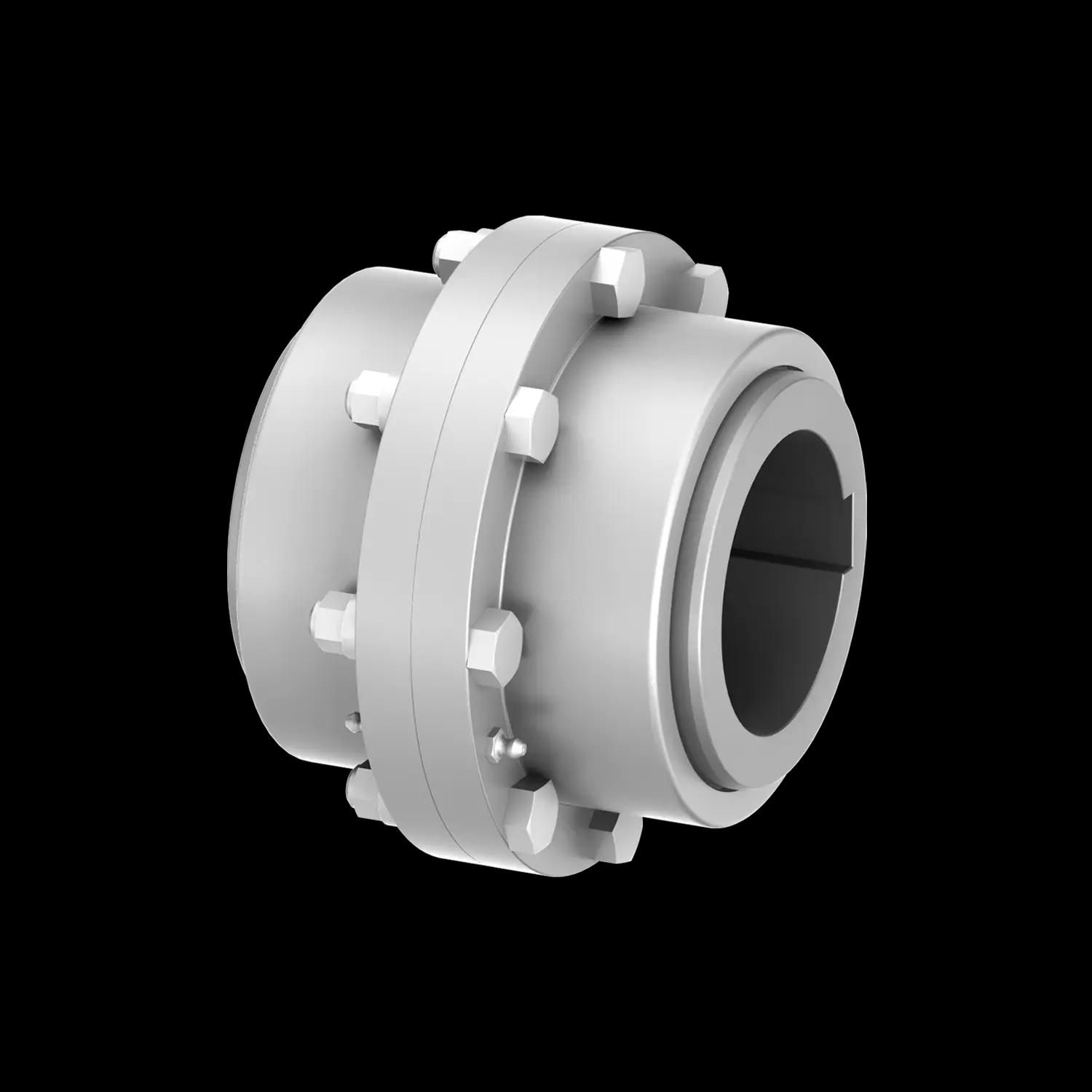

TNZ ZCA and ZCB

The RINGFEDER TNZ ZCA coupling is a gear coupling made up of two coupling halves connected by fitted bolts.

TND HDV

The hub is rotated 180° and positioned internally, enabling the TND HDV to compensate for significant misalignments with its double-cardanic design.

TND VDV

As the hubs are rotated 180° and are positioned internally, the TND VDV is able to compensate for maximum misalignments while keeping the overall length to a minimum.

TND QCQ

Despite its double-cardanic concept, the TND QCQ is very short. Thanks to the shrink disc connection, the fastening always remains completely backlash-free.

TND XDX

The TND XDX is available as a connecting shaft in various lengths. Thanks to the shrink disc connection, the fastening always remains completely backlash-free.

TND XSX

The TND XSX connects shafts frictionally using the shrink discs. This ensures that the fastening of the torsionally rigid disc coupling always remains completely backlash-free.

TND OCO

Despite its double-cardanic concept, the TND OCO is very short. The double-jointed design with two disc packs compensates for angular, axial and radial shaft misalignments with minimum axial space requirements.

TND HDH

The TND HDH is available as a connecting shaft in standardised or customised lengths.

TND HSH

The TND HSH is a straightforward, single-jointed, torsionally rigid disc coupling. The single-jointed design with an individual disc packs compensates for angular and axial shaft misalignments.

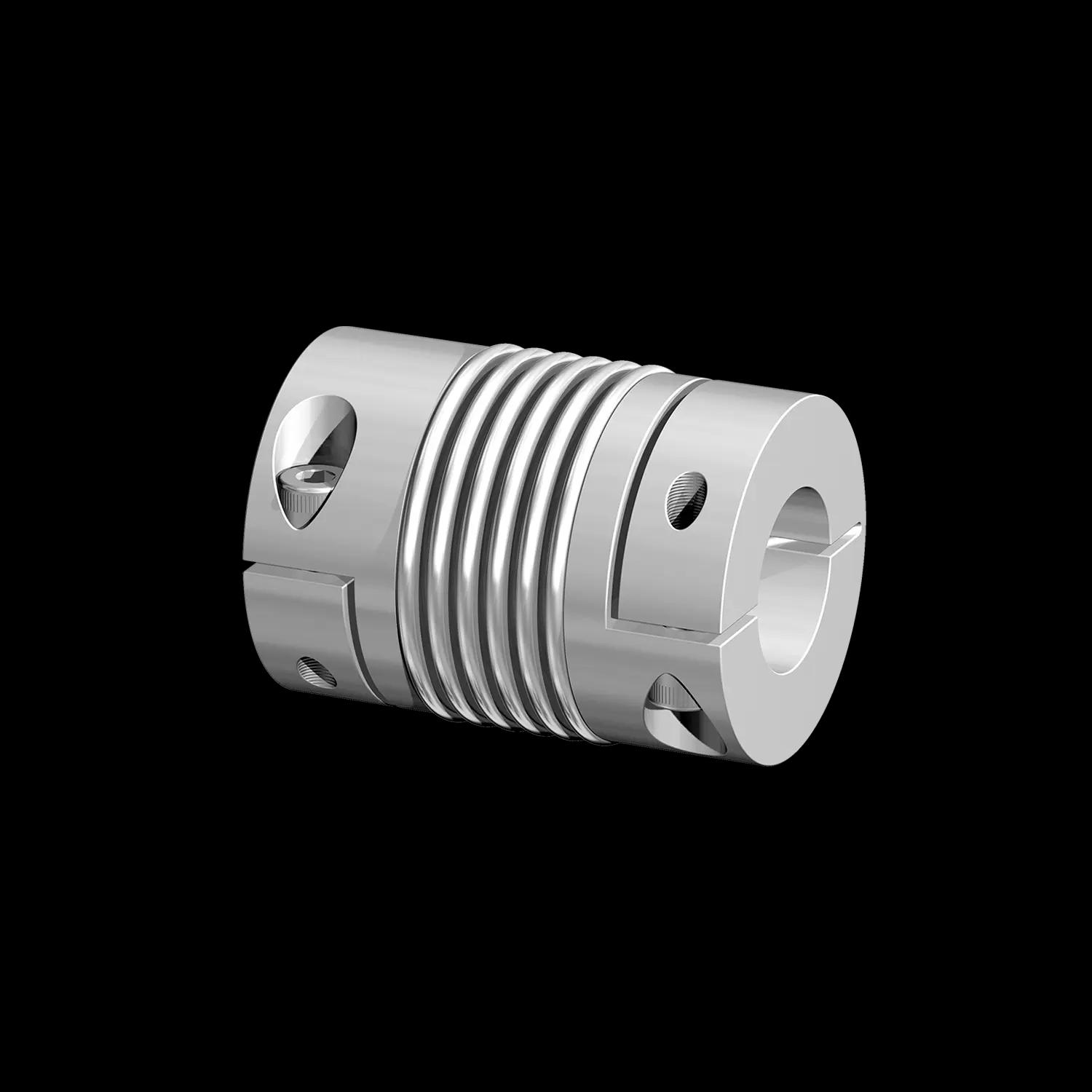

GWB AK

The AK metal bellows coupling is extremely compact and has been designed for high torques. The clamping ring hubs provide them with excellent radial run-out properties.

GWB AKD

The AKD metal bellows coupling is suitable for universal use. Thanks to the longer bellows, it can compensate for high levels of misalignment.

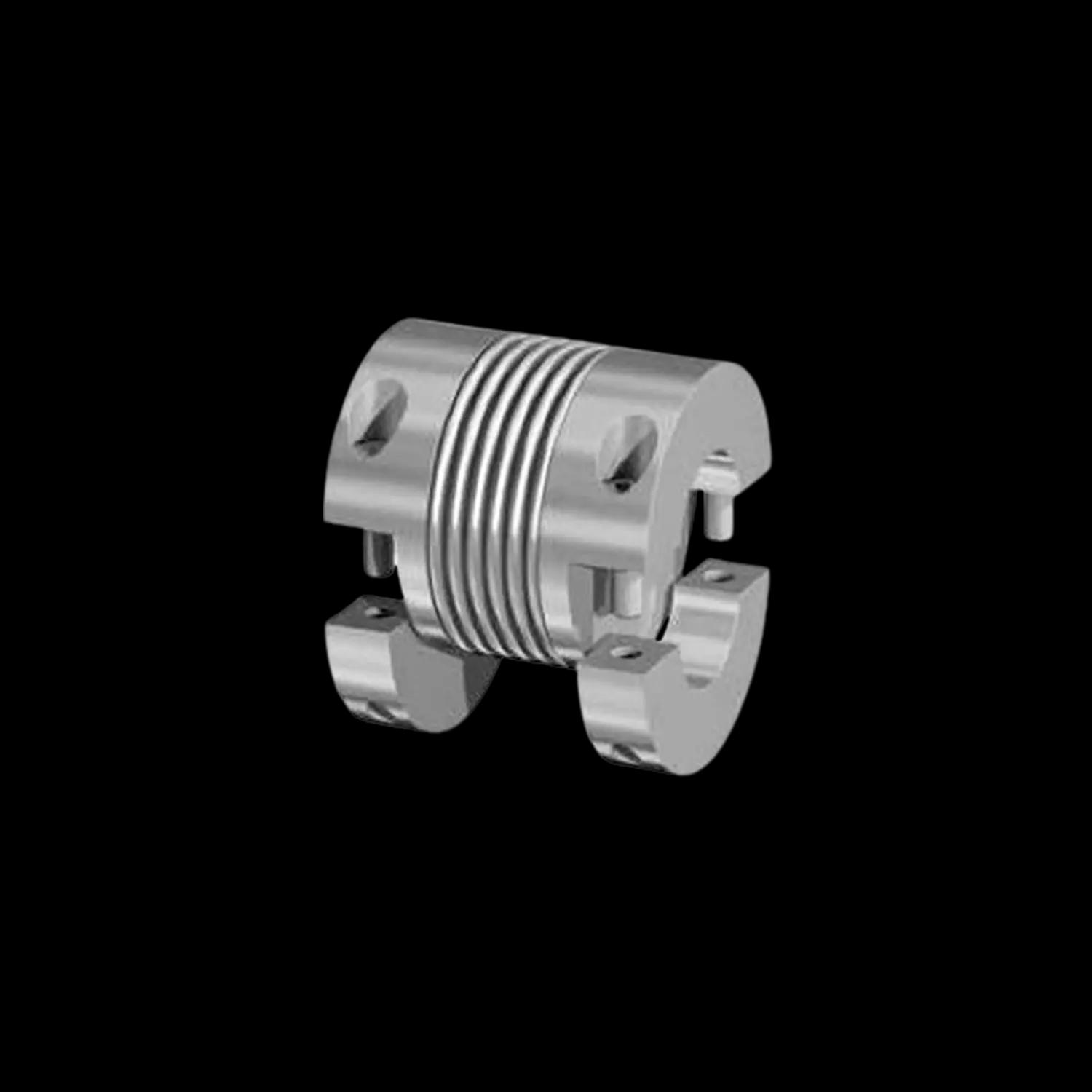

GWB AKD-H

The AKD-H metal bellows coupling is identical to the standard AKD type, except that it has half shells to enable installation and removal without having to move the attached parts axially.

GWB AKN

The AKN metal bellows coupling is extremely compact with a short design. Due to the shorter bellows, it is very rigid but is still able to compensate for misalignments.

GWB AKN-H

The AKN-H metal bellows coupling is identical to the standard AKN type, except that it has half shells to enable installation and removal without having to move the attached parts axially.